Patents

Literature

121 results about "Magnesium peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium peroxide (MgO₂) is an odorless fine powder peroxide with a white to off-white color. It is similar to calcium peroxide because magnesium peroxide also releases oxygen by breaking down at a controlled rate with water. Commercially, magnesium peroxide often exists as a compound of magnesium peroxide and magnesium hydroxide.

Internal breaker

InactiveUS6861394B2Easy to disassembleImprove productivityCleaning apparatusFluid removalAlkaline earth metalZinc

A wellbore fluid including a peroxide degradable polymer and an encapsulated peroxide source. The peroxide degradable polymer may be a polysaccharide. The peroxide source may include an inorganic peroxide, including zinc and alkaline earth metal peroxides, such as magnesium peroxide. The encapsulating material may be a polymer, including enteric polymers. The release of peroxide, from peroxide sources generally, can be controlled by means of pH such that peroxide source can be activated, and peroxide released, by a change in pH. In a wellbore, this pH change can be effected by using produced fluids to lower the pH of a more basic wellbore fluid.

Owner:MI

Method and composition for preventing tooth hypersensitivity when using passive bleaching agents

InactiveUS20060013778A1Avoid allergiesLonger contact/coating periodCosmetic preparationsGum massageZinc peroxidePotassium nitrate

Dental bleaching compositions, for example in the form of liquids, gels, creams, pastes and ointments, comprising a peroxide releasing compound and from 1% to 35% by weight of a potassium-containing compound such as potassium nitrate, wherein the potassium nitrate is present in a safe and effective amount to prevent tooth hypersensitivity in the patient during the bleaching process. The potassium nitrate contemplated by the invention is compatible with peroxide yielding bleaching compounds such as peroxide, carbamide peroxide, calcium peroxide, zinc peroxide, magnesium peroxide and sodium perborate. Potassium nitrate is complimentary and synergistic with the peroxide bleaching agents contemplated by the invention and enhances the release of oxygen to the tooth enamel. Also contemplated are methods of bleaching teeth comprising application of the dental bleaching compositions of the invention.

