Patents

Literature

63results about How to "Instant water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing towels by utilizing bamboo fiber and cotton fiber

InactiveCN101694037AImprove breathabilityInstant water absorptionWoven fabricsYarnCardingCotton fibre

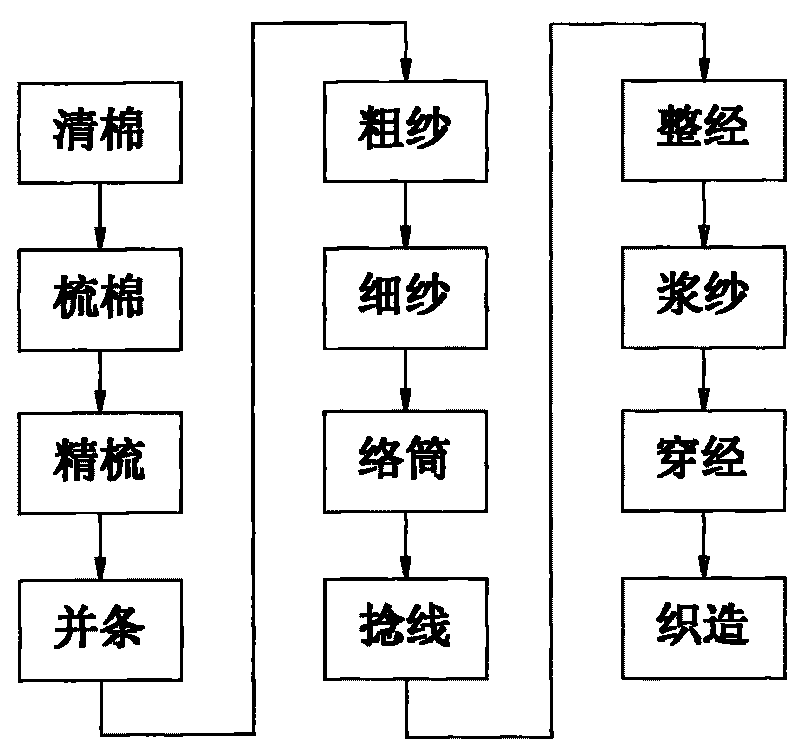

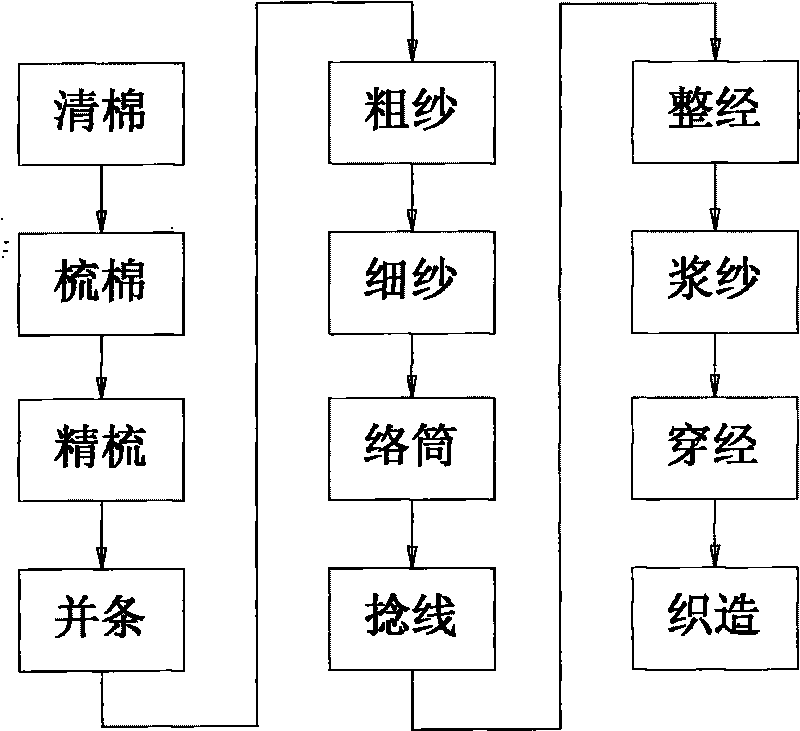

The invention relates to a method for producing towels by utilizing bamboo fiber and cotton fiber, comprising twelve steps such as cotton cleaning, cotton carding, combing, drawing, roving, spinning, winding, twisting, warping, sizing, passing, weaving, and the like, wherein in the fourth step, a finished cotton silver and the cotton silver of the cotton fiber are combined, a blending cotton silver is generated, and then the blending cotton silver is taken as the basis to implement the next steps, thereby leading the bamboo fiber and the cotton fiber to be mixed and taken as raw materials for weaving the towels; and the towels produced by the adopting the method have good air permeability, instant water absorption, strong wear resistance, good dyeing performance and other excellent performances.

Owner:黄学进

High-performance wood-plastic composite material and preparation method thereof

The invention discloses a high-performance wood-plastic composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 60 to 80 parts of peanut hull powder, 30 to 50 parts of bamboo powder, 60 to 90 parts of abandoned plastics, 15 to 25 parts of epoxy resin, 4 to 6 parts of mineral fibers, 5 to 7 parts of magnesium carbonate whiskers, 4 to 6 parts of nano calcium carbonate, 6 to 9 parts of maleic anhydride, 3 to 5 parts of an organosilicone water-proofing agent, 2 to 4 parts of an 168 antioxidant, 3 to 5 parts of a red phosphorus fire-retardant and 3 to 5 parts of a 788 light stabilizer. The preparation method comprises the processing steps of modified pre-treatment, mixing at high speed, hot press molding, cooling setting and the like. The wood-plastic composite material obtained through the method has the advantages of high compressive strength, high abrasive resistance, low cost, high distortion temperature and the like, and the material and the method, provided by the invention, also have the advantages of simple processing technique, short processing time, low cost and the like, and are suitable for industrial production.

Owner:许超群

Terylene, bamboo fiber and milk protein fiber blended yarn

The invention provides a terylene, bamboo fiber and milk protein fiber blended yarn which comprises the following components in parts by weight: 55-65 parts of terylene, 20-30 parts of bamboo fiber, and 10-20 parts of milk protein fiber. According to the blended yarn provided by the invention, the characteristics of the terylene, the bamboo fiber and the milk protein fiber are integrated, so as to play the advantages of the the terylene, the bamboo fiber and the milk protein fiber.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Alginate fiber electrostatic flocking fabric for medical treatment and manufacturing method thereof

ActiveCN103481549AWith far infrared raysWith insulationPattern makingLayered productsCelluloseAnti bacteria

The invention discloses an alginate fiber electrostatic flocking fabric for medical treatment, which comprises a nap layer, an adhesive layer and a base cloth layer, wherein the nap layer is made of alginate fiber, the base cloth is bamboo fiber plain woven cloth, and the middle adhesive layer is made of a hydroxymethyl cellulose adhesive. The invention also discloses a manufacturing method of the alginate fiber electrostatic flocking fabric, which is characterized by comprising the steps of cutting an alginate fiber strand into alginate fiber naps with length of 0.8-1.0mm, and performing electric conduction treatment and coloring treatment; pre-coating and primarily coating the flocking base cloth with an adhesive, wherein the total thickness of the adhesive is 0.15-0.2mm; generating an electric field by use of high-voltage alternating static electricity for flocking, and performing three-prevention treatment and baking on the cloth to obtain the alginate fiber flocking fabric. The fabric has anionic antibacterial and deodorant functions, is non-toxic and harmless, can be naturally degraded, realizes strong moisture absorbability and air permeability, prevents ultraviolet rays and can be applied to the medical treatment and healthcare industries.

