Method for preparing protein feed by solid fermenting potato slag

A potato residue and protein feed technology, applied in the field of protein feed, can solve the problems of difficult to accurately measure solid-state fermentation parameters, imperfect design of biochemical reactors, slow growth rate of microorganisms, etc. The effect of color improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

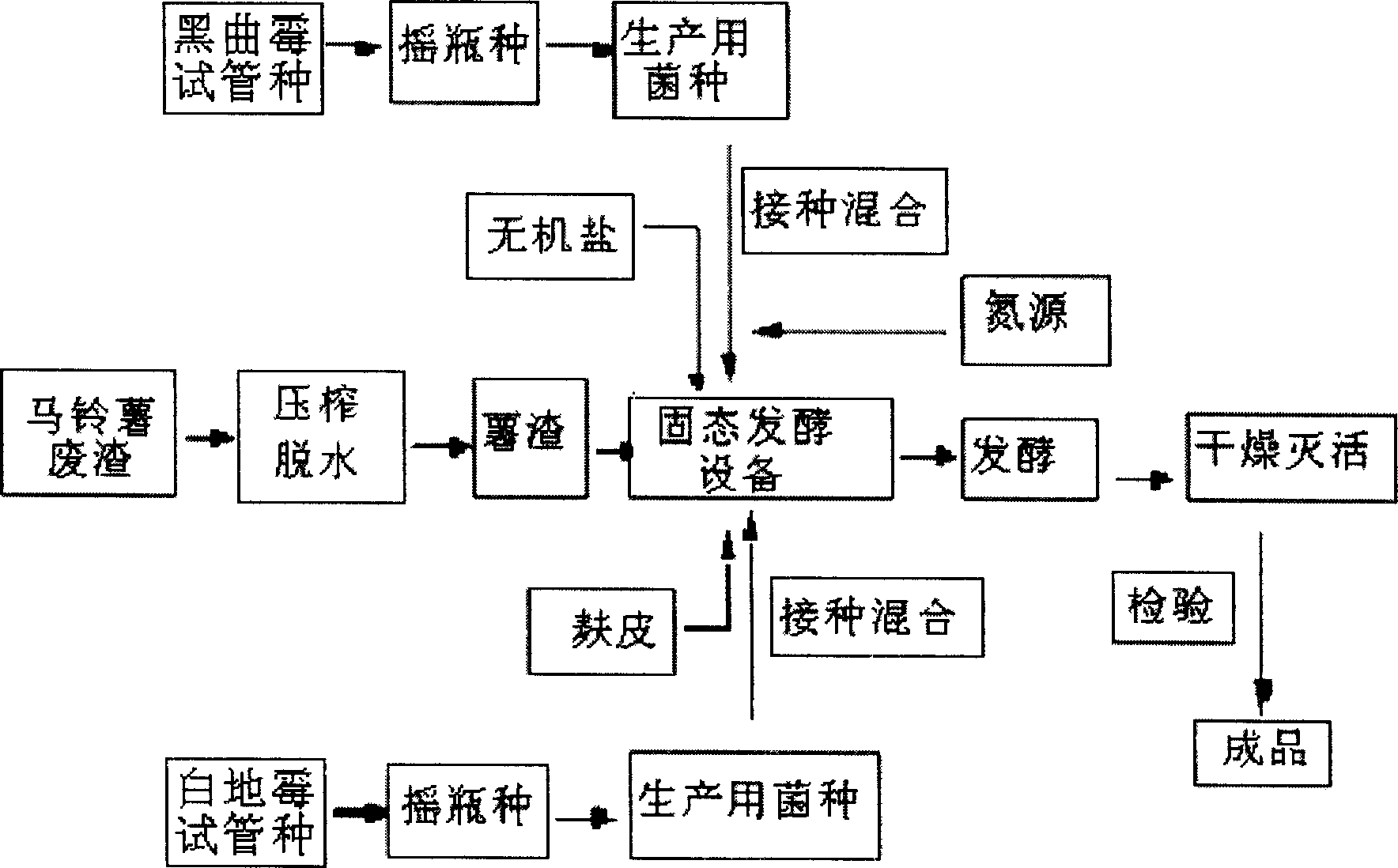

Image

Examples

Embodiment 1

[0065] (1) Preparation of slant strains

[0066] Use potato glucose slant medium or 5Be° wort slant medium to inoculate Aspergillus niger and Geotrichum candidum strains respectively (the preservation number of Aspergillus niger is ATCC 1004, and the preservation number of Geotrichum candidum is ATCC 10834) in strict accordance with aseptic procedures and cultivate them at 28°C Cultivate in the box for 60 hrs to make slant strains and store them in the refrigerator for later use.

[0067] (2) Expansion of primary strains

[0068] Potato glucose liquid medium was used to insert two rings of slant bacteria, and cultivated in a shaking incubator at 28°C and 180r / min for 48hrs.

[0069] (3) Secondary strain expansion

[0070] Stir the bran with water evenly, 1 kg / cm 2 Sterilize for 30 minutes, cool to 35°C to 40°C, then inoculate the first-grade strains with an inoculation amount of 1%, stir evenly and place in a shallow dish with a medium thickness of 2 to 4 cm, and cultivate ...

Embodiment 2

[0073] Take 100kg of potato dregs after pressing and dehydration, add 15% bran, 0.5% urea, 1.5% ammonium sulfate, and 0.75% superphosphate in proportion, inoculate 5% Aspergillus niger, 15% Geotrichum candidum, and the water content of the material is 68 %, fermented in a solid-state fermenter (provided by the Chinese Academy of Agricultural Mechanization Sciences), the fermentation temperature is 28-30°C, the humidity is 90%, and after 50 hours of fermentation, it is dried at 60-65°C for 5 hours to prepare the finished protein feed.

[0074] Comparison of inspection results between protein feed and potato dregs raw materials

Embodiment 3

[0076] The protein feed product and potato dregs raw material produced by the method of Example 2 are respectively inspected (through the pressing and dehydration step described in Example 2), wherein the assay method of crude protein content refers to GB / T14771-1993, and the assay method of amino acid content refers to GB / T18246-2000, the determination method of vitamin B1 content refers to GB / T12390-1990, the determination method of vitamin B2 content refers to GB / T12391-1990.

[0077] The comparison of test results is shown in Table 1. It can be seen from the results that the protein content of the feed product increases by more than 60%, and the content of various amino acids is improved compared with the raw material, and the nutritional value is improved. In addition, the vitamin B content in the protein feed is also significantly improved compared with the raw material. The safety of the feed product meets the feed standard, and the color of the product is obviously imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com