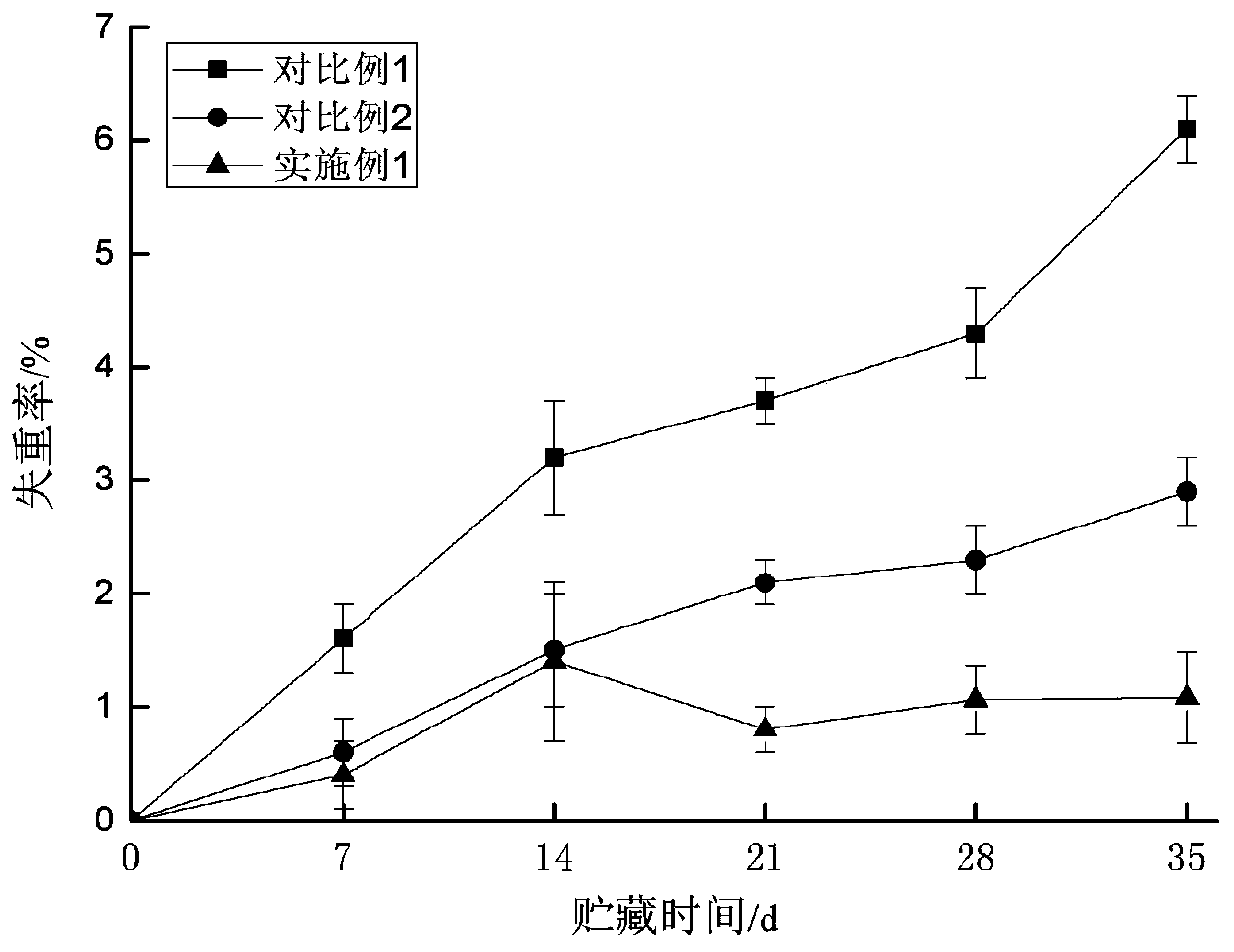

Full-biomass porous material slow-release antibacterial active preservative film and preparation method thereof

A technology of porous materials and antibacterial activity, applied in the field of all-biomass porous material slow-release antibacterial active fresh-keeping film and its preparation, can solve the problems of pollution, white pollution, etc., and achieve the effect of solving white pollution, low utilization rate, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