Owner:HODOSH MILTON

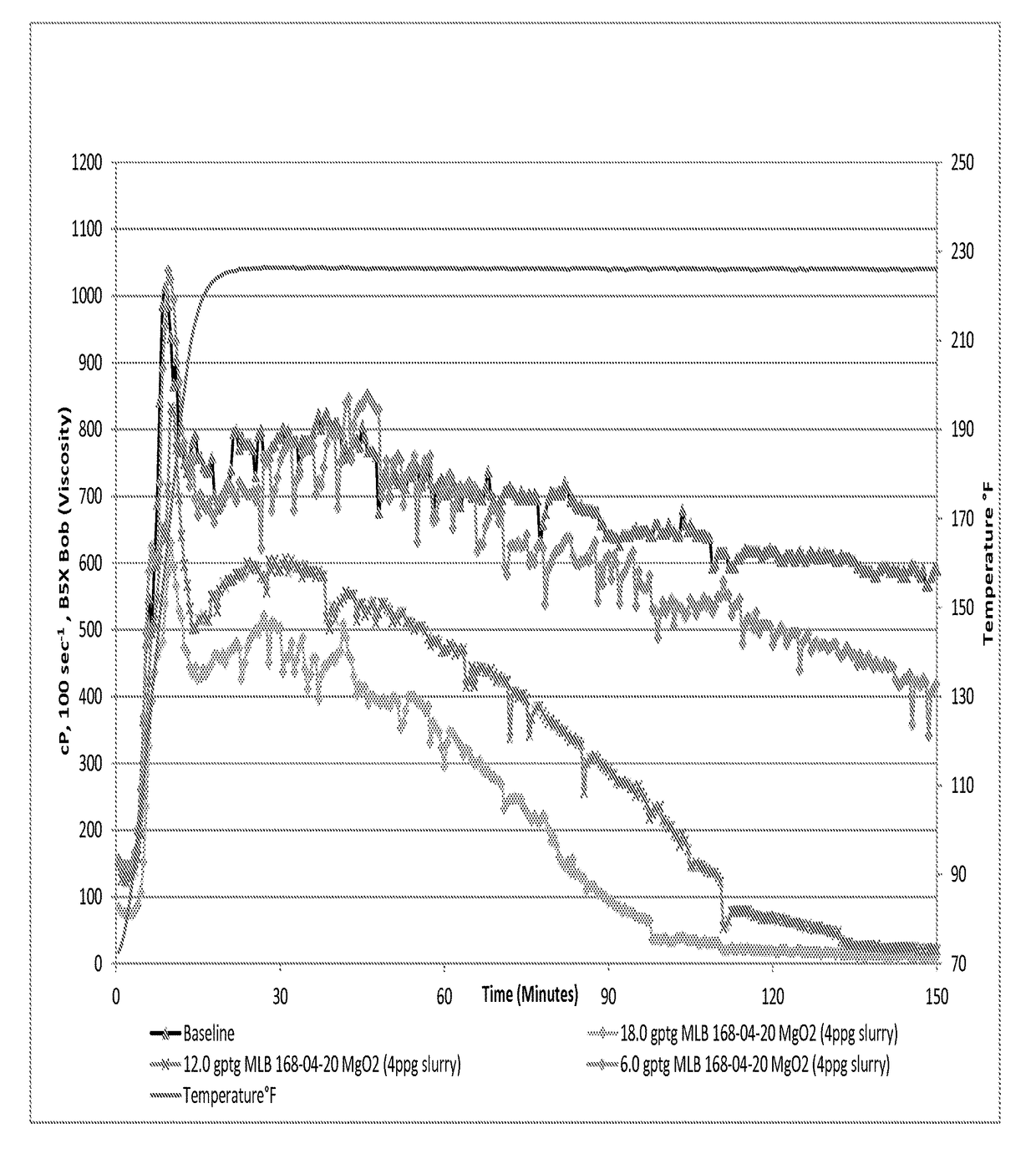

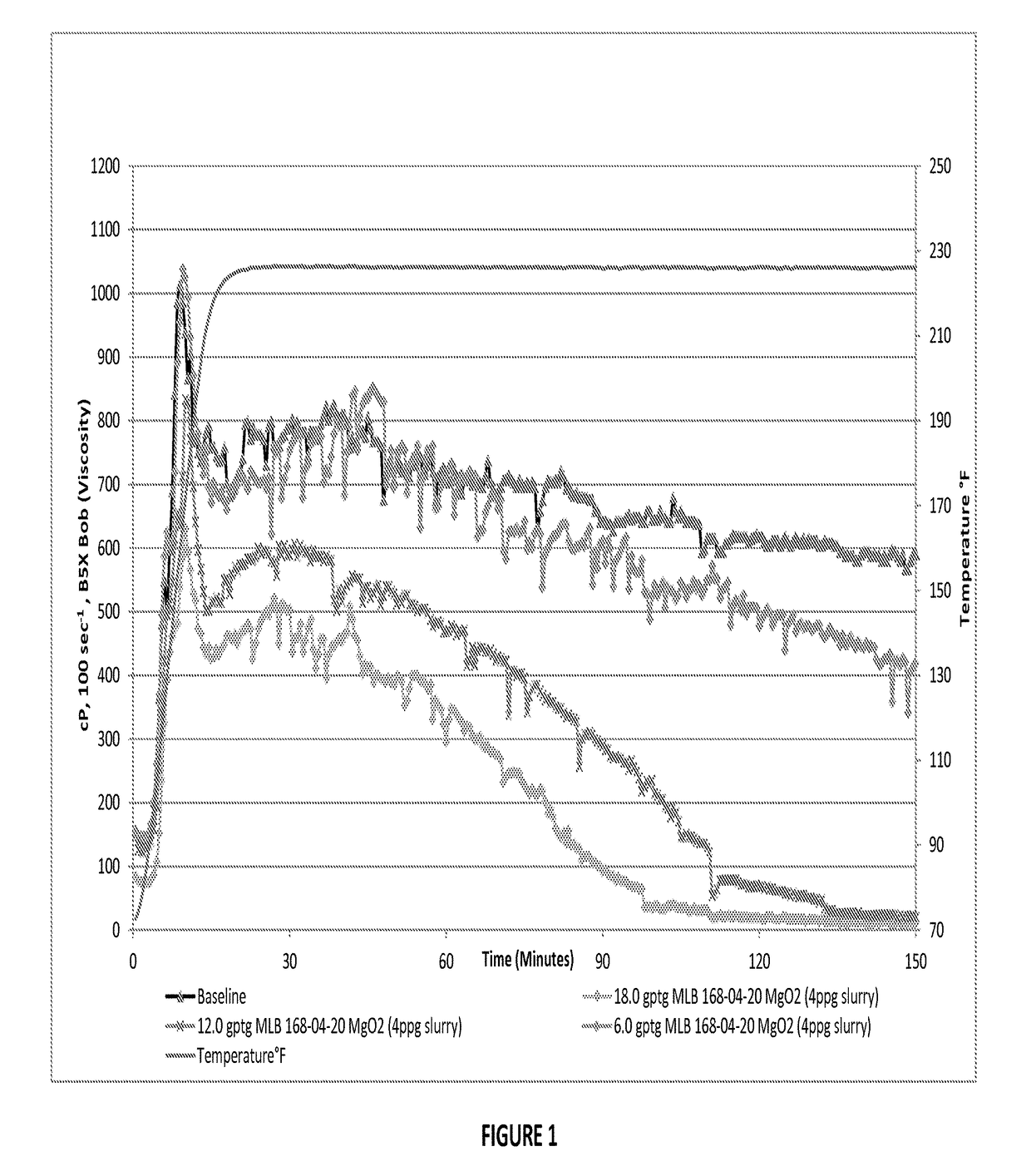

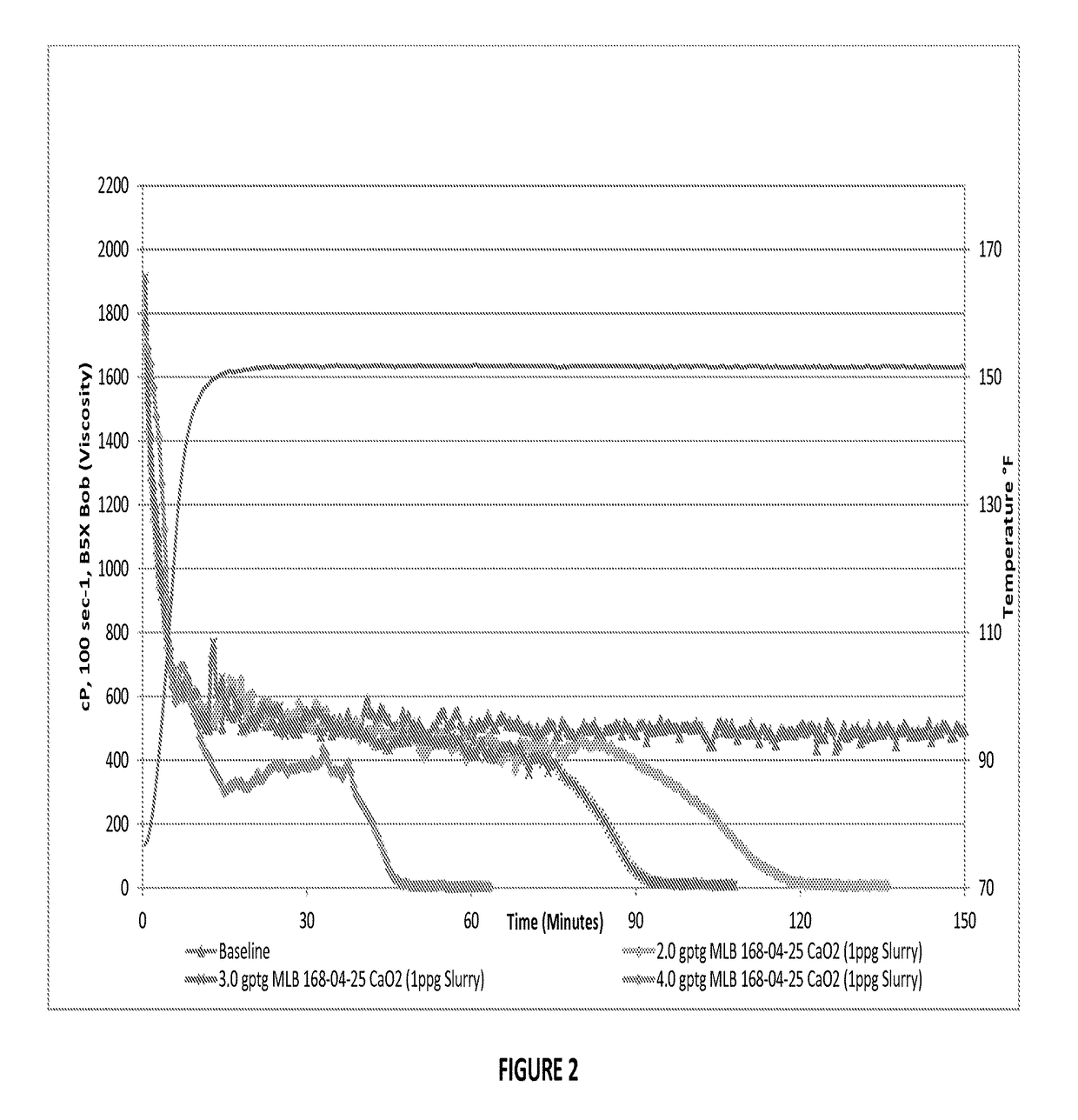

Oxidative breakers in a silicone based suspension

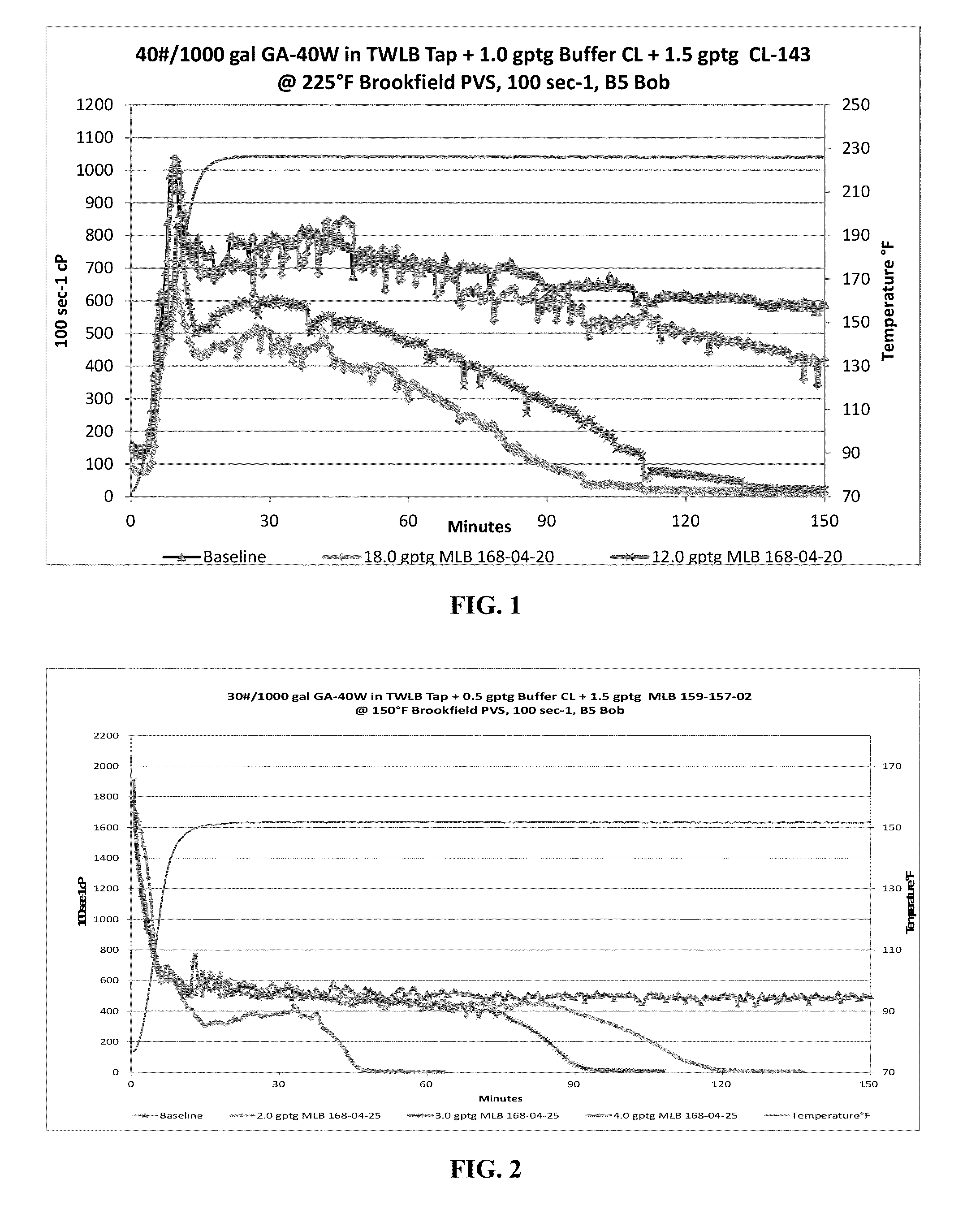

An oxidative breaker system for use in reducing the viscosity of a guar-based suspension includes a silicone oil carrier fluid, an oxidizer and a suspension aid. The suspension aid is preferably fumed silica. The oxidizer may be selected from the group consisting of alkali metal peroxide, transition metal peroxide, persulfate, bromide and bromate. In highly preferred embodiments, the oxidizer is magnesium peroxide or calcium peroxide. Also disclosed is a method for breaking a guar-based suspension with the inventive oxidative breaker system.

Owner:PNC BANK NAT ASSOC

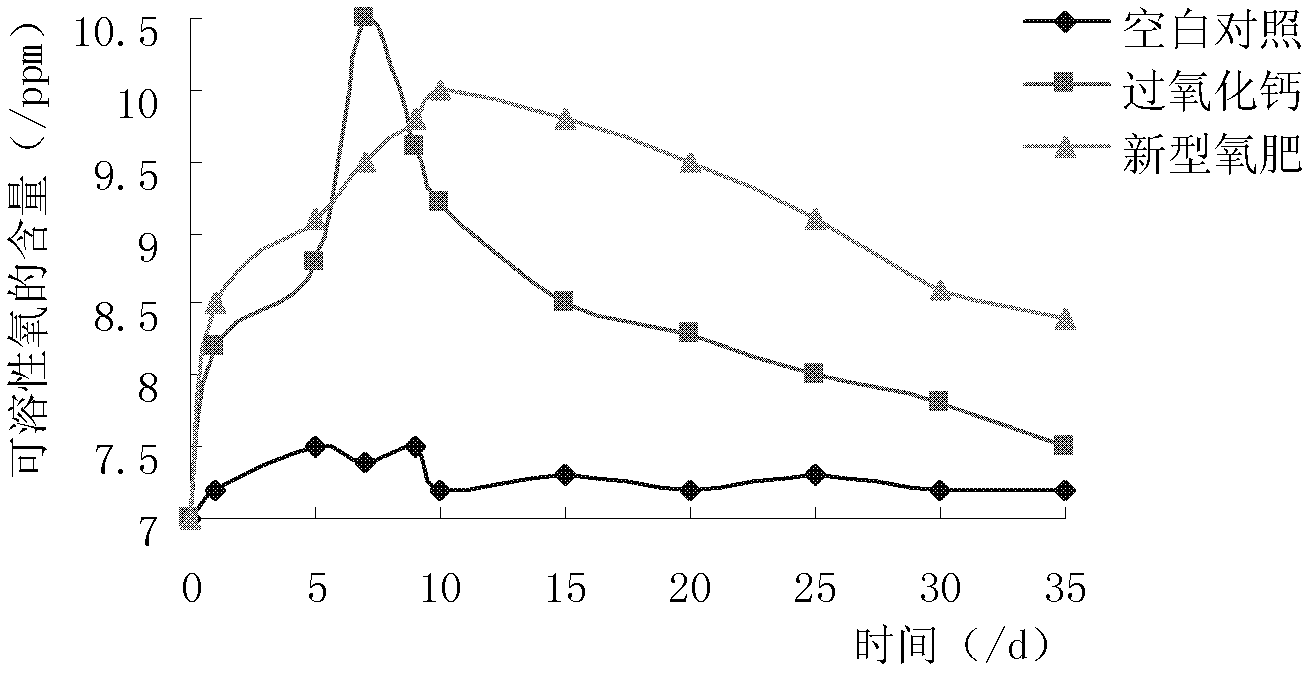

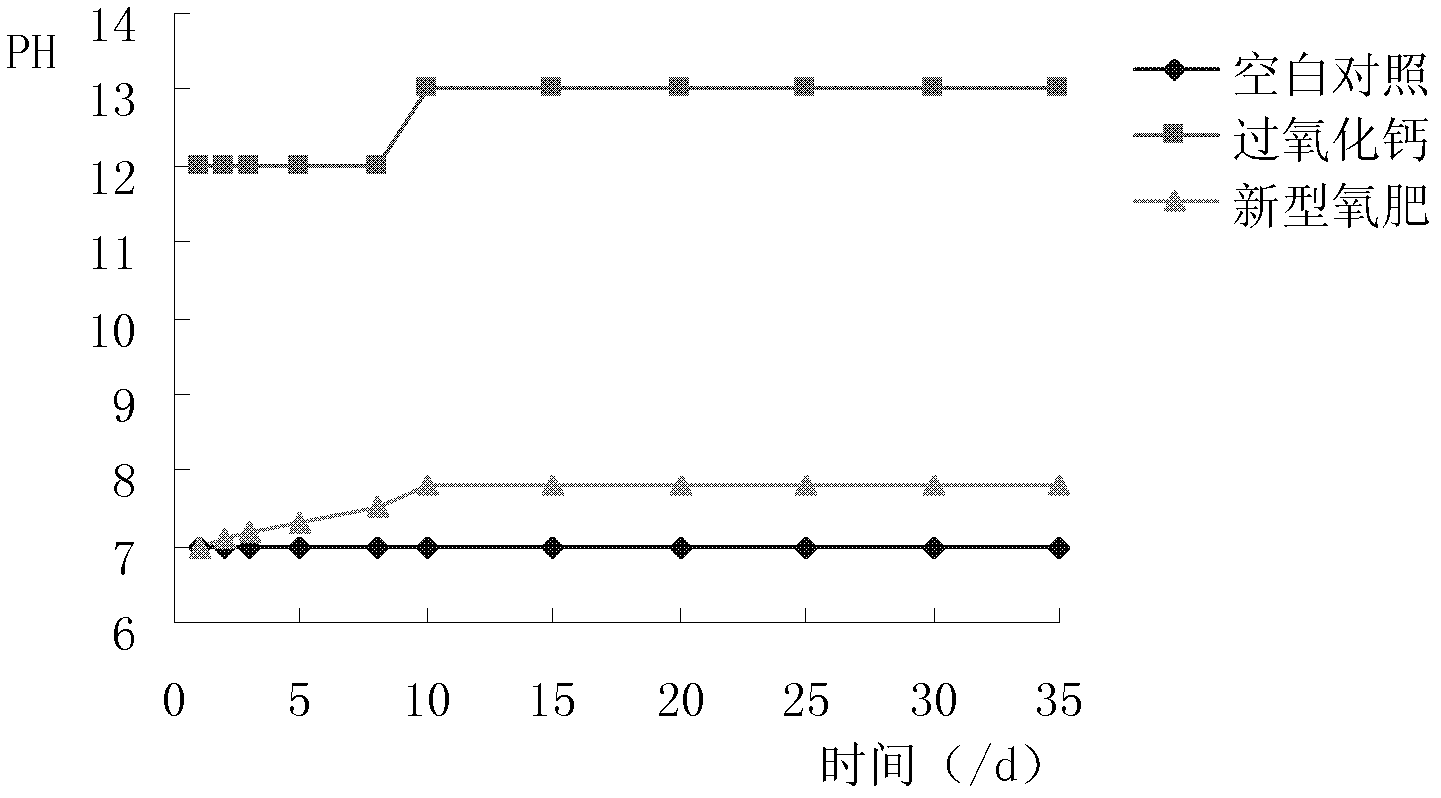

Oxygen fertilizer and preparation and application methods thereof

InactiveCN102584466ALift deathReduce economic costsFertilizer mixturesOxygen preparationSodium oxideChemistry

The invention discloses a novel oxygen fertilizer and preparation and application methods of the oxygen fertilizer. Mixtures of one or more of calcium peroxide, sodium peroxide and magnesium peroxide act as a core; nano chitosan doped with sodium alginate as the binding agent serves as a wrapping membrane; and the outer layer of the wrapping membrane is further wrapped by paraffin as a conditioner, so that a slow-release oxygen fertilizer is prepared. The oxygen fertilizer contains 70-75% of the core by weight, 20-25% of the wrapping membrane by weight, and 3-10% of the conditioner by weight and the particle diameter of the oxygen fertilizer particles is 3-10mm. The novel oxygen fertilizer prepared by the preparation method disclosed by the invention can supply oxygen to waterlogged plants for a long time and is convenient and simple to apply, simple in production process and environment-friendly, and saves time and labor and can be used widely.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

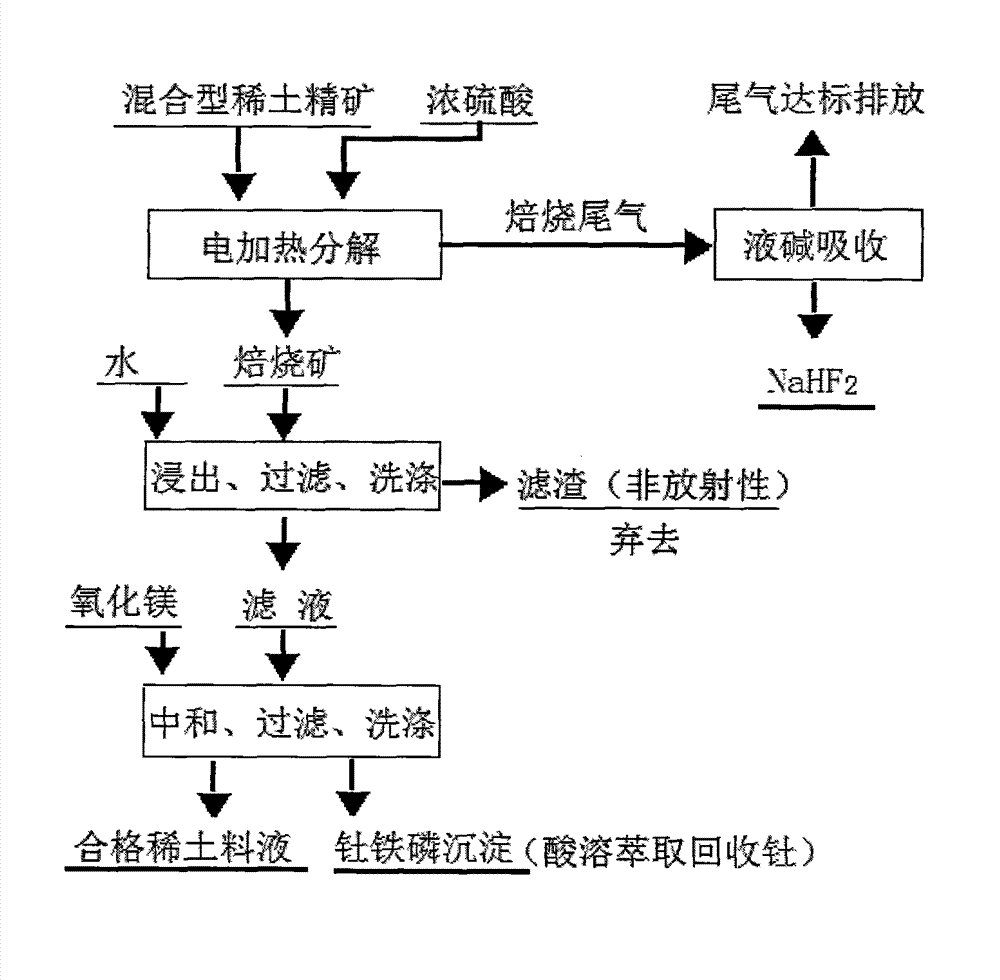

Process for extracting and separating thorium and extracting rare earth chloride from sulfuric and phosphoric mixed acid system

InactiveCN1394971AReduce radioactive contaminationReduce negative impactRadium compoundsRare earth metal compoundsKeroseneFractionation

The present invention belongs to a process for extracting and separating thorium from sulfo-phosphoric mixed acid and extracting rare earth chloride. Said process adopts primary amine added mixed alcohol as extracting agent, and makes direct fractionation of rare earth slurry to extract thorium, and the thorium content in the separated rare earth slurry is ThO2 / REO is less than or equal to 5X10 to the minus sixth. Said invention utilizes the thorium being in organic phase and adopts countercurrent reextraction process by means of nitric acid to obtain thorium nitrate product, its purity is 99%, and thorium recovery is up to 99%. Said invention adopts magnesium oxide precipitation method to remove the iron and phosphorus in the rare earth reffinate, uses ammoniated P507-kerosene to extract organic phase.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

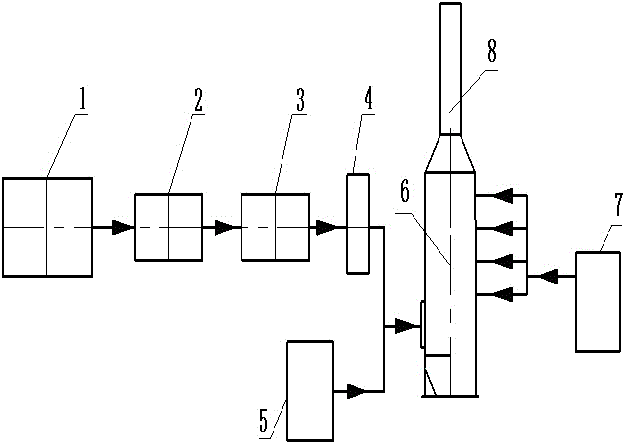

Gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process

InactiveCN104971594AEfficient removalReduce equipment costsDispersed particle separationAir quality improvementPotassium manganateSlurry

The invention discloses a gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process. According to the process, ozone is used as a gas-phase oxidant to oxidize one part of nitric oxide in flue gas into high-valence-state nitric oxide capable of being absorbed by slurry; any one or a mixture solution of more of hydrogen peroxide, sodium hypochlorite, sodium chlorite, sodium chlorate, sodium persulfate, potassium chlorate, potassium hypermanganate and potassium dichromate is sprayed to be used as a liquid-phase oxidant to oxidize the residual high-valence-state nitric oxide in the flue gas into the high-valence-state nitric oxide; and the flue gas enters an absorption tower and a magnesium hydroxide solution is sprayed to absorb the high-valence-state nitric oxide. Compared with the prior art, the process firstly adopts two times of oxidization of a gas phase and a liquid phase and a magnesium oxide wet process is used for absorbing so that a target of efficiently removing the nitric oxide is realized; and by virtue of the technical scheme, the use amount of the ozone is reduced, the equipment cost and operation cost are reduced and the denitration efficiency is improved and can reach more than or equal to 93%.

