Preparation method for nano magnesium peroxide

A technology of magnesium peroxide and magnesium oxide, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems such as product particle size not mentioned, and achieve good dispersion, uniform particle size, and low raw material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Accurately weigh 0.5g of commercially available analytical pure magnesium oxide, add 15ml of deionized water to a 250ml beaker, dissolve and grind for about 1 hour to obtain a magnesium oxide slurry with a mass percentage of about 3.2%. Weigh 1g of commercially available analytically pure ammonium chloride and dissolve it in 15ml of commercially available hydrogen peroxide with an analytically pure mass fraction of about 30%. After mixing completely, slowly add it to the ground magnesium oxide slurry while stirring. The reaction was continued for 3.5 h under mechanical stirring to obtain a white mixture, which was vacuum-dried at -80°C after suction filtration. The target product nano magnesium peroxide powder is obtained.

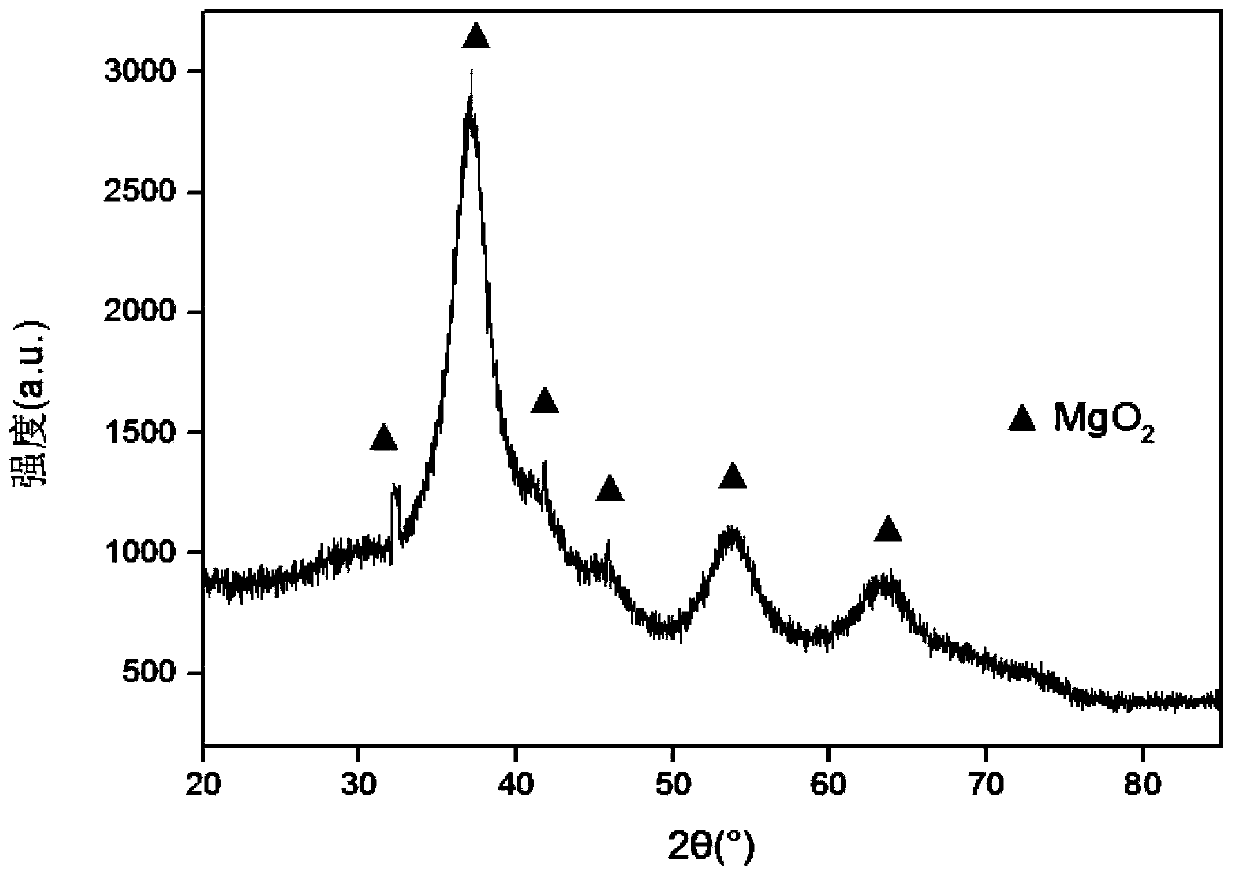

[0020] Tested by X-ray diffractometer figure 1 The XRD spectrum of the nano-magnesium peroxide prepared in Example 1 of the present invention is compared with the standard card, showing that the prepared substance is magnesium peroxide with a purit...