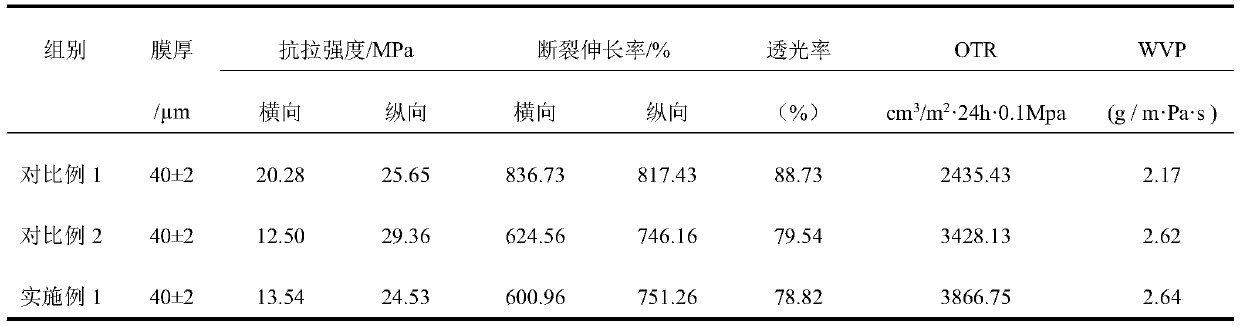

Examples

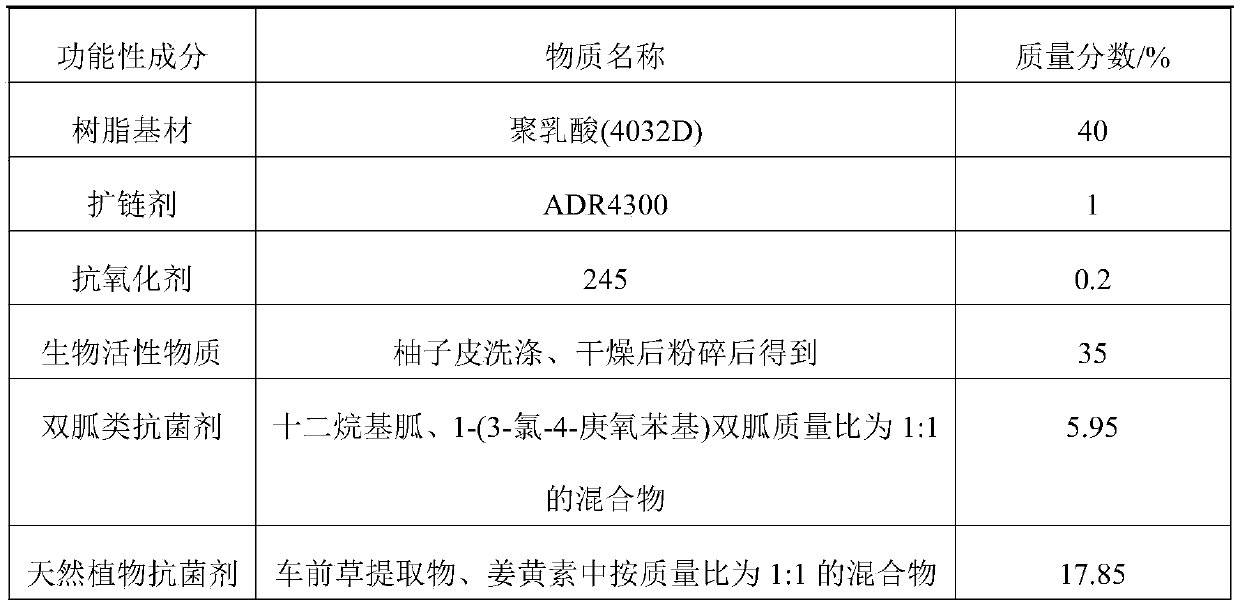

Embodiment 1

[0034] The preparation method of the slow-release antibacterial active fresh-keeping film of the whole biomass porous material comprises the following steps:

[0035] (1) Washing the pomelo peel as a biological raw material with distilled water, drying at 80°C for 24 hours to constant weight, cooling to normal temperature, pulverizing with a pulverizer, and passing through a 160-mesh sieve to obtain a biological porous substance;

[0036] (2) mixing and stirring the biological porous substance and the antibacterial agent in proportion for 10 minutes, so that the biological porous substance fully absorbs the antibacterial agent, and obtains a mixed material;

[0037] (3) After the mixture of resin base material polylactic acid and chain extender ADR4300, antioxidant 245 and step (2) is mixed evenly in proportion (as shown in Table 1), extrude granulation by twin-screw extruder, To obtain the resin masterbatch, the twin-screw extruder is provided with seven heating zones sequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com