Owner:山东领潮新材料有限公司

Bamboo fiber plush printed blanket and preparation method thereof

The invention discloses a bamboo fiber plush printed blanket and a preparation method thereof. The blanket is knitted by a double-needle-bed warp knitting machine; and the plush yarn of the blanket is a yarn obtained by blended knitting of bamboo fibers and acrylic fibers, wherein the double-yarn specification of the yarn obtained by the blended knitting is 32 double-strands or 16 single strands; the base elater of a base material terylene is warped, and then the coiled head is used as the knitting yarn and weft insertion yarn of the blanket; and the bamboo fibers account for 60-70% of the weight of the double-yarn. The preparation method comprises the following steps: starching and high-temperature setting of a white grey cloth, carding, lustering, shearing, plush cutting, flat screen printing, aging and fixation, washing, dehydrating and drying, fuzzing, lustering, shearing, binding and packaging and warehousing. The bamboo fiber plush printed blanket disclosed by the invention not only has good air permeability, instantaneous water absorbability, relatively strong abrasive resistance, but also has the functions of natural antibacterium, bacteriostasis, mite removal, deodorization and ultraviolet resistance at the same time.

Owner:JIANGSU QIYING HOME TEXTILE

Novel burn-out fabric and burn-out technology thereof

Owner:LILANG CHINA

Fabric made of high polymer material

InactiveCN106835676ALow costPlay an antibacterial effectBiochemical fibre treatmentLight resistant fibresFiberPolyester

The invention provides high polymer fabric made of a high polymer material. The fabric is prepared through following preparation processes: A, polyester fibers, bamboo fibers and cuprammonium fibers are subjected to melting granulation, then air-jet texturing filaments are spun and woven, and grey fabric is obtained; B, the grey fabric is put in a finishing liquid for dipping, dried and cooled, and finished fabric product is obtained, wherein the finishing liquidis prepared fromcomponents as follows: 12-20 g / L of titanium dioxide, 18-32 g / L of an acrylate binder, 1-3 g / L of glycerin, 3-4 g / L of a flame retardant, 1-2 g / L of alkyl polyoxyethylene ether succinatesulfonate, 1-2.5 g / L of tribenzylpolyoxyethylenephenol ether, 8-15 g / L of cetyl sodium sulfate and 1.5-3 g / L of an antibacterial agent,the natural antibacterial agent is a plant extract prepared from cudweed,floschrysanthemi, folium artemisiaeargyi, fructusforsythiae andherbahouttuyniae in a mass ratio being (1-2):(1-3):(1-3):(1-2):(1-1.5) through mixed extraction, and density of the plant extract is 1-1.5 g / ml. The pure-natural and non-toxic antibacterial extract is utilized to perform antibacterialtreatment on the fabric, so that the antibacterial effect is realized, the ecological problem in the prior art is solved very well, and energy-saving and environment-friendly effects are realized.

Owner:QINGDAO CHENYUN E COMMERCE CO LTD

Blended yarn of milk protein fibres, natural bamboo fibres and cotton fibres

The invention provides a blended yarn of milk protein fibres, natural bamboo fibres and cotton fibres. The blended yarn comprises the following components in parts by weight: 20 to 30 parts of the milk protein fibres, 25 to 35 parts of the natural bamboo fibres and 35 to 45 parts of the cotton fibres. According to the blended yarn provided by the invention, the characteristics of the three fibres, namely, the milk protein fibres, the natural bamboo fibres and the cotton fibres, can complement one another, and the advantages of the three fibres can be played.

Owner:NANTONG DOUBLE GREAT TEXTILE

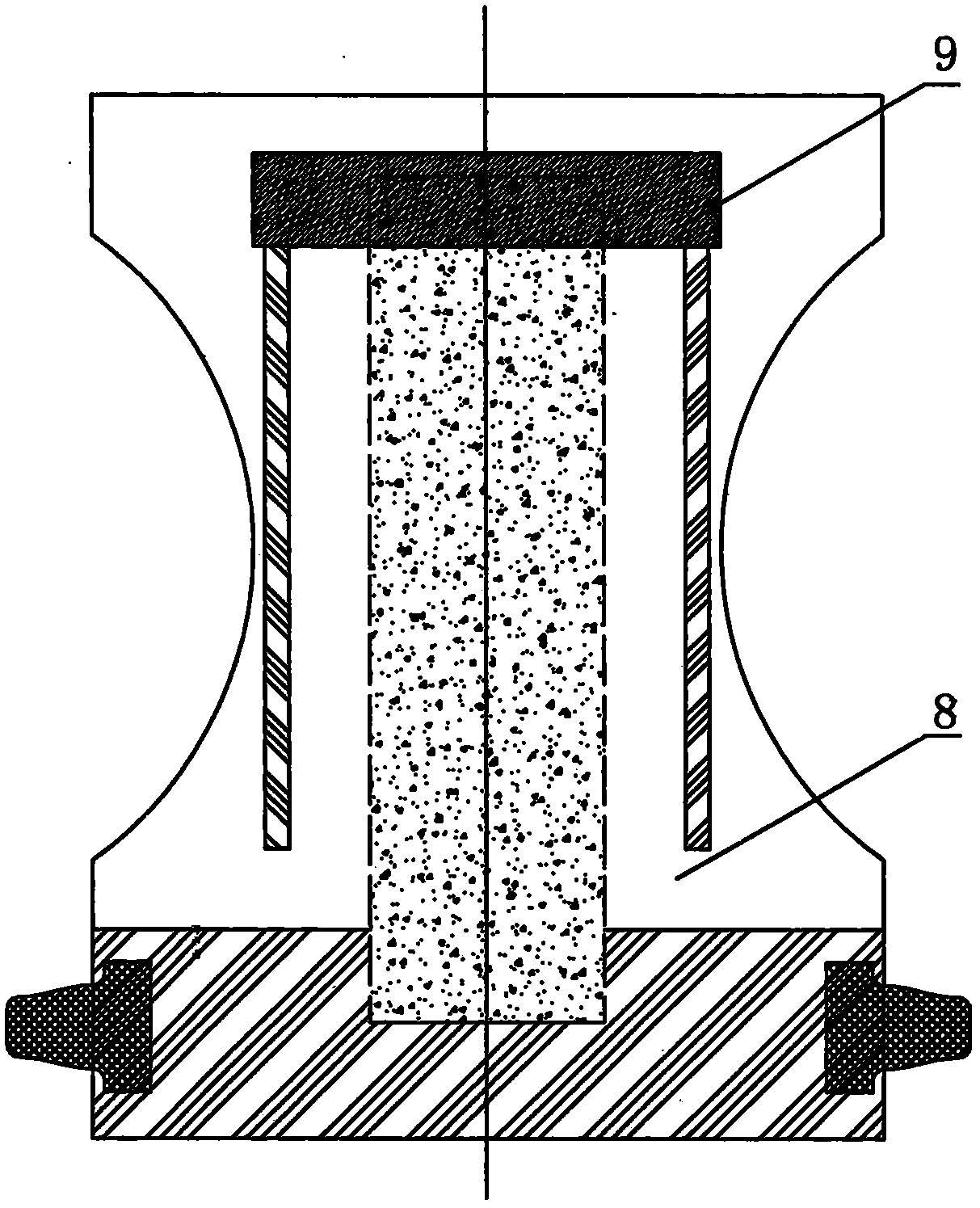

Processing technology of decorative plate

InactiveCN105082315AImprove breathabilityInstant water absorptionReed/straw treatmentDomestic articlesCarbon fibersDissolution

The invention discloses a processing technology of a decorative plate. The processing technology comprises the following specific steps that bamboo wood is cut into bamboo canes, and then the bamboo canes are placed in a steam cooker to be steamed; the steamed bamboo canes are placed in a high-speed fiber dissolution machine to obtain bamboo fibers through processing; magnesium oxychloride, red iron oxide pigment and the bamboo fibers are added to a mold and stirred into pulp by adding water; and phenolic resin, basalt fibers and carbon fibers are added to the mold and are rolled and leveled at the pressure of 1 kg / cm<2> after being evenly stirred, water in the mold is drained, and the decorative plate is obtained after curing. The decorative plate processed through the processing technology has the beneficial effects of having fire prevention performance and the like.

