Preparation method for carbide catalyst for organic carbon vapor phase growth and application thereof

A vapor phase growth, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve uneven distribution, uncontrollable catalyst particle shape, etc. problem, to avoid uneven distribution, efficient preparation, simple and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

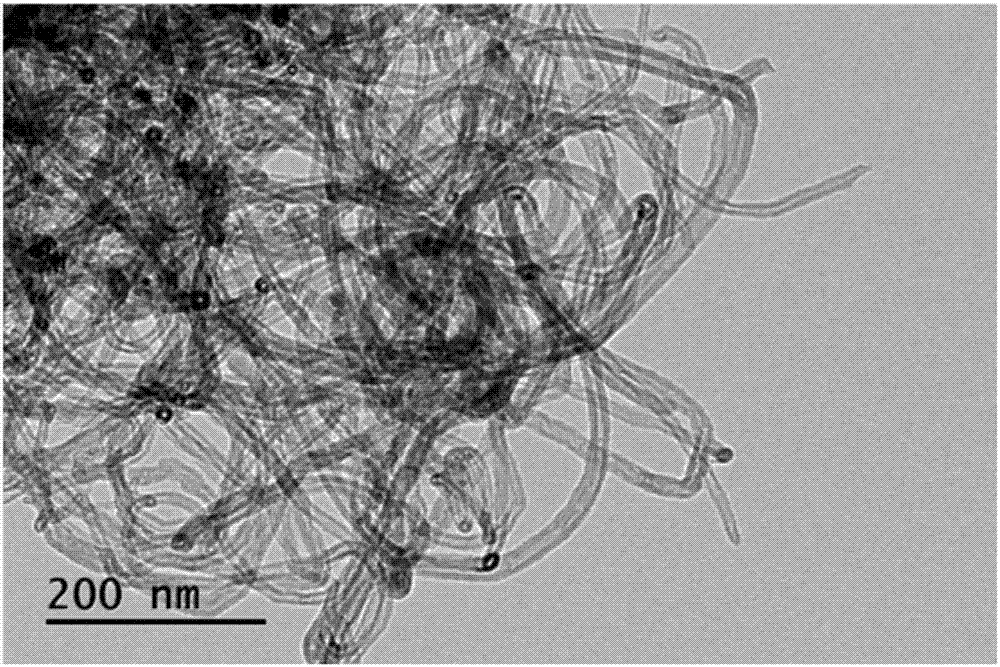

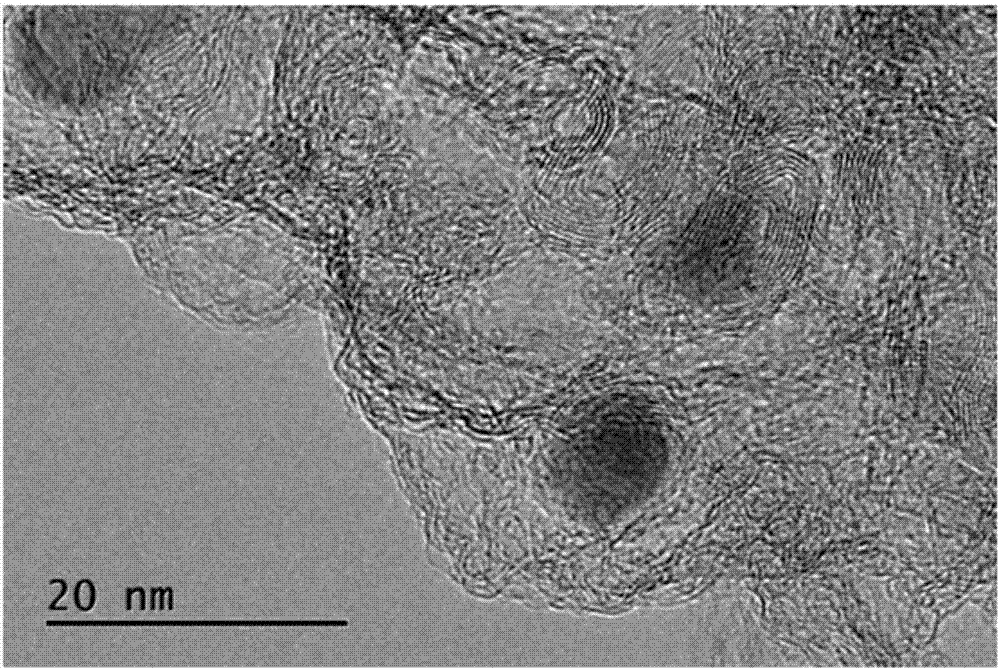

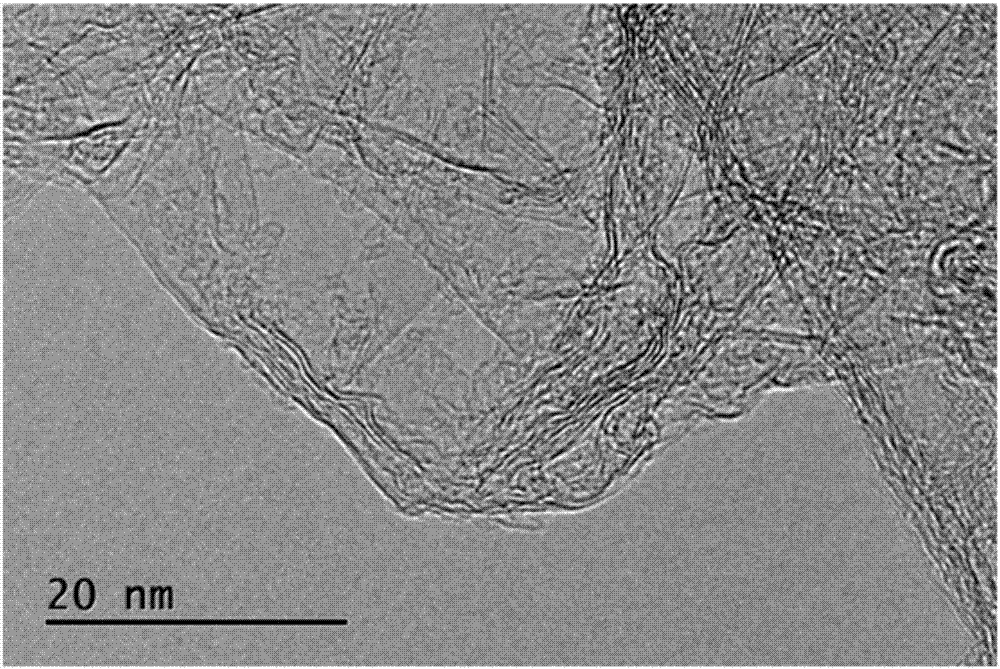

[0025] Embodiment 1, a preparation method of a catalyst used for vapor phase growth of organic carbon into carbides, the method comprising: adding 30% sodium hydroxide and 5% dodecylbenzenesulfonate to 30% ferric nitrate containing catalytic elements The mixed solution of the iron-containing catalyst precursor is prepared by the co-precipitation method and the high-pressure hydrothermal method. The percentages of the above substances are all mass percentage concentrations. The cyclone separator and bag filter of the spray dryer collect the catalyst precursor. The particle size of the catalyst precursor is 60-150 microns, and then it is calcined at 450°C for 3 hours in a rotary kiln to obtain a particle size of 50-120 microns and a specific surface area of 90m 2 / g of catalyst particles, the main composition of the catalyst is iron oxide (95%).

[0026] When the catalyst is applied, the catalyst is placed in a fixed bed, the temperature is controlled at 600-800° C., and a mix...

Embodiment 2

[0027] Embodiment 2, a kind of preparation method of the catalyst that is used for organic carbon gas phase growth to carbide, this method comprises: add 15% ammonium carbonate, 5% sodium phosphate to press co-precipitation method in 10% cobalt chloride containing catalytic