Embodiment 2

[0023] Accurately weigh 1 g of commercially available analytical pure magnesium oxide, add 25 ml of deionized water to a 250 ml beaker, dissolve and grind for 1.5 hours to obtain a magnesium oxide slurry with a mass percentage of about 3.8%. Accurately weigh 2g of commercially available analytically pure ammonium chloride and dissolve in 35ml of commercially available hydrogen peroxide with an analytically pure mass fraction of about 30%, and continue to react for 4h under mechanical stirring at 500r / min to obtain a white mixed solution. Freeze and vacuum dry at -80°C. The target product nano magnesium peroxide powder is obtained.

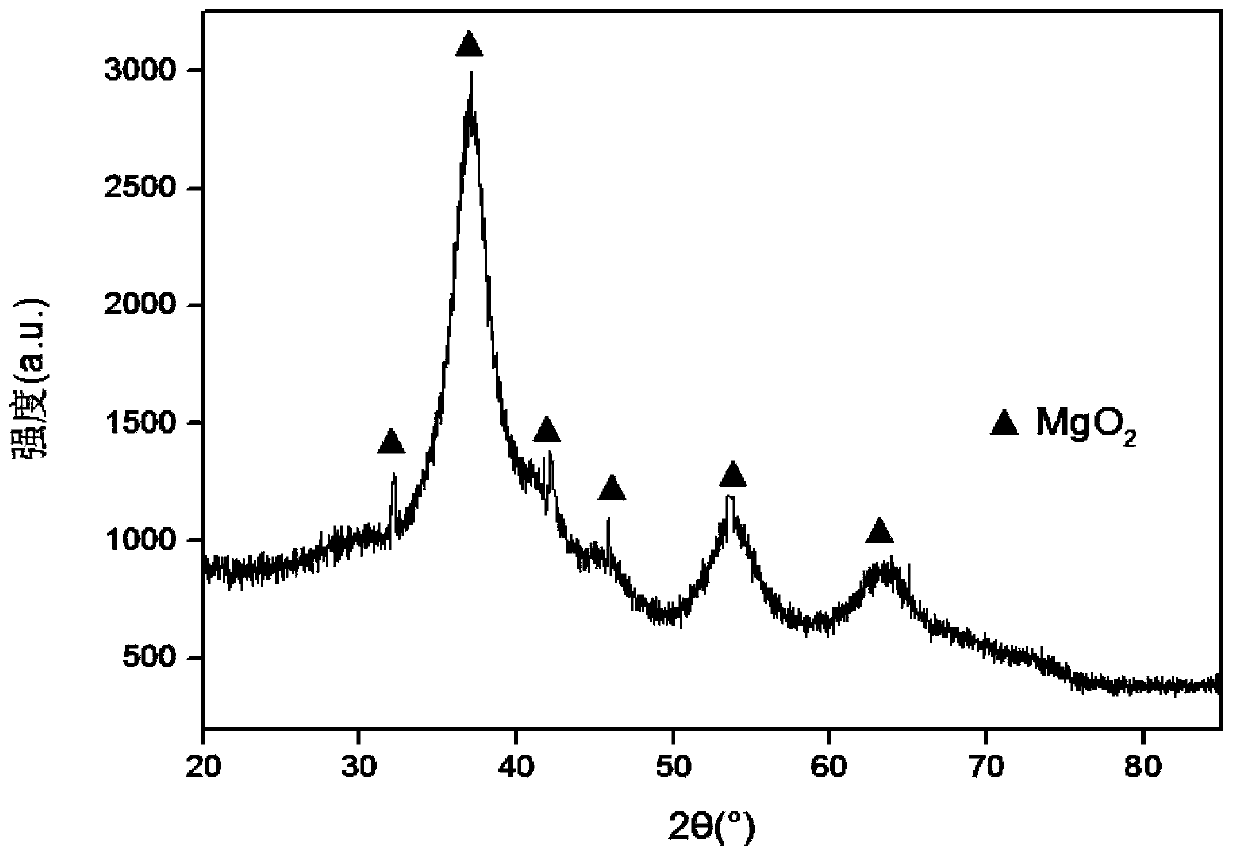

[0024] Tested by X-ray diffractometer figure 2 The XRD spectrum of the nano-magnesium peroxide prepared in Example 2 of the present invention is compared with the standard card, showing that the prepared substance is magnesium peroxide with a purity of 52%. Contains small amounts of magnesium oxide and magnesium hydroxide.

[0025] Such as Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com