Owner:阜阳祥云木业有限公司

Breathable cool clothing with anti-static function and production method thereof

InactiveCN109330055AGood antistatic functionGood warp breaking strengthElectroconductive/antistatic filament manufactureWoven fabricsMoisture absorptionStatic performance

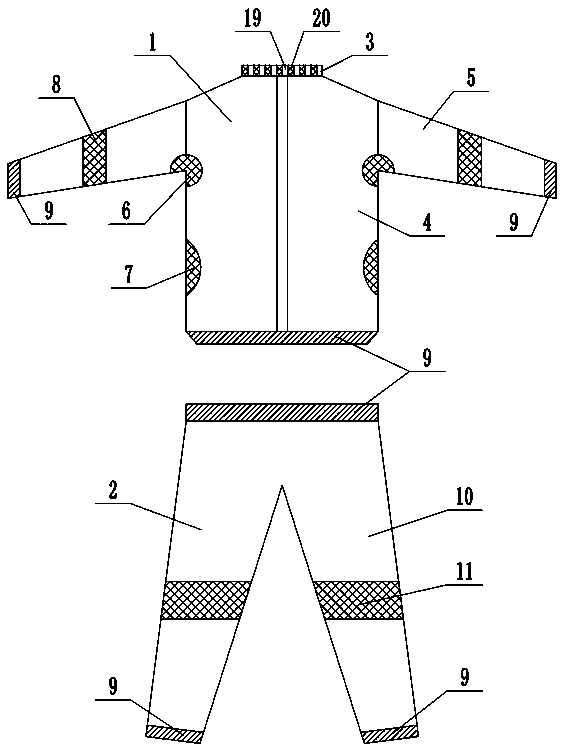

The invention provides breathable cool clothing with an anti-static function and a production method thereof, and belongs to the technical field of clothing. According to the breathable cool clothingwith the anti-static function, alar breathable bodies are sewn at the positions where an upper clothing body is connected with sleeve bodies, waist breathable bodies are sewn on the two sides of the upper clothing body, and arm breathable bodies are sewn on the sleeve bodies. The production method of the breathable cool clothing comprises the following steps of weaving of an anti-static fabric, weaving of a moisture-absorption fabric, combination of the anti-static fabric and the moisture-absorption fabric, weaving of a 3D anti-static gridding fabric, weaving of a breathable moisture-absorption fabric, sewing formation of an anti-static breathable gridding fabric, tailoring of an anti-static moisture-absorption fabric, tailoring of the 3D anti-static gridding fabric, tailoring of the breathable moisture-absorption fabric, sewing of the alar breathable bodies, waist breathable bodies, arm breathable bodies, knee breathable bodies and a collar breathable body, sewing of the anti-static upper clothing, sewing of anti-static trousers and installation of elastic cords. The clothing is good in anti-static performance and high in breathability, the production method is simple, and the cost is low.

Owner:亘美集团有限公司

Medical bamboo fiber bandage

The invention discloses a medical bamboo fiber bandage, which comprises a piece of sterile gauze, a bamboo fiber layer and a waterproof and breathable layer which are arranged in a mode of being sequentially superposed, wherein the sterile gauze is of a net-shaped structure which consists of 50-60% of cotton, 10-20% of spandex and 20-40% of bamboo fibers; a water-absorbent tape and a waterproof tape are sequentially arranged on two sides of the sterile gauze from inside to outside; and the waterproof and breathable layer comprises a PTFE (polytetrafluoroethylene) film which covers the upper end of the bamboo fiber layer and a fabric which is arranged at the upper end of the PTFE film. According to the medical bamboo fiber bandage disclosed by the invention, different from conventional gauze, the sterile gauze is added with the bamboo fibers; the bamboo fibers have the properties of being good in air permeability and instantaneous water-absorbing capacity, relatively strong in wear resistance, good in dyeing property and the like, and meanwhile, the bamboo fibers have functions of naturally resisting bacteria, inhibiting bacteria, inhibiting mites, preventing odor and resisting ultraviolet rays; the waterproof and breathable layer is made from combination of the PTFE film and the fabric, and the PTFE film takes glass fibers as a textile substrate thereof, therefore the waterproof and breathable layer is excellent in air permeability and water proofing property.

Owner:苏清安

Warm-keeping fabric

InactiveCN105780250AGood warmth retentionImprove breathabilityWeft knittingWarp knittingPolyesterWater vapor

The invention provides a warm-keeping fabric which comprises far infrared fibers, Tencel fibers, silk, nylon, acrylic fibers, viscose, polyester staple fibers, spandex and vinylon. The fabric manufactured by the formula has the advantages of good warm-keeping performance, good air permeability, high instant water-absorption performance, high wear resistance and good dyeing performance, etc. In addition, the fabric is also equipped with functions including natural anti-microbial performance, anti-bacteria performance, acarus killing, deodorization and ultraviolet light resistance. Clothes made of the fabric are soft and raped, have a unique touching feeling, and are elegant and dynamic, permeable to air and water vapor, plain and glossy.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

Knitted fabric capable of improving flame-retardant performance and preparation method thereof

The invention discloses a knitted fabric capable of improving flame-retardant performance. The knitted fabric is prepared from the following raw materials in parts by weight: 24 to 30 parts of preprocessed bamboo fibers, 16 to 22 parts of polypropylene fibers, 12 to 14 parts of pure cotton, 8 to 12 parts of needle-shaped wollastonite, 6 to 10 parts of a flame-retardant reinforcing agent, 4 to 8 parts of sepiolite fibers, 2 to 5 parts of sodium silicate, 1 to 3 parts of hindered phenol, 4 to 8 parts of micro-porous bamboo charcoal, and 1 to 3 parts of mullite powder. The invention aims at providing the knitted fabric capable of improving the flame-retardant performance. Compared with the knitted fabric in the prior art, the flame-retardant performance of the fabric is greatly improved. Theknitted fabric provided by the invention has high application value and good application prospect.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

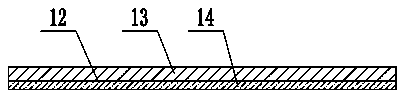

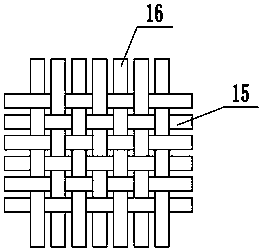

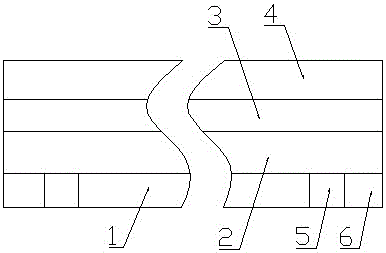

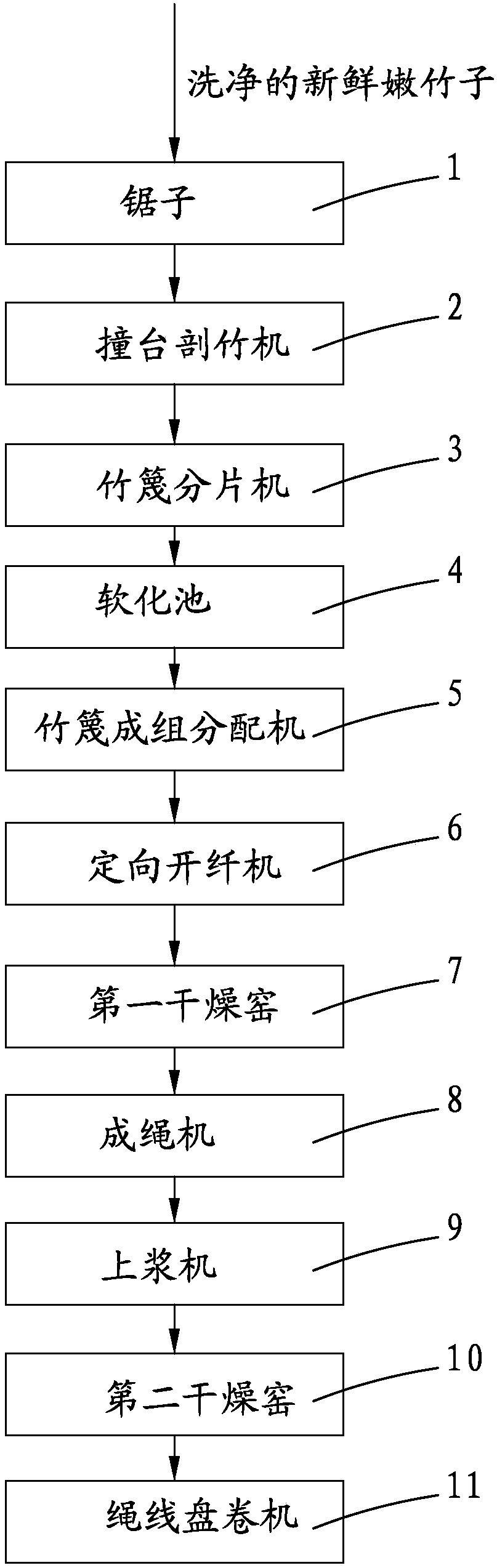

Preparation method and system for bamboo fiber rope

PendingCN109093797AImprove efficiencyIncrease profitWood treatment detailsCane mechanical workingChemistryYarn

