Method for treating solid waste through incineration

A technology for solid waste and furnace body, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of high environmental damage, insufficient combustion process, high dust content, save initial investment, save workshop and Equipment, the effect of low dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

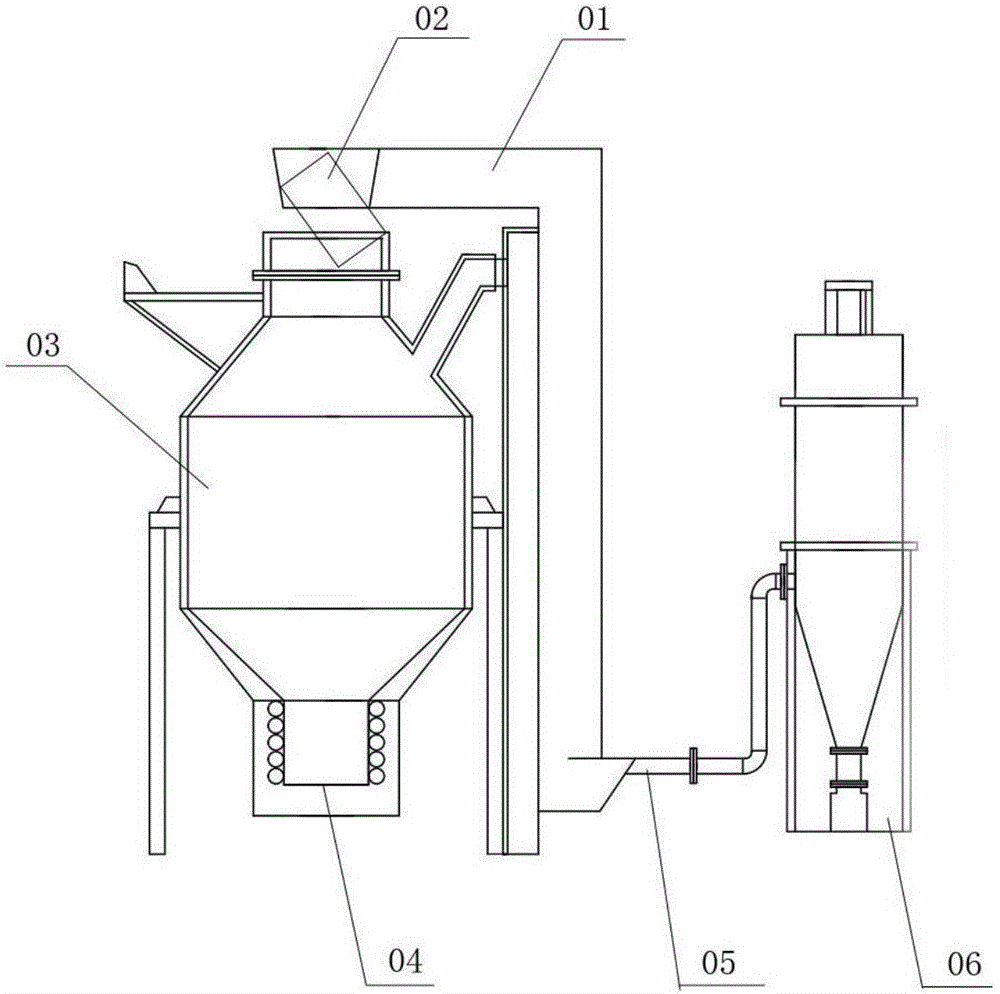

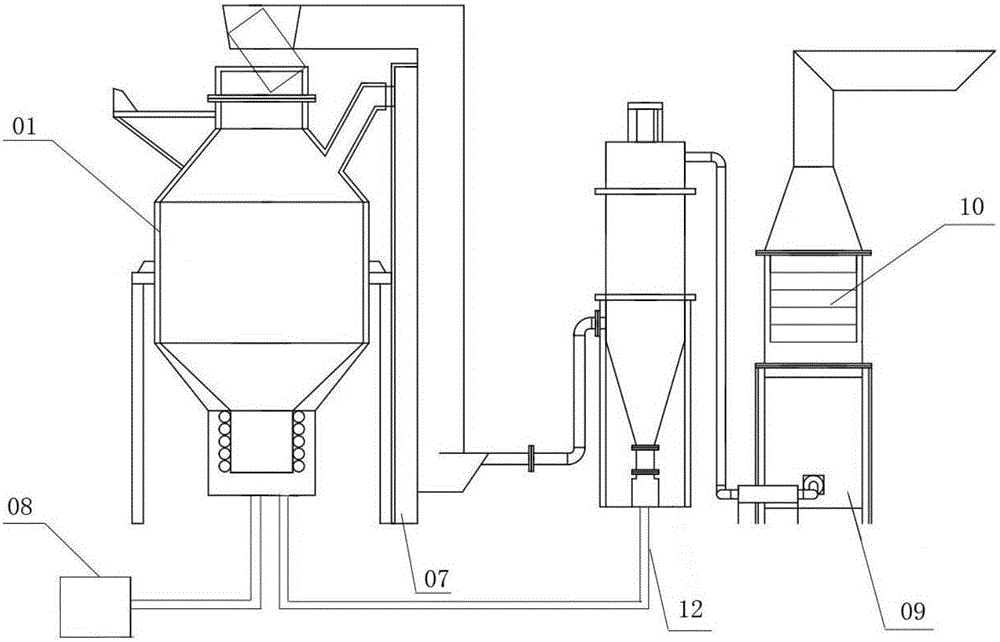

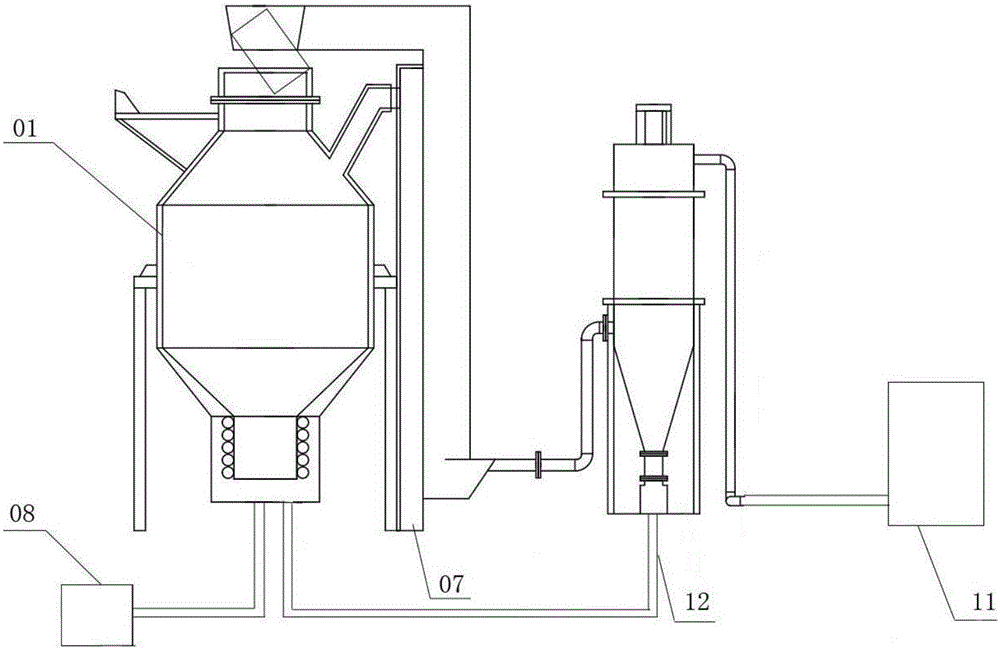

[0034] refer to figure 1 , a device for incinerating solid waste, including: elevator 01, input tank 02, ultra-high temperature pyrolysis gasification melting furnace body 03, induction furnace 04, flue gas pipeline 05, dust collector 06, ultra-high temperature pyrolysis The top of the furnace body 03 of the gasification melting furnace is provided with an input tank 02 , and the input tank 02 is fixed to the elevator 01 by welding, and the elevator 01 is independently located on one side of the furnace body 03 . The bottom of the furnace body 03 is provided with an induction furnace 04 for storing and discharging slag, and the upper part of the side is provided with a flue gas outlet and communicates with the middle part of the dust collector 06 through a flue gas pipe 05; The reserved hole position for separatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com