element 1. The mixed solution containing the cobalt catalyst precursor is prepared by the high-pressure hydrothermal method. The percentages of the above substances are all mass percentage concentrations. The mixed solution is added to the centrifugal spray dryer and sprayed and dried at a temperature of 280 ° C. The cyclone separation of the centrifugal spray dryer The catalyst precursor is collected by the filter and bag dust collector. The particle size of the catalyst precursor is 80-200 microns, and then it is calcined at 400°C for 2 hours in a rotary kiln to obtain a particle size of 60-150 microns and a specific surface area of 60m 2 / g of catalyst particles, the main composition of the catalyst is ...

Embodiment 3

[0029] Embodiment 3, a kind of preparation method of the catalyst that is used for organic carbon gas phase growth to carbide, this method comprises: Add 30% ammonium carbonate, 5% metaphosphoric acid to 20% nickel nitrate, 10% cobalt nitrate containing catalytic element Sodium, according to the co-precipitation method and high-pressure hydrothermal method, the mixed solution containing iron and cobalt catalyst precursors is prepared. The percentages of the above substances are all mass percentage concentrations. The mixed solution is added to the two-fluid spray dryer and sprayed at a temperature of 220 ° C. Drying, the cyclone separator and bag filter of the two-fluid spray dryer collect the catalyst precursor, the particle size of the catalyst precursor is 70-40 microns, and then calcined at 400 °C for 2 hours in a rotary furnace to obtain a particle size of 50-110 microns , specific surface area 100m 2 / g catalyst particles, the main composition of the catalyst is iron and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com