All-wood brush

A technology of wood and bristles, applied in the direction of brushes, brush bodies, bristles, etc., can solve the problems of easy mold, formaldehyde, and easy residual moisture in the bristles, and achieve the effect of good air permeability and strong wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

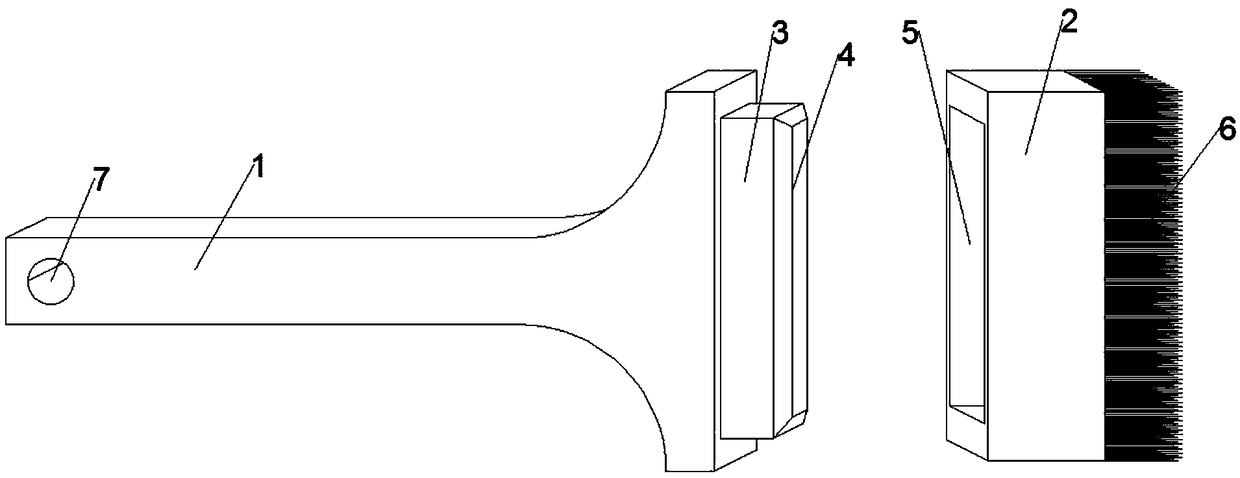

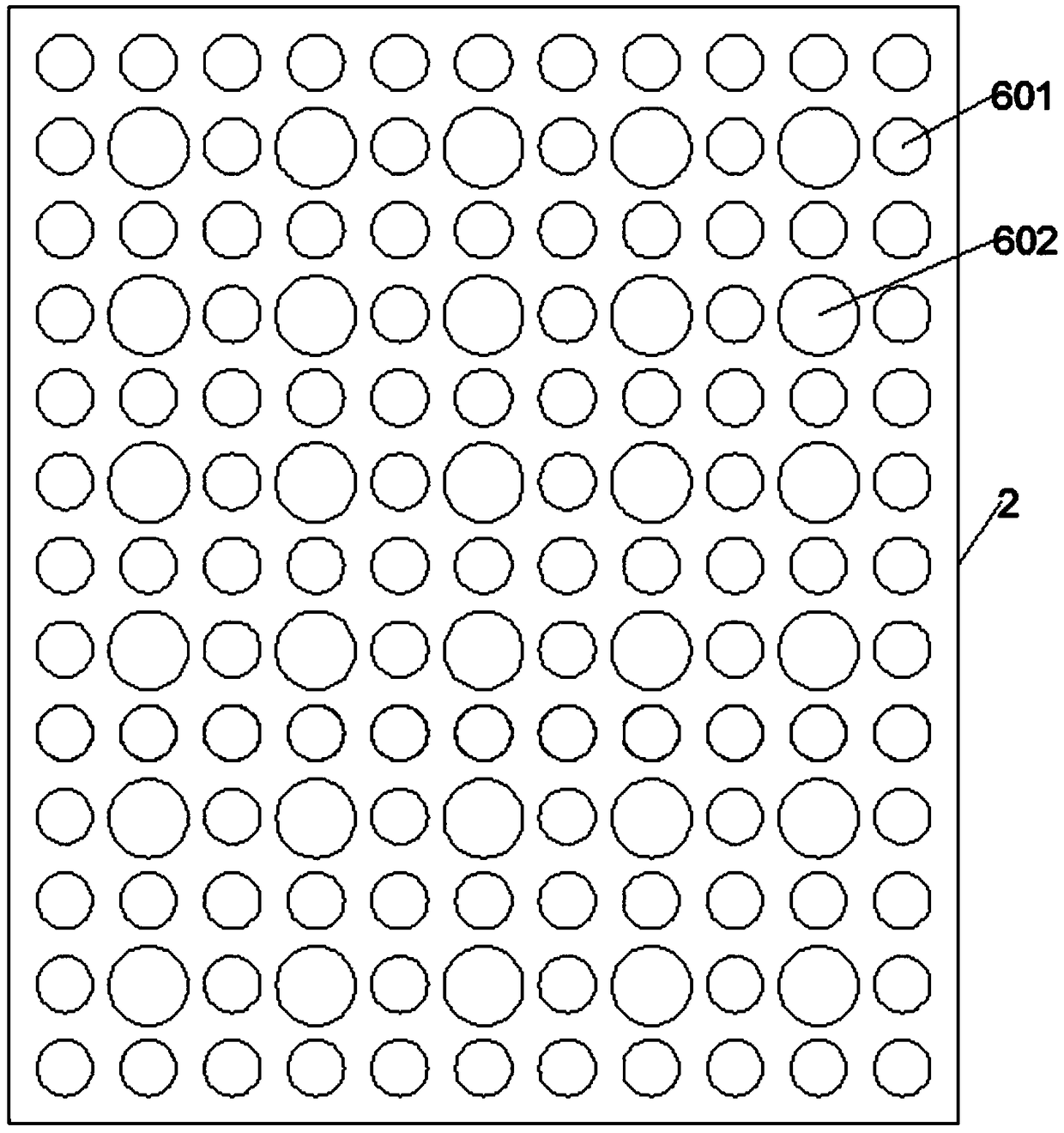

[0025] see Figure 1-2 As shown, an all-wood brush includes a brush handle 1, a brush head 2, one end of the brush handle 1 is provided with a block 3, one end of the block 3 is provided with an edge block 4, the brush handle 1, the block 3, and the edge block 4 is an integrally formed structure. One end of the brush head 2 is provided with a card slot 5 that is compatible with the block 3 and the edge block 4. The brush handle 1, the brush head 2, the block 3, and the edge block 4 are all carved from wood. The other end of the brush head 2 is provided with bristles 6, and the handle is provided with perforations 7.

[0026] The bristle is composed of the following raw materials in parts by weight: 80 parts of bamboo fiber, 6 parts of nano titanium dioxide, 100 parts of tourmaline powder, 15 parts of polyvinyl alcohol resin, 2 parts of phase solvent and 1 part of dispersant.

[0027] The bristles are prepared as follows:

[0028] (1) Take the raw materials of corresponding w...

Embodiment 2

[0034] The structure of the all-wood brush in this embodiment is the same as that of Embodiment 1, except that the raw material composition and preparation method of the bristles are different.