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

Viscosity Breaker for Polyacrylamide Friction Reducers

A well treating fluid useful in slickwater fracturing processes contains polyacrylamide friction reducer and a viscosity breaker capable of reducing the viscosity of the well treating fluid to about the viscosity of water at ambient temperatures of typical underground formations. The viscosity breaker is selected from the group consisting of hydrogen peroxide, calcium peroxide, magnesium peroxide, and zinc peroxide and is present in an amount above about 0.002% by weight.

Owner:SOLVAY USA

Compound high-temperature environment-friendly biomass fuel and preparation method thereof

InactiveCN104830397ASuitable for long term storageNo smellBiofuelsSolid fuelsEnvironmental resistanceRed mud

The invention discloses a compound high-temperature environment-friendly biomass fuel and a preparation method thereof. The compound high-temperature environment-friendly biomass fuel is composed of the following components in parts by weight: 25-35 parts of forestry and agricultural residues, 15-25 parts of household refuse, 15-25 parts of sludge, 15-25 parts of excrement, 15-25 parts of coal powder, 15-25 parts of scrap tire colloidal particle, and 2-10 parts of combustion improver; and the combustion improver is composed of dolomite dust, urea, red mud, calcium peroxide, manganese oxide, strontium peroxide, magnesium peroxide, cerium oxide, and boric sludge. The compound high-temperature environment-friendly biomass fuel is suitable for storing for a long time without foreign smell. The burning temperature of the compound high-temperature environment-friendly biomass fuel is high and is up to 1320-1380 DEG C, and the burning efficiency is improved by about 35% compared with that of the common biomass fuel; the calorific value is 4800-5200 kilocalorie / kg and per ton of the compound high-temperature environment-friendly biomass fuel is 0.7 ton of the standard coal; and the combustion gas is in accordance with the national related provisions, the sulphur removal rate is 98% and the nitrate removal rate is 95%.

