A water-regulated porous medium pulse isovolumic burner

A porous medium, isovolumetric combustion technology, applied in burners, gas fuel burners, combustion types, etc., can solve the problems of easy tempering, hidden dangers, and easy tempering without eliminating premixed combustion, so as to shorten the reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

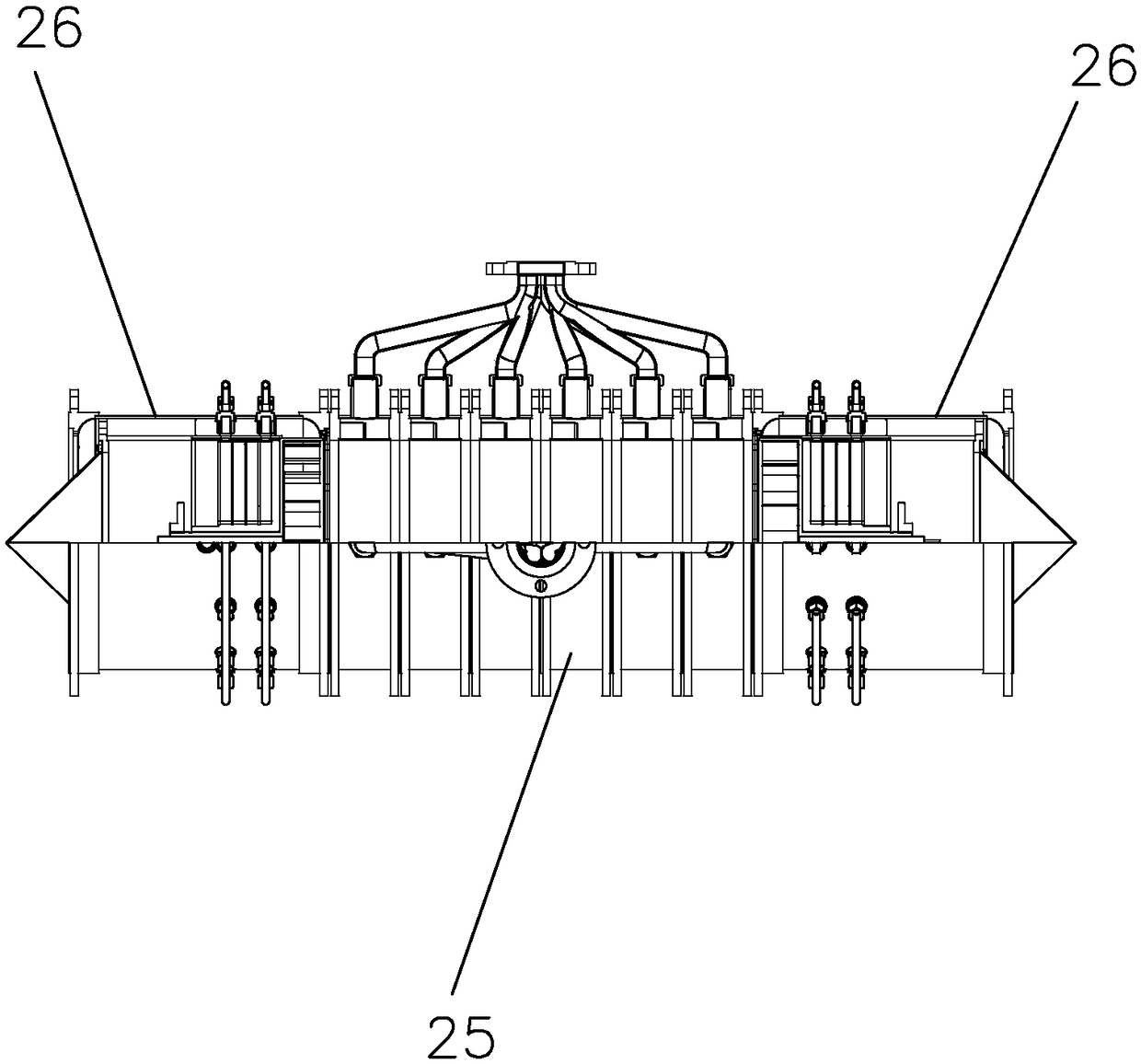

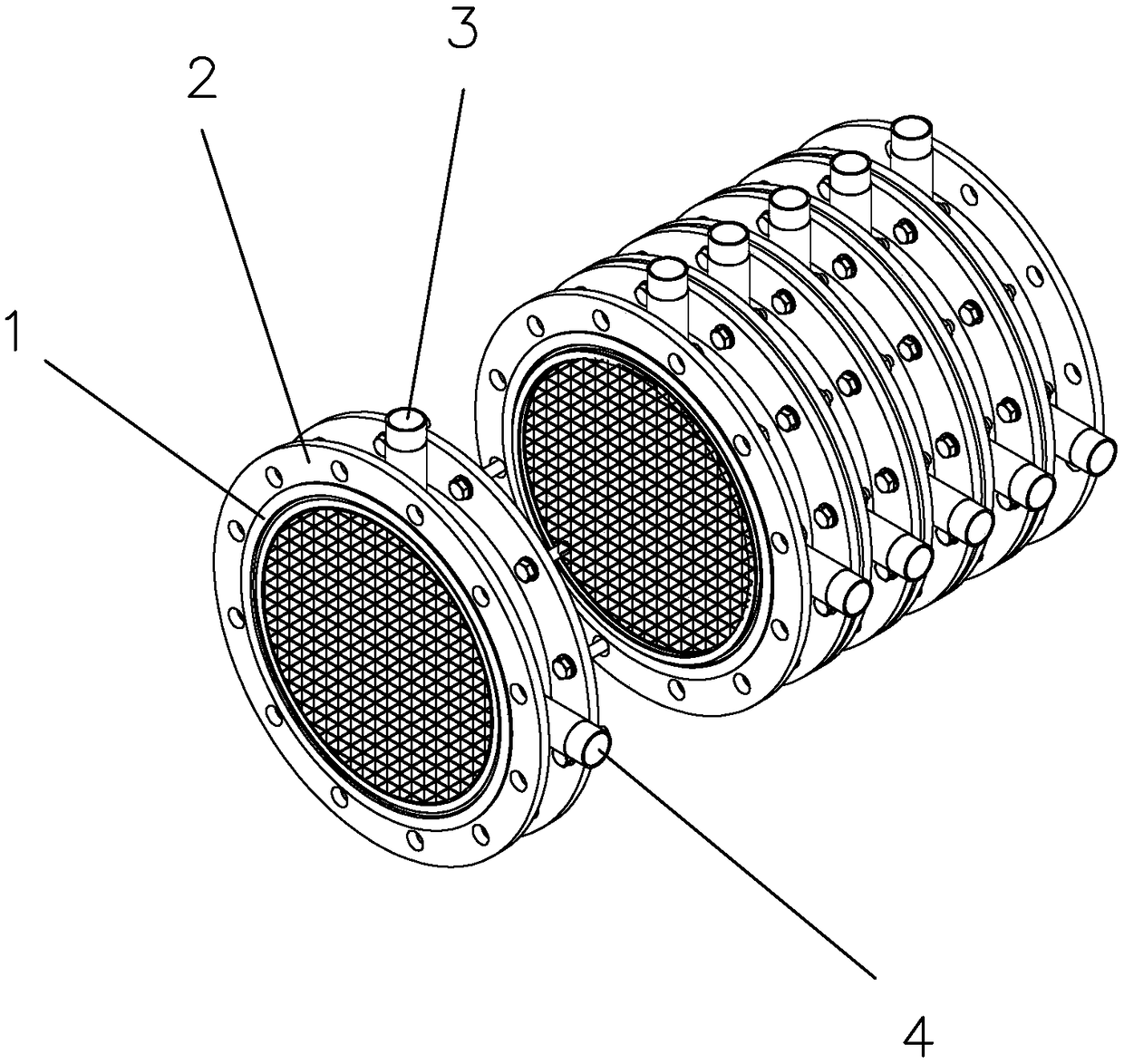

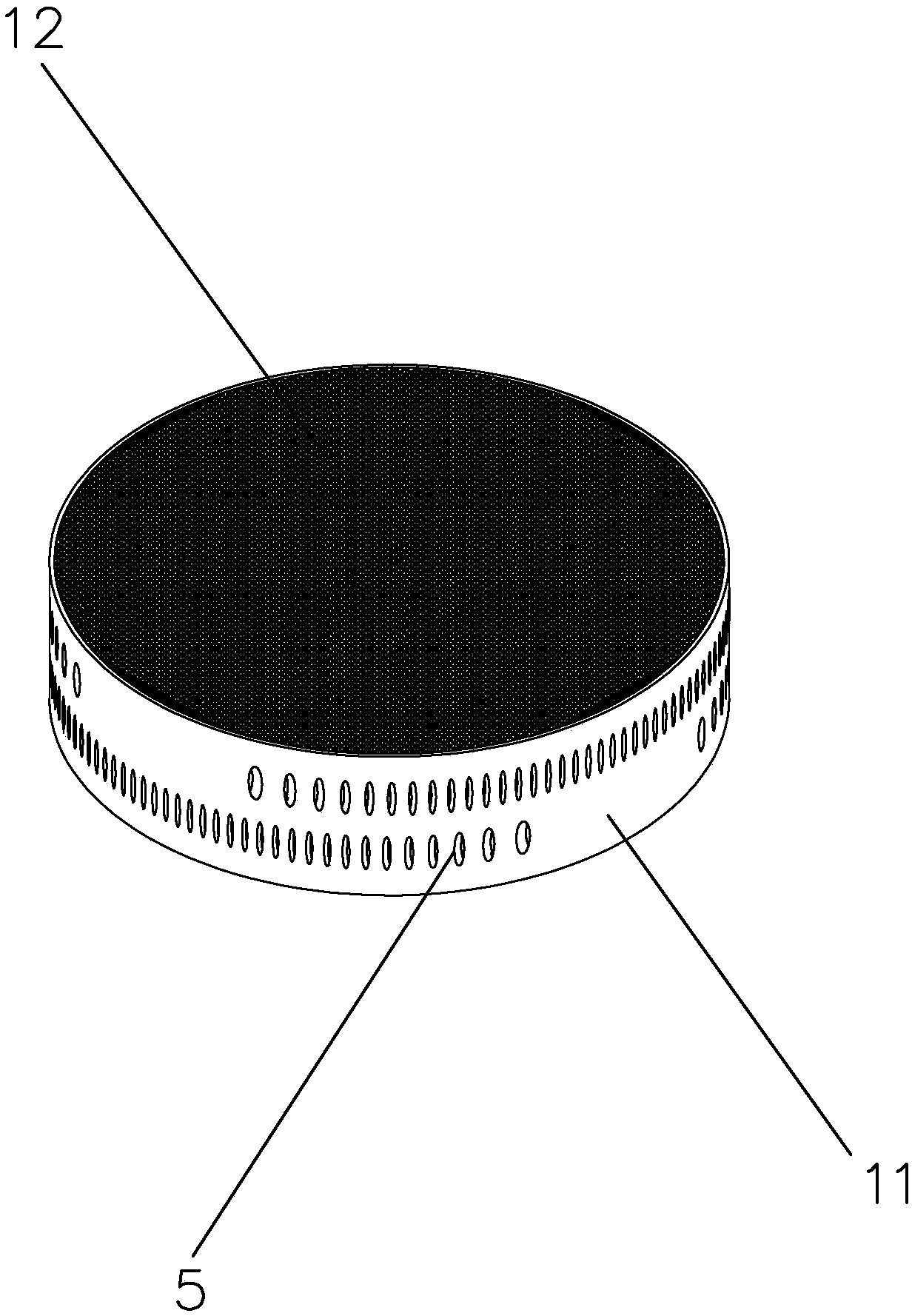

[0026] see Figure 1-Figure 6 As shown, a water temperature-regulated porous medium pulse constant volume burner according to the embodiment of the present invention is characterized in that it includes a liquid temperature-regulated porous medium combustion chamber 25, and two The two pulse-type equal-volume gas burner drive heads 26 on the side are fixedly connected between the three, and the liquid temperature-regulating porous medium combustion chamber 25 includes several water-temperature-regulating porous media 1 connected in sequence, all of which are arranged in the water The outer ring water jacket 2 outside the temperature-regulating porous medium 1, the temperature-regulating water inlet 3 and the temperature-regulating water outlet 4 arranged on the outer ring water jacket 2, the outer water jacket guide and the outer water jacket arranged in the outer ring water jacket 2 A confluence, the water-temperature-regulating porous medium 1 includes a water-temperature-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com