Novel antibacterial non-woven fabric and preparation method thereof

A new type of non-woven fabric technology, applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of general antibacterial effect, achieve strong wear resistance, reduce consumption, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

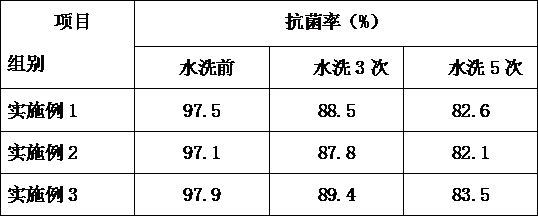

Examples

Embodiment 1

[0034] A new type of antibacterial non-woven fabric, including the following raw materials in parts by weight: 100 parts of polypropylene resin, 40 parts of poly(N-isopropylacrylamide), 13 parts of carboxymethyl chitosan, nano zirconium phosphate 3 parts of silver compound, 35 parts of short bamboo fiber, 10 parts of shellac, 1 part of erucamide, 4 parts of nano tourmaline powder, 2 parts of vinyl distearamide and 1 part of p-tert-butylbenzoic acid.

[0035] A kind of preparation method of novel antibacterial nonwoven fabric comprises the following steps:

[0036] 1) Pour 1 part of erucamide and 2 parts of vinyl bis stearic acid amide together into a mixer for mixing to prepare a mixture for later use;

[0037] 2) Divide the mixture prepared in step 1) into parts A and B equally, and set aside;

[0038] 3) Pour 100 parts of polypropylene resin, 3 parts of nano zirconium phosphate silver-loaded composite, 1 part of p-tert-butylbenzoic acid and the mixture of part A prepared in...

Embodiment 2

[0044]A new type of antibacterial non-woven fabric, including the following raw materials in parts by weight: 110 parts of polypropylene resin, 50 parts of poly(N-isopropylacrylamide), 20 parts of carboxymethyl chitosan, nano zirconium phosphate 5 parts of silver compound, 45 parts of short bamboo fiber, 12 parts of shellac, 3 parts of erucamide, 6 parts of nano tourmaline powder, 4 parts of vinyl distearamide and 3 parts of p-tert-butylbenzoic acid.

[0045] A kind of preparation method of novel antibacterial non-woven fabric, comprises the following steps:

[0046] 1) Pour 3 parts of erucamide and 4 parts of vinyl bis stearic acid amide into a mixer for mixing to prepare a mixture for later use;

[0047] 2) Divide the mixture prepared in step 1) into parts A and B equally, and set aside;

[0048] 3) Pour 110 parts of polypropylene resin, 5 parts of nano-zirconium phosphate silver-loaded composite, 3 parts of p-tert-butylbenzoic acid and the mixture of part A prepared in ste...

Embodiment 3

[0054] A new type of antibacterial non-woven fabric, including the following raw materials in parts by weight: 105 parts of polypropylene resin, 45 parts of poly(N-isopropylacrylamide), 15 parts of carboxymethyl chitosan, nano zirconium phosphate 4 parts of silver compound, 40 parts of short bamboo fiber, 11 parts of shellac, 2 parts of erucamide, 5 parts of nano tourmaline powder, 3 parts of vinyl bis stearic acid amide and 2 parts of p-tert-butylbenzoic acid.

[0055] A kind of preparation method of novel antibacterial non-woven fabric, comprises the following steps:

[0056] 1) Pour 2 parts of erucamide and 3 parts of vinyl bis stearic acid amide together into a mixer for mixing to prepare a mixture for later use;

[0057] 2) Divide the mixture prepared in step 1) into parts A and B equally, and set aside;

[0058] 3) Pour 105 parts of polypropylene resin, 4 parts of nano-zirconium phosphate silver-loaded composite, 2 parts of p-tert-butylbenzoic acid and the mixture of pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com