Patents

Literature

38results about How to "The process is simple and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

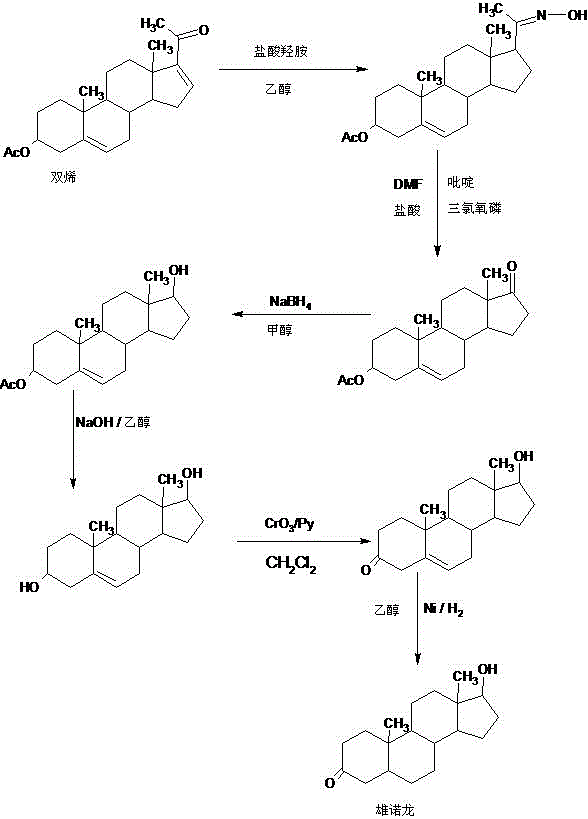

Preparation method of stanolone

InactiveCN106496297AWide variety of sourcesReduce manufacturing costEstrane derivativesDouble bondHydrolysis

A preparation method of stanolone comprises the following steps: with 4-androstenedione (shortened as 4AD) as a raw material, firstly performing an acid-catalyzed reaction on the 4AD and triethyl orthoformate in an organic solvent to obtain etherate 3-ethoxy-androst-3,5-diene-17-one; then, adding the etherate into the organic solvent, adding metal borohydride as a reducing agent, and reducing a 17-one group in a molecule of the etherate into a hydroxyl group to obtain the 3-ethoxy-androst-3,5-diene-17-ol; then, dissolving a reduced product into the organic solvent, adding a hydrogenation reaction catalyst, selectively catalyzing a 5-position double bond in the molecule of the reduced product to obtain hydride 3-ethoxy-androst-3-ene-17-ol; finally, performing acid-catalyzed hydrolysis on the hydride in the organic solvent to obtain the stanolone. Compared with the conventional production method, the preparation method provided by the invention has the advantages as follows: the raw material source is wide, the synthesis route is short, the preparation method is simple and environment-friendly in process, the product yield is high, the preparation method is economical and environment-friendly, the production cost is reduced by 35-40%, and the preparation method is very conductive to industrial production.

Owner:HUNAN KEREY BIOTECH

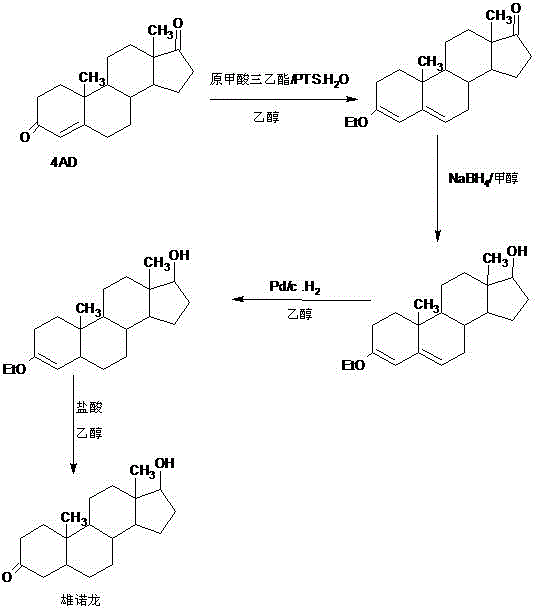

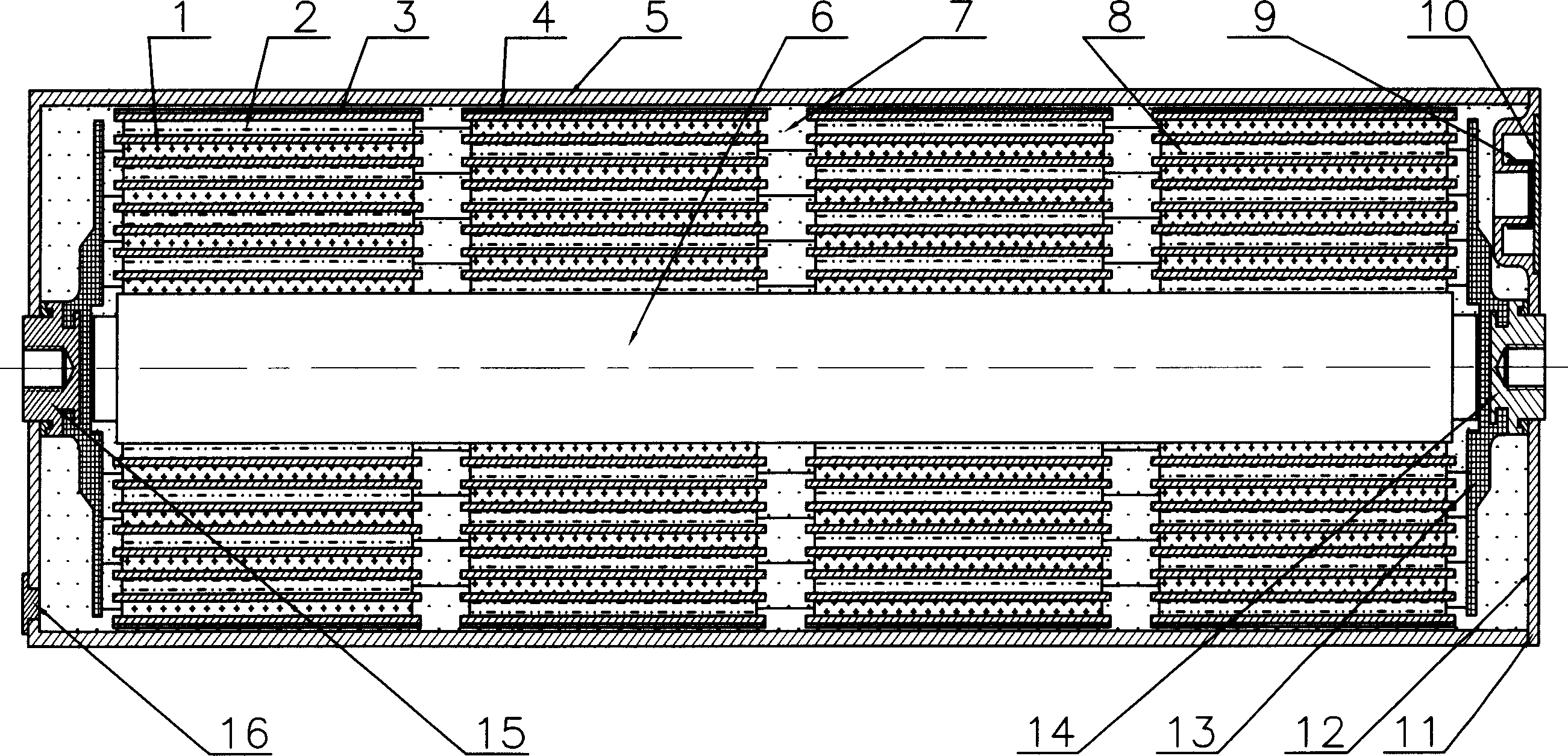

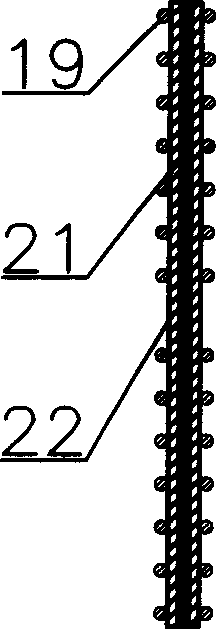

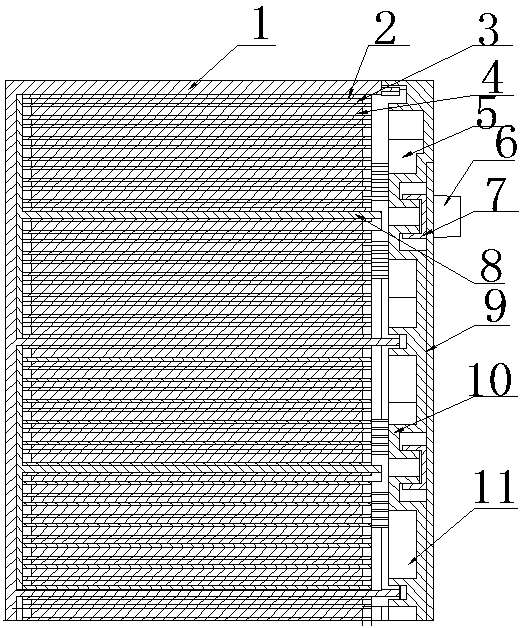

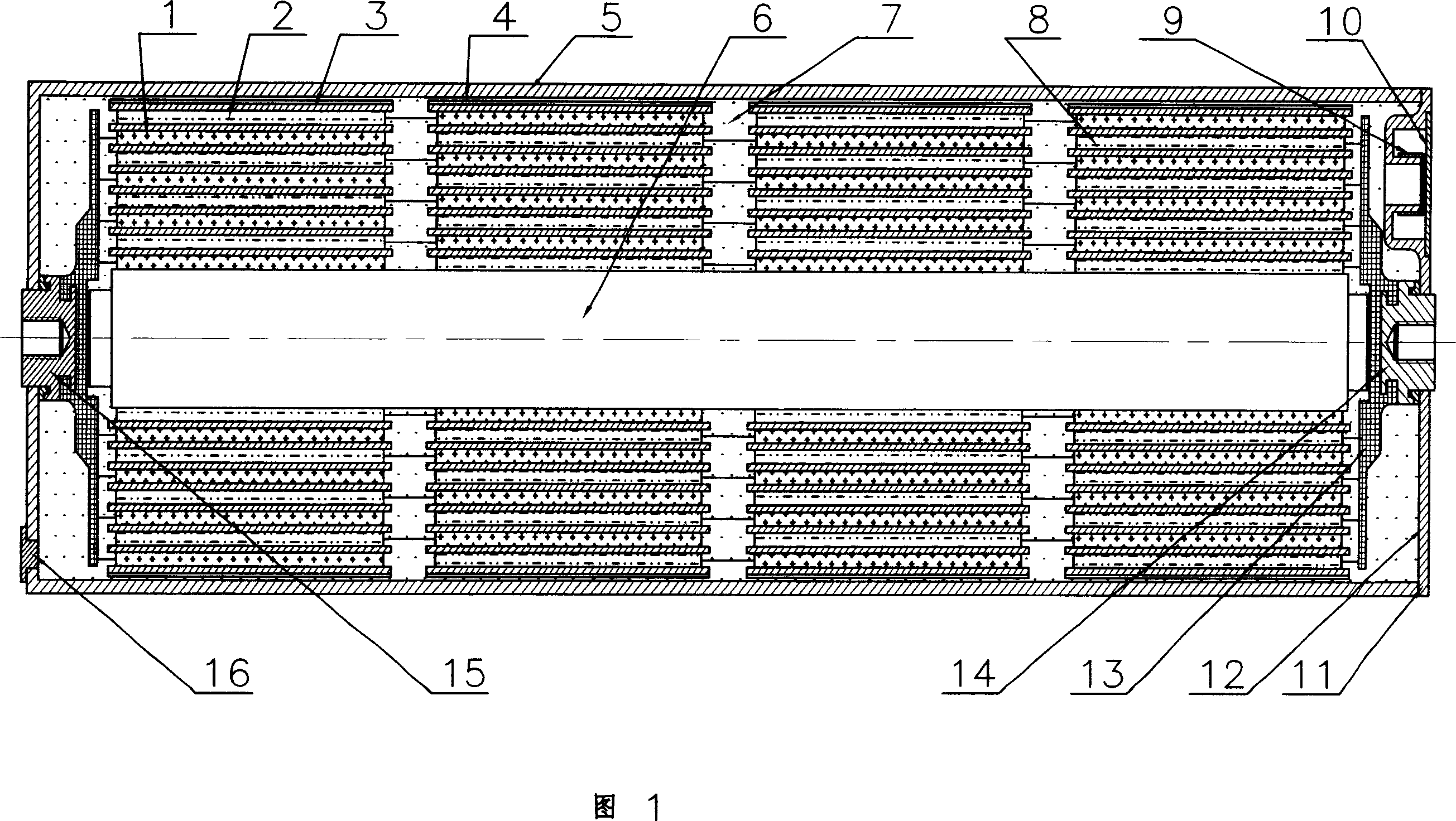

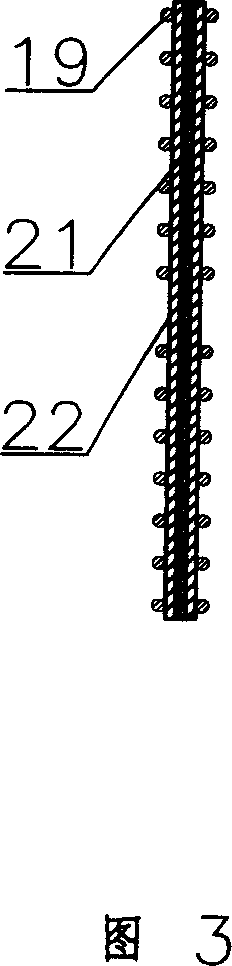

Quasi-two-pole winding-structure lead-acid battery and making method

InactiveCN1677736AIncrease specific energyImprove connection reliabilityFinal product manufactureLead-acid accumulators constructionInternal resistanceElectrical polarity

Positive active material and negative active material separated by lead wires are coated on two sides of composite slab lattice so as to constitute bipolar plate. The said lead wires can be cut into certainshape to become positive pole plate or negative pole plate with single pole. Single adjacent batteries separated by lead wires can be connected in series. Positive pole plate, diaphragm, and negative pole plate of single battery are winded on same core axle. Winded pole plates and diaphragm fixed by plastic fixture becomes battery core. Dried battery core is installed inside cylindrical battery box so as to complete electrochemical procedure. Then, firming agent is filled into the box. The invention combines advantages of both of quasi-bipolar battery and cylindrical winded battery, possessing features of low internal resistance, high specific energy, high specific power, and long service life.