The invention provides a preparation method and system for a bamboo fiber rope. The preparation method comprises the following steps that fresh bamboo is taken; branches and bamboo leaves are removed;the bamboo is sawed into bamboo tubes with the fixed length through a disc saw; the bamboo tubes are divided into bamboo chips through a collision table bamboo splitting machine; the bamboo chips aresubjected to bamboo strip dividing treatment through a bamboo strip dividing machine; bamboo strips are placed into a softening pool for to be softened; the softened bamboo strips ae combined and stacked through a bamboo strip group allocation machine; splitting is conducted through a directional splitting machine, and ramie-strip-shaped bamboo fibers are obtained; the ramie-strip-shaped bamboo fibers are pre-dried in a drying kiln; the pre-dried ramie-strip-shaped bamboo fibers are twisted into a rope through a rope forming machine; then slurry coating treatment is conducted through a sizingmachine; then bamboo fiber rope yarn is dried through the drying kiln; and finally, the bamboo fiber rope yarn is rolled through a rope yarn rolling machine to obtain the e bamboo fiber rope yarn. The unique process combination is adopted, the original ecological bamboo fiber rope yarn can be manufactured, and the obtained bamboo fiber rope yarn is basically uniform in evenness, high in strength,good in rigidity, good in antimicrobial property and breathability, high in instantaneous water absorption property, and good in elastic elongation performance.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Novel blended yarn

The invention relates to a novel blended yarn. The blended yarn is made of cotton fibers, seaweed carbon fibers, silkworm protein fibers and bamboo fibers. The blended yarn is characterized by comprising the following raw materials, by weight, 10-20 parts of the cotton fibers, 50-80 parts of the seaweed carbon fibers, 15-30 parts of the silkworm protein fibers and 15-30 parts of the bamboo fibers. The blended yarn has the advantages that the blended yarn is capable of emitting far infrared rays and generating anions, good in air permeability, moisture absorption and drapability, comfortable in hand feeling, high in wear resistance, and good in dyeing property, has the natural anti-microbial, anti-bacteria, snail killing, odor-resistant and uvioresistant functions, and can meet requirements of people.

Owner:邹雪芬

Fragrant antibacterial fabric

InactiveCN105082647AImprove breathabilityInstant water absorptionLayered productsPolymer scienceAdhesive

The invention discloses a fragrant antibacterial fabric, comprising a fabric body. The fabric body comprises a fabric base layer and a fabric surface layer which are connected through sewing; the fabric base layer is provided with uniform cavities in which perfume is placed, and the perfume is fixed in the cavities through an adhesive; and the fabric surface layer is prepared by adding an antibacterial agent into blending raw materials and then carrying out blending, and antibacterial raw materials comprise silk fiber, viscose fiber and bast fiber. The fragrant antibacterial fabric contains a plurality of fibrous raw materials and has the characteristics of good air permeability, instant water-absorbing quality, strong wear resistance, good dyeing property and the like; besides natural antibacterial, bacteriostatic, acaricidal, deodorizing and anti-ultraviolet functions, the fabic has better antibacterial effect due to addition of a nano-silver antibacterial agent; and the fabric has good moisture absorption performance and sweat releasing property, substantial sterilization and deodorization effects and soft and wear-resistant texture, and is applicable to the fields of underwear, outerwear, table linen, etc.

Owner:JIANGSU JUWEI NEW MATERIALS

Granular sand for covering excreta and preparation process for granular sand

The invention discloses granular sand for covering excreta and a preparation process for the granular sand and relates to the technical field of covering of the excreta. The granular sand comprises the following ingredients in percentage by weight: 60%-80% of raw bamboo fibers, 3%-6% of bamboo pulp, 3%-4% of plant stalks, 1%-3% of pine needle meal, 8%-20% of organic matter base stock, 1%-3% of edible gelatin, 1%-3% of bamboo vinegar and 3%-6% of water. According to the granular sand, the dust is little, the pollution to air is reduced, the anti-seepage capability is very high, and the granularsand has relatively good caking and flavor absorbing functions. The granular sand directly sucks up urine, can be directly discarded into a toilet bowl for flush-out and has no need of excessive cleaning usually. The service life is long. Bamboo-fiber cat litter can achieve complete odor inhibiting substantially, a faint-scent flavor of raw bamboos is maintained, and thus, the granular sand is different from the traditional cat litter that urine off odors are covered by addition of flavoring essences.

Owner:杭州复耐吸科技有限公司

Vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn

The invention provides vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn which is composed of, by weight, 55-65 parts of vinylon, 20-30 parts of bamboo fibers and 10-30 parts of silkworm pupa protein fibers. The vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn integrates characteristics of the vinylon, the bamboo fibers and the silkworm pupa protein fibers to bring advantages of the same into play.

Owner:NANTONG MEIMING CHINLON

Novel antibacterial non-woven fabric and preparation method thereof

InactiveCN112323257AImprove breathabilityInstant water absorptionNon-woven fabricsMonocomponent polyolefin artificial filamentBenzoic acidPolymer science

The invention discloses a novel antibacterial non-woven fabric and a preparation method thereof. The novel antibacterial non-woven fabric is prepared from the following raw materials in parts by weight: 100-110 parts of polypropylene resin, 40-50 parts of poly (N-isopropylacrylamide), 13-20 parts of carboxymethyl chitosan, 3-5 parts of a nano zirconium phosphate silver-loaded compound, 35-45 partsof bamboo fiber staple fibers, 10-12 parts of shellac, 1-3 parts of erucyl amide, 4-6 parts of nano tourmaline powder, 2-4 parts of vinyl bisstearamide and 1-3 parts of p-tert-butylbenzoic acid. Thenovel antibacterial non-woven fabric has a good antibacterial effect.