Owner:黑龙江天顶能源科技有限公司

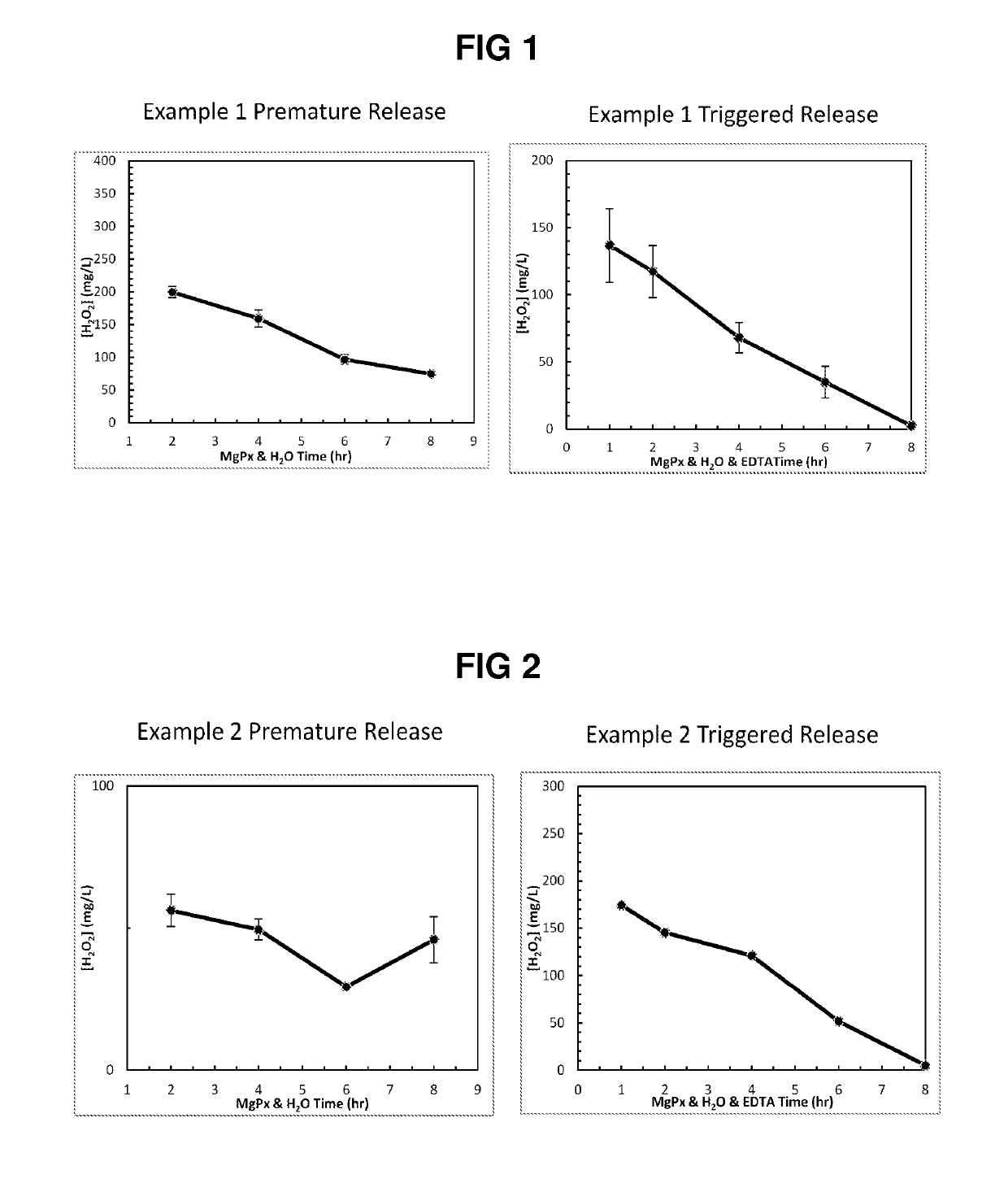

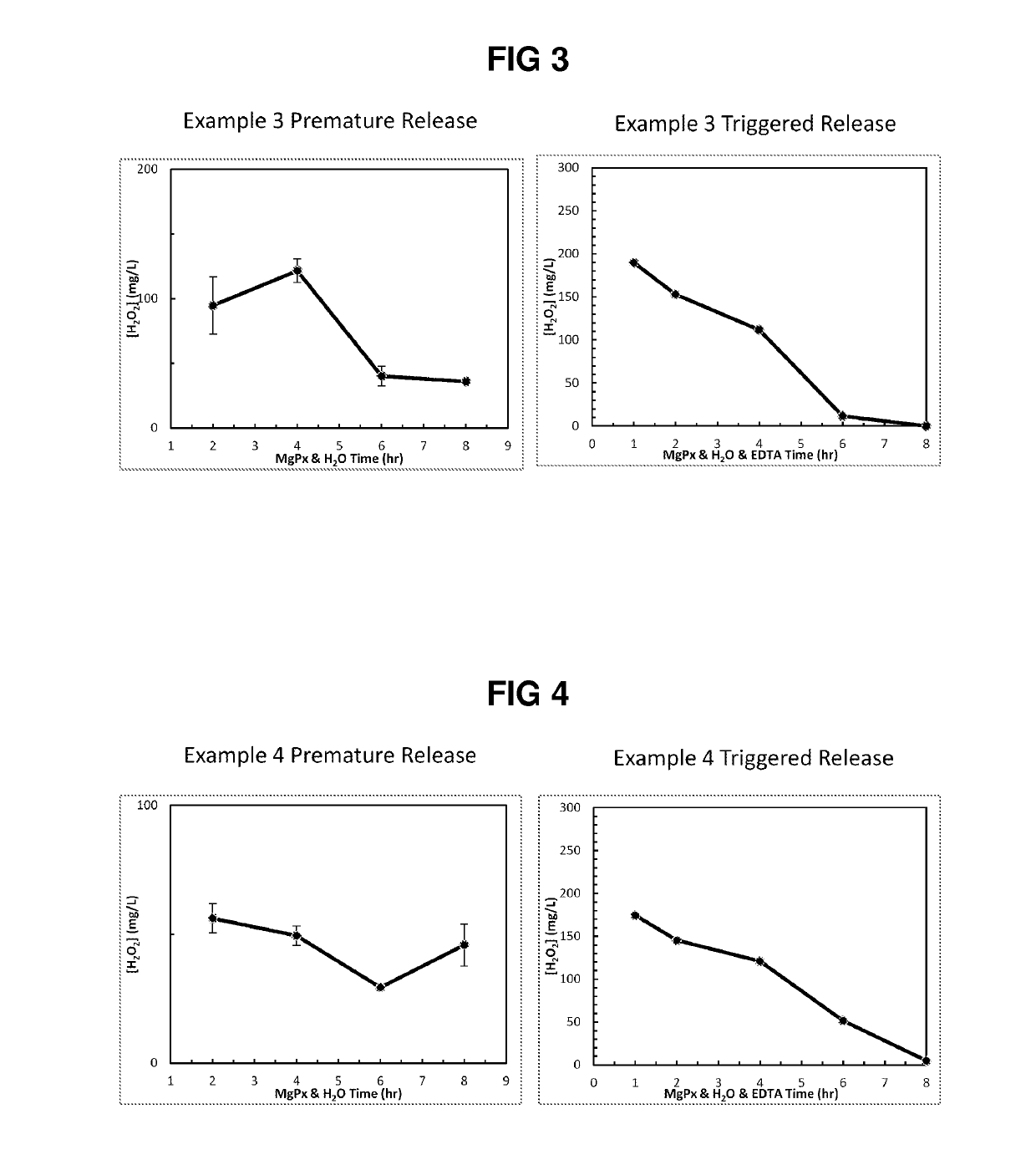

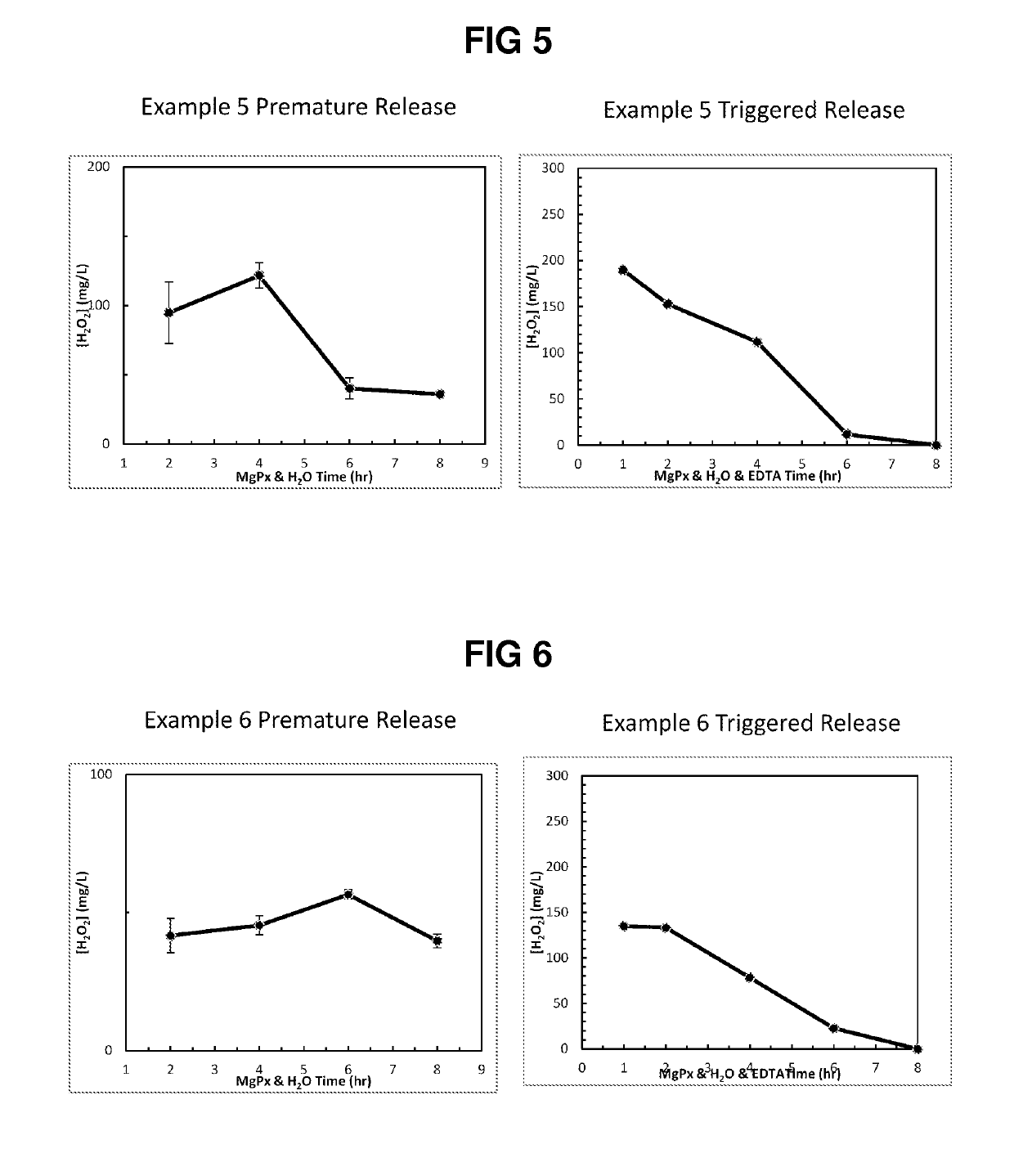

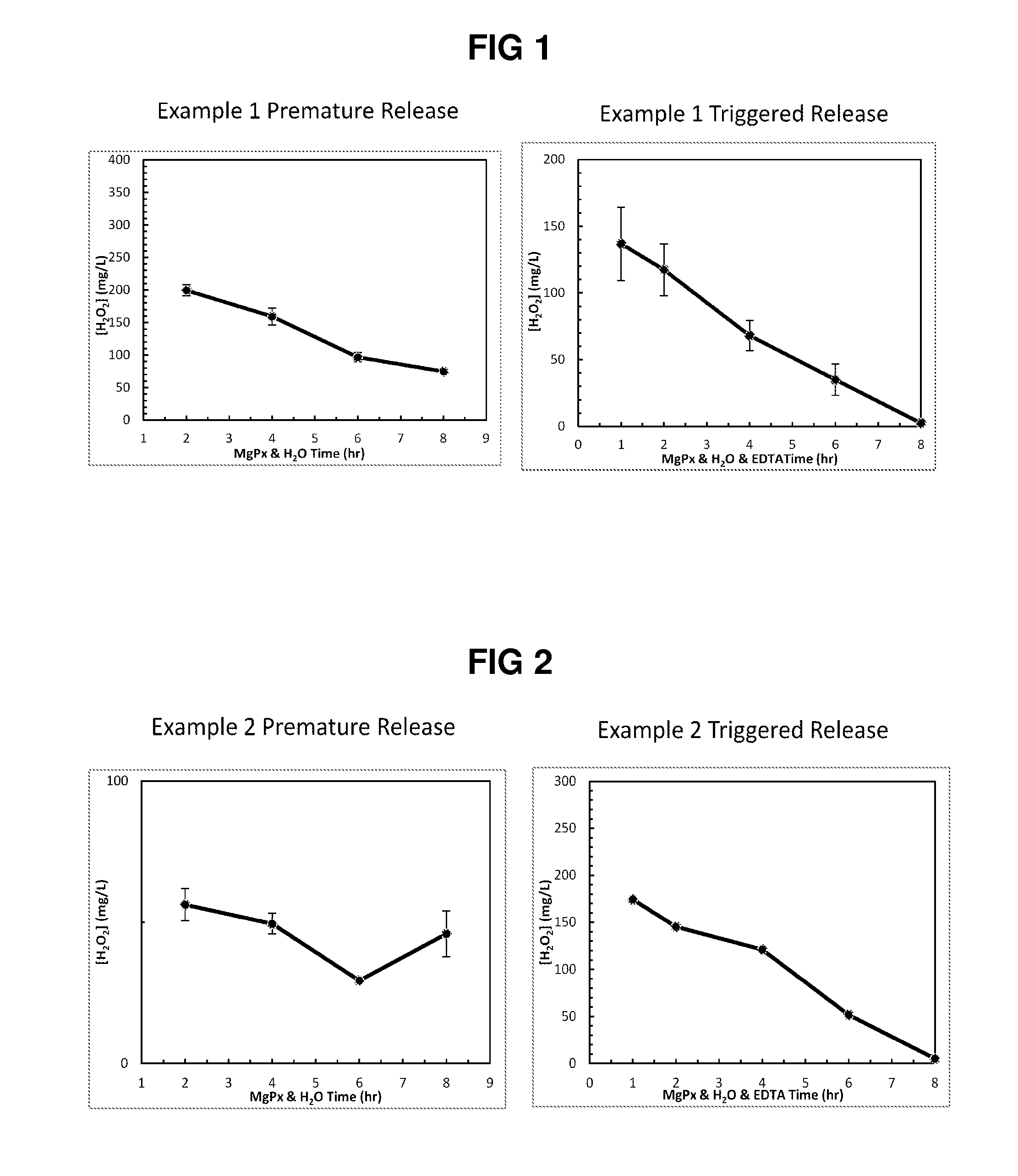

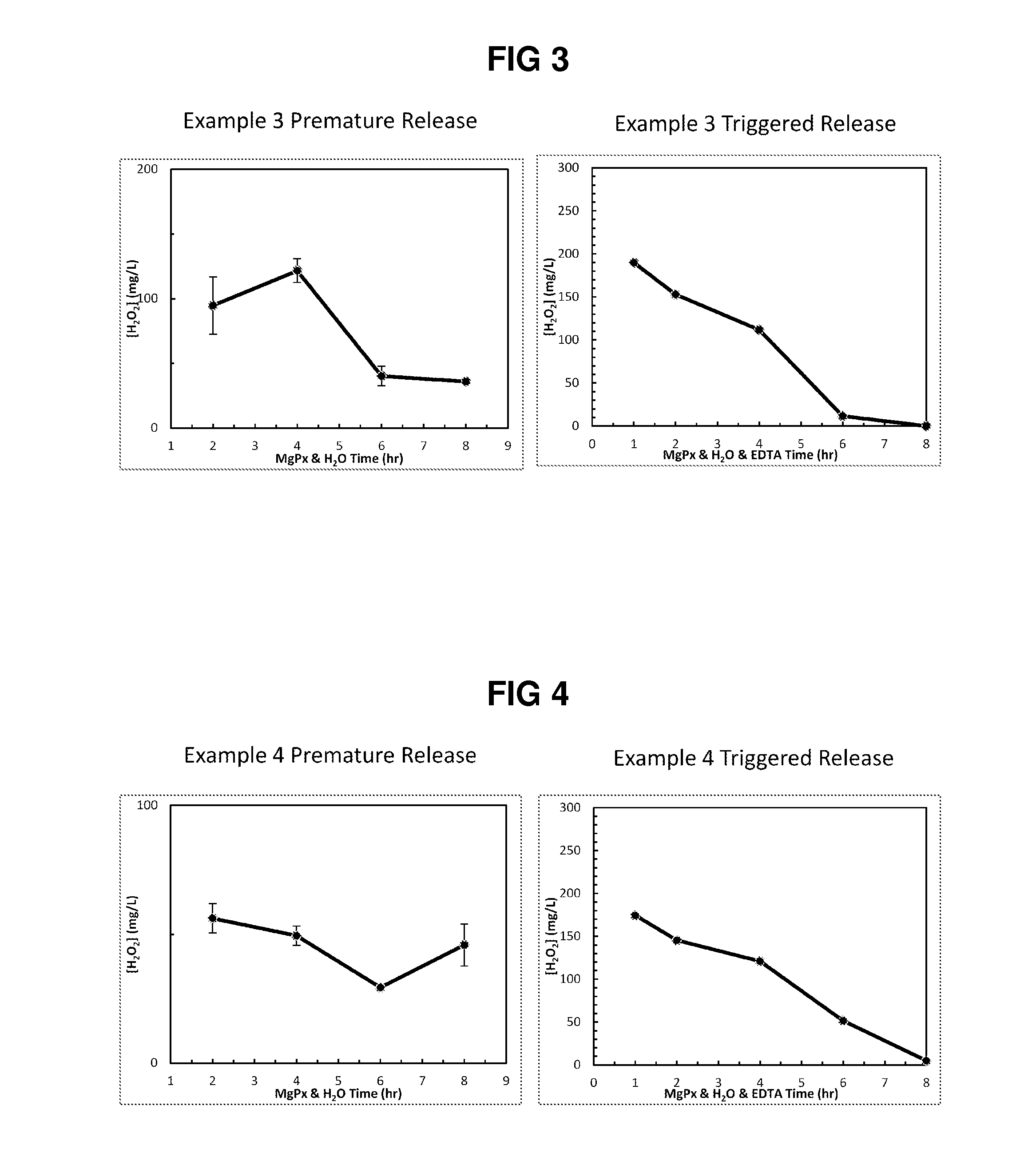

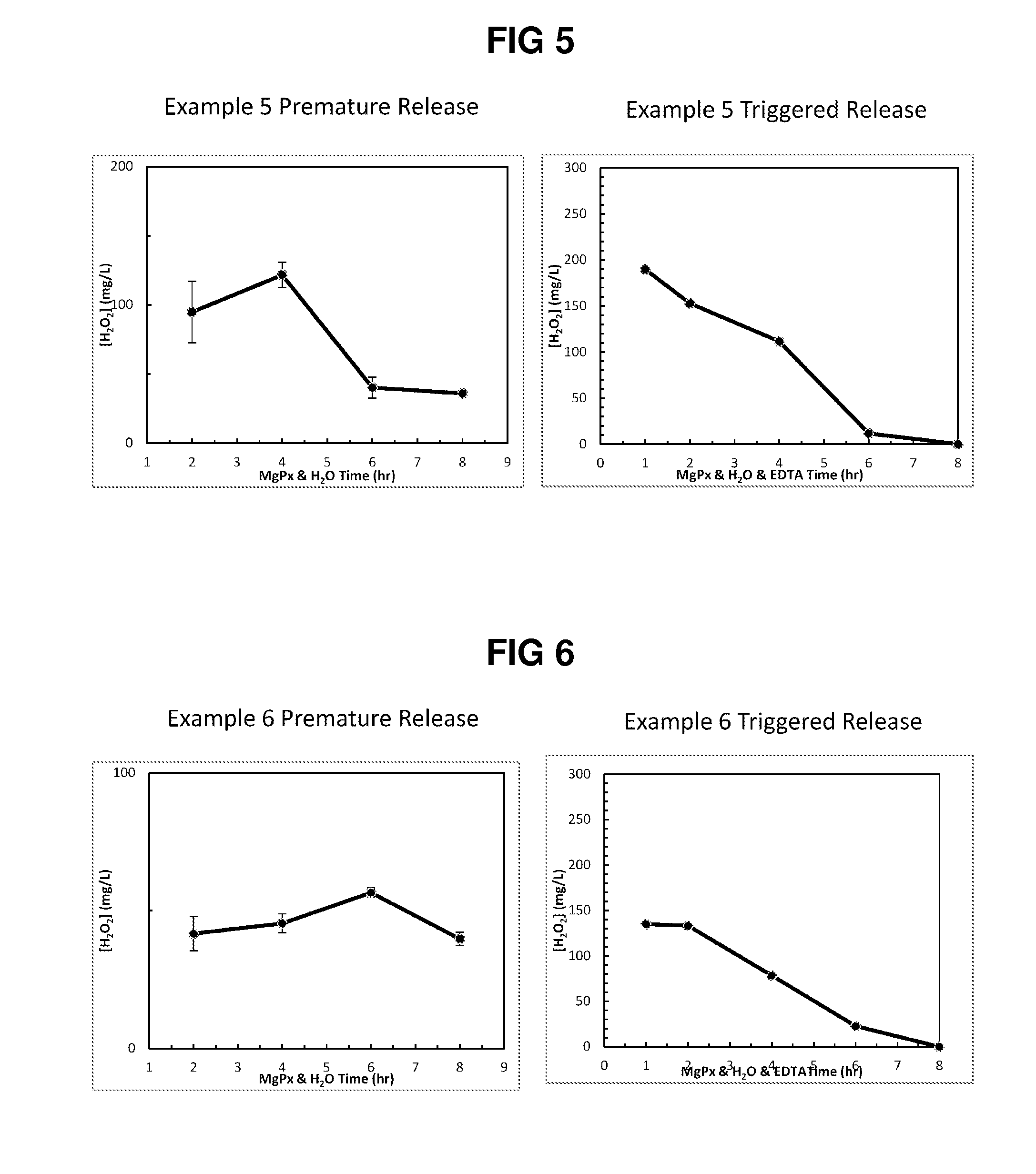

Encapsulated internal filter cake breakers with improved release properties

A wellbore fluid including a peroxide degradable polymer and an encapsulated peroxide source. The peroxide degradable polymer may be a polysaccharide. The peroxide source may include an inorganic peroxide, including zinc and alkaline earth metal peroxides, such as magnesium peroxide. The encapsulating material may be a polymer, including a metal crosslinked acrylic polymer. The release of peroxide, from peroxide sources generally, can be controlled by means of pH such that peroxide source can be activated, and peroxide released, by a change in pH. In a wellbore, this pH change can be effected by using produced fluids to lower the pH of a more basic wellbore fluid.

Owner:DOW GLOBAL TECH LLC +1

Superconductive liquid

InactiveCN1470592AFast heat exchangeExtended service lifeChemical industryHeat-exchange elementsMedical equipmentPotassium hydroxide

The present invention discloses a superconducting liquor, its composition contains (wt%) 65-71% of hydrogen peroxide, 3-6% of potassium hydroxide, 0.3-0.6% of magnesium peroxide, 0.3-0.6% of potassium sulfate and the rest is distilled water. Said superconducting liquor has several advantages of low electric consumption in application, quickly making heat exchange, long service life, saving energyby above 50% and others, and can be used in various energy source equipments, such as heating system, high-pressure boiler, normal pressure boiler, medical equipment, plastic greenhouse and waste heat recovery, etc.

Owner:袁桂生

Environment-friendly high-energy composite biomass fuel and preparation method thereof

The invention discloses an environment-friendly high-energy composite biomass fuel and a preparation method thereof. The environment-friendly high-energy composite biomass fuel contains the ingredients in parts by dry weight: 25-35 parts of agriculture and forestry wastes, 15-25 parts of domestic garbage, 15-25 parts of sludge, 15-25 parts of manure, 15-25 parts of coal powder, 15-25 parts of waste tire rubber particles and 2-10 parts of combustion improver, wherein the combustion improver is prepared from dolomite powder, black shale powder, serpentine powder, urea, potassium nitrate, red mud, calcium peroxide, manganese oxide, strontium peroxide, magnesium peroxide, cerium oxide and boric sludge. The environment-friendly high-energy composite biomass fuel disclosed by the invention is suitable for long-term storage and is free from odor generation. According to the environment-friendly high-energy composite biomass fuel disclosed by the invention, the combustion temperature is high and can reach 1,350-1,400 DEG C, and the combustion efficiency is increased by about 35% compared with that of ordinary biomass fuels; the calorific value can reach 4,900-5,300 kilo-calories per kilogram, and the environment-friendly high-energy composite biomass fuel per ton is equivalent to 0.7 ton of standard coal; combustion exhaust gases all meet relevant national provisions , the desulfurization ratio can reach 98%, and the denitrification ratio can reach 95%.

Owner:刘雷

Viscosity breaker for polyacrylamide friction reducers

A well treating fluid useful in slickwater fracturing processes contains polyacrylamide friction reducer and a viscosity breaker capable of reducing the viscosity of the well treating fluid to about the viscosity of water at ambient temperatures of typical underground formations. The viscosity breaker is selected from the group consisting of hydrogen peroxide, calcium peroxide, magnesium peroxide, and zinc peroxide and is present in an amount above about 0.002% by weight.

Owner:SOLVAY USA

High Temperature Crosslinked Polysulfones Used for Downhole Devices

Thermally crosslinked polysulfone may be made from linear polysulfone, such as polyethersulfone, in powder form blended with a powdered inorganic peroxide such as magnesium peroxide or another oxygen source, to form a mixture followed by compression inside a mold. The mixture is cured at a an elevated temperature, for instance above 325° C., for an effective period of time to form a dense object. The object is then boiled in water, optionally under pressure, to remove the salt to give a structure that is open and porous which may be used as a filtration device on a downhole tool for hydrocarbon recovery. If a powdered salt is not used, a thermally crosslinked, solid, void-free polysulfone is made which may be strong and rigid at ambient, surface temperatures, but is an elastomer at elevated downhole temperatures, and is thus suitable for use as a packer or an O-ring.

Owner:BAKER HUGHES INC

Acid reduction and humidity regulation method for red upland soilred-soil dryland

InactiveCN102972113AReduce acidityIncrease acidityOther chemical processesOrganic fertilisersResource utilizationNutrition

The invention discloses an acid reduction and humidity regulation method for the red upland soilred-soil dryland. The red upland soilred-soil dryland is covered by straws. The acid reduction and humidity regulation method for the red upland soilred-soil dryland is characterized in that alkaline acid reduction and humidity regulation composite modifying agent is applied to the red upland soilred-soil dryland before the red upland soilred-soil dryland is covered by straws; the alkaline acid reduction and humidity regulation composite modifying agent is one of calcium peroxide and magnesium peroxide; and 5.8-8.0kg of alkaline acid reduction and humidity regulation composite modifying agent is applied to each unit of area. According to the acid reduction and humidity regulation method for the red upland soilred-soil dryland, the alkaline acid reduction and humidity regulation composite modifying agent reacts with water in soil so as to provide OH<->, neutralize parts of H<+>, generate alkaline inorganic matter and oxygen and release heat; in the slow oxygen releasing process, the soil acidity is lowered, the soil redox potential is changed, the water and air ratio of the soil is regulated, the acid reduction and humidity regulation effects isare simultaneously generated to the red upland soilred-soil dryland, and the acidity, the temperature and the moisture of the red upland soilred-soil dryland covered by the spring straw can be obviously improved so as to accelerate agricultural synergy and farmer income increment; and in addition, calcium or magnesium nutrition can be provided for the crop growth and development, thereby being favorable for improving the resource use ratio.

