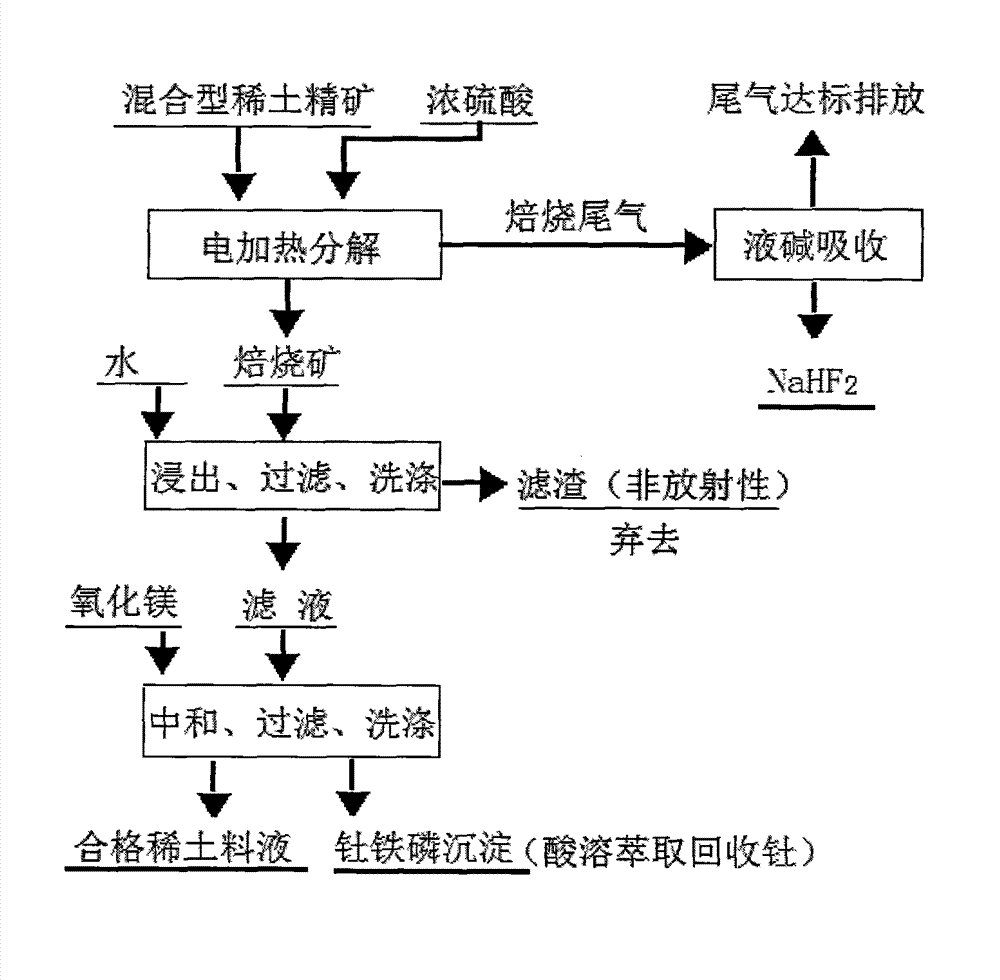

Electrical heating internal resistance electric melting method for decomposing mixed rare earth ore concentrate and electric heating decomposer thereof

A mixed rare earth and electric heating technology, which is applied in the field of rare earth metallurgy, can solve the problems of high operating cost, increased operating cost, and special requirements for equipment and materials, so as to reduce storage cost and environmental protection hazards, reduce investment and operating costs, and facilitate The effect of concentrated and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

