Simple preparation method of Al and Zr co-doped ultrahigh nickel ternary single crystal material

A single crystal material, co-doping technology, applied in the direction of chemical instruments and methods, nickel compounds, electrical components, etc., can solve problems such as in-situ doping, ultra-high nickel ternary single crystal positive electrode material preparation complexity, etc., to avoid Calcination treatment, improvement of electrochemical performance, and sufficient growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

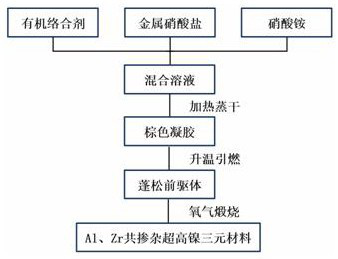

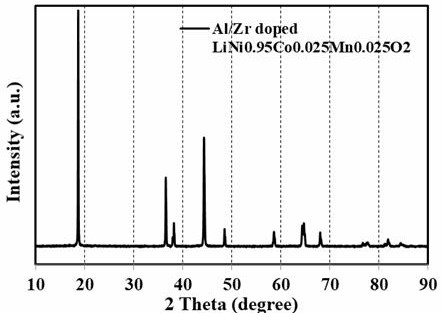

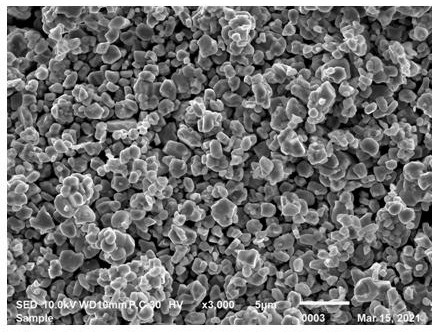

[0029] A kind of simple preparation method of Al, Zr co-doped ultra-high nickel ternary single crystal material, comprises the following steps:

[0030] S1, Lithium nitrate, nickel nitrate, cobalt nitrate, manganese nitrate according to molecular formula LiNi 0.95 co 0.025 mn 0.025 o 2 The molar ratio is dissolved in deionized water, and aluminum nitrate and zirconium nitrate are added relative to the target product 1000ppm doping amount, the metal ion concentration is 1mol / L, then add glycine and ammonium nitrate, wherein glycine and metal ion molar ratio is

[0031] 1:1, the molar ratio of ammonium nitrate and glycine is 1:1, stir evenly to obtain a mixed solution;

[0032] S2. Heating the above mixed solution to 80° C., evaporates and loses water and becomes viscous gradually, and finally obtains a brown gel substance;

[0033] S3. Continue to raise the temperature of the obtained brown gel to about 200° C., and keep it warm for 2 hours, so that the dry gel undergoes se...

Embodiment 2

[0037] A kind of simple preparation method of Al, Zr co-doped ultra-high nickel ternary single crystal material, comprises the following steps:

[0038] S1, Lithium nitrate, nickel nitrate, cobalt nitrate, manganese nitrate according to molecular formula LiNi 0.95 co0.03 mn 0.02 o 2 The molar ratio is dissolved in deionized water, and aluminum nitrate and zirconium nitrate are added relative to the target product 1500ppm doping amount, the metal ion concentration is 1.5mol / L, and then acrylic acid and ammonium nitrate are added, wherein the molar ratio of acrylic acid to metal ion is 2 :1, ammonium nitrate and acrylic acid mol ratio are 2:1, stir to obtain mixed solution;

[0039] S2. Heat up to 90°C to heat the above mixed solution, evaporate and lose water and gradually become viscous, and finally obtain a brown gel substance;

[0040] S3. Continue to raise the temperature of the obtained brown gel to about 250° C., and keep it warm for 1.5 hours, so that the dry gel unde...

Embodiment 3

[0043] A kind of simple preparation method of Al, Zr co-doped ultra-high nickel ternary single crystal material, comprises the following steps:

[0044] S1, Lithium nitrate, nickel nitrate, cobalt nitrate, manganese nitrate according to molecular formula LiNi 0.96 co 0.02 mn 0.02 o 2 The molar ratio is dissolved in deionized water, and aluminum nitrate and zirconium nitrate are added relative to the target product 2000ppm doping amount, the metal ion concentration is 2mol / L, then add citric acid and ammonium nitrate, wherein the citric acid and metal ion molar ratio is 2:1, the molar ratio of ammonium nitrate to citric acid is 1:1, stir evenly to obtain a mixed solution;

[0045] S2. Heating the above mixed solution to 95° C., evaporates and loses water and becomes viscous gradually, and finally obtains a brown gel substance;

[0046] S3. Continue to raise the temperature of the obtained brown gel to about 300° C., and keep it warm for 1 hour, so that the dry gel undergoes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com