Device of oxygen control growth in single crystal furnace

A single crystal furnace and furnace cover technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of high heater, increase the contact time and opportunity between oxygen and single crystal, and the inconsistency of the guide mechanism of the cooling guide device. It is ideal and other problems to achieve the effect of strengthening the thermal insulation effect, simple structure, and reducing the generation of oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

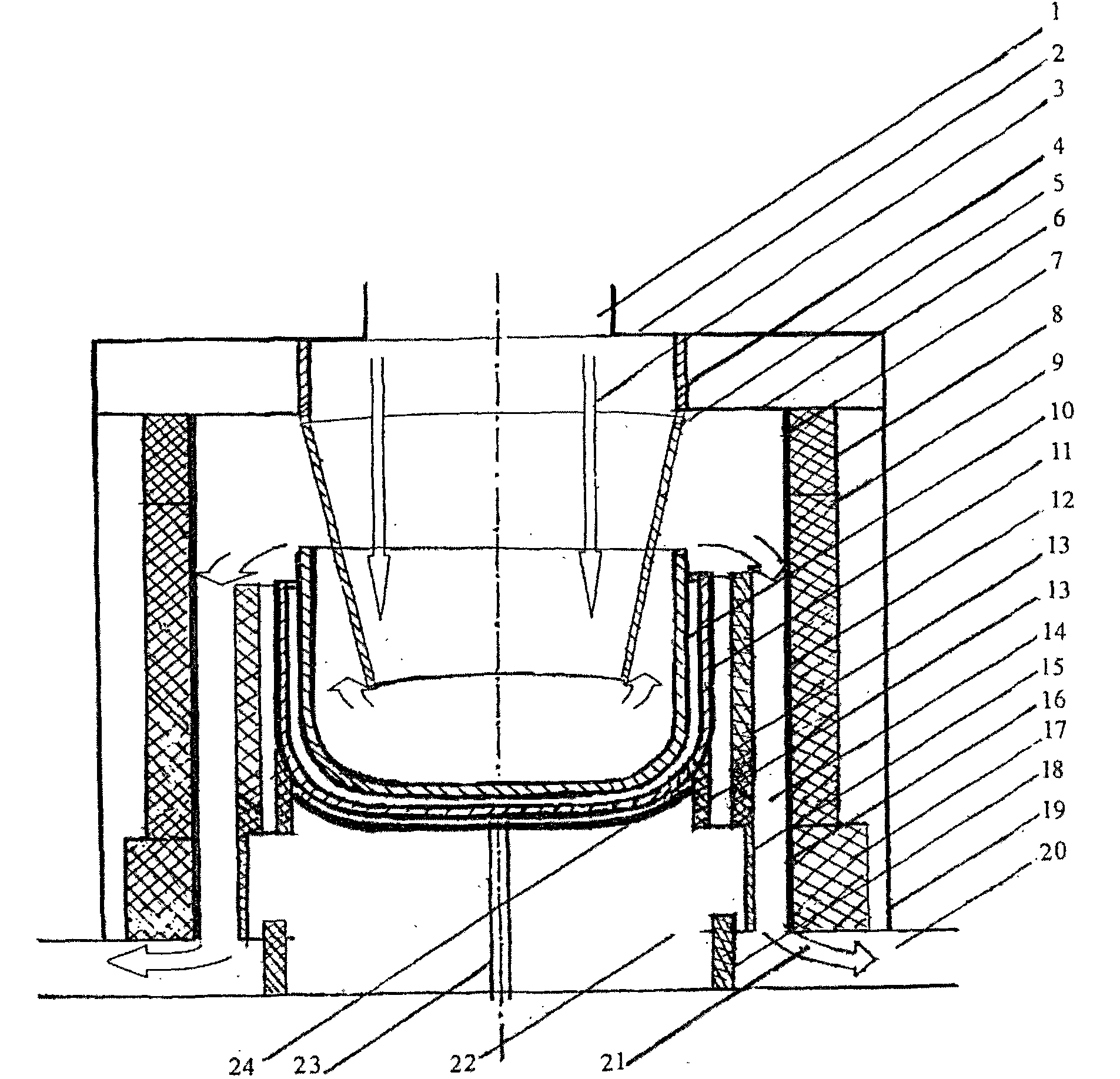

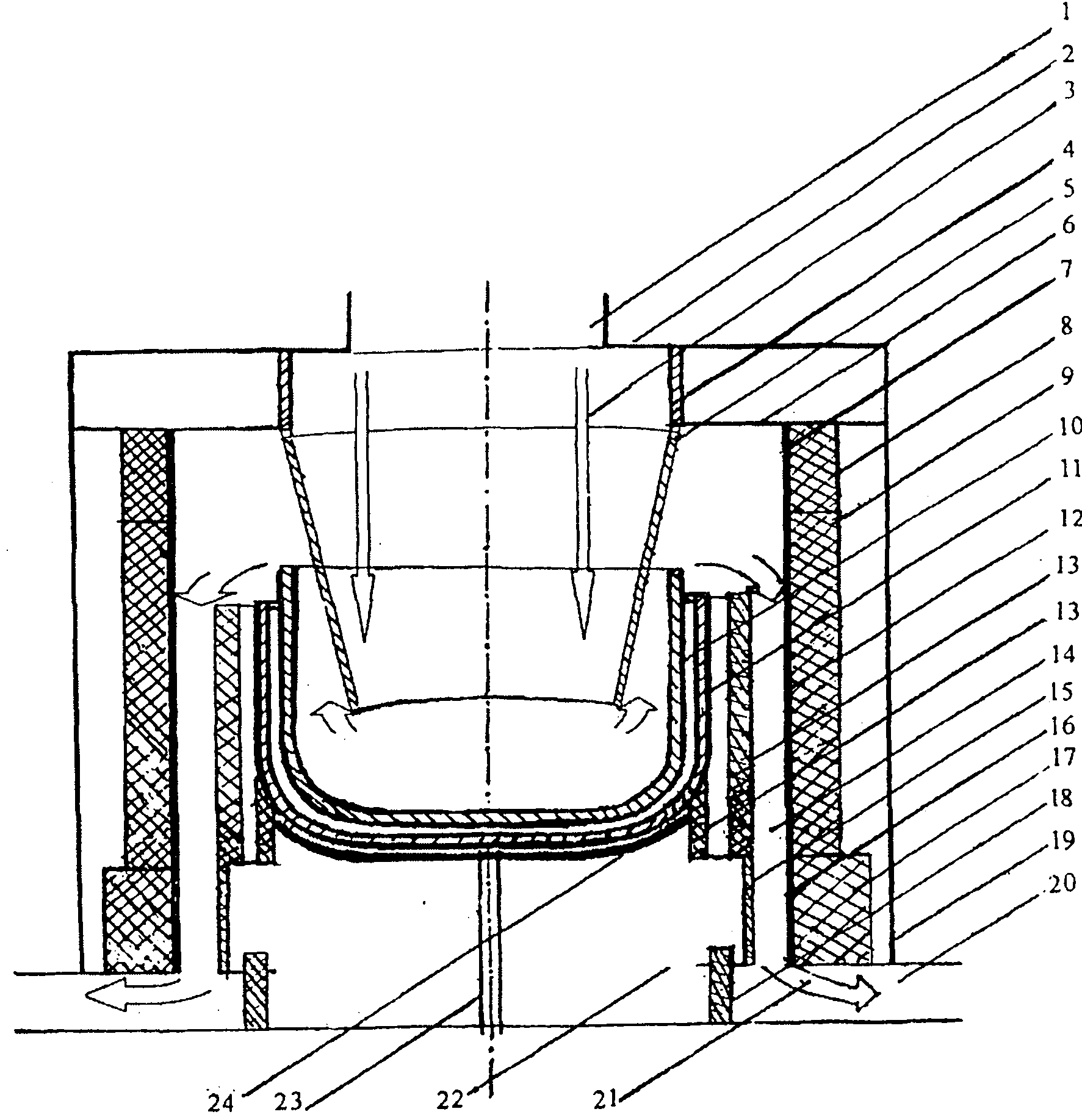

[0015] Such as figure 1 As shown, the operation steps of the oxygen-controlled growth device for Czochralski silicon single crystal growth provided by the present invention mainly include: thermal field installation, charging, heating, crystal pulling, cooling, etc.; thermal field installation: each part in the installation furnace ( are all graphite parts), and should be installed from bottom to top (that is, the first dismantled graphite parts are then installed, and the last dismantled graphite parts are first installed); the key is that when the heater (13) is installed, the electrodes and electrode screws must be tightened, Ensure that the heater (13) does not shake, and the installation of each part will be centered as far as possible, and the heat insulation effect of the lower heat preservation cylinder (16) will be strengthened, and the number of carbon felt layers will be increased to 10-12 layers. 7), the number of layers of carbon felt on the top is 6-8 layers. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com