Owner:JIANGXI INST OF REO SOIL

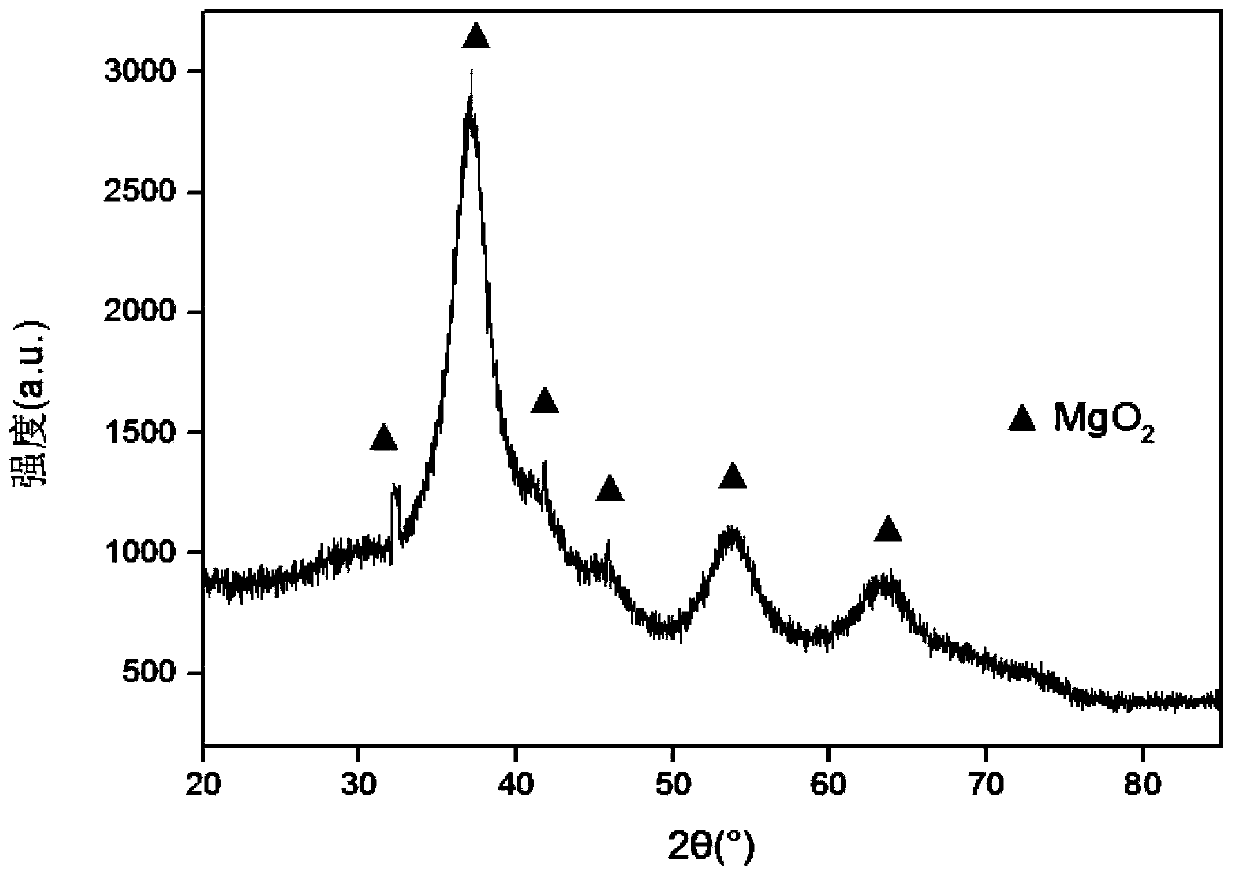

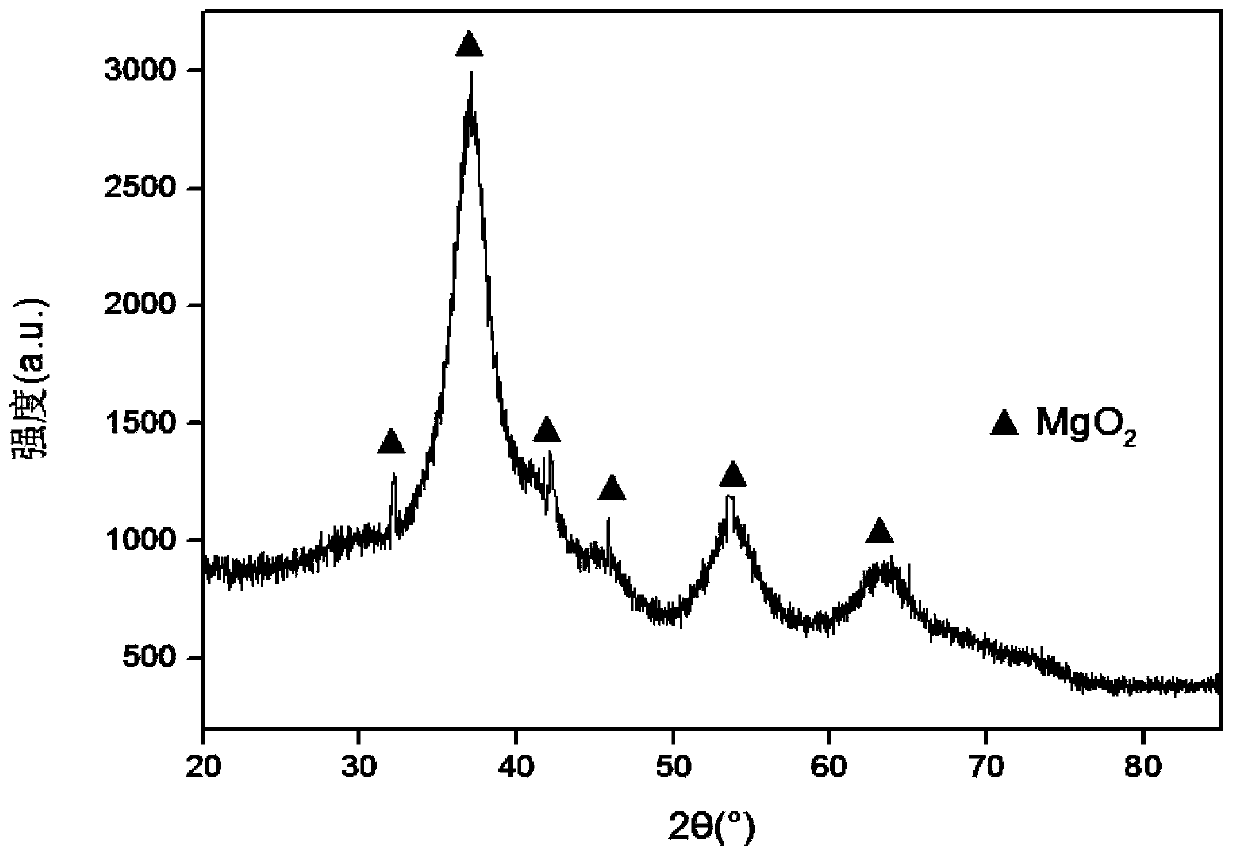

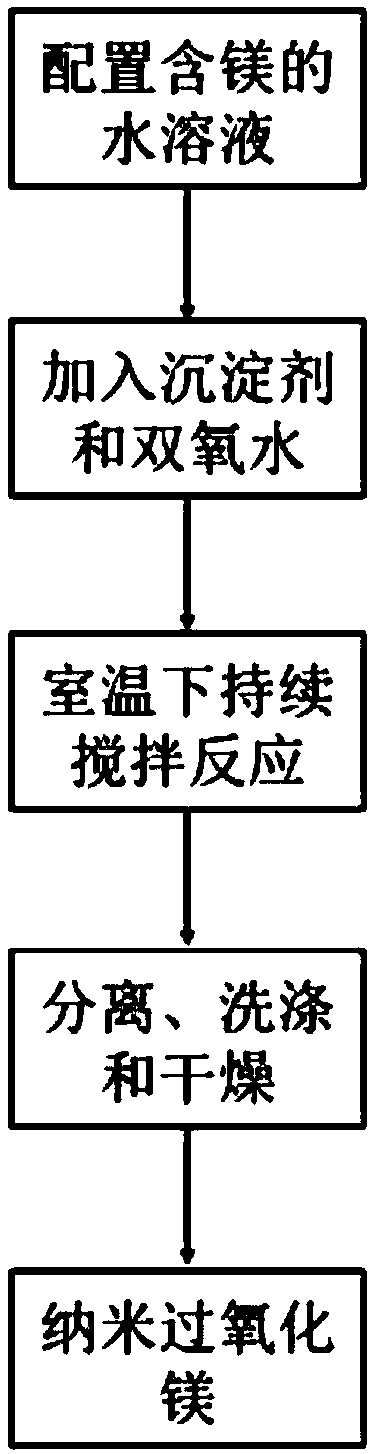

Method for preparing magnesium peroxide by non-emulsion process

InactiveCN101613088ALow costAvoid utilizationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesTemperature controlEmulsion

The invention provides a method for preparing magnesium peroxide by a non-emulsion process. The method comprises the following steps: taking organic phosphonic acid and salts thereof or inorganic phosphonic acid and salts thereof as a stabilizer, taking soluble magnesium salts, hydrogen peroxide solution and base as raw materials, and reacting in an aqueous solution system for 2-10h with the system temperature controlled at 10-30 DEG C; filtering, washing and drying the reaction products to obtain white magnesium peroxide powder. The method is characterized by taking soluble magnesium salts as raw materials for preparing magnesium peroxide, which avoids high cost and low utilization ratio of hydrogen peroxide due to taking magnesia as raw materials; the magnesium peroxide content of the obtained product is more than 40%, the production process is simple, energy consumption is low, and the method is applicable to large-scale industrial production.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Prepn of magnesium peroxide

InactiveCN1370736AImprove stabilityImprove heat and humidity stabilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesInorganic ChemicalRaw material

The present invention relates to an improved preparation process of magnesium peroxide. The process is characterized by that dilute hydrogen peroxide solution, magnesia, powder as raw material and organic phosphonic acid and its salt as stabilizer are added to produce wet magnesium peroxide, which is dried to obtain white magnesium peroxide powder. The added amount of phosphonic acid and its saltby weight of P2O5 is 0.01-1.5 wt% of magnesia. By the process stability of magnesium peroxide is raised during reaction to produce magnesium peroxide product with magnesium peroxide content over 30%.In addition, the process is simple, low in power consumption and high in yield and is suitable for large scale production.

