Technique for improving interfacial compatibility of bamboo fiber and polybutylene succinate based on polydopamine bionic interfacial modification modifier

A technology of polybutylene succinate and polydopamine, which is applied in the field of polymer biomodifiers, can solve problems such as infeasibility, high cost, and difficult operation, and achieve improved utilization rate and good dimensional stability , the effect of improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

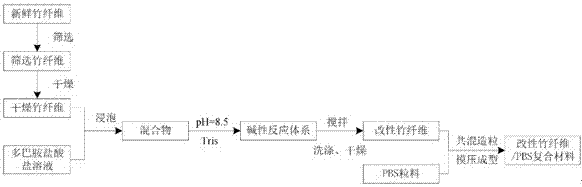

Method used

Image

Examples

Embodiment 1

[0015] (1) Test material.

[0016] Bamboo fiber, mixed particle size 40-60 mesh, fiber length less than 380μm, purchased from Anhui Sentai Wood Plastic Group Co., Ltd.; polybutylene succinate (PBS), flow index 2.0g / 10 min, crystallinity Percentage 32%, density 1.24g / cm3, purchased from Shanghai Showa Polymer Co., Ltd.; dopamine hydrochloride (98.5%) and tris(hydroxymethyl)methylaminomethane (99.9%), purchased from Beijing Suo Laibao Technology Co., Ltd. ; Hydrochloric acid, solid paraffin and deionized water were purchased from Beijing Sinopharm Chemical Reagent Beijing Co., Ltd. All materials were used without further purification.

[0017] (2) Test equipment.

[0018] DLZ-6510 vacuum drying oven, Shanghai Donglu Instrument Equipment Co., Ltd.; HJB-S 450 laboratory mixer, Shanghai Huiwei Mechanical and Electrical Equipment Co., Ltd.; SHR-A high-speed mixer, Zhangjiagang Tongsha Plastic Machinery Co., Ltd. ; SJSH30 twin-screw extruder, Nanjing Rubber and Plastic Machinery F...

Embodiment 2

[0026] (1) Test material.

[0027] Bamboo fiber, mixed particle size 40-60 mesh, fiber length less than 380μm, purchased from Anhui Sentai Wood Plastic Group Co., Ltd.; polybutylene succinate (PBS), flow index 2.0g / 10 min, crystallinity Percentage 32%, density 1.24g / cm3, purchased from Shanghai Showa Polymer Co., Ltd.; dopamine hydrochloride (98.5%) and tris(hydroxymethyl)methylaminomethane (99.9%), purchased from Beijing Suo Laibao Technology Co., Ltd. ; Hydrochloric acid, solid paraffin and deionized water were purchased from Beijing Sinopharm Chemical Reagent Beijing Co., Ltd. All materials were used without further purification.

[0028] (2) Test equipment.

[0029] DLZ-6510 vacuum drying oven, Shanghai Donglu Instrument Equipment Co., Ltd.; HJB-S 450 laboratory mixer, Shanghai Huiwei Mechanical and Electrical Equipment Co., Ltd.; SHR-A high-speed mixer, Zhangjiagang Tongsha Plastic Machinery Co., Ltd. ; SJSH30 twin-screw extruder, Nanjing Rubber and Plastic Machinery Fac...

Embodiment 3

[0037] (1) Test material.

[0038] Bamboo fiber, mixed particle size 40-60 mesh, fiber length less than 380μm, purchased from Anhui Sentai Wood Plastic Group Co., Ltd.; polybutylene succinate (PBS), flow index 2.0g / 10 min, crystallinity Percentage 32%, density 1.24g / cm3, purchased from Shanghai Showa Polymer Co., Ltd.; dopamine hydrochloride (98.5%) and tris(hydroxymethyl)methylaminomethane (99.9%), purchased from Beijing Suo Laibao Technology Co., Ltd. ; Hydrochloric acid, solid paraffin and deionized water were purchased from Beijing Sinopharm Chemical Reagent Beijing Co., Ltd. All materials were used without further purification.

[0039] (2) Test equipment.

[0040] DLZ-6510 vacuum drying oven, Shanghai Donglu Instrument Equipment Co., Ltd.; HJB-S 450 laboratory mixer, Shanghai Huiwei Mechanical and Electrical Equipment Co., Ltd.; SHR-A high-speed mixer, Zhangjiagang Tongsha Plastic Machinery Co., Ltd. ; SJSH30 twin-screw extruder, Nanjing Rubber and Plastic Machinery F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com