Owner:李向秀

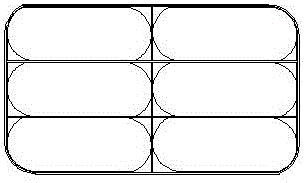

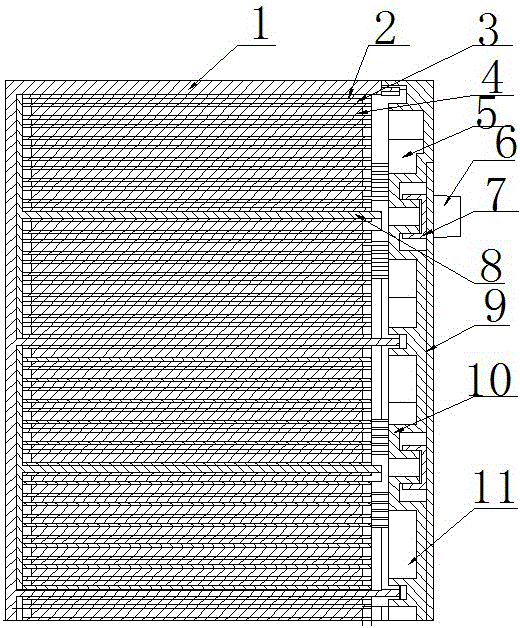

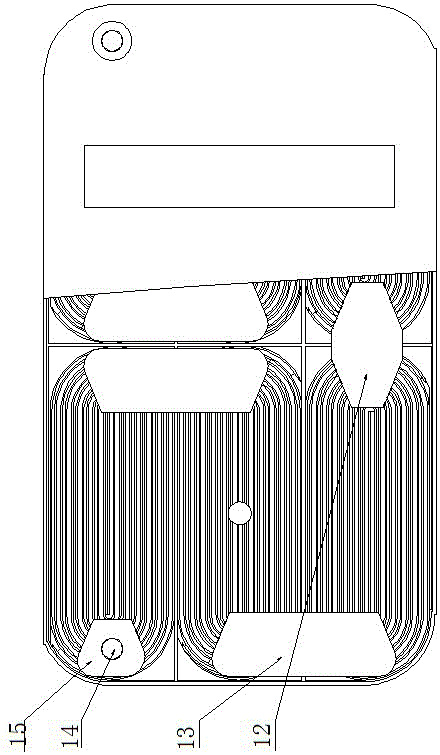

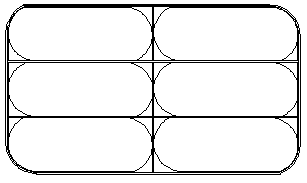

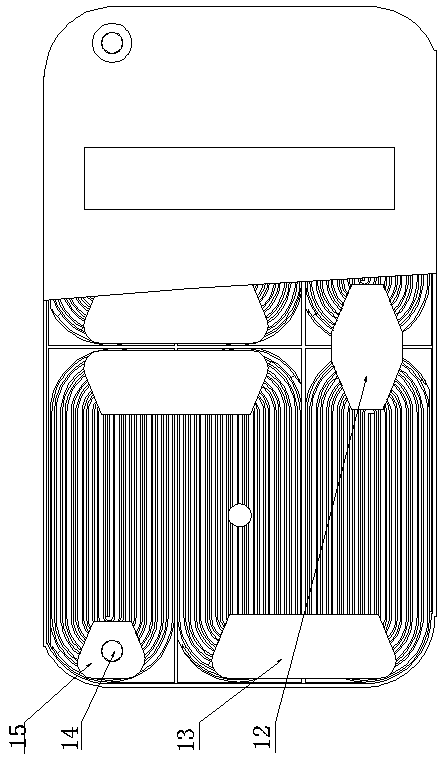

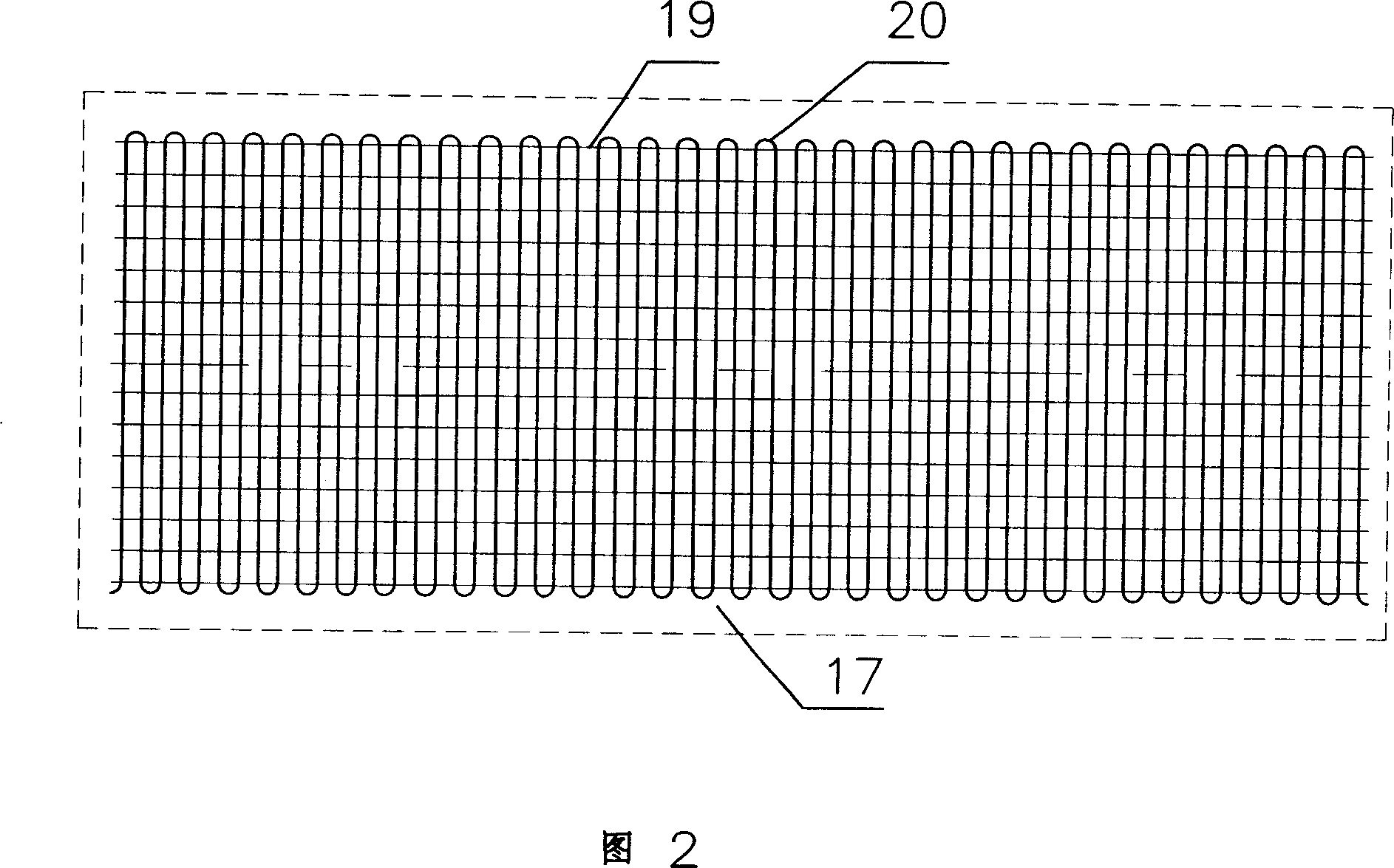

Lead-acid storage battery with square winding structure and manufacturing method of lead-acid storage battery

ActiveCN106159128AReduce weightIncreased energy-to-weight ratioFinal product manufactureSmall-sized cells cases/jacketsPunchingInternal resistance

The invention discloses a lead-acid storage battery with a square winding structure and a manufacturing method of the lead-acid storage battery. Flexible plate grids obtained by expanding, punching, continuous casting or other forms are respectively coated with positive electrode and negative electrode active substances to form a positive electrode plate and a negative electrode plate; the positive electrode plate, a separation board and the negative electrode plate are wound on the same core plate to form a battery cell; the battery cell is arranged in a battery jar with circular arc transition at two ends and a straight line in the middle; after the battery cell is dried by a special technology, a series of physical and electrochemical processes of cast welding, sealing, acid filling, forming and the like are finished, and finally, the lead-acid storage battery which can be repeatedly charged and discharged for use is obtained. The lead-acid storage battery disclosed by the invention combines the advantages of a cylindrical winding battery and a traditional square flat plate battery, has the characteristics of low internal resistance, high specific power and long service life of the winding battery as well as high volume utilization rate and wide application range of the traditional battery, and has broad application prospect; the limit that the cylindrical winding battery is only suitable for being produced into medium-small capacity batteries is broken through.

Owner:山东超威磁窑电源有限公司

Metal derusting agent

The invention discloses a metal derusting agent. The metal derusting agent is prepared from the following raw materials in concentration: 100-400g / L of hydrochloric acid, 20-50g / L of phosphoric acid, 200-500g / L of oxalic acid, 20-50g / L of sodium lauryl sulfate, 20-50g / L of sodium carboxymethyl cellulose and the balance of deionized water. The metal derusting agent has the advantages that the formula is reasonable, the derusting effect is good, and the metal derusting agent is environmental-friendly, non-toxic, energy-saving and pollution-free.

