A kind of pre-combustion type plasma igniter and ignition method

A plasma and igniter technology, applied in the direction of machines/engines, gas turbine devices, turbine/propellant fuel delivery systems, etc., can solve problems such as difficult to achieve high-altitude secondary ignition, unable to meet the needs of aircraft, and reduced chemical reaction rates, etc., to achieve Easy assembly, easy industrial production and processing, and the effect of promoting combustion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described now in conjunction with accompanying drawing.

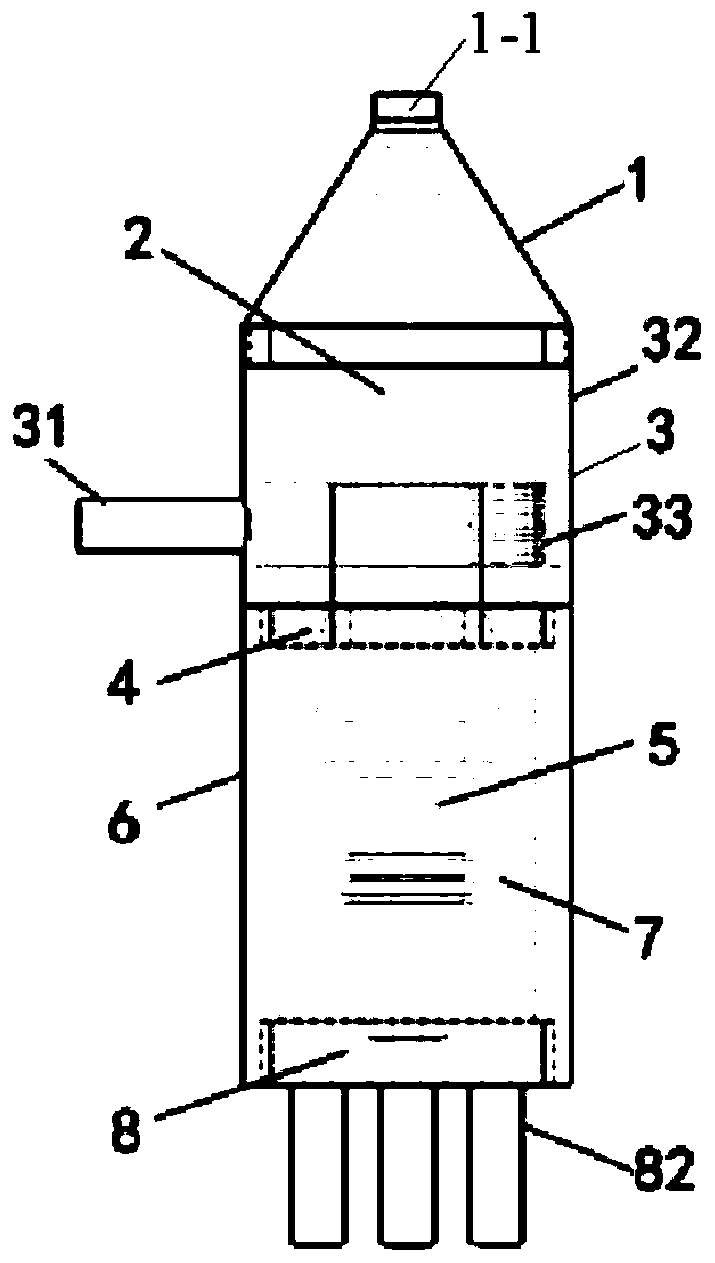

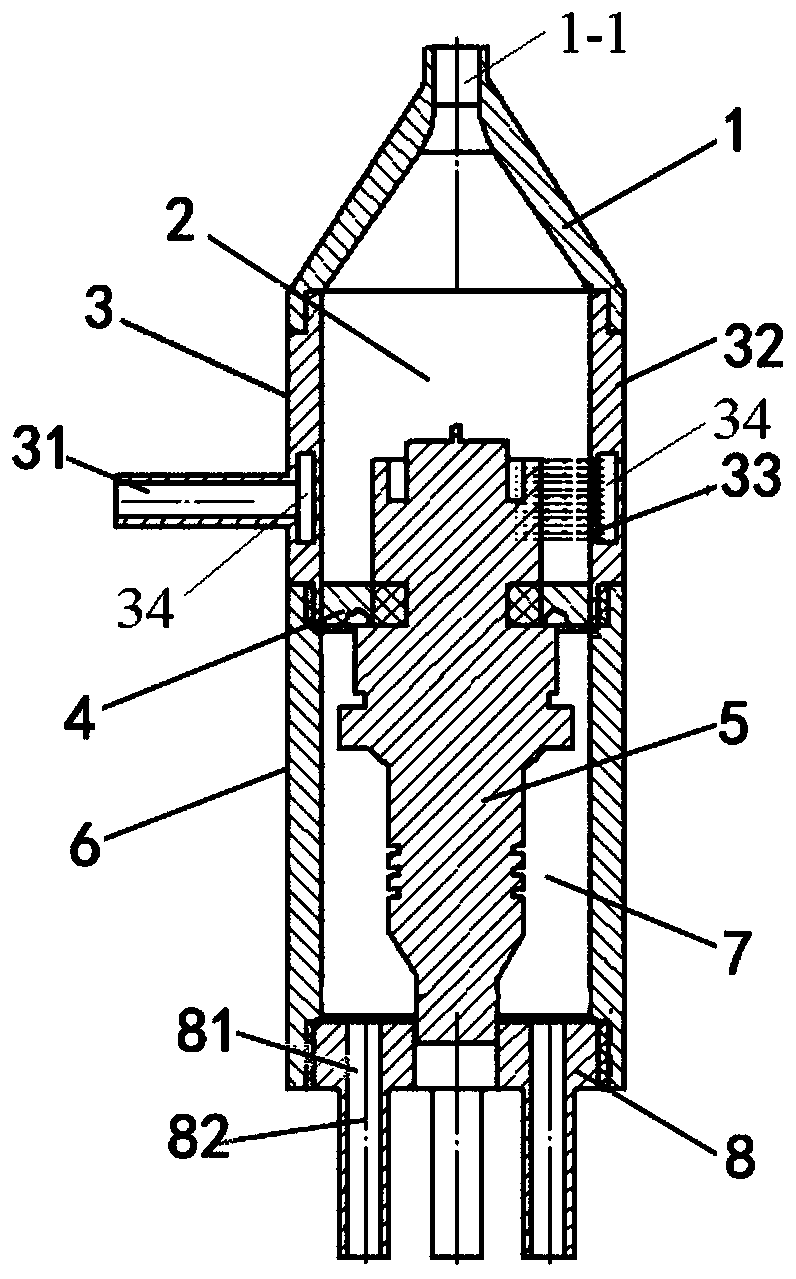

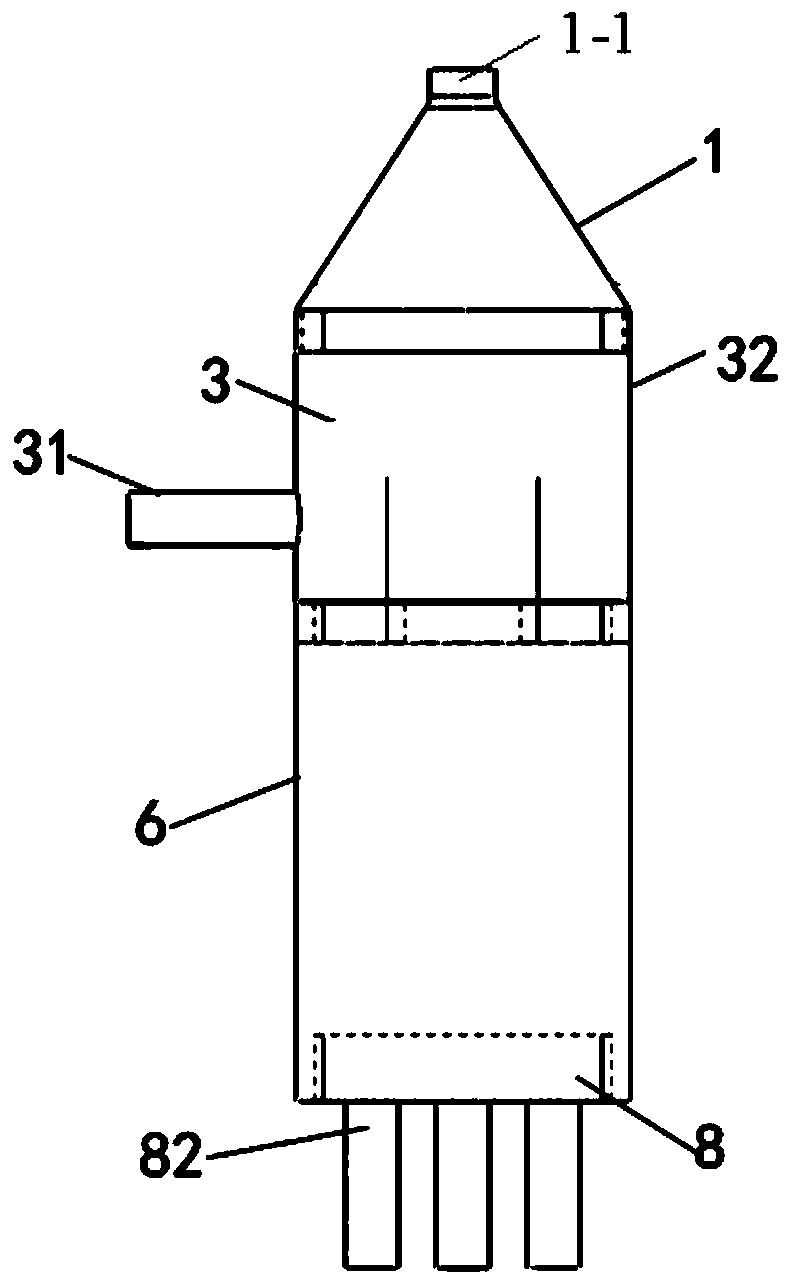

[0038] Such as Figure 1 to Figure 12 As shown, the pre-combustion plasma igniter of the present invention includes a nozzle 1, a pre-combustion chamber 2, a thin-walled fuel tube 3, a swirler 4, a spark plug 5, a sleeve 6, a rectifying chamber 7 and an air passage 8 base. The interior of the pre-combustion plasma igniter is a cavity structure, which is divided into upper and lower parts by the cyclone 4: the upper part is the pre-combustion chamber 2, and the lower part is the rectifying chamber 7. The part corresponding to the pre-combustion chamber 2 is composed of the thin-walled fuel pipe 3 and the nozzle 1. The fuel flows into the annular cavity oil delivery chamber 34 opened in the thin-walled fuel pipe 3 through the oil delivery pipe 31, and is atomized under the action of pressure. The hole 33 is ejected to the pre-combustion chamber 2; the corresponding part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com