Soil conditioner for preventing soil hardening and preparation method of soil conditioner

A soil conditioner and soil compaction technology, which is applied in the field of soil conditioner for preventing soil compaction and its production, can solve the problems of destroying surface coverage and increasing the risk of soil erosion and surface soil compaction, so as to prevent soil compaction, improve soil air permeability, The effect of loosening the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

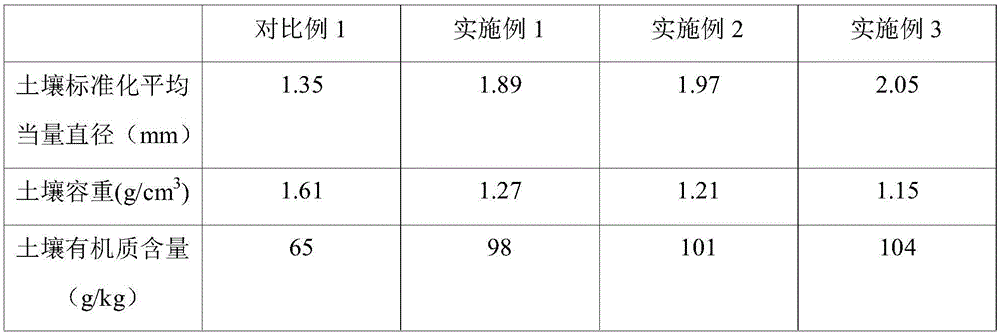

Examples

Embodiment 1

[0027] A soil conditioner for preventing soil compaction, comprising the following raw materials in parts by weight:

[0028]70 parts of rice husk, 60 parts of wheat husk, 15 parts of banana fiber, 10 parts of coconut fiber, 10 parts of bark, 40 parts of peat, 30 parts of legume straw, 10 parts of bean grains, 10 parts of distiller's grains, 8 parts of coffee grounds, 10 parts of rapeseed cake, 10 parts of cottonseed cake, 8 parts of fish meal, 8 parts of bone meal, 10 parts of medical stone powder, 10 parts of zeolite powder, 10 parts of bentonite, 6 parts of urea, 2 parts of ammonium sulfate, 3 parts of potassium dihydrogen phosphate, 1 part of ferrous sulfate, 1 part of magnesium sulfate, 1 part of zinc sulfate, 3 parts of potassium chloride, 4 parts of superphosphate, 2 parts of calcium peroxide, 1 part of magnesium peroxide, 5 parts of borax, 2 parts of agricultural water retaining agent and 0.5 part of microbial agent.

[0029] Wherein, the agricultural water-retaining ...

Embodiment 2

[0039] A soil conditioner for preventing soil compaction, comprising the following raw materials in parts by weight:

[0040] 90 parts of rice husk, 80 parts of wheat husk, 20 parts of banana fiber, 20 parts of coconut fiber, 12 parts of bark, 50 parts of peat, 40 parts of legume straw, 20 parts of bean grains, 20 parts of distiller's grains, 10 parts of coffee grounds, 20 parts of rapeseed cake, 20 parts of cottonseed cake, 10 parts of fish meal, 10 parts of bone meal, 15 parts of medical stone powder, 15 parts of zeolite powder, 12 parts of bentonite, 8 parts of urea, 4 parts of ammonium sulfate, 5 parts of potassium dihydrogen phosphate, 3 parts of ferrous sulfate, 2 parts of magnesium sulfate, 2 parts of zinc sulfate, 5 parts of potassium chloride, 6 parts of superphosphate, 4 parts of calcium peroxide, 3 parts of magnesium peroxide, 7 parts of borax, 4 parts of agricultural water retaining agent and 0.7 part of microbial agent.

[0041] Wherein, the agricultural water-re...

Embodiment 3

[0051] A soil conditioner for preventing soil compaction, comprising the following raw materials in parts by weight:

[0052] 80 parts of rice husk, 70 parts of wheat husk, 18 parts of banana fiber, 150 parts of coconut fiber, 11 parts of bark, 45 parts of peat, 35 parts of legume straw, 15 parts of bean grains, 15 parts of distiller's grains, 9 parts of coffee grounds, 15 parts of rapeseed cake, 15 parts of cottonseed cake, 9 parts of fish meal, 9 parts of bone meal, 12 parts of medical stone powder, 12 parts of zeolite powder, 11 parts of bentonite, 7 parts of urea, 3 parts of ammonium sulfate, 4 parts of potassium dihydrogen phosphate, 2 parts of ferrous sulfate, 1.5 parts of magnesium sulfate, 1.5 parts of zinc sulfate, 4 parts of potassium chloride, 5 parts of calcium superphosphate, 3 parts of calcium peroxide, 2 parts of magnesium peroxide, 6 parts of borax, 3 parts of agricultural water retaining agent and 0.6 part of microbial agent.

[0053] Wherein, the agricultura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com