Method and system for improving metallurgical coke strength by utilizing waste plastics

A technology of metallurgical coke and waste plastics, applied in coke ovens, petroleum industry, etc., can solve the problems of coke strength not being significantly improved, reduce coke reactivity, increase coke strength, etc., achieve good industrial application prospects, and reduce coke ratio , Increase the effect of coal injection ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

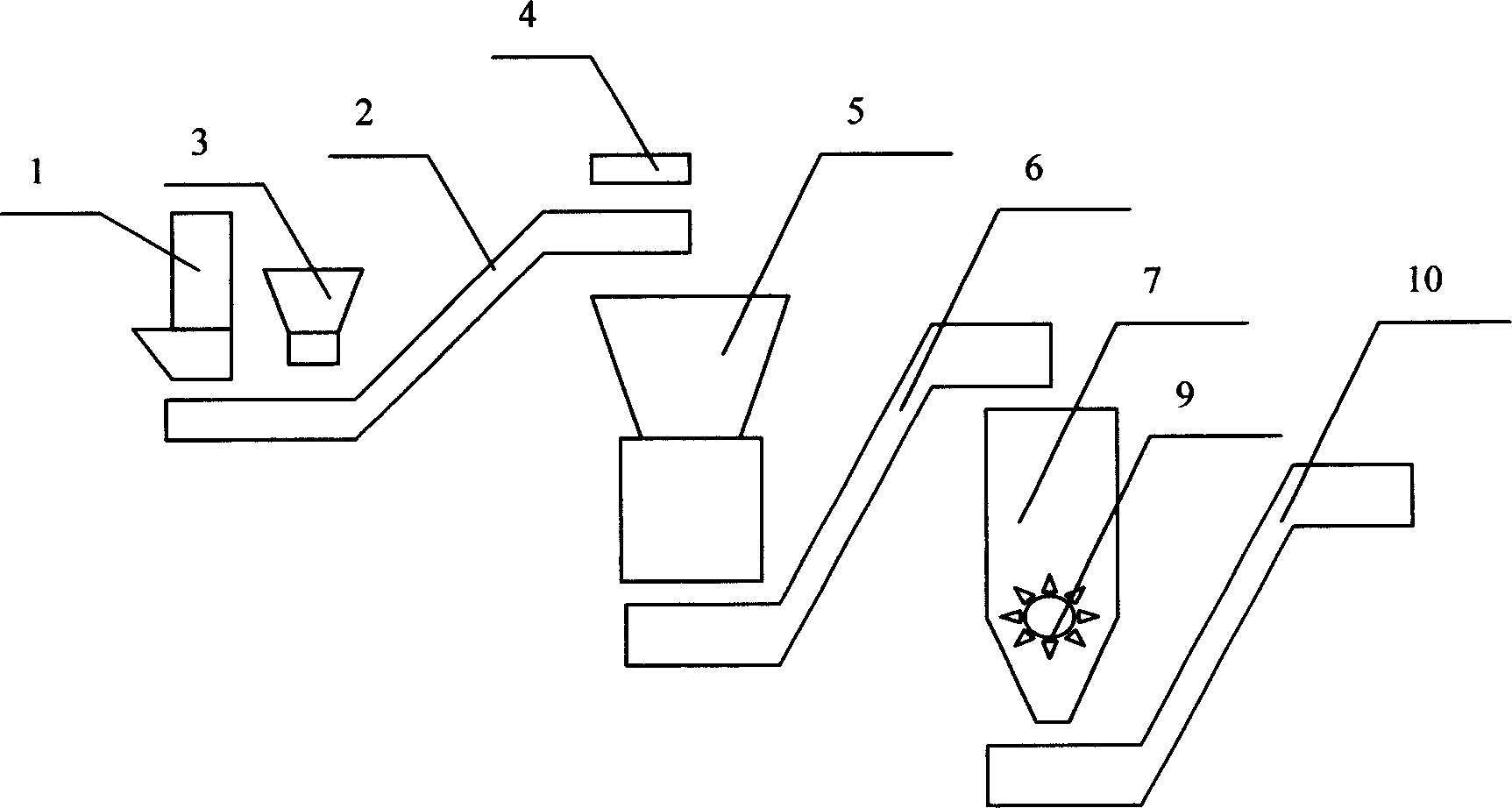

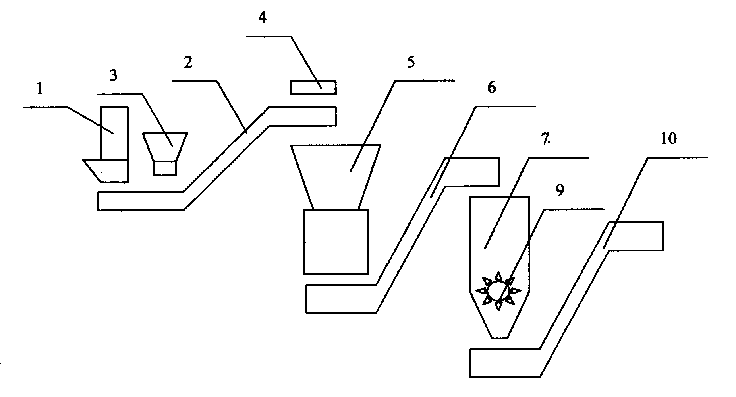

[0024] The method of using waste plastics to improve the strength of metallurgical coke, including waste plastics collection method, waste plastics and additives mixed processing method, waste plastics and additives and coking coal blending quantitative and uniform mixing method into furnace, waste plastics and additives mixture material and coal co-coking method And a method for recovering co-coking products. The collection methods of waste plastics include: (1) manual collection and sorting of waste plastics in office areas, commercial areas, campuses, residential areas, etc.; (2) collection and recycling of plastics from plastic production, processing, sales, and waste plastics Collection and sorting of waste plastics; (3) Collect waste plastics from municipal solid waste sorting stations, transfer stations and comprehensive garbage disposal sites through a combination of mechanical sorting and manual sorting. The waste plastic processing method mainly adopts the crushing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com