[0035] The bristle is composed of the following raw materials in parts by weight: 83 parts of bamboo fiber, 7 parts of nano-titanium dioxide, 110 parts of tourmaline powder, 23 parts of polyvinyl alcohol resin, 3 parts of phase solvent, and 2 parts of dispersant.

[0036] The bristles are prepared as follows:

[0037] (1) Take the raw materials of corresponding weight parts respectively;

[0038] (2) Put nano-titanium dioxide, polyvinyl alcohol resin, phase solvent, and dispersant into a kneader, knead for 1.5 hours, obtain auxiliary materials, and set aside;

[0039] (3) Tourmaline powder is made into microfiber, obtains tourmaline powder fiber, for subsequent use;

[0040] (4) Divide the auxiliary material into two parts on average, one part is put into the kneader with bamboo fib...

Embodiment 3

[0043] The structure of the all-wood brush in this embodiment is the same as that of Embodiment 1, except that the raw material composition and preparation method of the bristles are different.

[0044] The bristle is composed of the following raw materials in parts by weight: 86 parts of bamboo fiber, 8 parts of nano-titanium dioxide, 120 parts of tourmaline powder, 30 parts of polyvinyl alcohol resin, 5 parts of phase solvent and 3 parts of dispersant.

[0045] The bristles are prepared as follows:

[0046] (1) Take the raw materials of corresponding weight parts respectively;

[0047] (2) Put nano-titanium dioxide, polyvinyl alcohol resin, phase solvent, and dispersant into a kneader, knead for 2 hours, obtain auxiliary materials, and set aside;

[0048] (3) Tourmaline powder is made into microfiber, obtains tourmaline powder fiber, for subsequent use;

[0049] (4) The auxiliary material is divided into two parts on average, one part is put into the kneader with bamboo fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com