Owner:姚春风

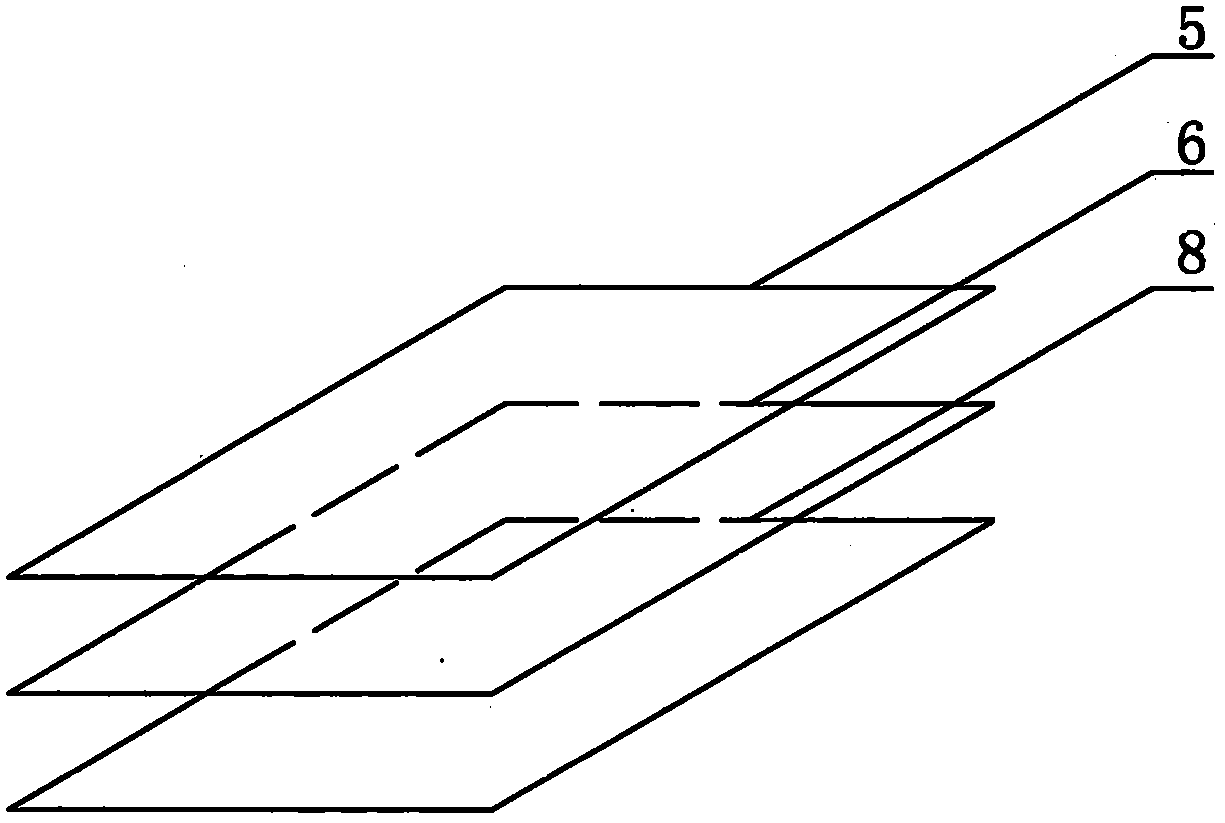

One-time molded fabric and production method thereof

The invention relates to a one-time molded fabric and a production method thereof. The fabric is composed of multiple corresponding textile units distributed at intervals along a warp direction in equal distance, wherein each textile unit comprises multiple warp yarns and weft yarns in different interweaving manners; and a cutting area used for identification is formed in each of the textile units. The corresponding warp yarns and weft yarns of the fabric are produced and woven on an air-jet loom by virtue of preparation procedures such as beaming, slashing, denting and the like according to apreset weave diagram, and own lines are formed by virtue of a denting method sequence of designing the warp yarns and a yarn weaving manner. Then, the fabric that can be formed by virtue of one-timeweaving is designed and developed, and the production efficiency of the product is greatly improved. Moreover, the product is well received by clients and customers, and great profit is created for the company.

Owner:JIHUA 3509 TEXTILE

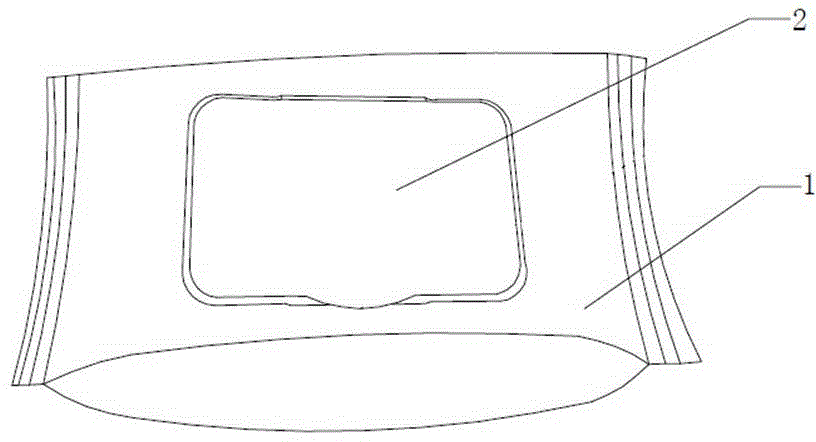

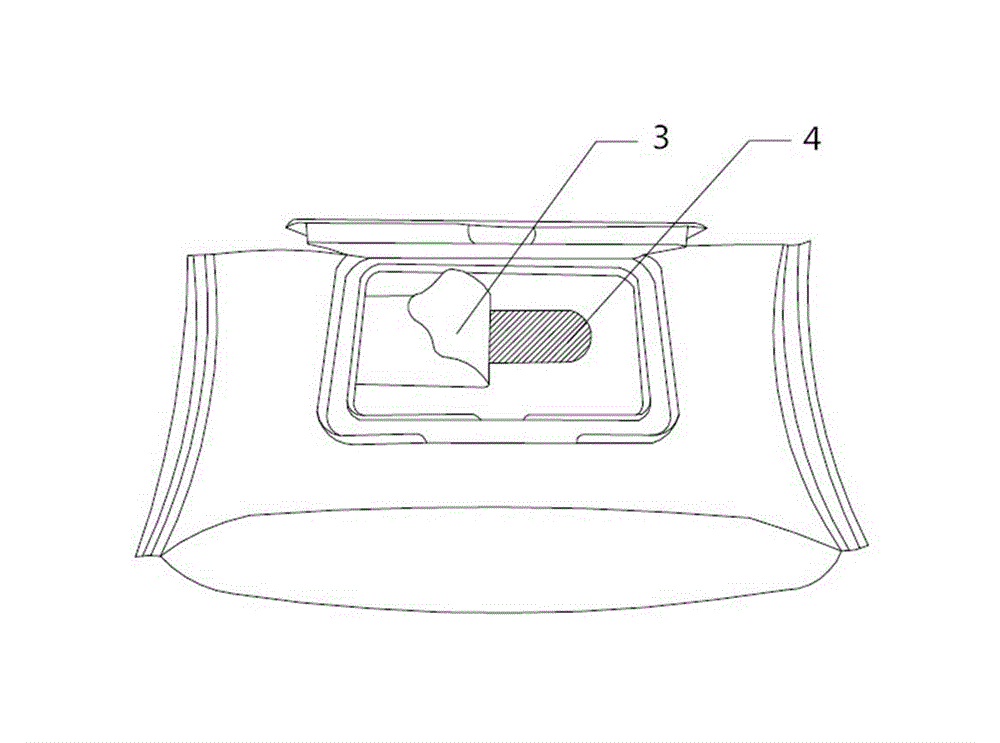

Wet tissue substitute convenient for baby to use

InactiveCN104434546AReduce shipping costsGood air permeabilityCosmetic preparationsToilet preparationsWoven fabricBiomedical engineering

The invention discloses a wet tissue substitute convenient for a baby to use. The wet tissue substitute comprises a packaging bag and a dry wet tissue contained in the packaging bag. The dry wet tissue is formed by a non-woven fabric layer and auxiliaries added on the non-woven fabric layer, and the auxiliaries can be arranged on the non-woven fabric layer and can also be arranged inside the non-woven fabric cloth. Non-woven fabric is formed by processing bamboo fibers, and the residual space, except the dry wet tissue, in the packaging bag contains plain boiled water, wherein the weight of the plain boiled water is 3.5 times that of the non-woven fabric layer. Compared with the prior art, due to the fact that a preservative does not need to be added for mold prevention, use is more healthy and safer, and the wet tissue substitute is especially suitable for the baby. Furthermore, due to the fact that the whole wet tissue substitute is dry, the weight of the wet tissue substitute can be lowered to one fifth of the original weight under the same sheet number and the same size, the transportation cost is greatly lowered, and better energy conservation and better environmental friendliness are achieved.