Owner:QINGDAO LIANGLI PRECISION CASTING

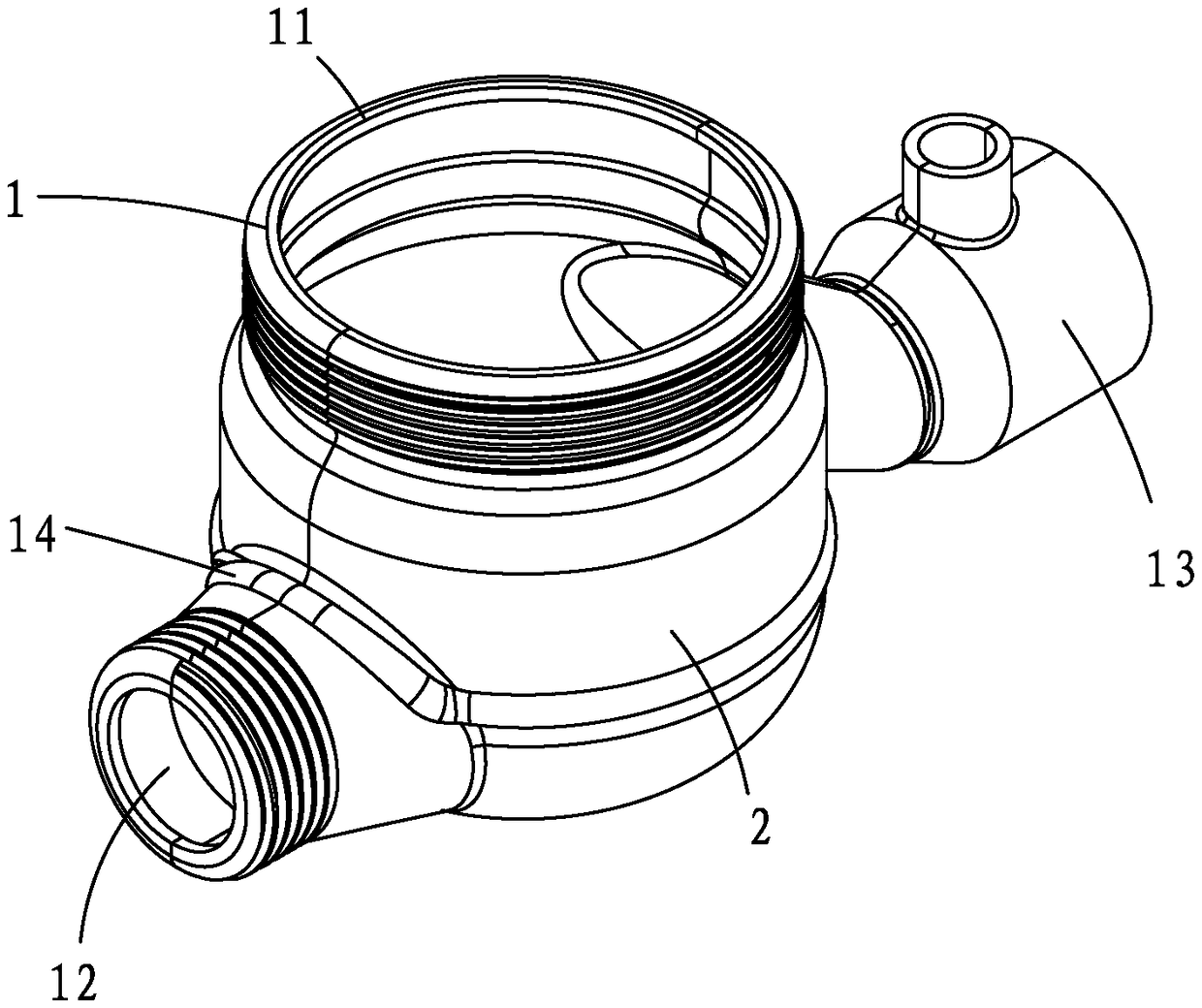

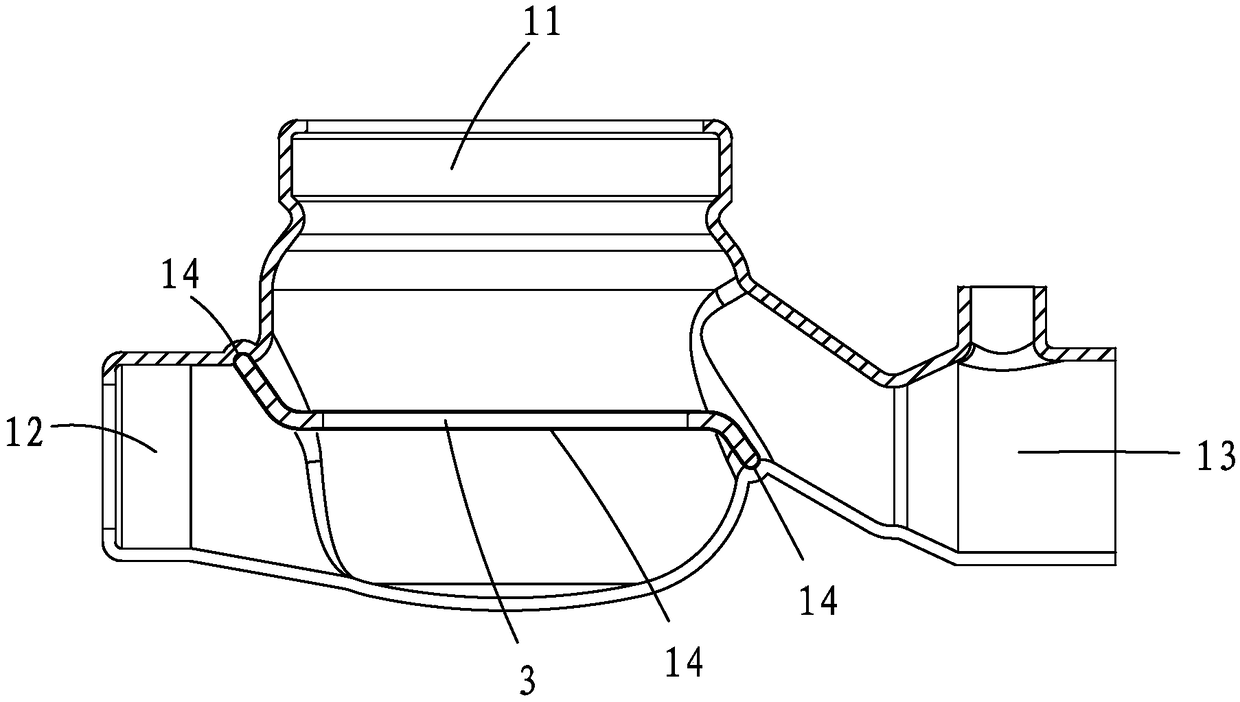

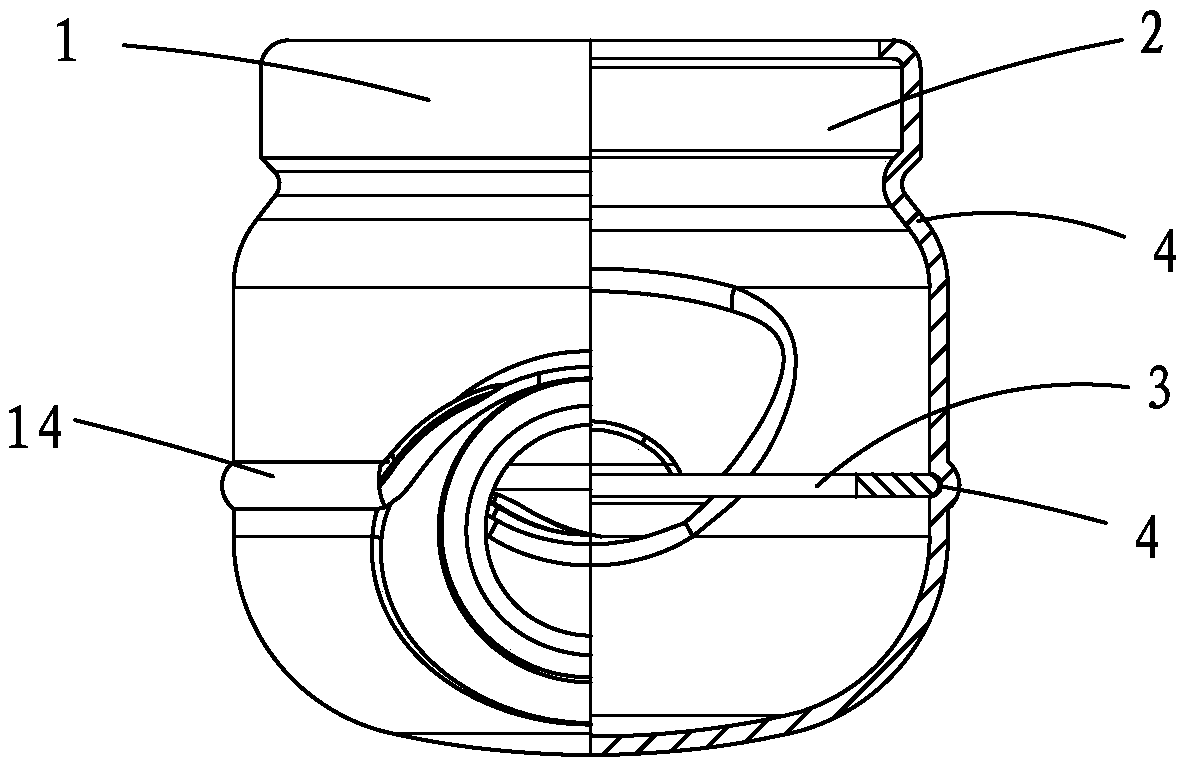

Two-half type splicing water meter casing and processing method thereof

PendingCN108759968ASolve positioningSolve the sealing problemVolume meteringNumerical controlPunching

The invention relates to a two-half type splicing water meter casing, which comprises a left cavity, a right cavity and a water separation plate, wherein the left cavity and the right cavity are mutually matched; each of the left cavity and the right cavity comprises a middle case, a water inlet end and a water outlet end which are integrally formed; a water separation plate positioning grooves are formed in the inner walls of the left cavity and the right cavity; when the left cavity, the right cavity and the water separation plate are assembled; the edges of the water separation plate are totally clamped in the positioning grooves of the water separation plate, so that the water separation plate is arranged in the casing in a sealed way. The invention also relates to a processing methodof the water meter casing. The method also comprises the steps of assembly punching shaping, blank assembling, welding and shaping and numerical control machine processing. The water separation platepositioning groove is formed in the left and right cavities; during the assembly, a braze welding material welding process is used as an auxiliary process to solve the problems of casing assembly positioning and sealing. The two-half type splicing water meter casing has the advantages that no pollution is caused during the processing; the process is simple and convenient, and achieves the environment-friendly effects; the production efficiency is high; the period is short; the product qualification rate is obviously improved. Meanwhile, the product surface is smooth and like a mirror surface;the appearance is novel and bright.

Owner:SANCHUAN WISDOM TECH CO LTD

Neck nursing composition and preparation method and application thereof

InactiveCN109498526AImprove cell activityInhibit cell carcinogenesisCosmetic preparationsToilet preparationsNutrientAdemetionine

The invention discloses a neck nursing composition and a preparation method and application thereof. The composition is prepared from the following components in parts by weight: 0.1-3 parts of actinidia chinensis seed powder, 0.01-1 part of camellia-seed oil, 0.01-1 part of peony seed oil, 0.01-1 part of plukenetia volubilis seed oil, 0.001-1 part of citrus amara oil and 0.1-3 parts of walnut shell powder. A mild formula provided for skin characteristics of the neck can soften cutin and clean pores effectively and remove waste on the surface of the skin and meanwhile, promotes the skin to absorb nutrient, nourishes and whitens the skin of the neck, desalts melanin deposition, plays roles of moisturizing and supplementing moisture and is very good in skin type adaptability.

