Energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln with size of phi 2000*18 meters

An electromagnetic induction, energy saving and environmental protection technology, applied in the direction of rotary drum furnace, furnace type, furnace, etc., can solve the problems of low production efficiency, environmental pollution, high energy consumption, etc., to avoid environmental pollution, obvious economic and social benefits, and simplify fuel procurement Effectiveness of transport and safety management efforts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further describe the technical scheme of the present invention below in conjunction with accompanying drawing:

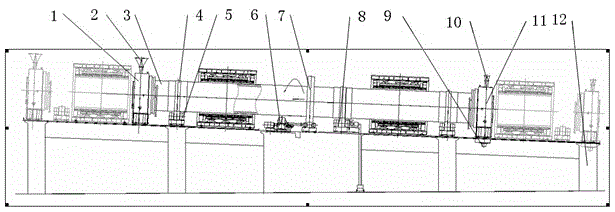

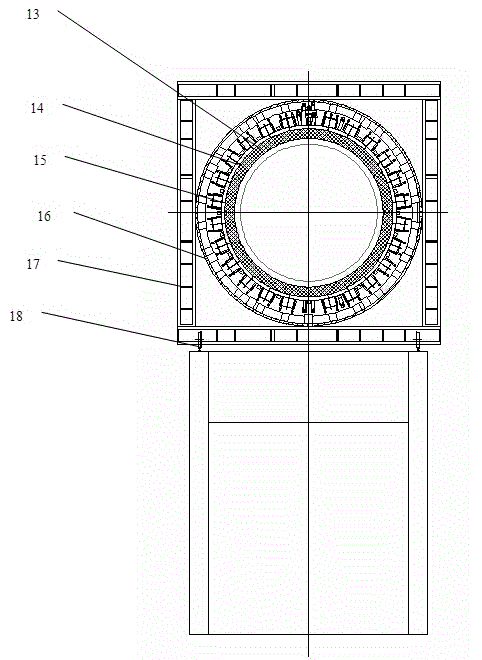

[0026] as attached figure 1 And attached figure 2 As shown, a φ2000×18m energy-saving and environment-friendly mercury smelting electromagnetic induction roasting rotary kiln, its structure includes kiln head cover 1, mercury ore feeding hopper 2, high-temperature alloy steel liner kiln cylinder 3, wheel belt 4, movable Type supporting wheel group 5, transmission device 6, gear pair 7, fixed supporting wheel group 8, waste ore discharge pipe 9, mercury vapor discharge pipe 10, kiln tail cover 11, cement pier 12, heat preservation ring 13, induction heating ring 14. Magnetic yoke 15, furnace shell 16, furnace frame 17, track 18; one of them has a thermal insulation ring 13, one induction heating ring 14, twenty-four yokes 15, one furnace shell 16 and one furnace frame 17, forming an induction Heater; three wheel belts 4 are welded and fixed on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com