Owner:付强

Bamboo fiber mat

InactiveCN109090898AImprove breathabilityImprove wear resistanceStuffed mattressesSpring mattressesPolyesterSurface layer

The invention discloses a bamboo fiber mat. The bamboo fiber mat is formed by mixing and hot pressing of bamboo fibers and polyester fibers, wherein the weight percentage of the bamboo fibers in the fiber mat body is 82% to 84%, the balance is the polyester fibers, the bamboo fibers are raw bamboo fibers, and the raw bamboo fibers are natural bamboo fibers, bamboo pulp fibers or bamboo charcoal fibers. The bamboo fiber mat using the bamboo fibers has high air permeability, instant water absorption, strong wear resistance, high dyeability and the like, and has natural antibacterial, anti-mite,deodorant and anti-ultraviolet functions. According to the bamboo fiber mat made by a bamboo fiber mat manufacturing process, not only is an integrated fiber layer formed, but also the bamboo fiber mat does not have upper and lower surface layers, does not have a three-layer structure or even a polyester fiber layer, so the air permeability and the instant water absorption are more prominent.

Owner:GUANGDONG YIXIN HOUSEHOLD MATERIALS GROUP CO LTD

Blended yarn of fine denier nylon yarns, bamboo fibers and viscose fibers

The invention provides a blended yarn of fine denier nylon yarns, bamboo fibers and viscose fibers. The blended yarn comprises following components in parts by weight: 45-55 parts of the fine denier nylon yarns, 30-40 parts of the bamboo fibers and 20-30 parts of viscose fiber. The blended yarn can complement the characteristics of the fine denier nylon yarns, the bamboo fibers and the viscose fibers and can express the advantages of the three types of fibers.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

Method for processing copper fiber, bamboo fiber and cotton fiber blended yarns

The invention discloses a method for processing copper fiber, bamboo fiber and cotton fiber blended yarns. The method includes bamboo fiber strip processing working procedures, combed cotton silver processing working procedures and blending processing working procedures. The method is characterized in that the copper fiber, bamboo fiber and cotton fiber blended yarns comprise, by weight, 25-49% of bamboo fibbers, 20-39% of copper fibers and the balance cotton fibers. According to the scheme, the method has the advantages that the copper fiber, bamboo fiber and cotton fiber blended yarns on the basis of integration of the copper fibers, the cotton fibers and polyester fibers are extremely high in comfort and have certain strength, antistatic capacity, electromagnetic radiation resistance and sterilization characteristics.

Owner:NANTONG JINSHAN TEXTILE

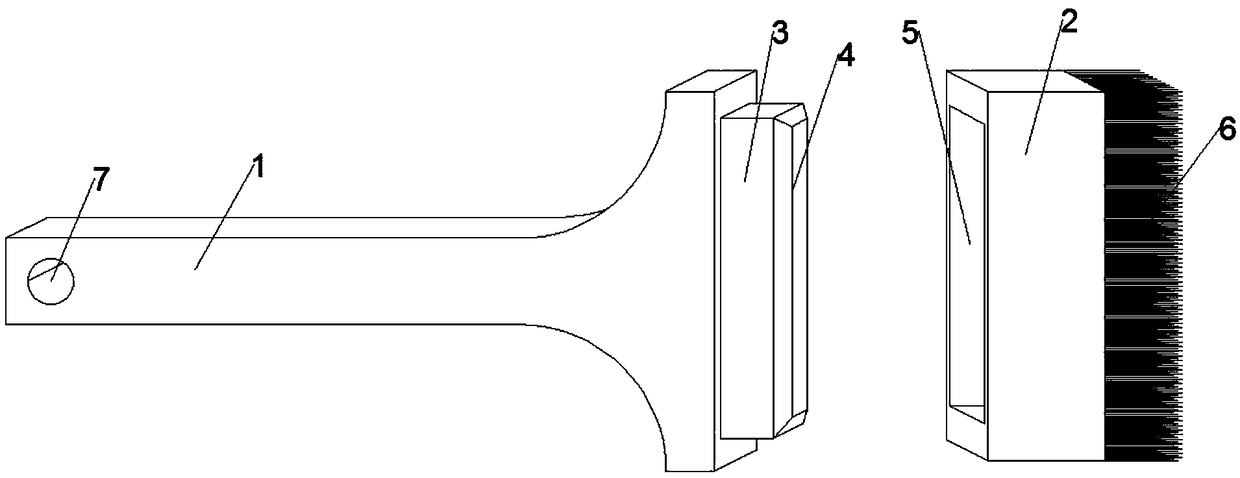

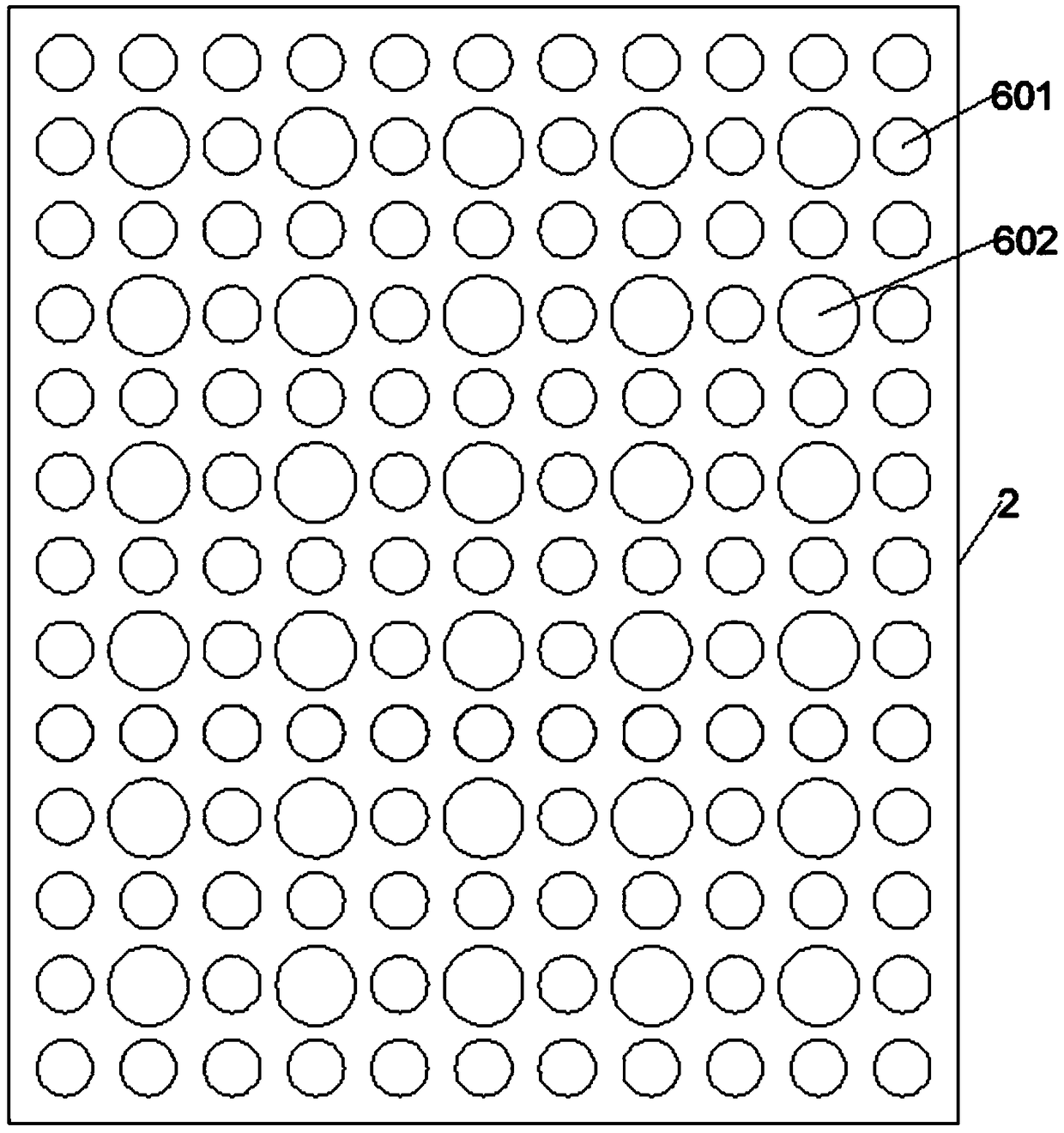

All-wood brush

InactiveCN109008175AGood air permeabilityStrong wear resistanceBrush bodiesBristleEngineeringBristle

The invention discloses an all-wood brush comprising a brush handle and a brush head. One end of the brush handle is provided with a clamp block. One end of the clamp block is provided with a prismatic block. The brush handle, the clamp block and the prismatic block are integrally formed. One end of the brush head is provided with a clamp groove matching the clamp block and the prismatic block. The brush handle, the brush head, the clamp block and the prismatic block are all carved from wood. The other end of the brush head is provided with bristles. The all-wood brush is environmentally friendly and durable, and the bristles are not easy to mildew, so that the service life of the bristles can be prolonged.