Owner:ZHUZHOU QIANJIN PHARMA

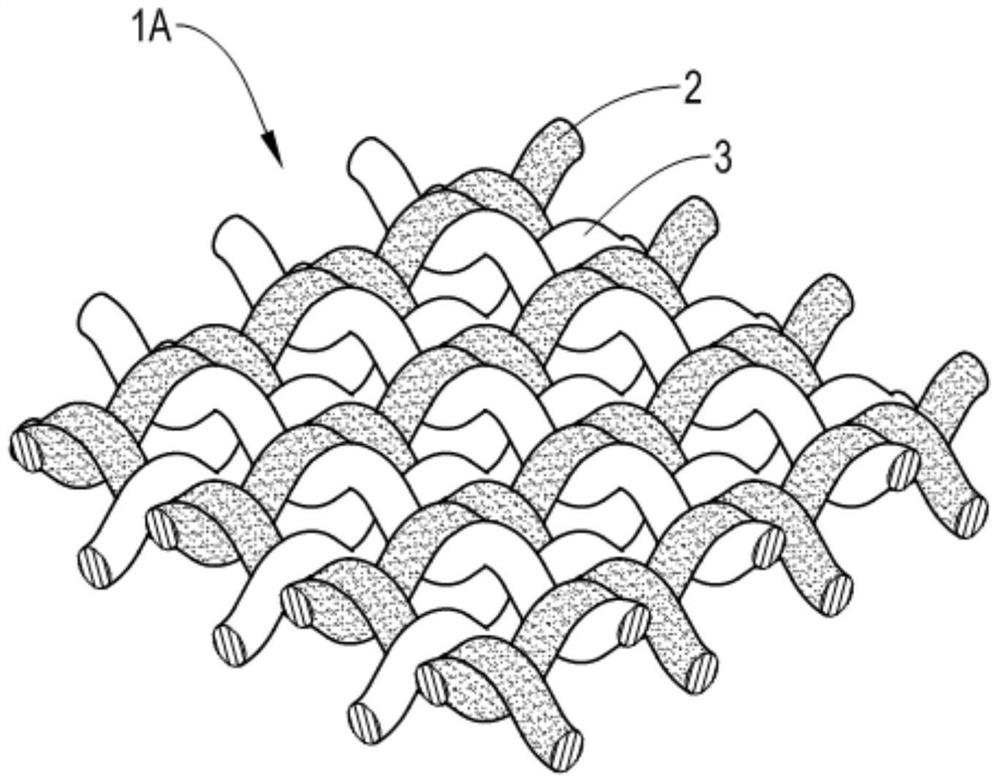

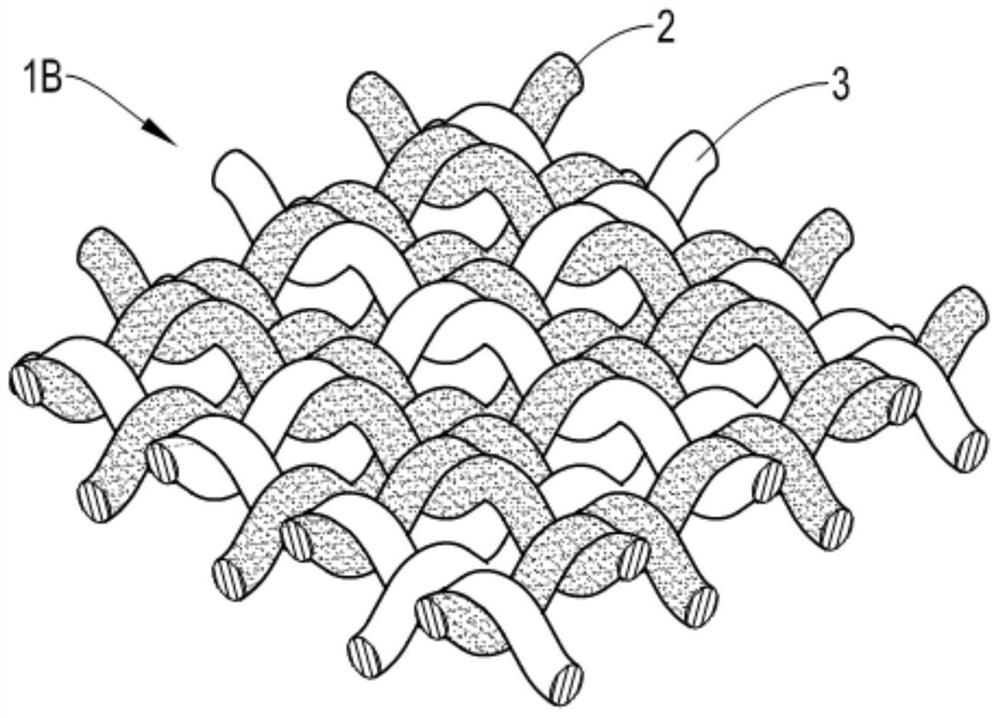

Composite reinforced textile and production method thereof

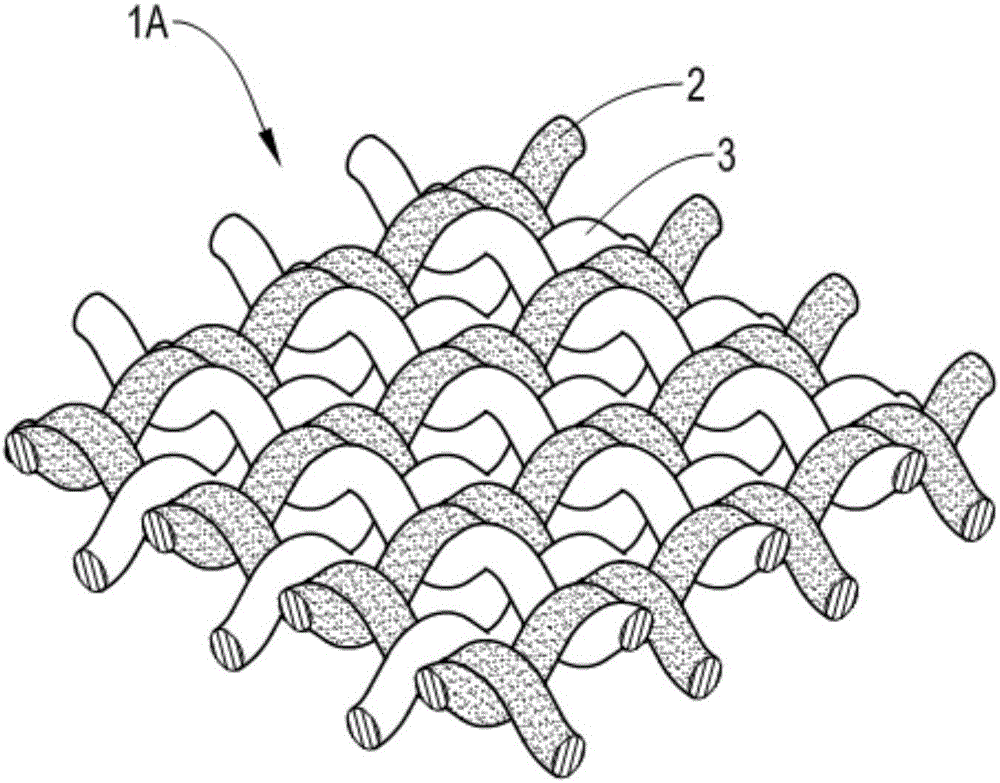

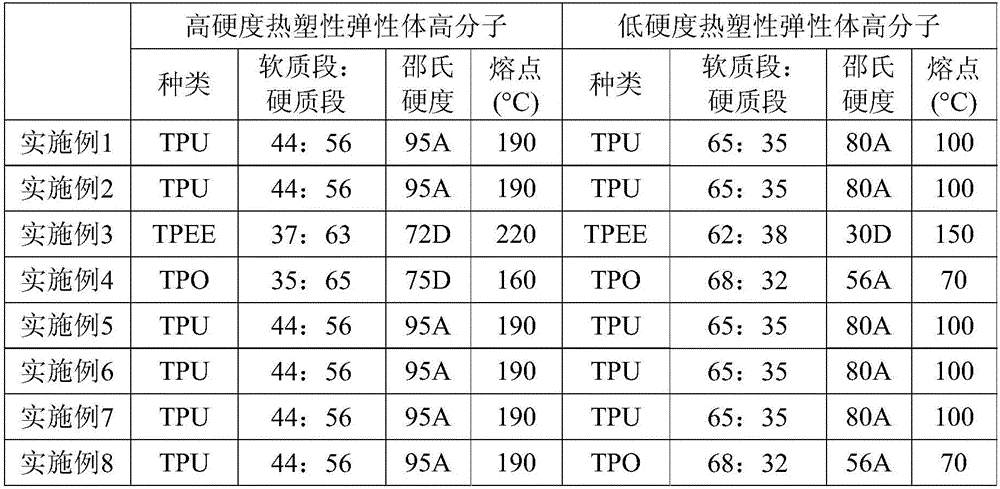

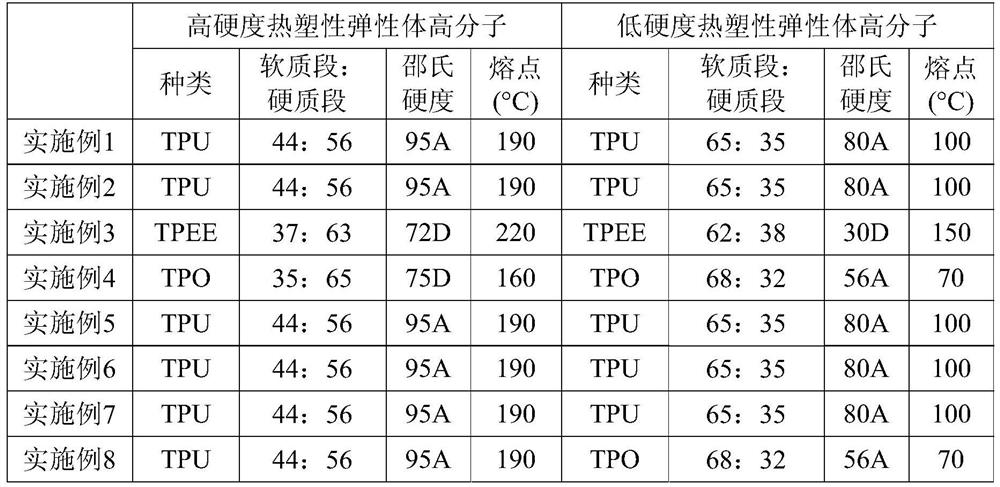

ActiveCN107523920AHigh tensile strengthHigh impact strengthWeft knittingHeating/cooling textile fabricsElastomerYarn

The invention provides a composite reinforced textile and a production method thereof. The composite reinforced textile comprises high-hardness thermoplastic elastomeric yarn and low-hardness thermoplastic elastomeric yarn, and the surface of the low-hardness thermoplastic elastomeric yarn is attached to that of the high-hardness thermoplastic elastomeric yarn after being micro-melted. The production method of the composite reinforced textile comprises the steps that the high-hardness thermoplastic elastomeric yarn and the low-hardness thermoplastic elastomeric yarn are woven into a textile body, wherein the melting point of the low-hardness thermoplastic elastomeric yarn is between 50 DEG C and 150 DEG C; at a hot-press temperature, the textile body is hot-pressed to obtain the composite reinforced textile, wherein the hot-press temperature is larger than or equal to the melting point of the low-hardness thermoplastic elastomeric yarn and smaller than the melting point of the high-hardness thermoplastic elastomeric yarn. Through above technical means, the composite reinforced textile with high tensile strength and high impact strength can be obtained through a simple convenient environmentally-friendly technology.

Owner:SHUN YI MATERIALS CO LTD

Preparation method of washing-free mask

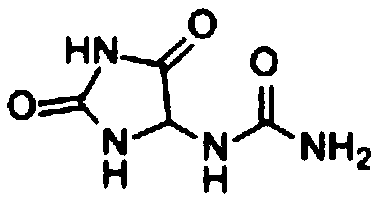

InactiveCN108158849AThe process is simple and environmentally friendlyGood biocompatibilityCosmetic preparationsToilet preparationsChemistryCarbon nanotube

A preparation method of a washing-free mask comprises following steps: at first, preparing carbon nanotubes; then modifying carbon nanotubes by polyethylene glycol; loading chitosan on polyethylene glycol modified carbon nanotubes; preparing collagen by boiling fish skin and pig skin; and finally loading collagen on the chitosan composite material to obtain the washing-free mask. The preparation method is simple and environmentally friendly. Moreover, the composite membrane has good biocompatibility, the degradation speed can be controlled effectively, the nutrients can be better absorbed by skin, and the time for nutrient absorption is prolonged.

Owner:重庆岚灏科技有限责任公司

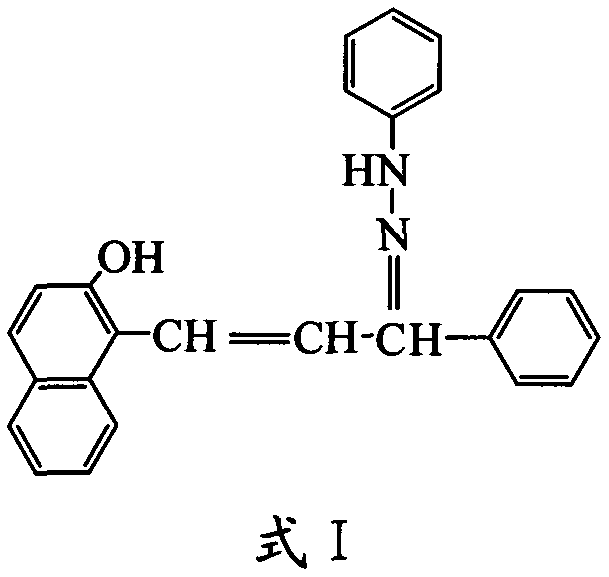

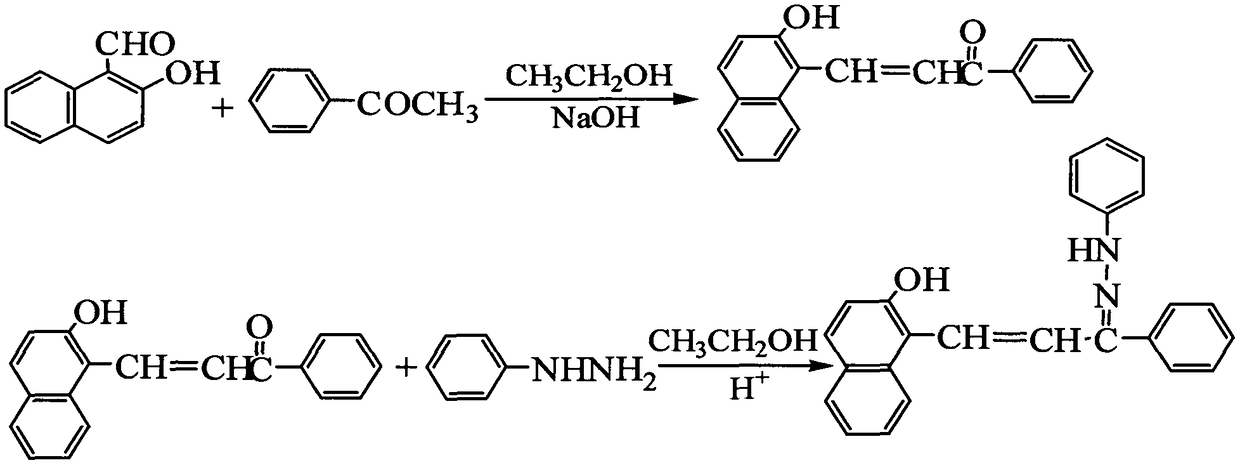

Corrosion inhibitor for pickling of copper and alloys thereof and preparation method of corrosion inhibitor

InactiveCN108179426AThe synthetic route is simpleThe process is simple and environmentally friendlyOrganic acidAcetophenone

The invention discloses a corrosion inhibitor for pickling of copper and alloys thereof and a preparation method of the corrosion inhibitor and belongs to the corrosion protection technologies of chemical cleaning processes of metals. The corrosion inhibitor is prepared by the following steps: taking phenylhydrazone derivatives of acetophenone and 2-hydroxy-1-naphthaldehyde condensation compoundsas core corrosion inhibition components, and compounding with ethanol or organic acids and surfactants to prepare an aqueous solution, so as to obtain the product. The corrosion inhibitor for pickling, disclosed by the invention, is simple in formula, simple and convenient in preparation and safe in operation and is a low-toxicity and high-efficiency environmental-friendly corrosion inhibitor.