Owner:陶华西

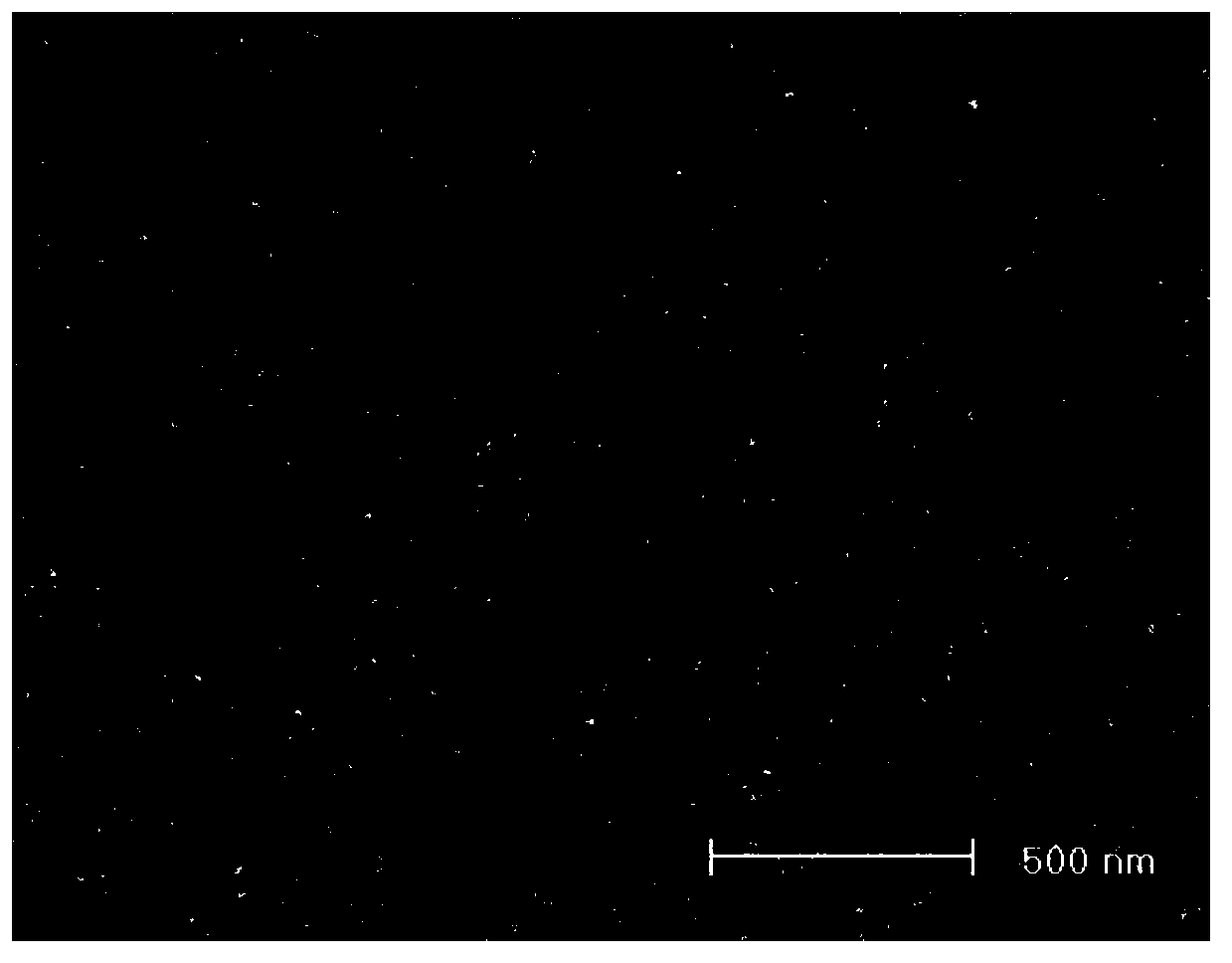

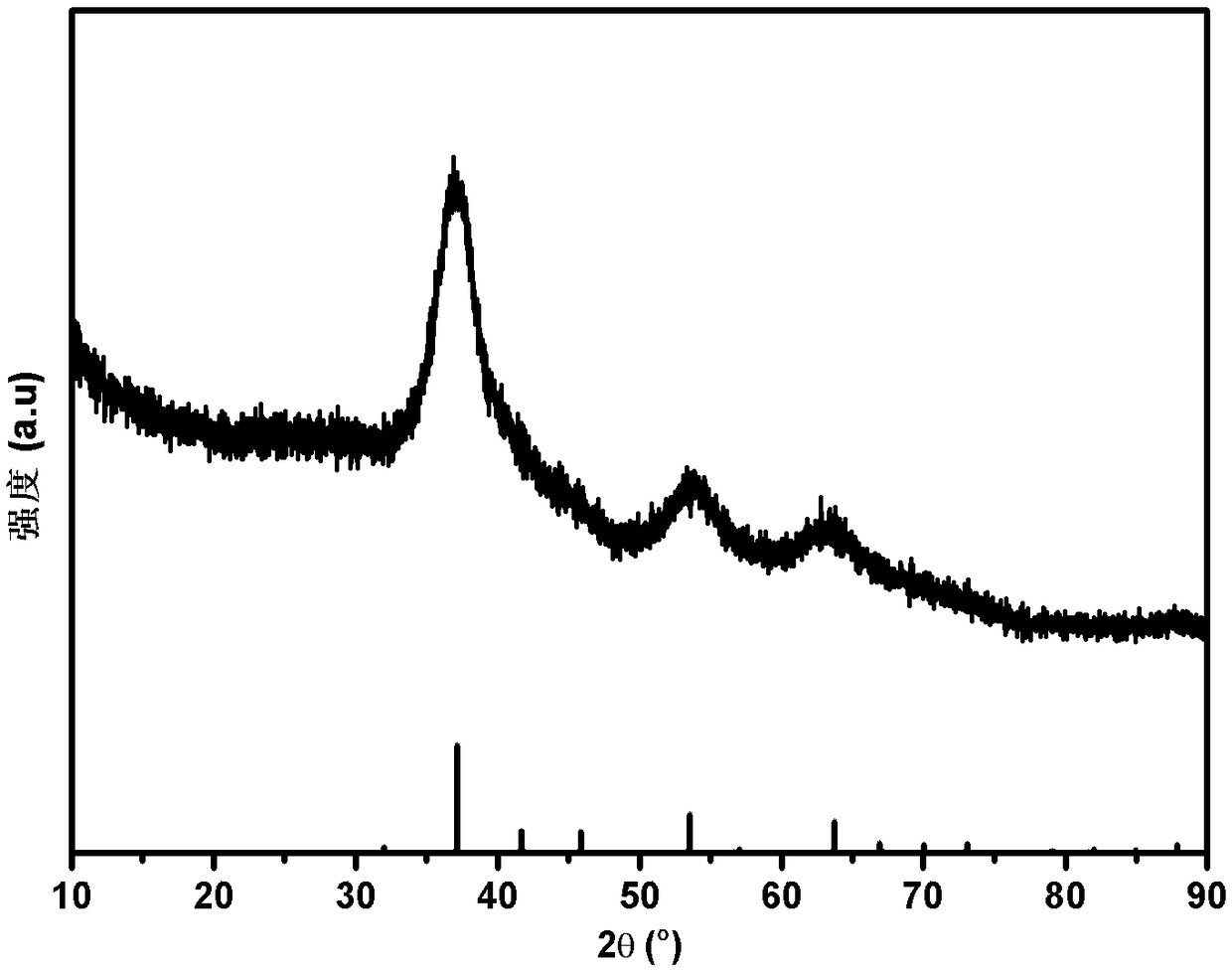

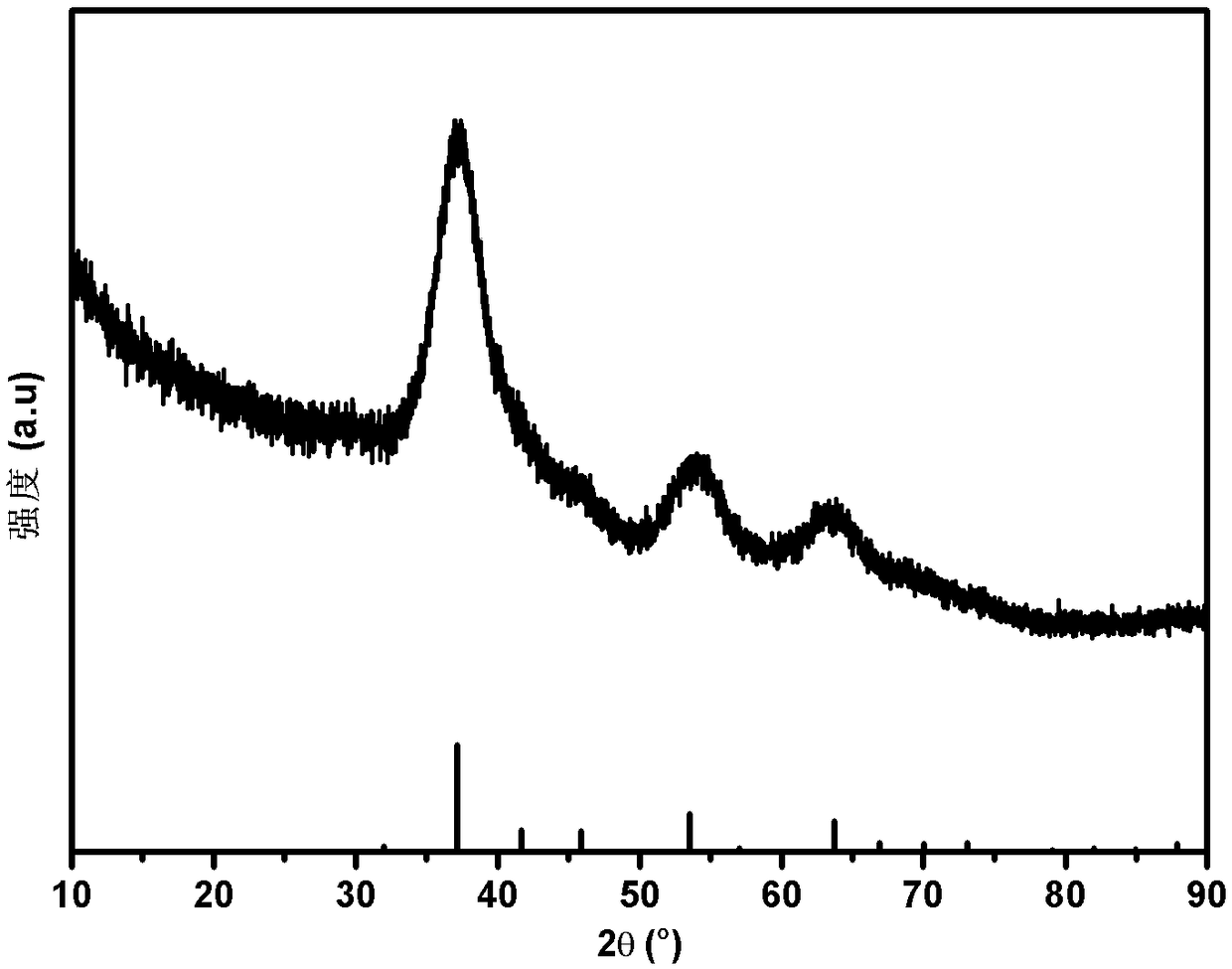

Preparation method for nano magnesium peroxide

ActiveCN103420342ALow costUniform particle sizeMaterial nanotechnologyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDispersityVacuum drying

The invention relates to a preparation method for nano magnesium peroxide. Using magnesium oxide, ammonium chloride, and oxydol with mass percentage of 30% according to the mass ratio of 1:(1.5-2.5):(30-40); dissolving the magnesium oxide into deionized water and grinding into magnesium oxide size mixture with the mass percentage of 3-4%; dissolving the ammonium chloride into the oxydol, and stirring and slowly adding into the ground magnesium oxide size mixture; keeping the reaction under the continuous stirring at 500 r / min for 3-4 h to obtain white precipitate mixed solution; filtering the white precipitate mixed solution to obtain a wet filter cake; performing freezing vacuum drying at -80 DEG C to obtain a target product of nano magnesium peroxide powder with particle size of 20 nm, good dispersity, and purity higher than 50%. The method is simple to operate and is suitable for large-scaled industrialized production.

Owner:TONGJI UNIV

Catalytic combustion improver for blast furnace coal injection and application method thereof

ActiveCN103013616APromote combustionImprove the reducing atmosphereSolid fuelsBlast furnace detailsChemical reactionDolomite

The invention discloses a catalytic combustion improver for blast furnace coal injection and an application method thereof. The catalytic combustion improver is prepared from the following raw materials in percentage by mass through milling and mixing: 1-5% of ferrocene or potassium permanganate, rare metal catalysts including 1-2% of lanthanum oxide and cerium oxide, 30-35% of calcium peroxide, 15-20% of magnesium peroxide, 15-20% of active manganese dioxide and 1-3% of copper sulfate, and a carrier including 15-20% of calcium carbonate or dolomite, wherein the particle size of the product is 0.076 mm, and the content is greater than or equal to 95%. The catalytic combustion improver for blast furnace coal injection, disclosed by the invention, is used in a pulverized coal mass rate of 0.4-0.45%, the particle size of pulverized coal is required to be 0.076 mm, and the content of pulverized coal is required to be greater than or equal to 50%. According to the invention, through prompting the early release of coal chemical energy, the combustion efficiency of pulverized coal is increased, and the purposes of saving energy and reducing consumption are achieved. After a catalytic combustion improver product disclosed by the invention is added into pulverized coal, through a chemical reaction, C-C bonds in the pulverized coal are forcedly fractured, therefore, the ignition temperature of the pulverized coal is reduced, and the pulverized coal is completely combusted in a short time.

Owner:MAANSHAN JIUPENG JIATENG MACHINERY IND

Encapsulated internal filter cake breakers with improved release properties

A wellbore fluid including a peroxide degradable polymer and an encapsulated peroxide source. The peroxide degradable polymer may be a polysaccharide. The peroxide source may include an inorganic peroxide, including zinc and alkaline earth metal peroxides, such as magnesium peroxide. The encapsulating material may be a polymer, including a metal crosslinked acrylic polymer. The release of peroxide, from peroxide sources generally, can be controlled by means of pH such that peroxide source can be activated, and peroxide released, by a change in pH. In a wellbore, this pH change can be effected by using produced fluids to lower the pH of a more basic wellbore fluid.

Owner:DOW GLOBAL TECH LLC +1

Oxidative breakers in a silicone based suspension

An oxidative breaker system for use in reducing the viscosity of a polysaccharide-based or derivatized polysaccharide-based suspension includes a silicone carrier fluid, an oxidizer, and a suspension aid. The suspension aid is preferably fumed silica. The oxidizer may be selected from the group consisting of alkali metal peroxide, transition metal peroxide, persulfate compound, bromide compound, and bromate compound. In highly preferred embodiments, the oxidizer is magnesium peroxide or calcium peroxide. Alternative carrier fluids and suspension agents are also included in the art. Also disclosed is a method for breaking a polysaccharide-based suspension with the inventive oxidative breaker system.

Owner:FLOTEK CHEM LLC

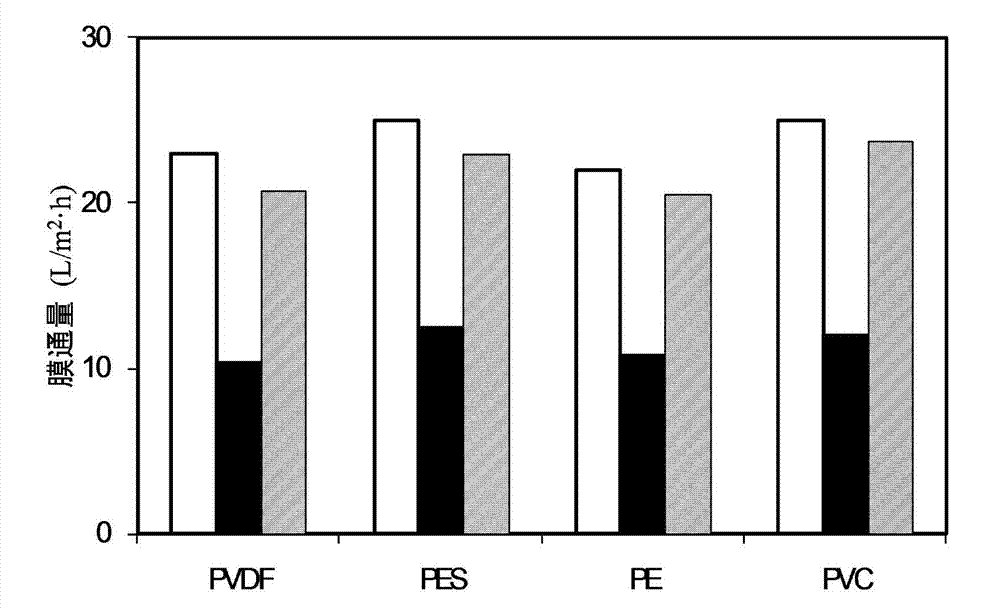

Method for cleaning membrane pollution with high-activity singlet oxygen

InactiveCN103521081AEasy to cleanAccelerated destructionSemi-permeable membranesSinglet oxygenPotassium

The invention discloses a method for cleaning membrane pollution with high-activity singlet oxygen, and relates to methods for cleaning membranes. The method for cleaning the membrane pollution with the high-activity singlet oxygen comprises the steps that solid bleaching powder and inorganic solid peroxide are added to a pool with a polluted membrane component, and the polluted membrane component is stirred, soaked and then bleached. The peroxide is calcium peroxide, magnesium peroxide, barium peroxide, sodium percarbonate and potassium percarbonate. Hypochlorite ions provided by the bleaching powder in the method for cleaning a membrane fast react with hydrogen peroxide released after the peroxide is dissolved in water to generate the high-activity singlet oxygen, the high-activity singlet oxygen directly acts on biological cells with the membrane pollution, the enzymatic structure is fast damaged, and the membrane cleaning effect is good. The high-activity singlet oxygen is an environment-friendly reagent, poisonous and harmful by-products cannot be generated in the cleaning process, and waste liquid can be directly discharged after the cleaning. The high-activity singlet oxygen can be directly added for use as a solid reagent, equipment does not need to be additionally arranged, the operation is simple and easy to carry out, the agents are convenient to transport and store, the price is low, and the agents are easy to obtain.

Owner:HARBIN INST OF TECH

Method and composition for preventing tooth hypersensitivity when using passive bleaching agents

InactiveUS20070065376A1Avoid allergiesLonger contact/coating periodCosmetic preparationsToilet preparationsZinc peroxidePotassium nitrate

Dental bleaching compositions, for example in the form of liquids, gels, creams, pastes and ointments, comprising a peroxide releasing compound and from 1% to 35% by weight of a potassium-containing compound such as potassium nitrate, wherein the potassium nitrate is present in a safe and effective amount to prevent tooth hypersensitivity in the patient during the bleaching process. The potassium nitrate contemplated by the invention is compatible with peroxide yielding bleaching compounds such as peroxide, carbamide peroxide, calcium peroxide, zinc peroxide, magnesium peroxide and sodium perborate. Potassium nitrate is complimentary and synergistic with the peroxide bleaching agents contemplated by the invention and enhances the release of oxygen to the tooth enamel. Also contemplated are methods of bleaching teeth comprising application of the dental bleaching compositions of the invention.

Owner:HODOSH MILTON

Dissolved oxygen releasing compound

InactiveUS20050173672A1Reduce probabilityExtension of timeSolid waste disposalContaminated soil reclamationCompound aSodium Bentonite

Owner:E S P ENVIRONMENTAL SERVICE PROD

Internal breaker

InactiveUS20050090404A1Easy to disassembleIncrease ratingsDrilling compositionBorehole/well accessoriesAlkaline earth metalZinc

A wellbore fluid including a peroxide degradable polymer and an encapsulated peroxide source. The peroxide degradable polymer may be a polysaccharide. The peroxide source may include an inorganic peroxide, including zinc and alkaline earth metal peroxides, such as magnesium peroxide. The encapsulating material may be a polymer, including enteric polymers. The release of peroxide, from peroxide sources generally, can be controlled by means of pH such that peroxide source can be activated, and peroxide released, by a change in pH. In a wellbore, this pH change can be effected by using produced fluids to lower the pH of a more basic wellbore fluid.