Owner:安徽玉达工具有限公司

Antibacterial raw bamboo fiber sanitary napkin

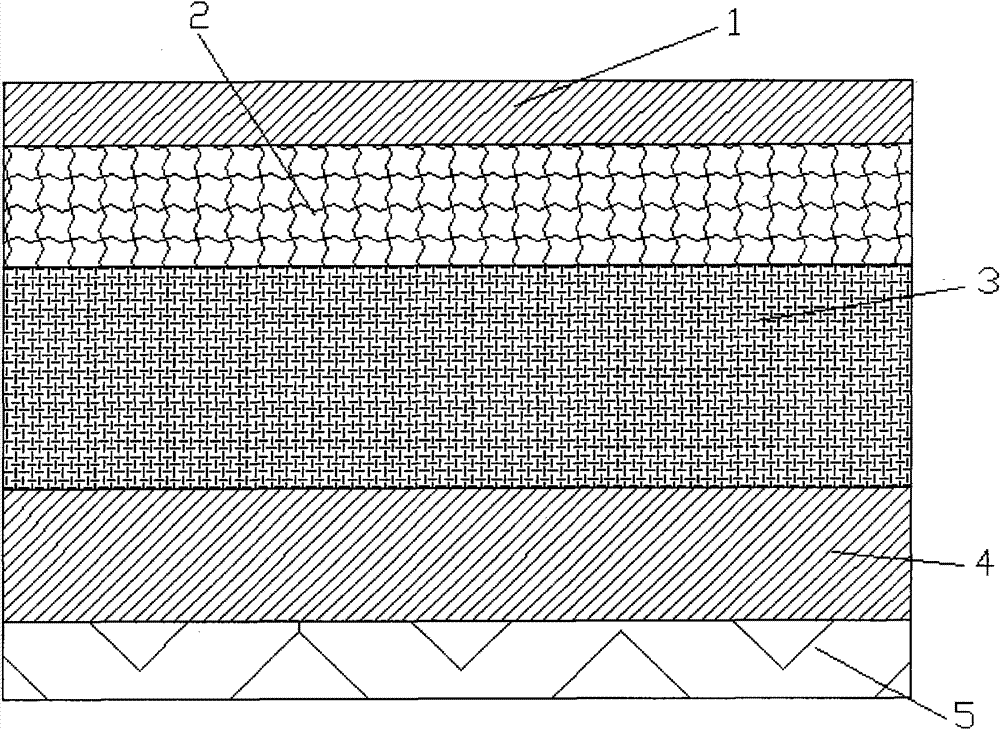

InactiveCN104510576AImprove breathabilityInstant water absorptionAbsorbent padsSurface layerAbsorption layer

The invention provides an antibacterial raw bamboo fiber sanitary napkin which comprises a surface layer, an antibacterial layer, a water absorption layer, a waterproof layer and a bottom layer. The antibacterial raw bamboo fiber sanitary napkin is characterized in that the surface layer is adhered with the bottom layer, the antibacterial layer is arranged between the surface layer and the water absorption layer, the waterproof layer is arranged between the water absorption layer and the bottom layer, and the antibacterial layer is a raw bamboo fiber layer. The raw bamboo fiber layer is arranged between the surface layer and the water absorption layer, menstrual blood is deodorized and sterilized by the antibacterial layer after the sanitary napkin absorbs the menstrual blood, effects are remarkable, action duration is long, undesirable odor of women in a menstrual period is effectively decreased, and bacterial infection is avoided.

