Hydrogen-ignited ammonia-hydrogen mixed combustion zero-carbon engine and control method

A hybrid combustion and engine technology, applied in the direction of combustion engine, engine control, internal combustion piston engine, etc., can solve the problem that hydrogen cannot be ignited, achieve the effect of increasing flame propagation speed and eliminating ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

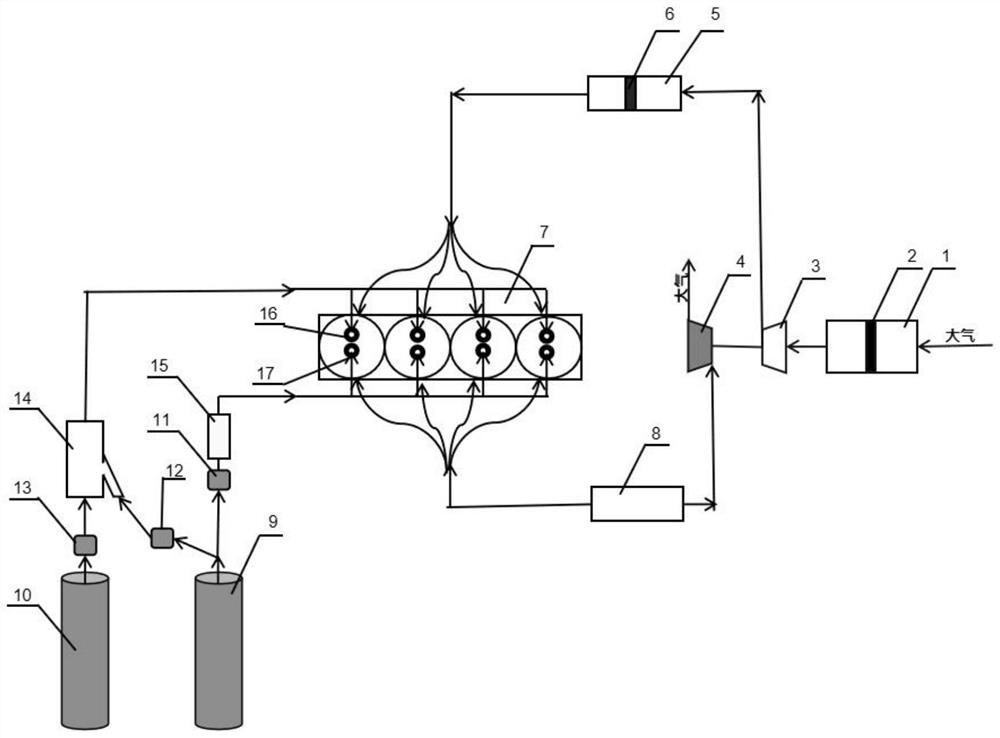

[0015] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0016] combine figure 1 , The structure of the zero-carbon combustion test bench for an ammonia / hydrogen mixed fuel engine ignited by hydrogen includes: intake pipeline I1, heating resistance wire 2, compressor 3, turbine 4, intake pipeline II5, thermometer 6, engine 7, exhaust gas Pipeline 8, hydrogen storage tank 9, ammonia storage tank 10, flowmeter I11, flowmeter II12, flowmeter III13, fuel supply pipeline I14, fuel supply pipeline II15, fuel injector I16, fuel injector II17. The air enters the compressor 3 through the heating resistance wire 2 through the intake pipeline I, and the compressor 3 is connected to the engine 7 through the intake pipeline II. The temperature of the intake air can be measured by the thermometer 6 in the intake pipeline II, and then the heating resistance The wire adjusts the intake air temperature, the engine 7 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com