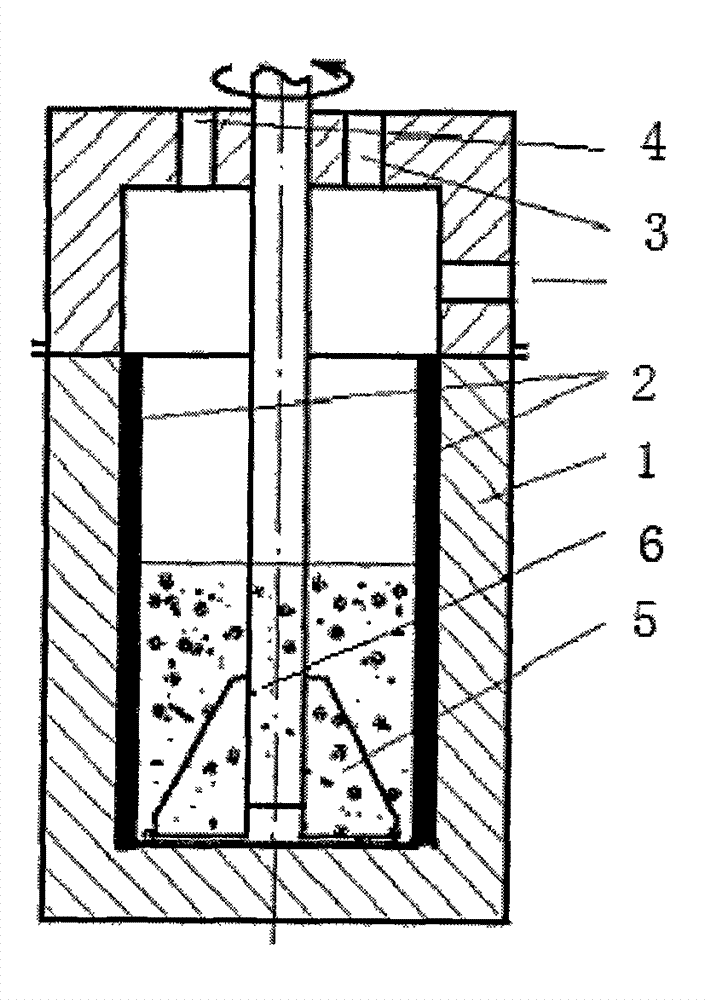

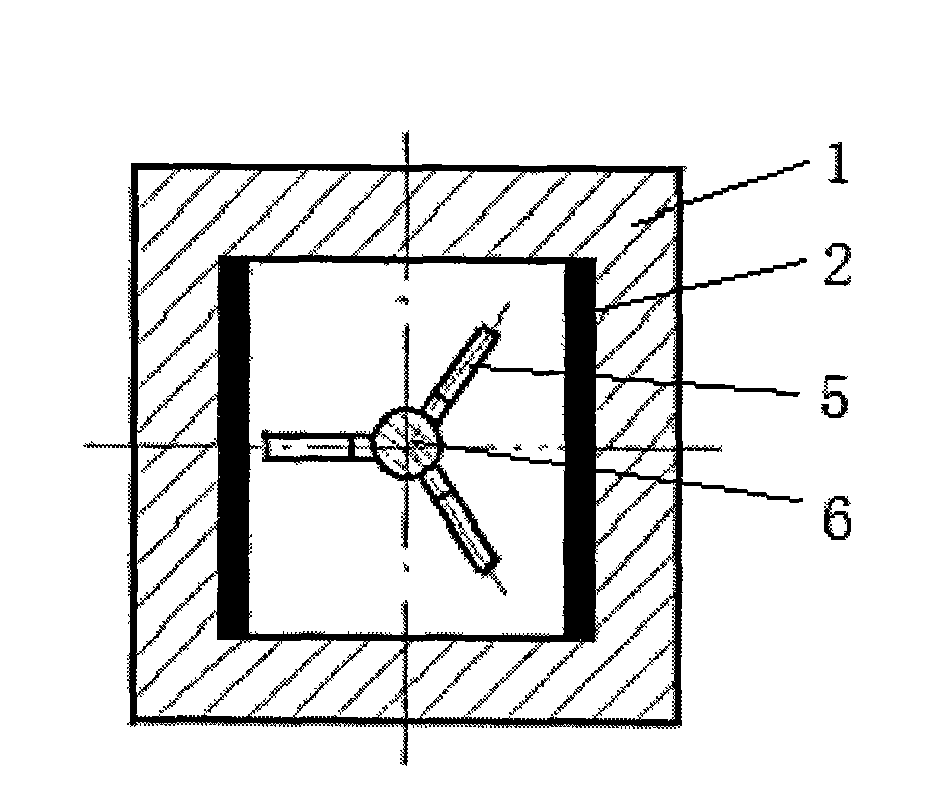

Examples

Embodiment

[0036] Get 5kg mixed type rare earth concentrate, the main components of the concentrate are as follows (mass percentage):

[0037] REO F P CaO TFe ThO 2

[0038] 52.19 8.79 4.10 7.90 5.40 0.21

[0039] Take 7.5kg of industrial sulfuric acid with a concentration of 95%, add the sulfuric acid to the decomposition tank, then add the above-mentioned rare earth concentrate to the decomposition tank, start the agitator and mix for about 10 minutes; at this time, the sulfuric acid reacts with the water in the concentrate and some minerals to release heat. The temperature measuring instrument shows that the temperature of the material reaches 80°C, stop stirring; turn on the AC to heat the material, adjust the size of the input current, and slowly increase the temperature of the material from 80°C to 200°C within 4 hours; properly increase the input current, within 2 hours Raise the temperature of the material from 200°C to 280°C; power off, lower the decomposition tank body to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com