Owner:王志全

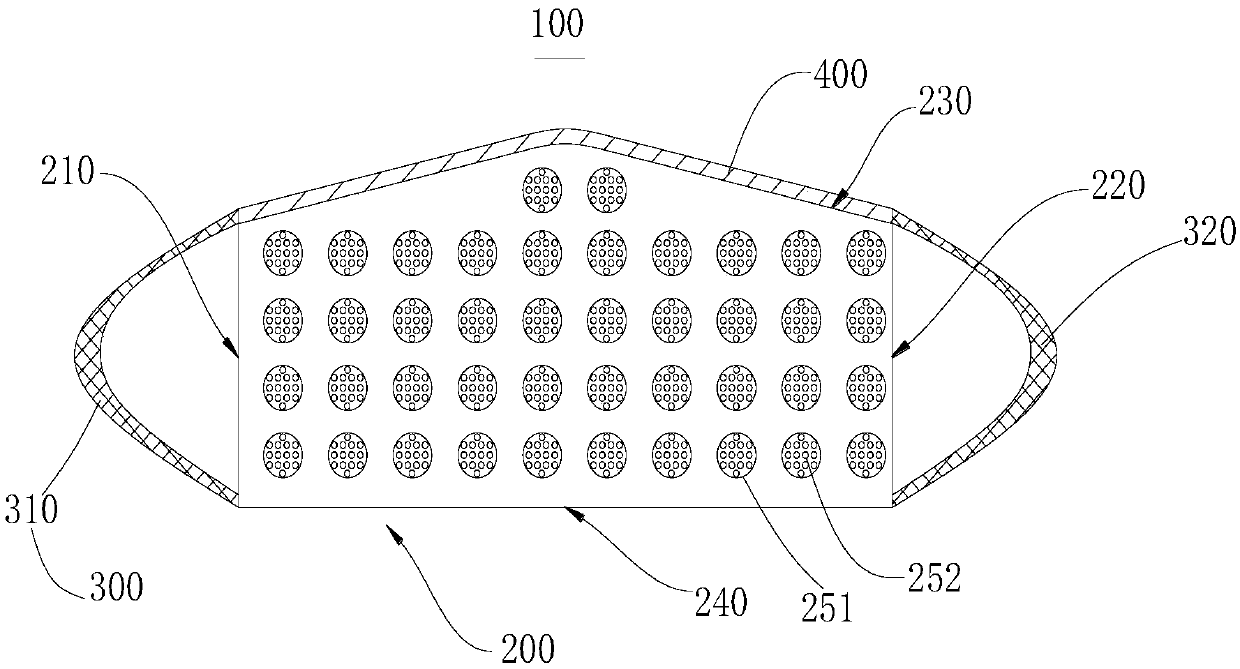

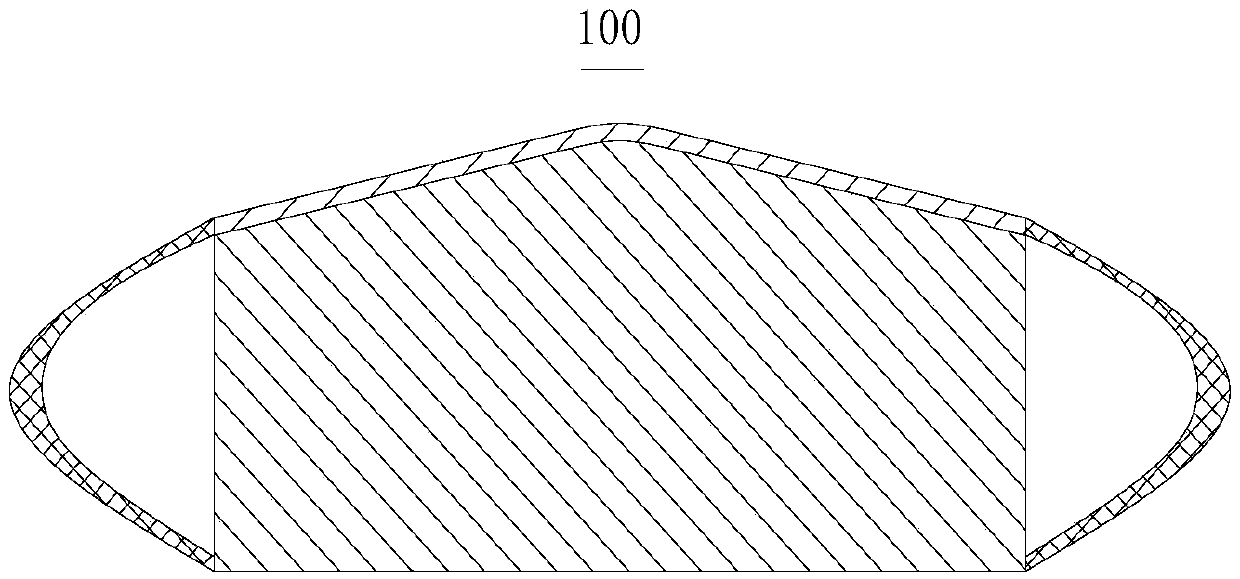

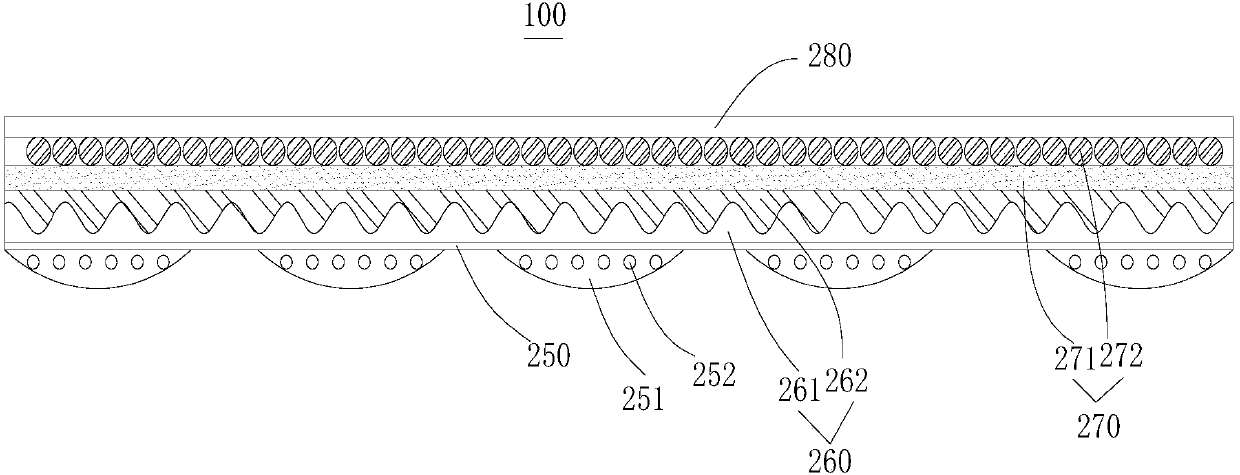

Essential oil respirator

InactiveCN109567288AImprove comfortAvoid moving aroundGarment special featuresProtective garmentEveryday objectEssence oil

The invention provides an essential oil respirator and belongs to the field of articles for daily use. The essential oil respirator comprises a facial mask, an ear band and a nose bridge strip, wherein the facial mask comprises a first end, a second end, a third end and a fourth end, wherein the first end and the second end are oppositely arranged; the third end and the fourth end are oppositely arranged; the ear band is connected with both the first end and the second end; the nose bridge strip is connected with the third end; the facial mask sequentially comprises a lining layer, a filteringlayer, an essential oil layer and a fabric layer from inside to outside; a plurality of bulges are arranged at the end, far away from the filtering layer, of the lining layer; the essential oil layercomprises a first essential oil layer and a second essential oil layer; the first essential oil layer is prepared by soaking a plurality of bamboo fibers in plant essential oil; the second essentialoil layer is a plant essential oil ball; the plant essential oil comprises rose essential oil, jasmine essential oil, lavender essential oil, lemon essential oil, mint essential oil, green tea essential oil and sweet orange essential oil with a mass ratio of 4:2:5:3.5:2:1.5:1. Through the combination and the natural volatilization of a variety of natural plant essential oils, a respiratory environment can be effectively improved within a long time; meanwhile, the respirator also has better comfortable feeling.

Owner:四川省乐至贵均卫生材料有限公司

Manufacturing method for multifunctional wool spinning fabric

InactiveCN105401297ABreak through the limitations of taking seasonOvercoming the shortcomings of the cooling approachSolvent-treatmentDyeing processYarnTransmittance

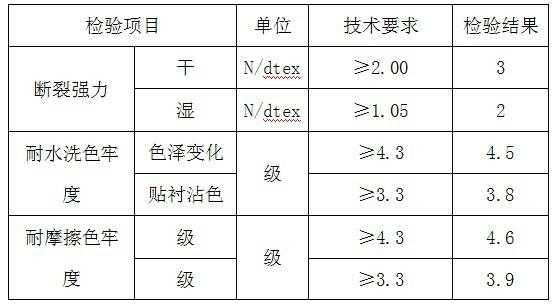

The invention relates to a manufacturing method for a multifunctional wool spinning fabric. The fabric comprises non-shrinkable wool whose specifications are 70 S-80 S of fineness and 60-70 mm of length, and ultraviolet prevention bamboo fibers whose specification is 4-5 dtex*(65-70) mm. Mass percent of the two components of the non-shrinkable wool and the ultraviolet prevention bamboo fibers is 30-60% to 70-40%. The non-shrinkable wool balls are dyed to make into color wool tops. The ultraviolet prevention bamboo fibers are dyed, through silver blending, the yarns are woven into spun yarns, and through posterior spinning, fine yarns are obtained. A wool spinning fabric is made by the manufacturing method, and the fabric is made into the multifunctional wool spinning fabric through two-time soaking and binding fabric processing. The fabric and the manufacturing method can effectively improve transmittance, moisture permeability and air permeability. The fabric has good ultraviolet protection performance, fastness to rubbing, color fastness to washing, and has good antistatic property, flame retardant property, and permeability, and has health care effect.

Owner:JIANGSU SUNSHINE

Bamboo carbon fiber fly-knitted vamp

InactiveCN109736096AImprove breathabilityInstant water absorptionMonocomponent polyurethanes artificial filamentFiberHot weather

The invention relates to the technical field of fly-knitted vamps and particularly relates to a bamboo carbon fiber fly-knitted vamp knitted by virtue of bamboo carbon fibers. The bamboo carbon fibershave the characteristics of good air permeability, instant water-absorbing property, relatively strong wear resistance, winter warmness, summer coolness and the like, further have a series of functional characteristics of natural antibacterial property, bacteriostatic property, mite removal property, deodorization property and ultraviolet resistance and are applied to the fly-knitted vamps, the fly-knitted vamps can be dry, comfortable, air-permeable, healthy and odor-free when being worn in outdoor hot weather, are cool and comfortable when being worn in winter, are warm in winter and cool in summer and can meet the mental and wearing comfortable feels of customers. The fly-knitted vamps have great market superiorities and breakthrough effects.

Owner:东莞市喜宝体育用品科技有限公司

A medicate diaper with sterilization and ventilation effect

InactiveCN109259939AEasy to solveImprove protectionAnthropod material medical ingredientsAntipyreticIrritationPhysical well being

A medicate diaper with sterilization and ventilation effect comprises elastic waist band, magic buckle, crotch area, elastic leg band, surface coating layer, absorbent core lay, leak-proof retaining wall, base cloth and front waist paste. The diaper can absorb urine quickly and effectively, the surface is soft, comfortable, dry and permeable, and can provide dry and comfortable environment for infants. The surface coating layer is made of hydrophilic non-woven material and made of forsythia suspensa, Chinese herbal medicine liquid of mountain sesame, Chinese nutgall, small flying yam grass, coptis root and wild chrysanthemum flower is mixed according to proportion, which has no irritation and allergic reaction to baby's tender skin, good permeability, instant water absorption, sterilization, heat clearing and dehumidification, reduces the occurrence of diaper rash and eczema of baby, and protects baby's health.

Owner:江苏第六通道科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com