Owner:MI

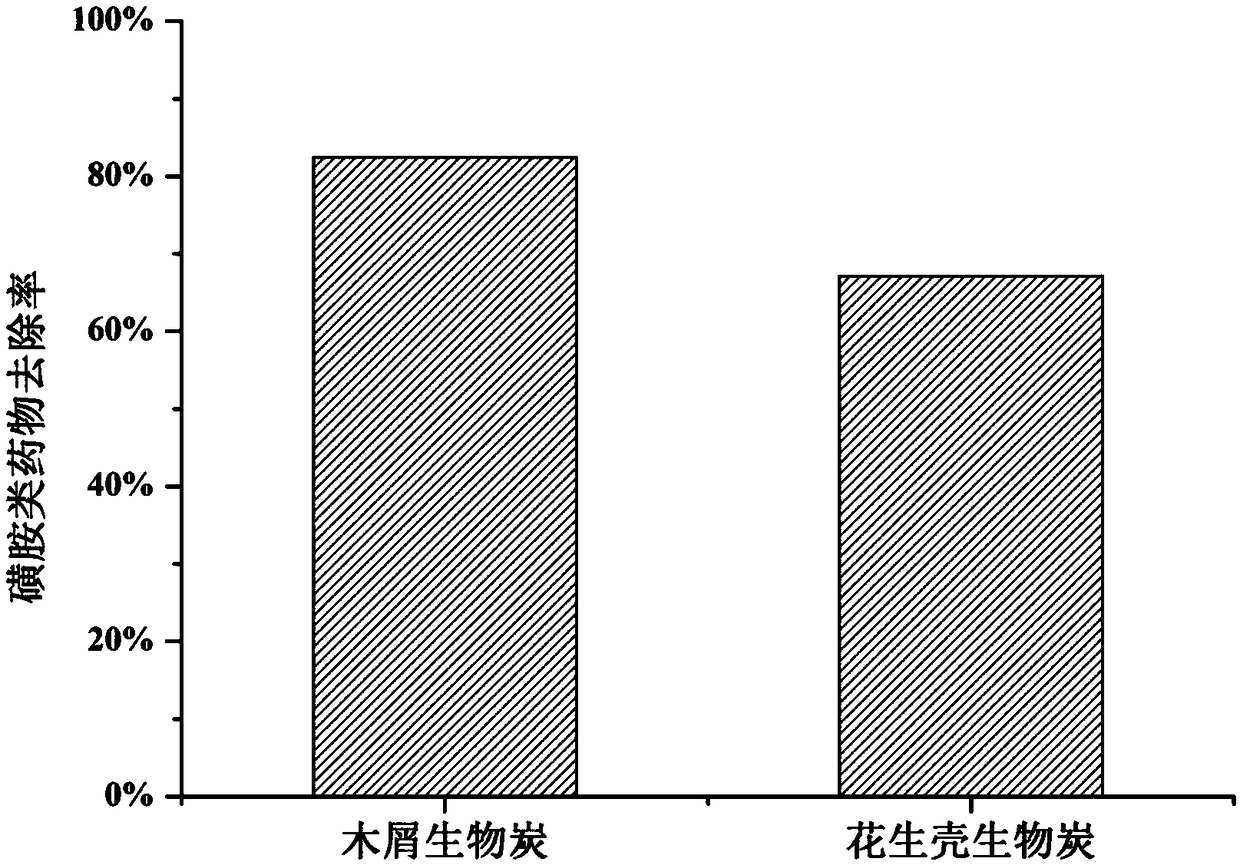

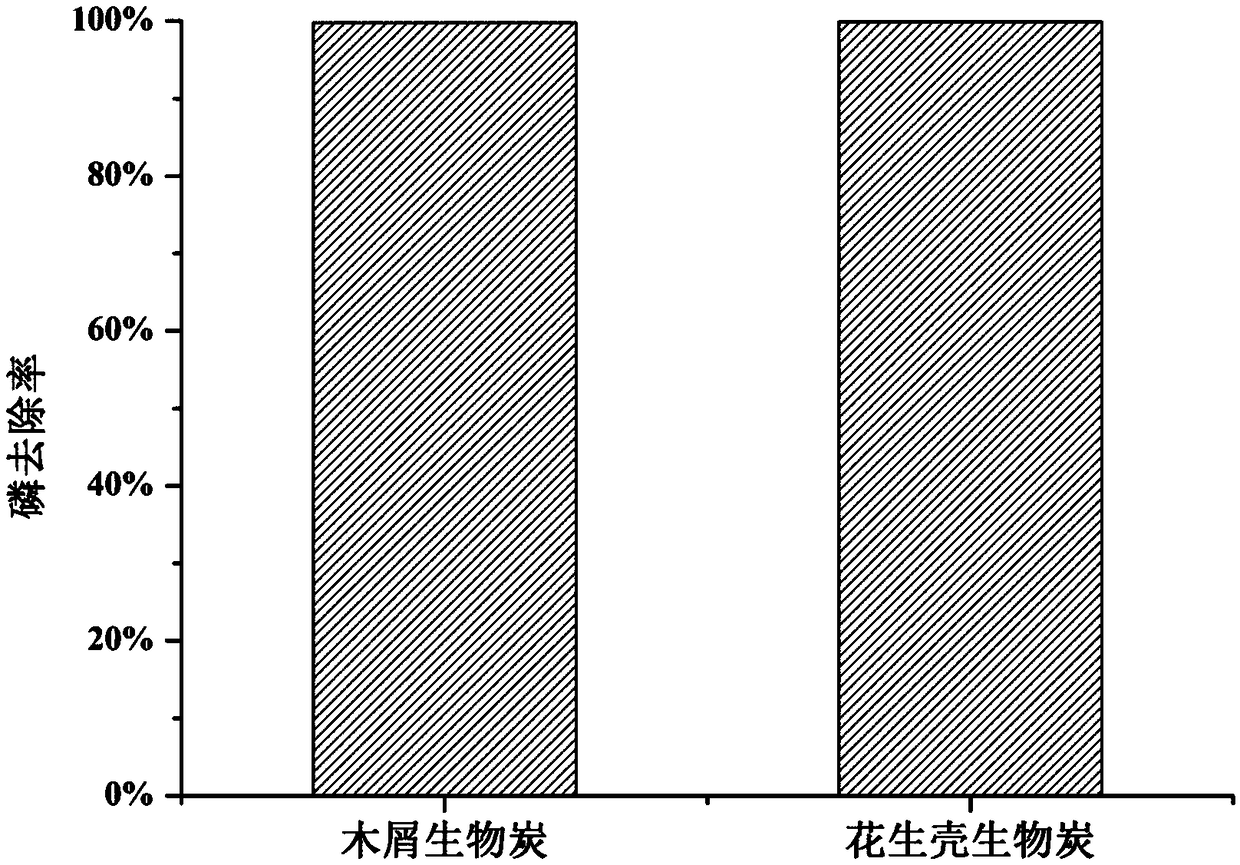

Combined treatment method for recovery of nitrogen and phosphorus elements in urine wastewater based on biological carbon

InactiveCN109160572ARaise the pHEasy to useOther chemical processesAlkali orthophosphate fertiliserSulfur drugMagnesium phosphate

The invention relates to a combined treatment method for recovery of nitrogen and phosphorus elements in urine wastewater based on biological carbon. The method mainly comprises the steps of selectionof biological carbon preparation materials, treatment of the preparation materials, preparation of the biological carbon and combined use of the biological carbon and magnesium peroxide. When the method is used for treating the urine wastewater, on the one hand, the biological carbon has relatively good absorbability, and can effectively absorb pollutants contained in the wastewater, such as sulfonamides and the like after the biological carbon is added into the urine wastewater; on the other hand, the addition of magnesium peroxide provides a feasible approach for the recovery of nitrogen and phosphorus resources in the urine wastewater; magnesium ions can react with ammonia nitrogen and phosphorus in the urine wastewater to generate magnesium phosphate (Mg3(PO4)2) and struvite (MgNH4PO4.6H2O); in addition, the biological carbon is a material prepared from waste biomass, which belongs to the scope of resource recycling; and therefore, the method exerts an excellent effect in the urine wastewater treatment and resource recycling.

