Degradable double-layer plastic express bag and preparation method thereof

A plastic, double-layer technology, applied in the field of degradable double-layer plastic express bags and its preparation, can solve the problems of white pollution and achieve the effect of solving white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

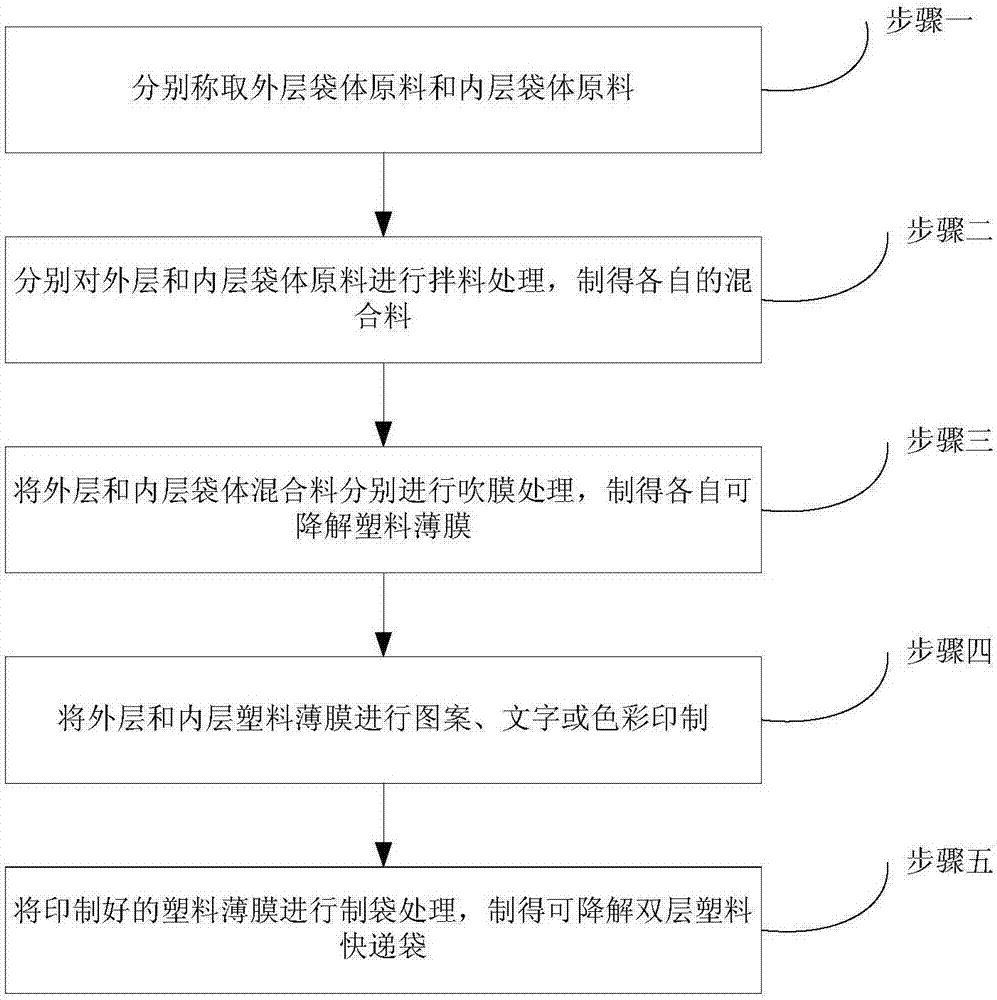

[0056] The preparation method of degradable double-layer plastic express bag, such as figure 1 shown, including the following steps:

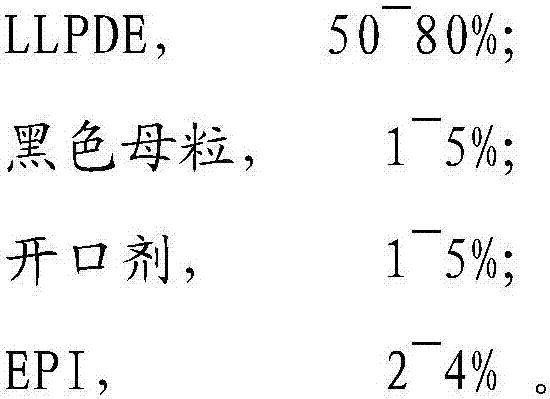

[0057] Step 1, according to the mass percentage, weigh the outer bag body raw materials: LDPE 1.0kg, LLPDE 7.0kg, white masterbatch 2.0kg; inner bag body raw materials: LDPE 3.0kg, LLPDE 6.5kg, black masterbatch 0.1kg, opening agent 0.2kg, EPI 0.2kg;

[0058] Step 2, put the above-mentioned inner bag body raw materials and outer layer bag body raw materials into the mixer respectively for mixing, as follows:

[0059] Inner bag raw material mixing treatment: add LDPE, LLDPE, and white masterbatch to the mixer in sequence, and then mix and mix for 15 minutes to obtain the inner bag mixing material;

[0060] Processing of raw materials for the outer bag body: add LDPE, LLDPE, black masterbatch, anti-blocking agent, and EPI to the mixer in sequence, and then mix the materials for 15 minutes to obtain the outer bag body mixture;

[0061] Step 3: ...

Embodiment 2

[0065] The preparation method of degradable double-layer plastic express bag comprises the following steps:

[0066] Step 1: According to the mass percentage, weigh the raw materials of the outer bag: 3.0kg of LDPE, 5.0kg of LLPDE, 2.0kg of white masterbatch; the raw materials of the inner bag: 1.0kg of LDPE, 7.6kg of LLPDE, black masterbatch 0.5kg, opening agent 0.5kg, EPI 0.4kg;

[0067] Step 2, put the above-mentioned inner bag body raw materials and outer layer bag body raw materials into the mixer respectively for mixing, as follows:

[0068] Inner bag raw material mixing treatment: add LDPE, LLDPE, and white masterbatch to the mixer in sequence, and then mix and mix for 20 minutes to obtain the inner bag mixing material;

[0069]Processing of raw materials for the outer bag body: add LDPE, LLDPE, black masterbatch, anti-blocking agent, and EPI to the mixer in sequence, and then mix the materials for 20 minutes to obtain the outer bag body mixture;

[0070] Step 3: Put ...

Embodiment 3

[0074] The preparation method of degradable double-layer plastic express bag comprises the following steps:

[0075] Step 1. According to the mass percentage, weigh the raw materials of the outer bag: 2.5kg of LDPE, 5.5kg of LLPDE, 2.0kg of white masterbatch; the raw materials of the inner bag: 2.7kg of LDPE, 6.6kg of LLPDE, black masterbatch 0.2kg, opening agent 0.2kg, EPI 0.3kg;

[0076] Step 2, put the above-mentioned inner bag body raw materials and outer layer bag body raw materials into the mixer respectively for mixing, as follows:

[0077] Inner bag raw material mixing treatment: add LDPE, LLDPE, and white masterbatch to the mixer in sequence, and then mix and mix for 30 minutes to obtain the inner bag mixing material;

[0078] Material mixing treatment of the outer layer bag body: add LDPE, LLDPE, black masterbatch, anti-blocking agent, EPI to the mixer in sequence, and then mix the material for 30 minutes to obtain the outer layer bag body mixture;

[0079] Step 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com