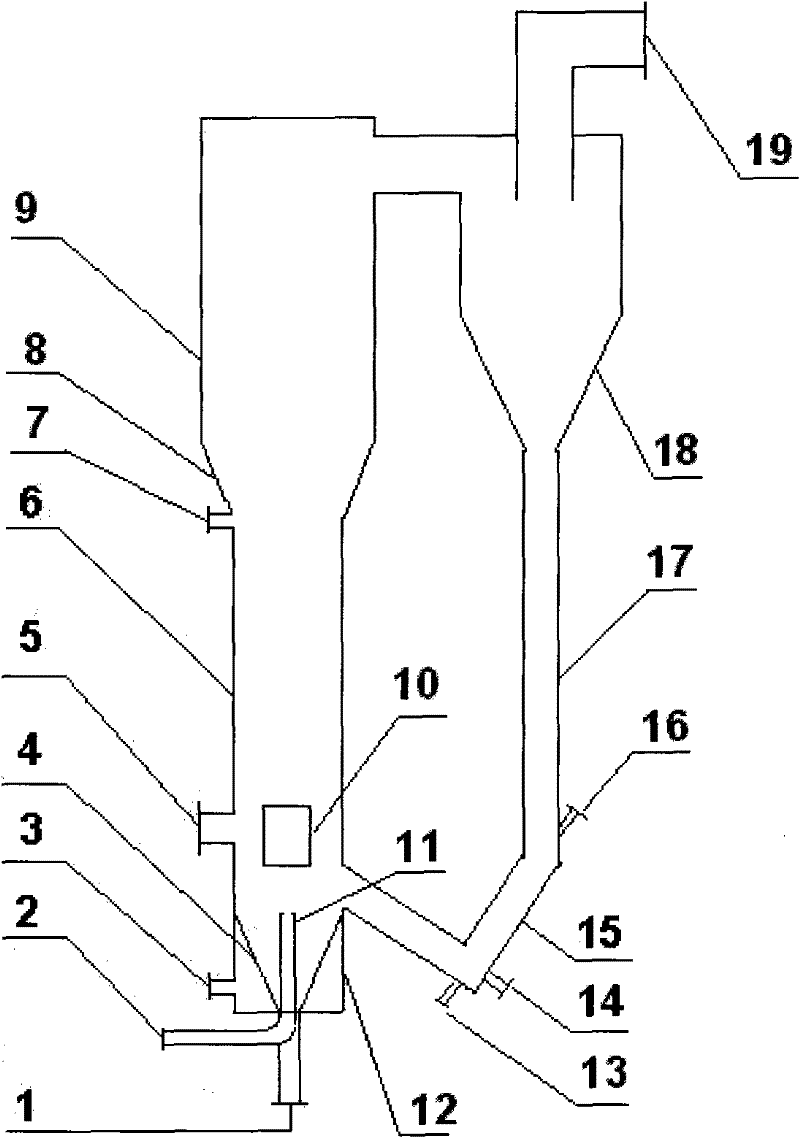

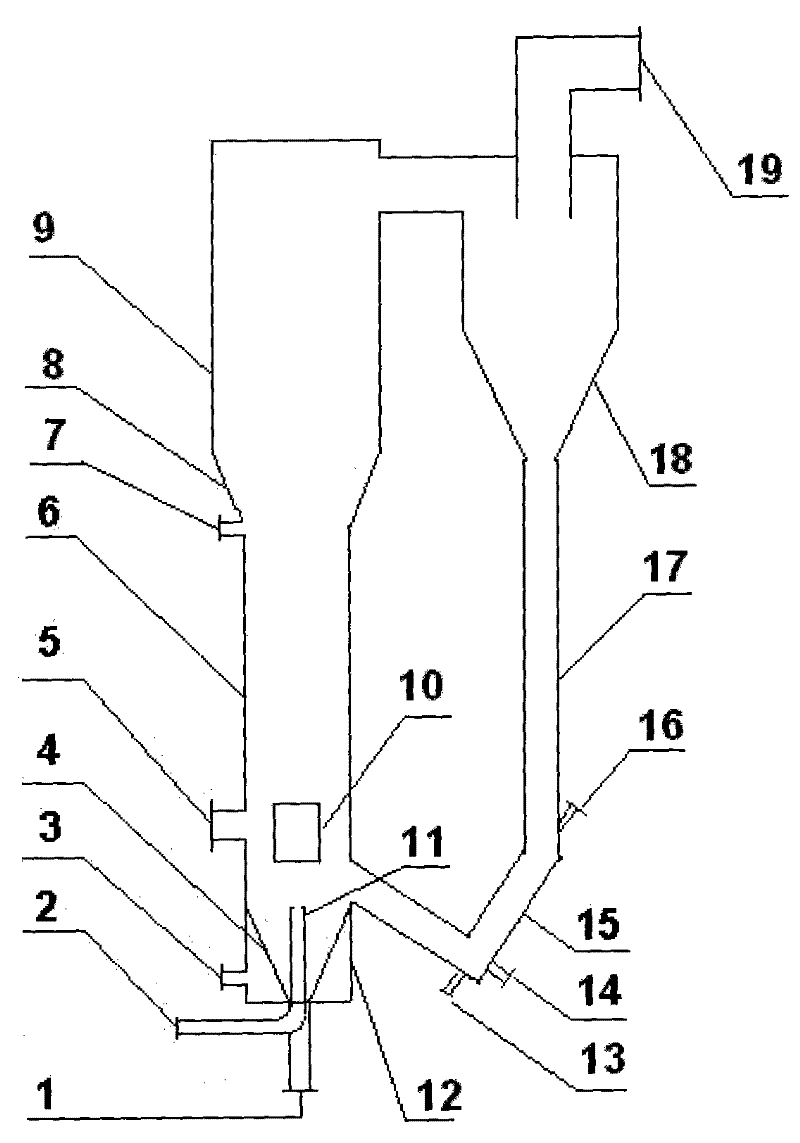

A co-combustion device for biomass and coal circulating fluidized bed controlled by jet flow

A circulating fluidized bed and biomass technology, which is applied in the directions of fluidized bed combustion equipment, fuels burned in a molten state, and combustion methods, etc., can solve problems such as limited supply, difficulty in maintaining normal operation of biomass burning enterprises alone, and corrosion. , to reduce carbon dioxide, promote combustion reaction and heat transfer, and improve reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Biomass is pneumatically conveyed by oxygen-enriched air and enters the lower bed body 6 of the fluidized bed through the biomass jet feed pipe 2, forming a continuous jet flow above the biomass jet feed pipe 2, and the raw coal enters through the raw coal inlet 5, and is connected with the The biomass forms a countercurrent movement, and under the disturbance of the jet flow, the biomass and coal are completely mixed, and the oxygen-enriched air enters the bed through the primary air inlet 3 and the gas distributor 4, so that the entire bed is in a stable fluidized state. Biomass and coal undergo a combustion exothermic reaction under the action of oxygen-enriched air, and the biomass is heated to generate biomass oil, which is further cracked into small molecule combustible gas by the biomass tar cracker 10, and together with the gas generated by coal combustion, entrains a large amount of ash Slag, unburned coal particles, semi-coke, etc. move upward from the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com