Owner:TIANJIN UNIV

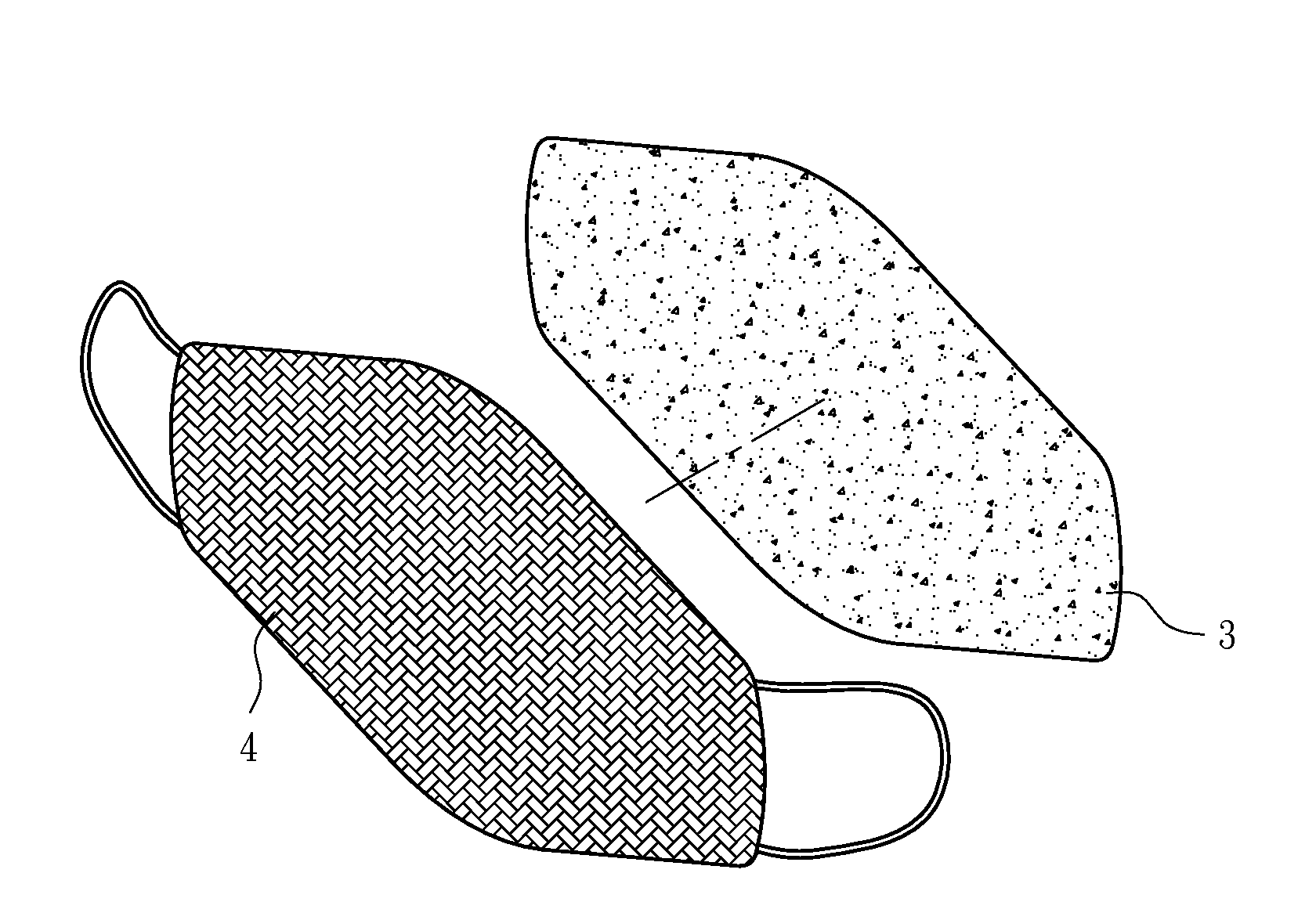

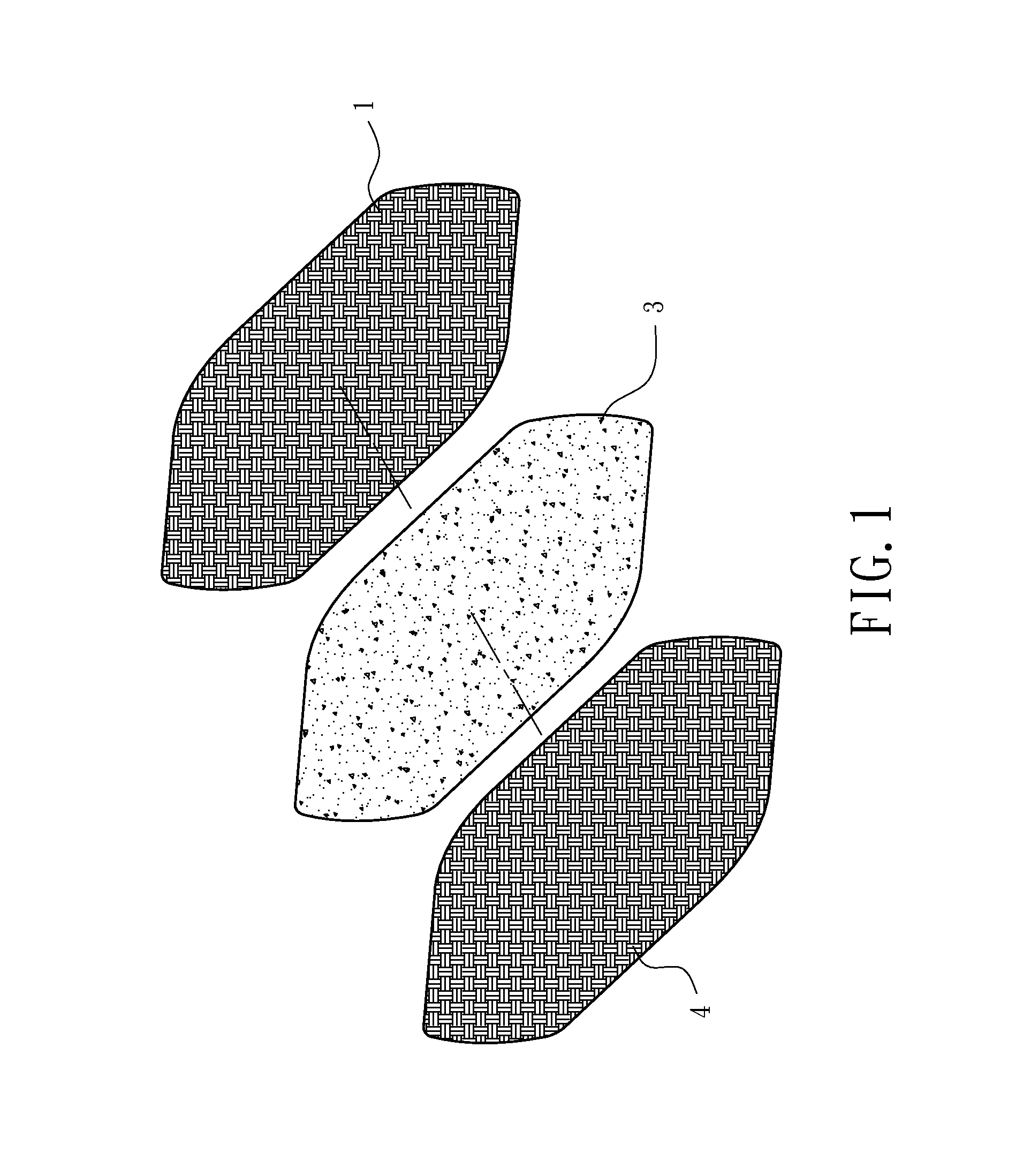

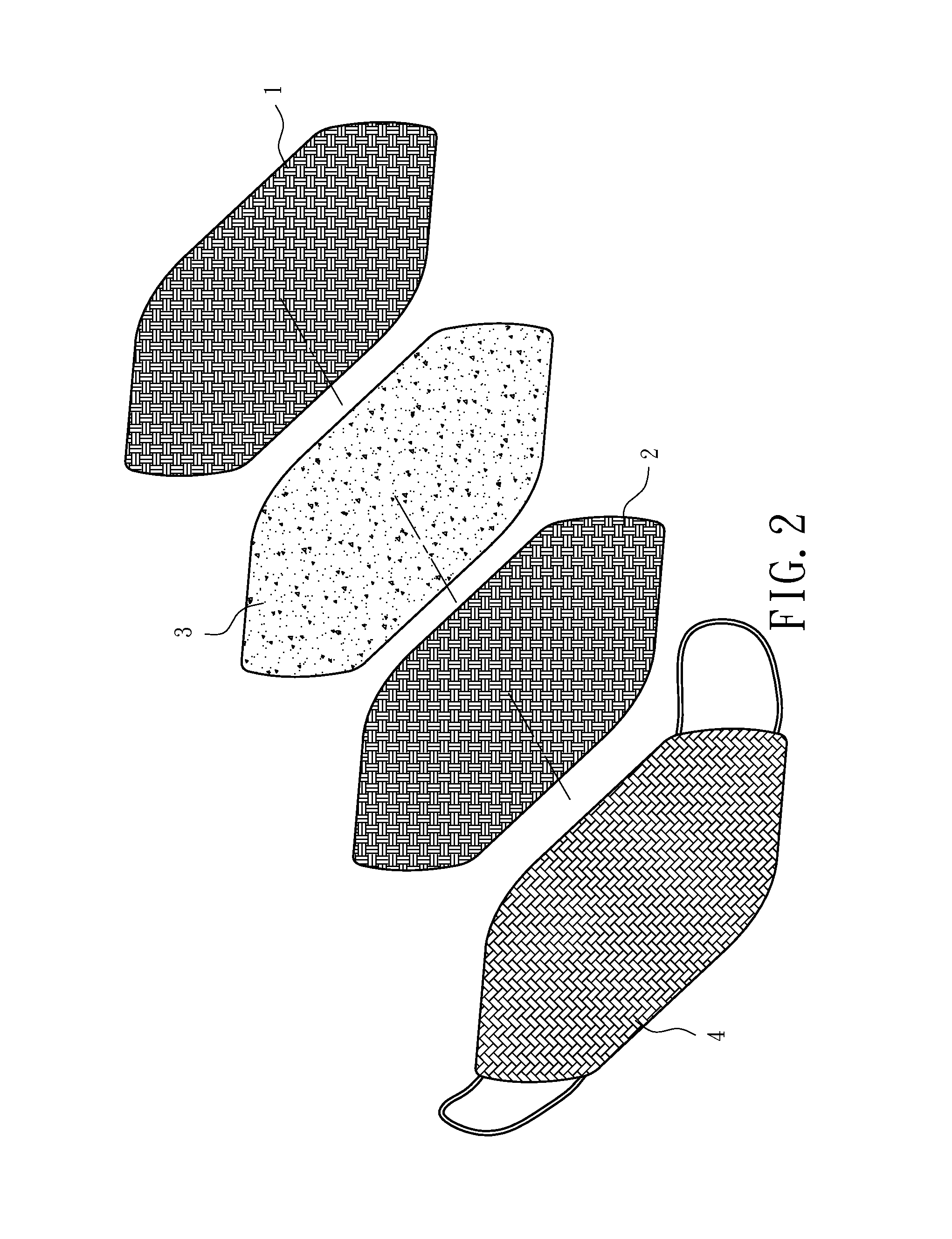

Air permeable mask

The present disclosure relates to a mask providing oxygen and removing water vapor in which a functional layer for oxygen production, moisture removal and better air quality is embedded; the functional layer can be inserted between an outer layer and an inner layer of the mask, taken as an inner layer or a sole layer, or held in a receiving pocket or attach / adhere to an innermost side of the mask; the functional layer comprises metal peroxide, metal superoxide, metal oxide and nonmetal oxide to remove water vapor and provide oxygen; the metal peroxide is selected from the group consisting of magnesium peroxide, potassium peroxide, sodium peroxide and calcium peroxide; the metal superoxide comprises potassium superoxide or sodium superoxide; the metal oxide is selected from the group consisting of magnesium oxide, calcium oxide and sodium oxide; the nonmetal oxide can be silicon dioxide.

Owner:TSAUR GARRY +2

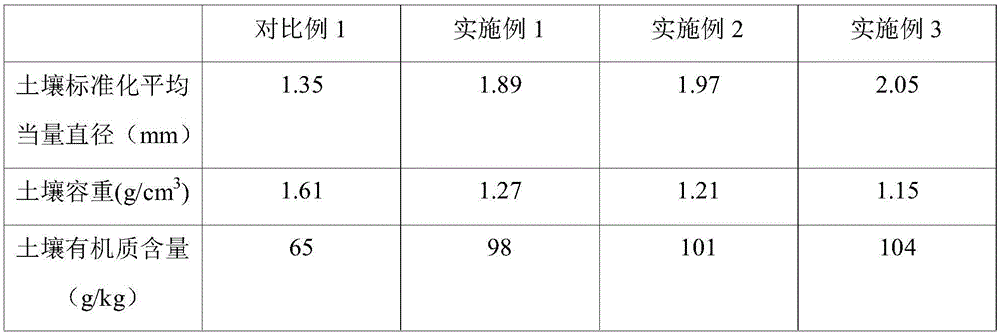

Soil conditioner for preventing soil hardening and preparation method of soil conditioner

InactiveCN106699355AReduce the degradation ratePrevent compactionCalcareous fertilisersBio-organic fraction processingMicrobial agentMonopotassium phosphate

The invention discloses a soil conditioner for preventing soil hardening. The soil conditioner is prepared from the following raw materials: rice husks, wheat hulls, banana fiber, cocoanut fiber, barks, turf, leguminous plant straws, bean cakes, vinasse, coffee residues, rape seed cakes, cottonseed cakes, fish meal, bone meal, medical stone powder, zeolite powder, bentonite, urea, ammonium sulfate, monopotassium phosphate, ferrous sulfate, magnesium sulfate, zinc sulfate, potassium chloride, calcium superphosphate, calcium peroxide, magnesium peroxide, borax, an agricultural water-retaining agent and a microbial agent. The invention further provides a preparation method of the soil conditioner for preventing soil hardening. The soil conditioner disclosed by the invention is low in raw material cost and scientific in component, and can well adjust the soil structure and prevent the soil hardening.

Owner:广西科茂信息咨询有限公司

Method for preparing high-content nanometer magnesium peroxide by one-pot precipitation and product of high-content nanometer magnesium peroxide

ActiveCN108658047AReduce manufacturing costEasy to operateMaterial nanotechnologyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRoom temperatureEnergy consumption

The invention belongs to the field of peroxide preparation methods, and discloses a method for preparing high-content nanometer magnesium peroxide by one-pot precipitation and a product of the high-content nanometer magnesium peroxide. The method comprises the steps as follows: firstly, a magnesium-containing compound is dissolved in water, a particle size control agent is added or not added, a proper quantity of precipitant and hydrogen peroxide are added randomly to form a suspension, the mass concentration of hydrogen peroxide in the mixed solution is 8%-15%, the mixed solution is stirred for reaction at room temperature, finally, precipitate after the reaction is separated, washed and dried, and nanometer magnesium peroxide with the content higher than 80wt% is obtained. Nanometer magnesium peroxide is prepared by one-pot precipitation, the raw materials are abundant and cheap, the preparation process is simple, energy consumption is low, no phosphorus-containing stabilizer is added, the product has small particle size and high purity, and the method is suitable for large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

Chlorine salt acid system prior complexing-selective iron precipitation chromium-iron separation method

ActiveCN106244804AAvoid hydrolysisEfficient separationProcess efficiency improvementPrecipitationFerric

The invention discloses a chlorine salt acid system prior complexing-selective iron precipitation chromium-iron separation method. Sodium formate and the like are used as a complexing agent; and the proper complexing agent is selected to perform prior complexing for iron in hydrochloric acid solution to change the ion existence form so as to prevent quick mass hydrolytic precipitation of iron in the precipitating phase and the caused chromium inclusion loss. The method improves the iron ion complexing effect through adjusting the complexing agent and the use level thereof, the original solution pH, the complexing temperature and the complexing time, and adjusts the solution pH value through such alkali mediums as magnesium oxide to realize prior iron hydrolytic precipitation and effective chromium separation. The chromium solution after solid-liquid separation can be directly used for preparing different chromium salts. Compared with other traditional technologies, the method is simple in operation process, needs no special complex equipment, and is a new method with economy, effectiveness and operation easiness.

Owner:JIANGXI UNIV OF SCI & TECH +1

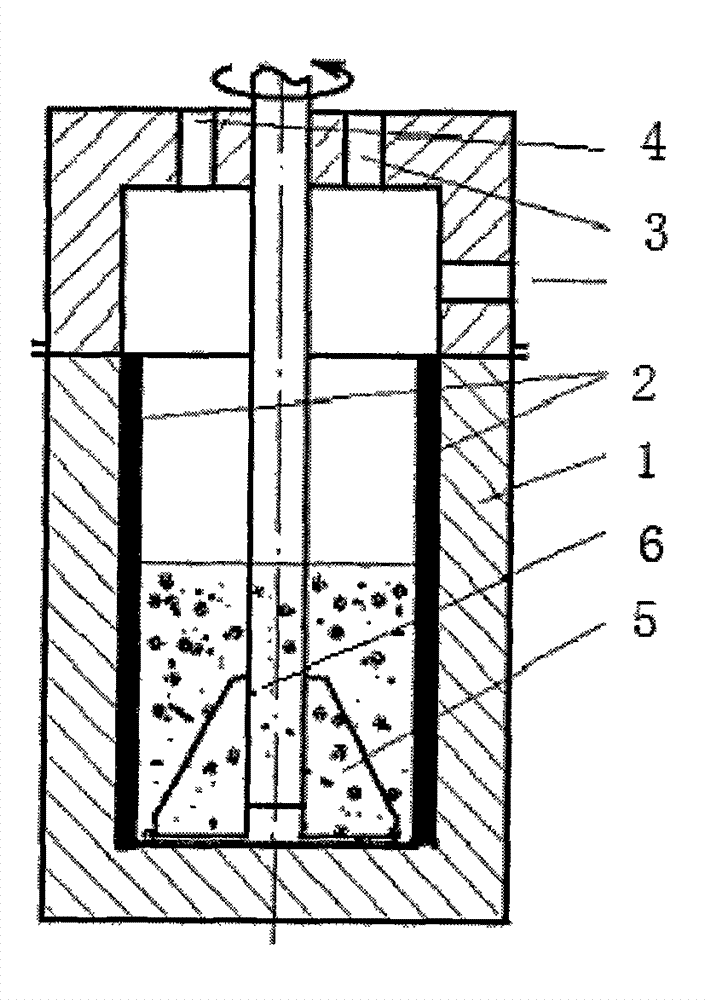

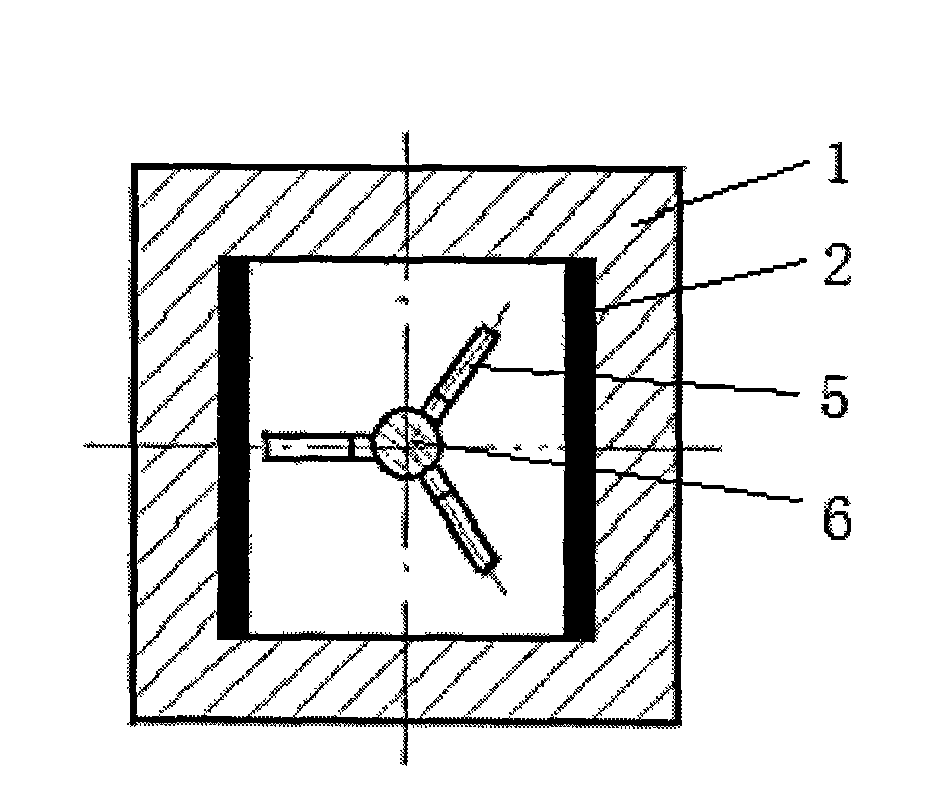

Electrical heating internal resistance electric melting method for decomposing mixed rare earth ore concentrate and electric heating decomposer thereof

The invention provides a decomposition method for rare earth ore concentrate. The method comprises the following process steps: (1) mixing mixed rare earth ore concentrate with concentrated sulfuric acid according to mass ratio in an electric heating decomposer; (2) heating the material with resistance heat generated by current flowing through the material after energization of the electric heating decomposer; (3) leaching output roasted ore by water; and neutralizing the solution with magnesium oxide to obtain iron phosphate, thorium phosphate precipitate and phosphorus phosphate precipitate; (4) removing sulfuric acid mist and dust in roasting tail gas; then spraying with liquid caustic soda to absorb fluorine, so as to precipitate sodium acid fluoride; and emptying the gas with acid and fluoride removed; and (5) cleaning and discharging the leached slag. The method provided by the invention employs electric heating to substitute fuel burning heating to lower processing capacity of waste gas and wastewater to 5% of that of an original process, so as to save energy, investment and operation cost; waste gas and waste residue reach discharge standards, and waste water can be recycled; and recovery rate of rare earth, thorium and fluorine is improved, so as to solve the problem of reuse of thorium and fluoride.

Owner:INNER MONGOLIA TECHNICAL COLLEGE OF MECHANICS & ELECTRICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com