Owner:SUZHOU UNIV OF SCI & TECH

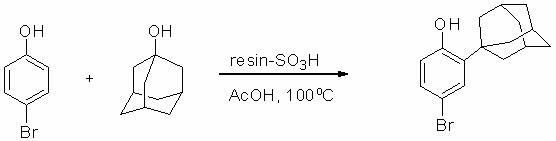

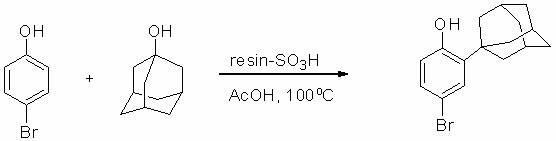

Method for preparing 2-(1-adamantyl)-4-bromophenol

InactiveCN101955417AHigh yieldEasy to operateOrganic chemistryOrganic compound preparationAcetic acidAcetic anhydride

The invention relates to a method for preparing 2-(1-adamantyl)-4-bromophenol, belonging to the technical field of fine chemical industry. The method is characterized in that 4-bromophenol reacts with 1-adamantanol in acetic acid under the catalysis of acidic ion exchange resin to form the target product 2-(1-adamantyl)-4-bromophenol in high selectivity, and water is a byproduct; after the reaction, the byproduct water can react with an equal amount of acetic anhydride to be converted into the acetic acid which is used as a solvent and can be recycled; and the ion exchange resin catalyst can also be recycled after being filtered and dried, thereby realizing zero discharge in the whole preparation processes. The invention has the advantages of simple and environment-friendly processes, high yield and simple operation; the acetic acid and the ion exchange resin can be directly recycled after being treated, thereby realizing the zero discharge in the production processes; and the molar yield of the product 2-(1-adamantyl)-4-bromophenol can reach 92-99%, and the purity can reach more than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

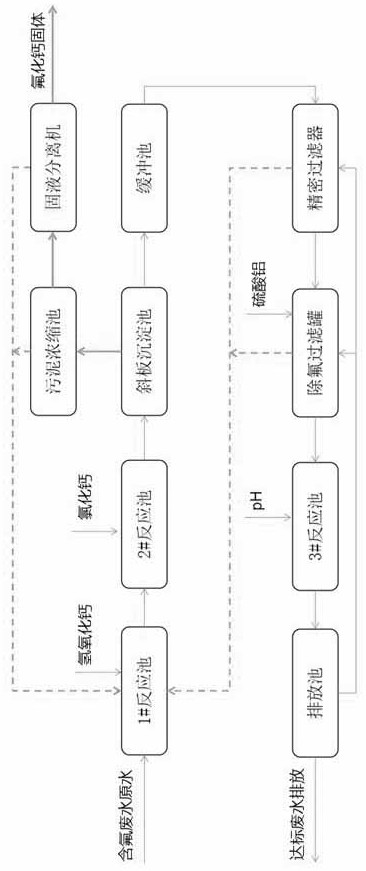

Method for producing calcium fluoride by utilizing high-fluorine-content industrial wastewater

PendingCN114436448AImprove recycling efficiencyRealize resource utilizationSpecific water treatment objectivesCalcium/strontium/barium fluoridesCalcium hydroxideIndustrial waste water

The invention discloses a method for producing calcium fluoride by utilizing high-fluorine-content industrial wastewater, and belongs to the technical field of fluorine-containing wastewater treatment. The method comprises the following steps: introducing fluorine-containing wastewater into a 1 # reaction tank, adding calcium hydroxide to adjust the pH value to 9-11, stirring for 30 minutes, introducing upper-layer wastewater into a 2 # reaction tank, adding calcium chloride to adjust the chloride ion concentration to 300-400 mg / L, stirring for 30 minutes, introducing the upper-layer wastewater into an inclined plate sedimentation tank, introducing supernate of the inclined plate sedimentation tank into a buffer tank, and filtering to obtain the fluorine-containing wastewater. Sludge generated by the inclined plate sedimentation tank is discharged into a sludge concentration tank; pumping the sludge in the concentration tank into a solid-liquid separator to obtain a mixture solid product with the calcium fluoride content of 30-35% for recycling; and pumping the wastewater in the buffer pool into a precision filter, removing suspended matters in the wastewater, feeding the wastewater into a defluorination filtering tank filled with a special adsorption material, filtering the effluent with the fluoride concentration not higher than 1.5 mg / L, adjusting the pH value of the effluent to 6-9, and discharging the effluent. The problems that in an existing fluorine-containing wastewater treatment technology, material consumption and energy consumption are large, products cannot be recycled, and secondary pollution of different degrees is derived are solved.

Owner:辽宁博创环保技术有限公司

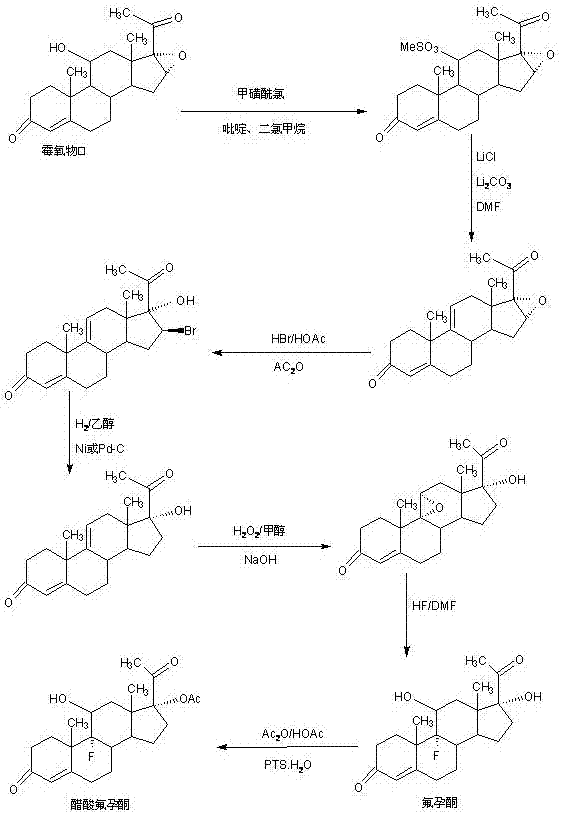

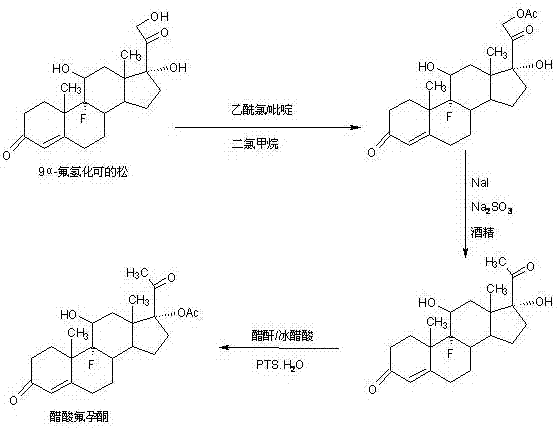

Preparation method of flurogestone acetate

InactiveCN107365341AWide variety of sourcesShort synthetic routeSteroidsAcetic anhydrideSodium iodide

The invention discloses a preparation method of flurogestone acetate. The preparation method comprises the following steps: using 9a-cortisone bifluoride as a raw material, dissolving 9a-cortisone bifluoride into an organic solvent, and reacting with acyl chloride under the existence of an acid-binding agent to obtain a 9a-cortisone bifluoride-21-O-ester; then reacting the ester with sodium iodide and a sulfur-containing reducing agent in the organic solvent for deesterification, and synthesizing flugestone; and finally reacting the flugestone with acetylchloride or acetic anhydride in the organic solvent, and synthesizing flurogestone acetate. According to the preparation method, 9a-cortisone bifluoride is used as the raw material, flurogestone acetate is synthesized through three-step reaction of 21-site esterification, then reduction and de-esterification and finally 17-site ethyl esterification, and compared with a traditional synthetic method for using a mold removal object acquired through diosgenin processing as a raw material, the preparation method has the advantages such as wide raw material source, short synthetic route, simple, convenient and environmentally-friendly process, few invested equipment and high product yield, and the production cost in the method is reduced by 25% to 30% as compared with a traditional method; and a solvent used in the production can be recycled and circularly used, and is easy for industrial production.

