Tea making technology using light microwaves

A light wave and microwave technology, applied in the field of optical microwave processing technology, can solve the problems of bad influence of tea production process, inability to kill microorganisms, poor sterilization effect, etc., to reduce the green grass gas of tea, shorten the processing time, and reduce the loss of effective components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

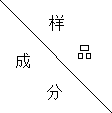

Image

Examples

Embodiment 1

[0029] Step 1: Sunshine with light waves. Put 5 kg of selected fresh tea leaves into the light wave equipment (the equipment is self-assembled, which is a technology that can be realized by ordinary technicians, it includes light microwave chamber, light source and switch, microwave source and switch), turn on the light source, light wave The wavelength range is 250-800 nm, the power is 3000 W, and the illumination time is 3 min.

[0030] Step 2: light microwave cleaning, drying and sterilization. Turn on the light source and the microwave source at the same time, the microwave frequency used is 2450 MHz, the power is 1000 W, the light wave wavelength range is 250-800 nm, the power is 3000 W, and the frying time is 8 min. During the process, the tea leaves are constantly turned, so that the tea leaves are heated evenly. Pass 95°C hot air into the optical microwave chamber of the light wave equipment, so that the hot air can quickly take away the water vapor.

[0031] Step 3...

Embodiment 2

[0035] Step 1: Sunshine with light waves. Put 3 kg of selected fresh tea leaves into the light wave equipment, turn on the light source, the light wave wavelength range is 250-800 nm, the power is 1000 W, and the light time is 3 min.

[0036] Step 2: light microwave cleaning, drying and sterilization. Turn on the light source and the microwave source at the same time, the microwave frequency used is 2450 MHz, the power is 800 W, the light wavelength range is 250-800 nm, the power is 1000 W, and the frying time is 4 min. During the process, the tea leaves are constantly turned, so that the tea leaves are heated evenly. Pass 90°C hot air into the optical microwave chamber of the light wave equipment, so that the hot air can quickly take away the water vapor.

[0037] Step 3: light wave Titian. The light wavelength range is 1.5-15 μm, the power is 2000 W, and the illumination time is 2 min.

[0038] Step 4: Freeze. After the hot tea leaves are taken out of the optical microw...

Embodiment 3

[0041]Step 1: Sunshine with light waves. Put 500g of selected fresh tea leaves into the light wave equipment, turn on the light source, the light wave wavelength range is 250-800 nm, the power is 500 W, and the light time is 1 min.

[0042] Step 2: light microwave cleaning, drying and sterilization. Turn on the light source and the microwave source at the same time, the microwave frequency used is 2450 MHz, the power is 500 W, the light wave wavelength range is 250-800 nm, the power is 500 W, and the frying time is 2 min. During the process, the tea leaves are constantly turned, so that the tea leaves are heated evenly. Pass 85°C hot air into the optical microwave chamber of the light wave equipment, so that the hot air can quickly take away the water vapor.

[0043] Step 3: light wave Titian. The light wavelength range is 1.5-15 μm, the power is 1000 W, and the illumination time is 1 min.

[0044] Step 4: Freeze. After the hot tea leaves are taken out of the optical micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com