Owner:HUNAN KEREY BIOTECH

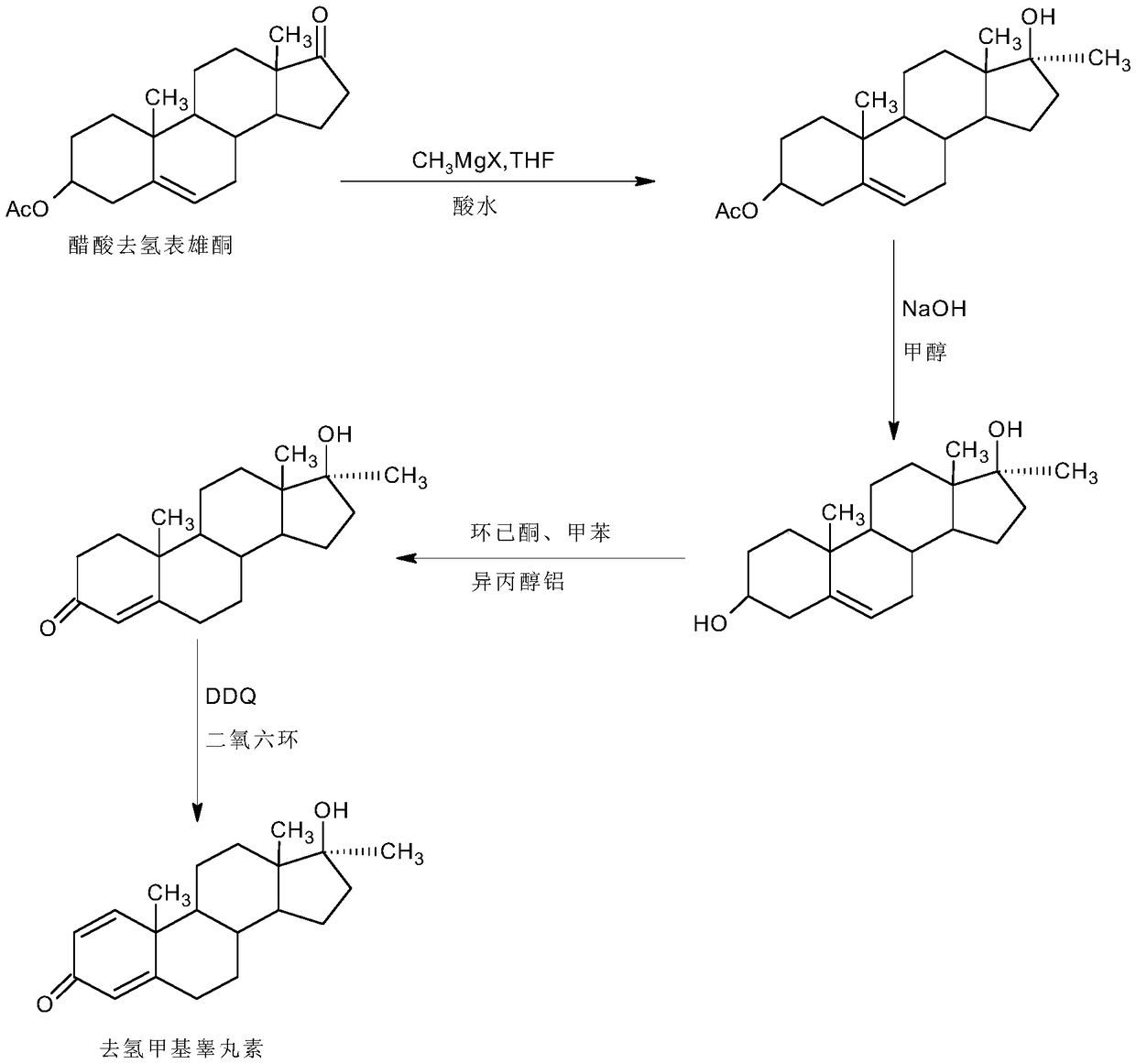

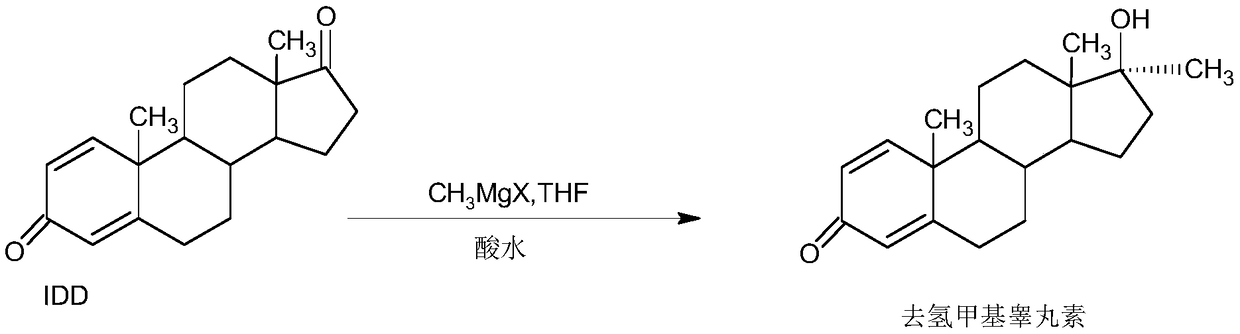

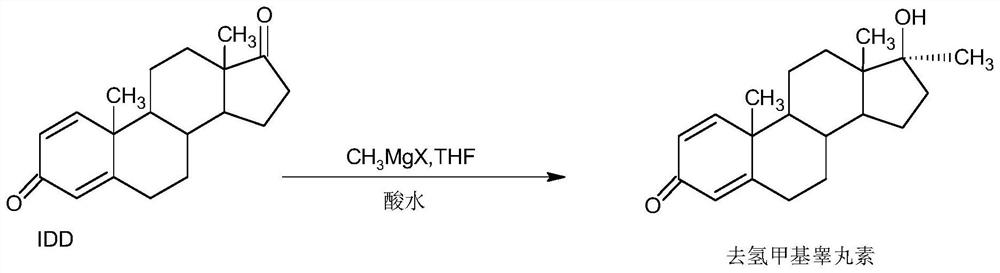

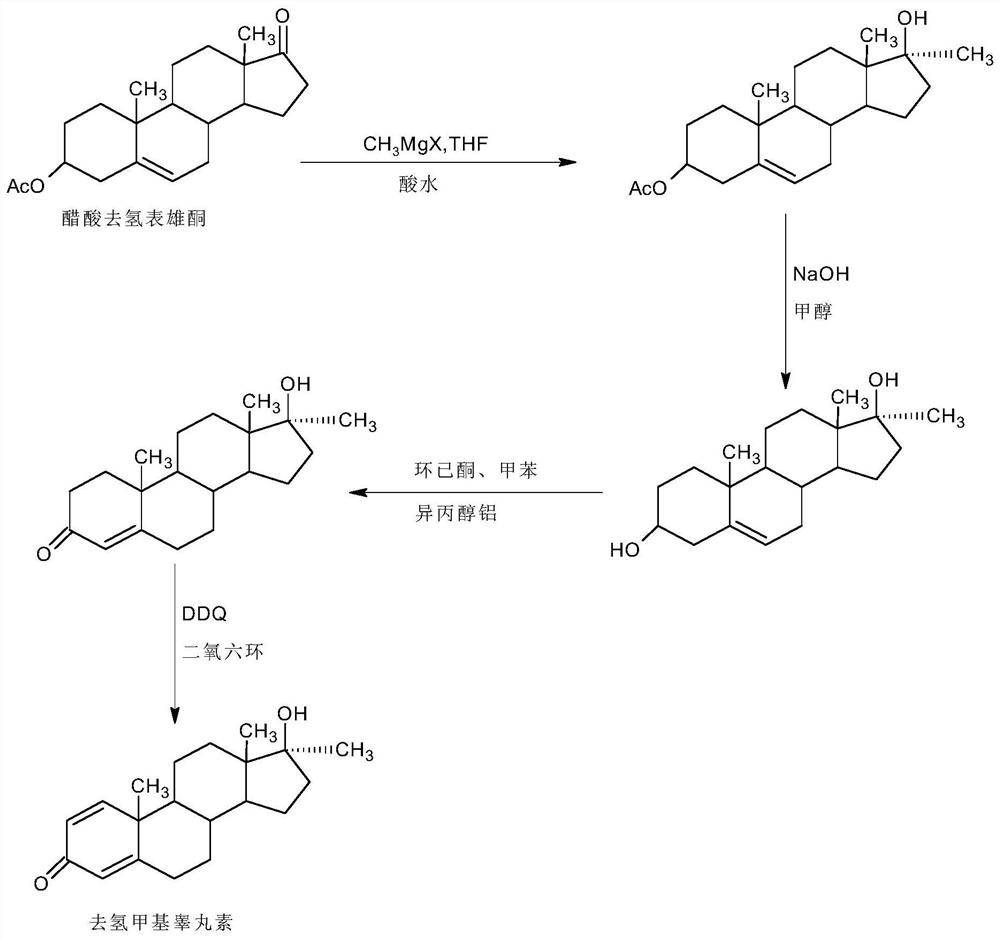

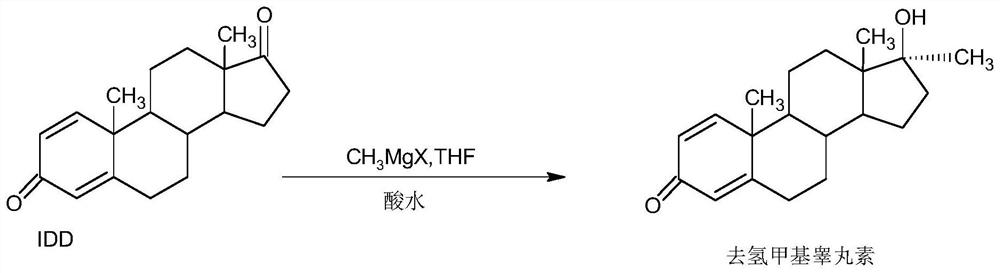

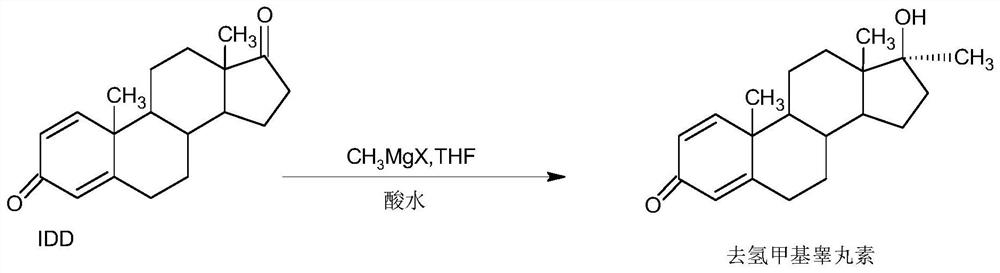

Method for preparing metandienone

ActiveCN109369760AWide variety of sourcesProcess economy and environmental protectionSteroidsFermentationPhytosterol

The invention provides a method for preparing metandienone, the method comprises firstly using a nutrient medium and one or more microbial strains, performing microbial fermentation on phytosterol toprepare 1,4-androstenedione, namely IDD, then using the IDD as the raw material, introducing alpha-CH3 and beta-OH into a 17 site with the existence of methyl magnesium halide, an organic solvent andan acid, and preparing the metandienone. The method uses the IDD as the raw material to prepare the metandienone, compared with the traditional method taking diosgenin as the raw material, the sourceof the raw material is wide, the process is economical and environmentally friendly, and the production cost is greatly reduced. Compared with the traditional production method, the synthesis route isshort, the process is simple, convenient and environmentally friendly, the yield of a product is high, the quality is high, and the cost of the raw material for production is reduced by 40-45% according to the current price of the raw material.

Owner:HUNAN KEREY BIOTECH

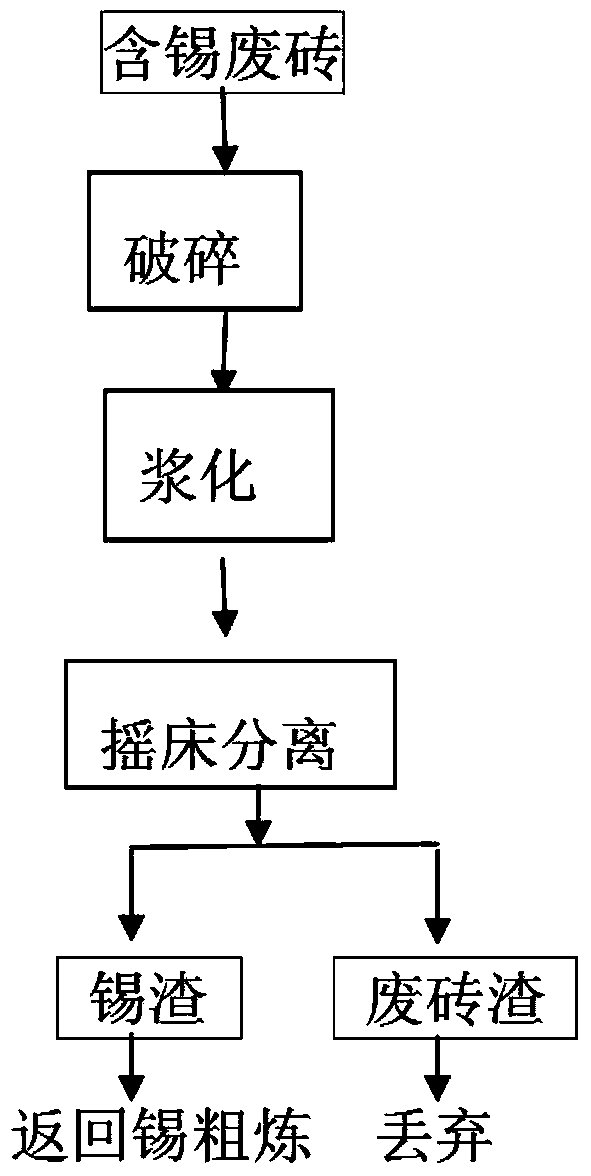

Method for recovering tin metal from tin-containing waste bricks

InactiveCN104195352ASolve pollutionSolve resource problemsProcess efficiency improvementBrickResource utilization

The invention discloses a method for recovering tin metal from tin-containing waste bricks. The method comprises the following steps: crushing the tin-containing waste bricks in a crusher, thus obtaining crushed blocks with particle size being 6-15mm; finely milling the crushed blocks in a ball mill, thus obtaining fine sand with particle size being less than 2mm; feeding coarse sand to a pulpifying tank, injecting water into the pulpifying tank according to the weight ratio of the coarse sand to water being 1 to (3-4), stirring for 0.5-1 hour, so as to obtain ore pulp; pumping the ore pulp to a table concentrator through an ore pulp pump, and separating out solder spatter and waste brick residue through the table concentrator, wherein the solder spatter returns to a coarse smelting process of tin ore and the waste brick residue is cast off. The method has the advantages of simple procedure, easy control over process and high recovery rate, the problems of environmental pollution and resource waste caused when the tin-containing waste bricks are treated by a conventional method are solved, and the utilization rate of resources is increased.

Owner:LAIBIN CHINA TIN SMELTING

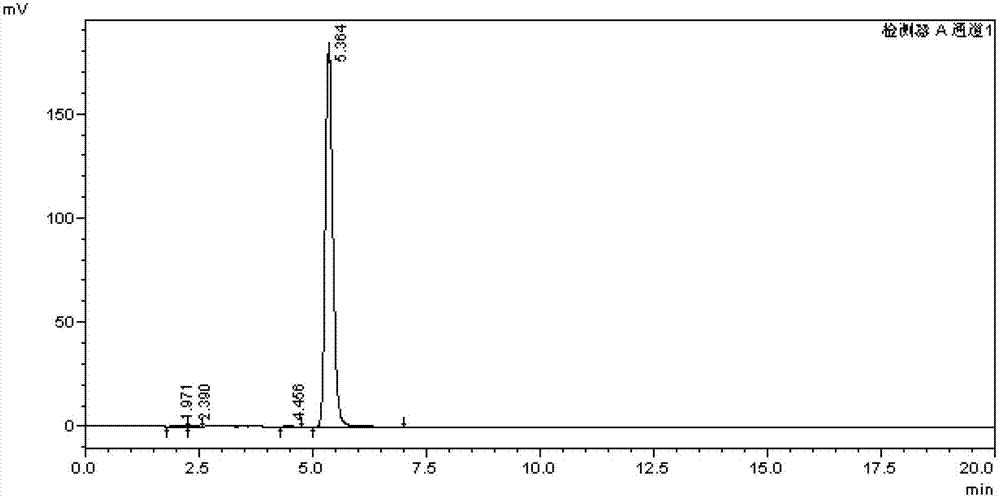

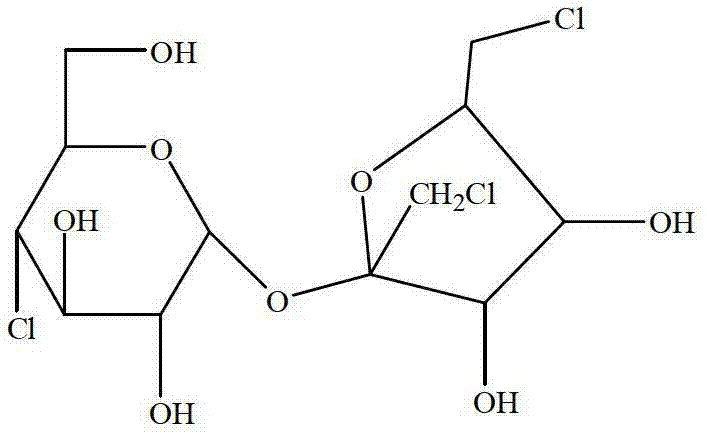

Method for preparing sweetening agent sucralose by one-pot process

ActiveCN103113426BHigh yieldHigh puritySugar derivativesSugar derivatives preparationSucroseWastewater

Owner:XINFA PHARMA

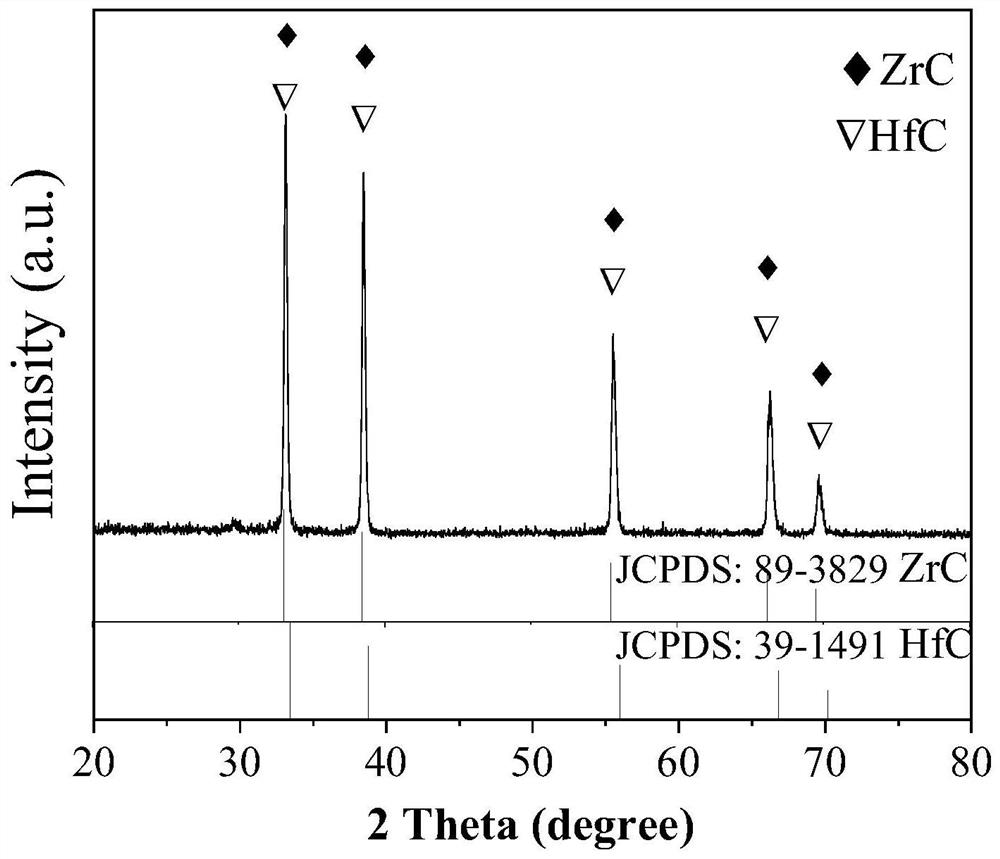

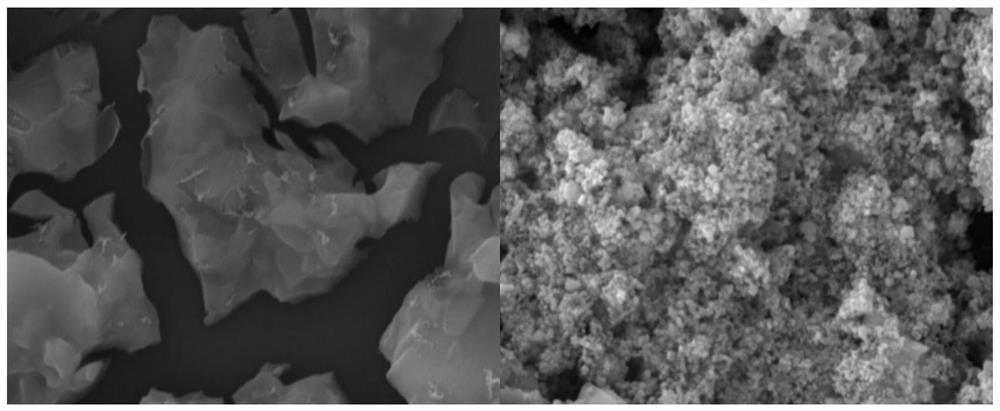

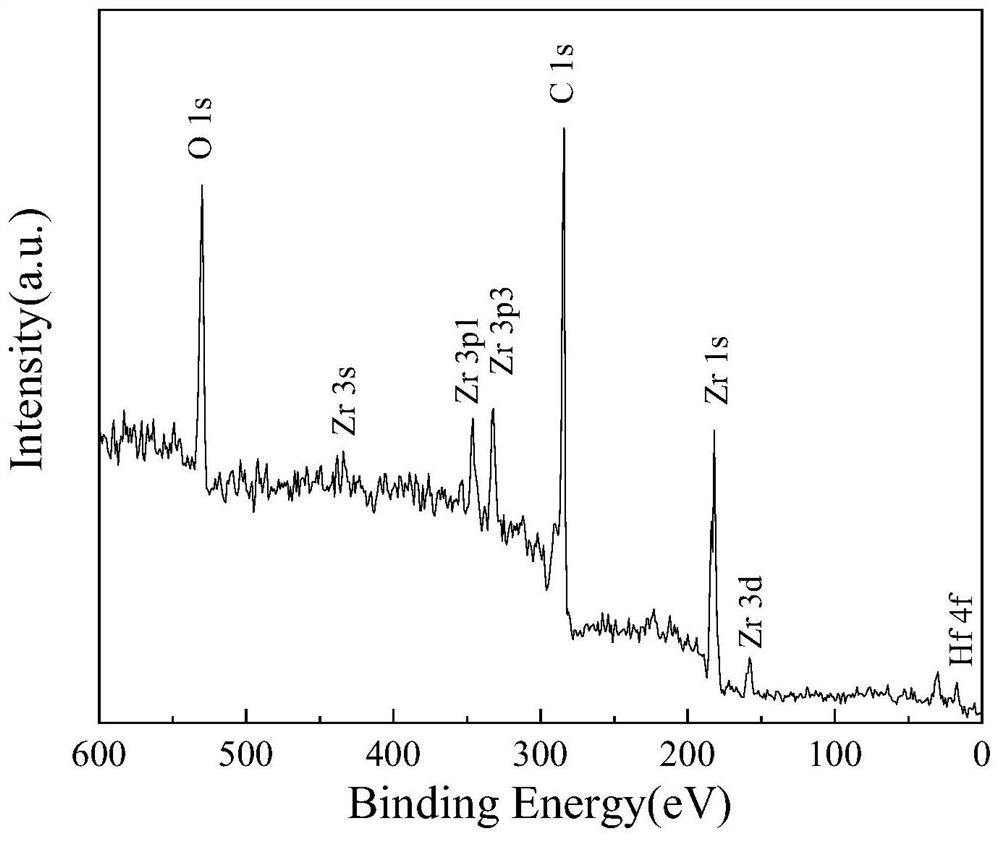

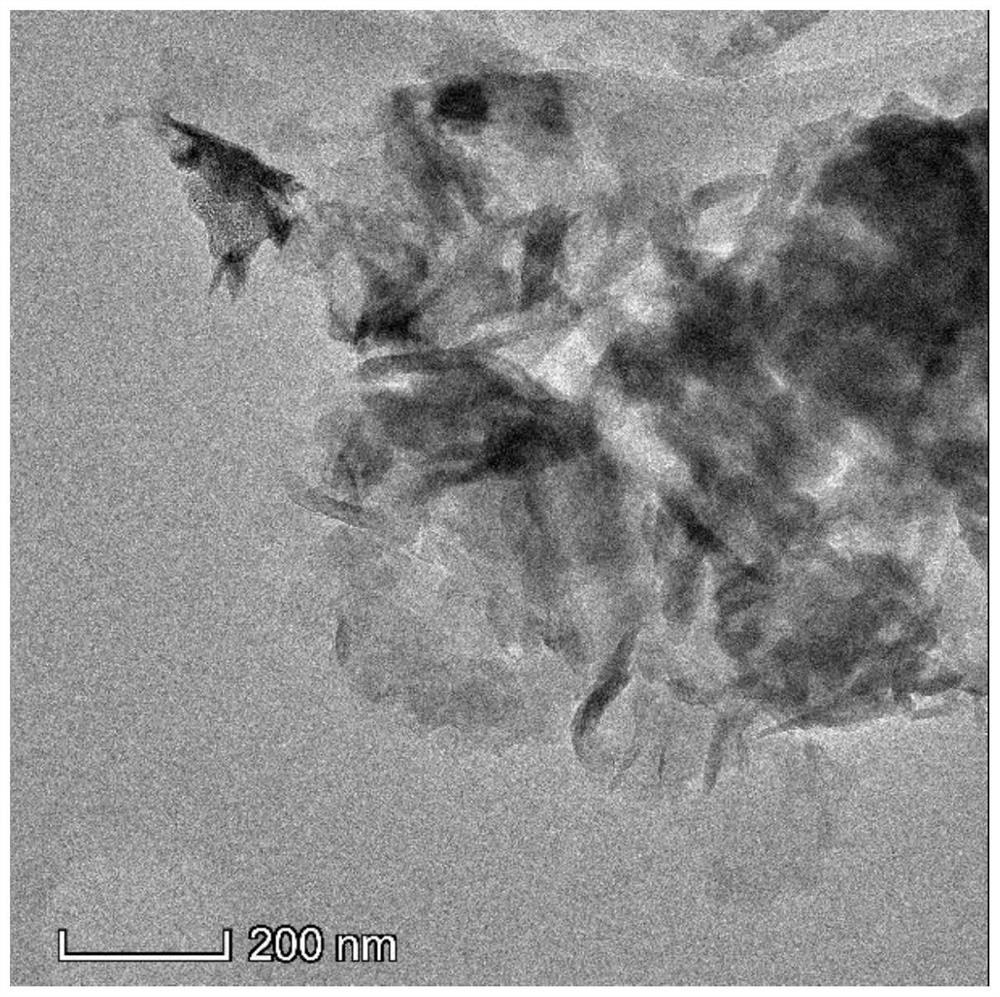

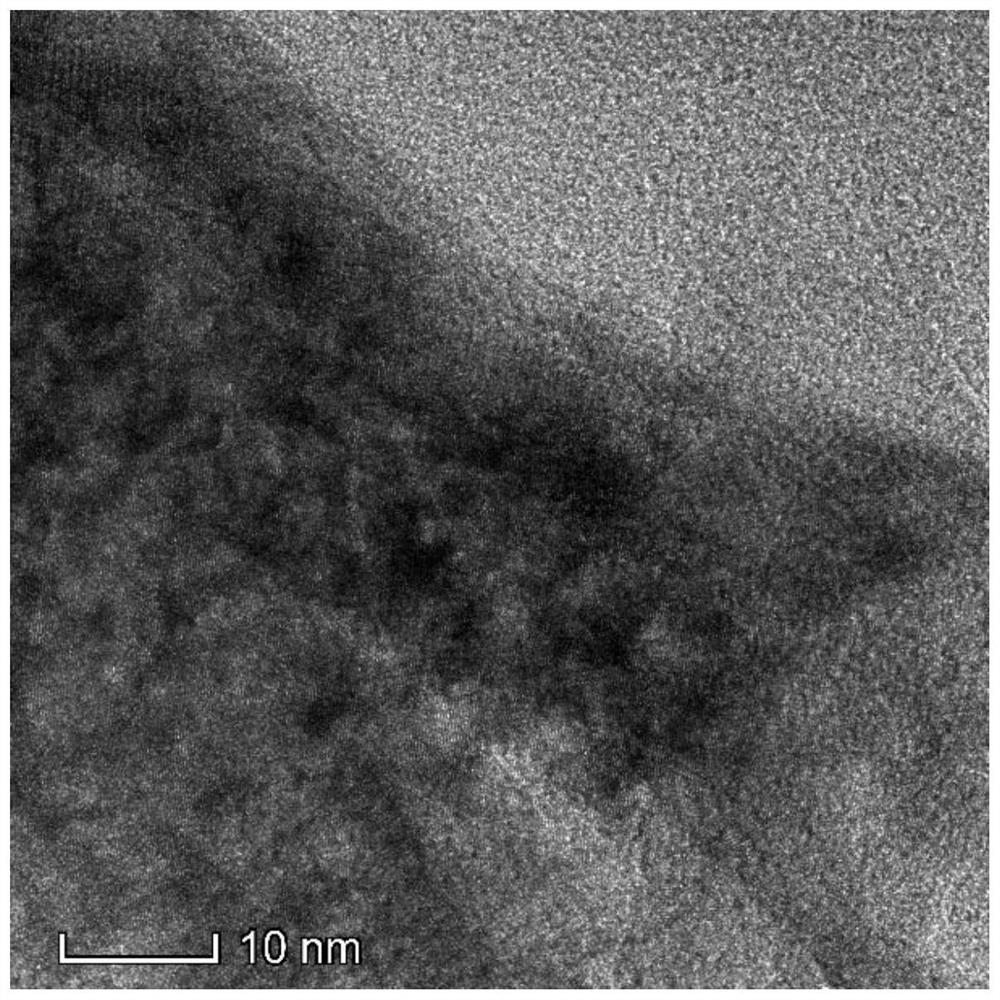

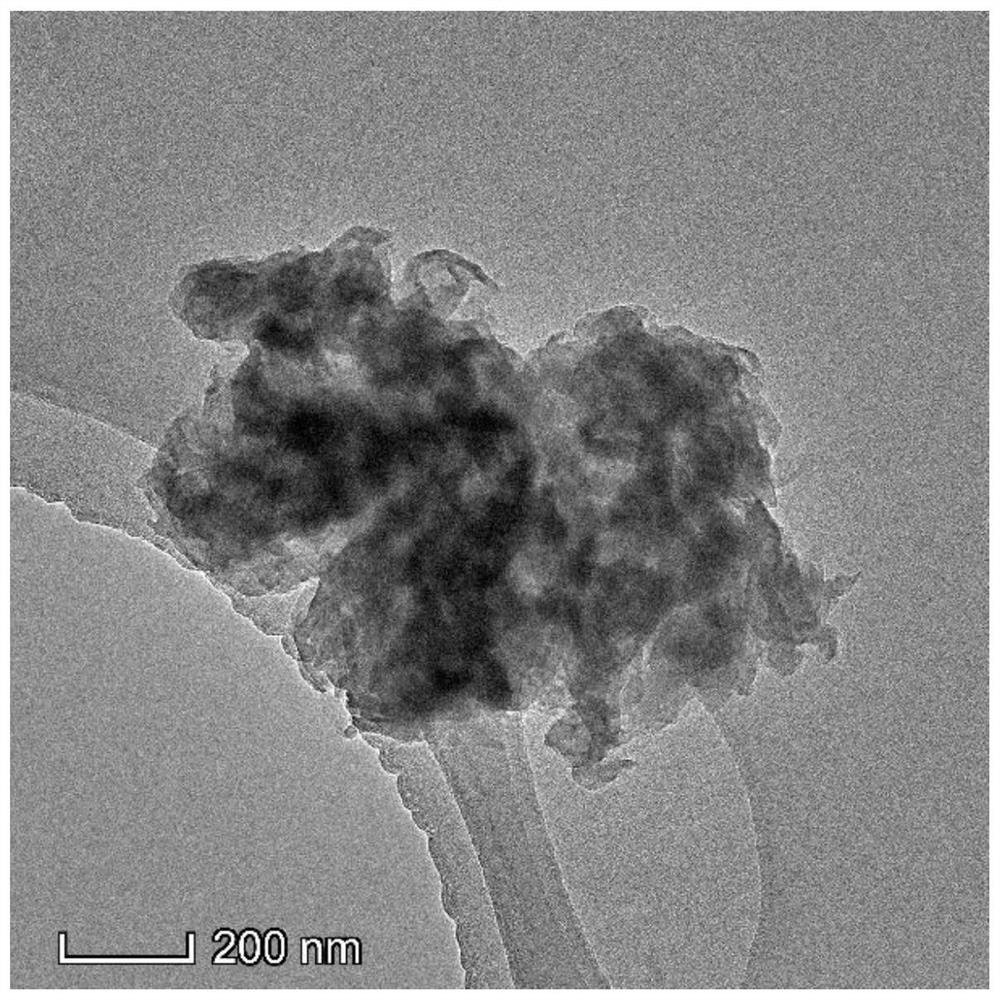

Preparation method of zirconium carbide/hafnium carbide nano composite particles

The invention discloses a preparation method of zirconium carbide / hafnium carbide nano composite particles. The preparation method is specifically implemented according to the following steps: 1, preparing a zirconium salt solution system; 2, preparing a tartaric acid solution system; 3, preparing a ZrC / HfC mixed system; 4, preparing a ZrC / HfC organic composite precursor through rotary evaporation; 5, preparing ZrC / HfC nanoparticles through high-temperature sintering. The zirconium carbide nano composite particles prepared by the method disclosed by the invention are simple in preparation process, low in cost and environment-friendly.

Owner:XIAN UNIV OF TECH

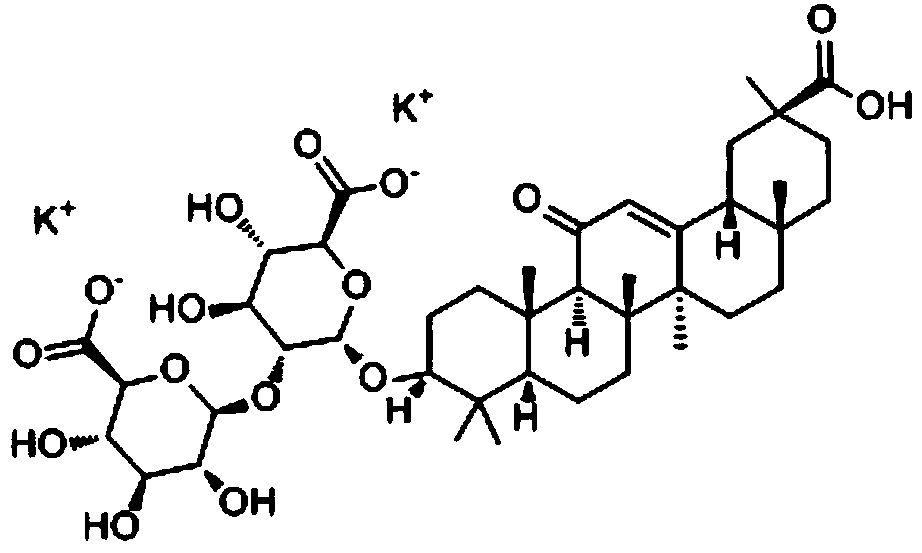

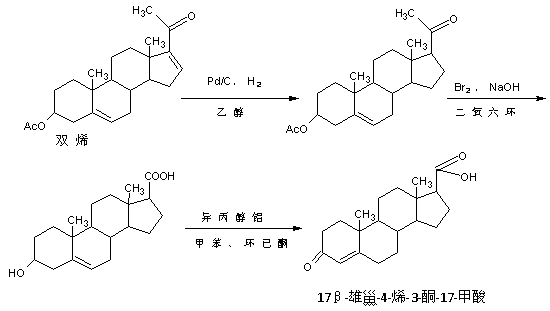

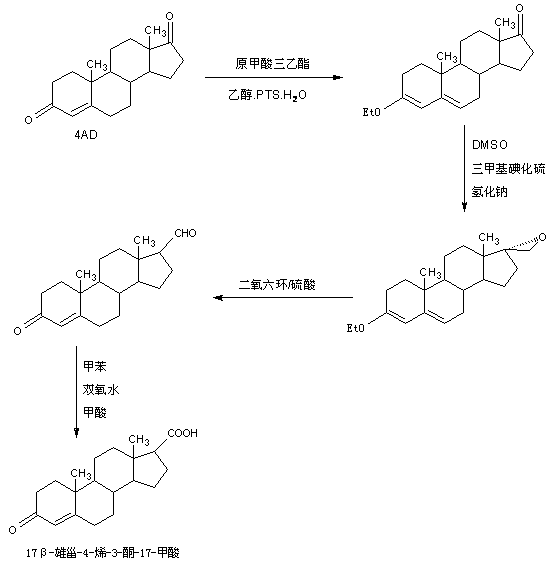

Preparation method of 17β-androst-4-en-3-one-17-carboxylic acid

ActiveCN107629101BRaw materials are cheap and easy to getThe process is simple and environmentally friendlySteroidsCatalytic oxidationOrganosolv

The invention discloses a preparation method of 17 beta-androst-4-ene-3-one-17-carboxylic acid. The preparation method comprises that 4-androstenedione (called as 4AD for short) as a raw material andtriethyl orthoformate undergo a reaction in an organic solvent under acid catalysis, the reaction product is after-treated to form an etherate, the etherate is dissolved in an organic solvent and undergoes a reaction with trimethylsulfonium iodide under strong base catalysis, the product is after-treated to form an epoxide, the epoxide is dissolved in an organic solvent and then is subjected to rearrangement under acid catalysis to form an aldehyde, and aldehyde is dissolved in an organic solvent and undergoes a catalytic oxidation reaction with hydrogen peroxide acid to produce 17 beta-androst-4-ene-3-one-17-carboxylic acid. The 17 beta-androst-4-ene-3-one-17-carboxylic acid has a melting point of 244-246 DEG C, HPLC content of 99.0% or more and a reaction weight total yield of 70-72%. Compared with the traditional method, the preparation method utilizes cheap and easily available raw materials, has simple and environmental friendly processes and a high synthesis yield, produces highquality products, reduces a cost by 30-40% and is conducive to industrial production.

Owner:HUNAN KEREY BIOTECH

VO2/g-C3N4 composite photocatalyst as well as preparation method and application thereof

ActiveCN112657532AMild reaction conditionsEasy to handlePhysical/chemical process catalystsCarbonyl compound preparation by oxidationPhenethyl alcoholAcetophenone

The invention provides a VO2 / g-C3N4 composite photocatalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: dissolving g-C3N4 into a solvent to obtain a g-C3N4 solution, dissolving VO2 into the solvent to obtain a VO2 solution, adding the VO2 solution into the g-C3N4 solution, ultrasonically stirring, then heating, stirring and evaporating until the solution is pasty, drying and cooling and grinding to obtain the VO2 / g-C3N4 composite photocatalyst. The photocatalyst disclosed by the invention is simple in synthesis process and excellent in reusability, and has excellent selectivity on aromatic alcohol. VO2 / g-C3N4 is used as a photocatalyst for the first time, an LED lamp is used as a light source, oxygen is used as an oxidizing agent, 1-phenylethanol is subjected to selective photocatalytic oxidation in an acetonitrile solution to form acetophenone, and the prepared photocatalyst has high oxidation efficiency and excellent selectivity for selective oxidation of 1-phenylethanol.

Owner:SHANDONG UNIV OF SCI & TECH

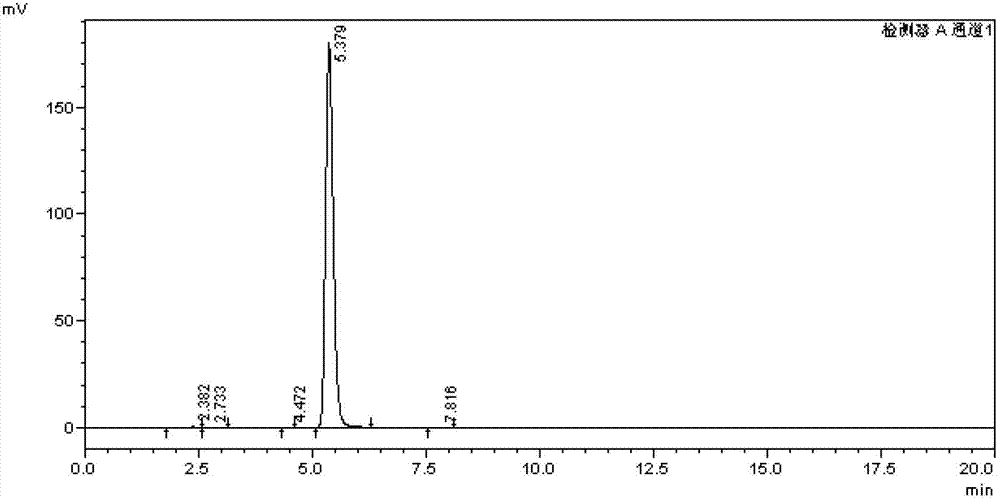

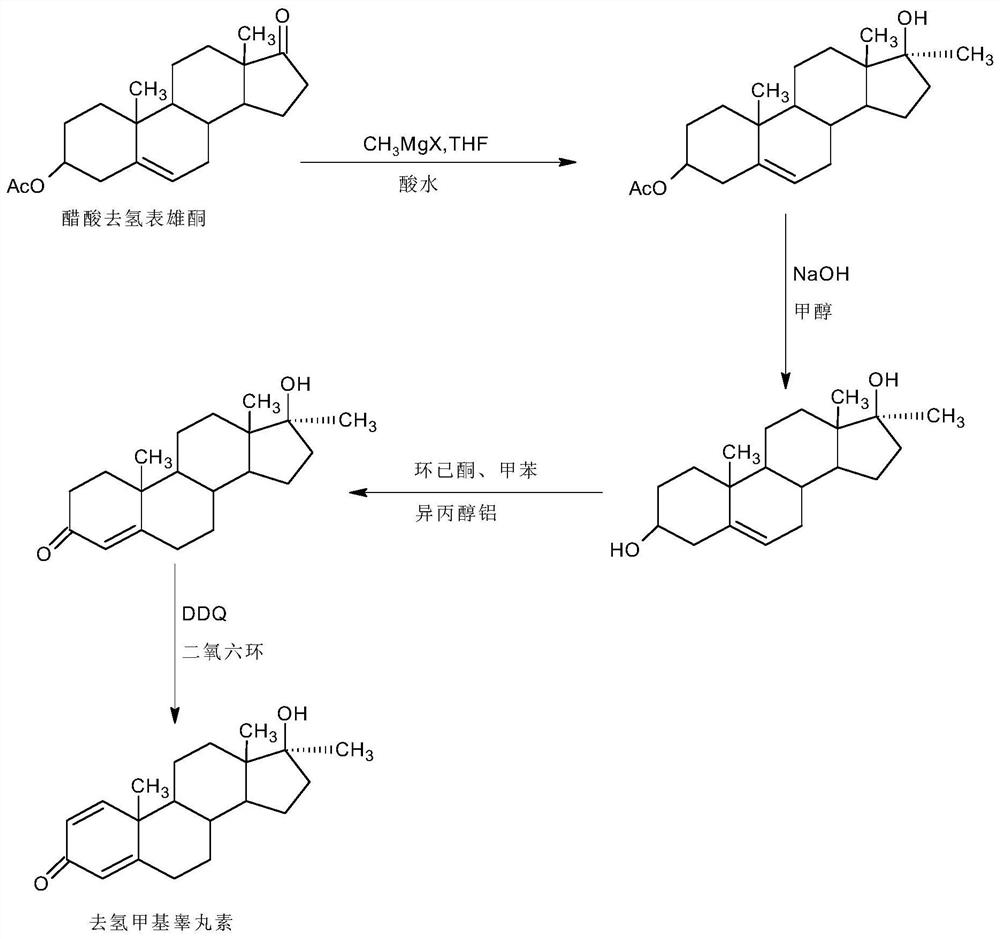

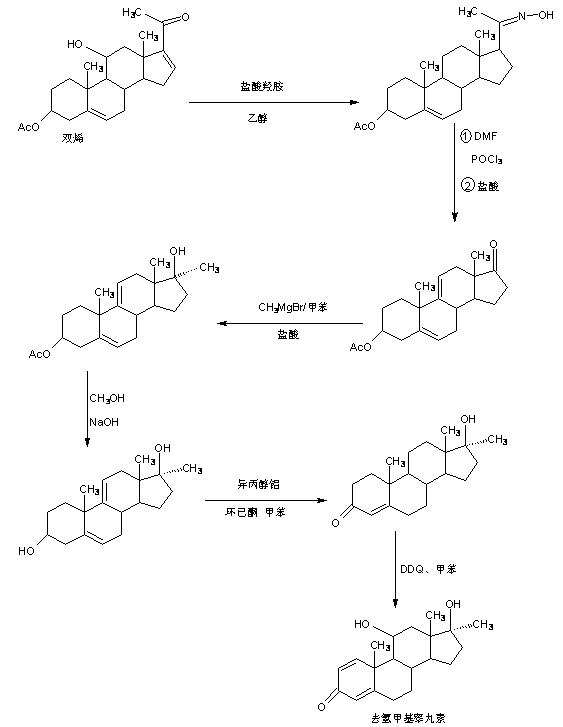

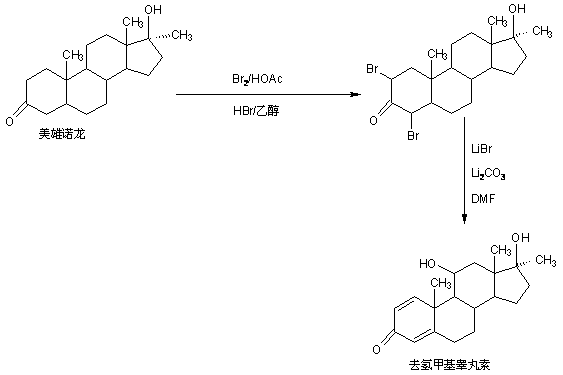

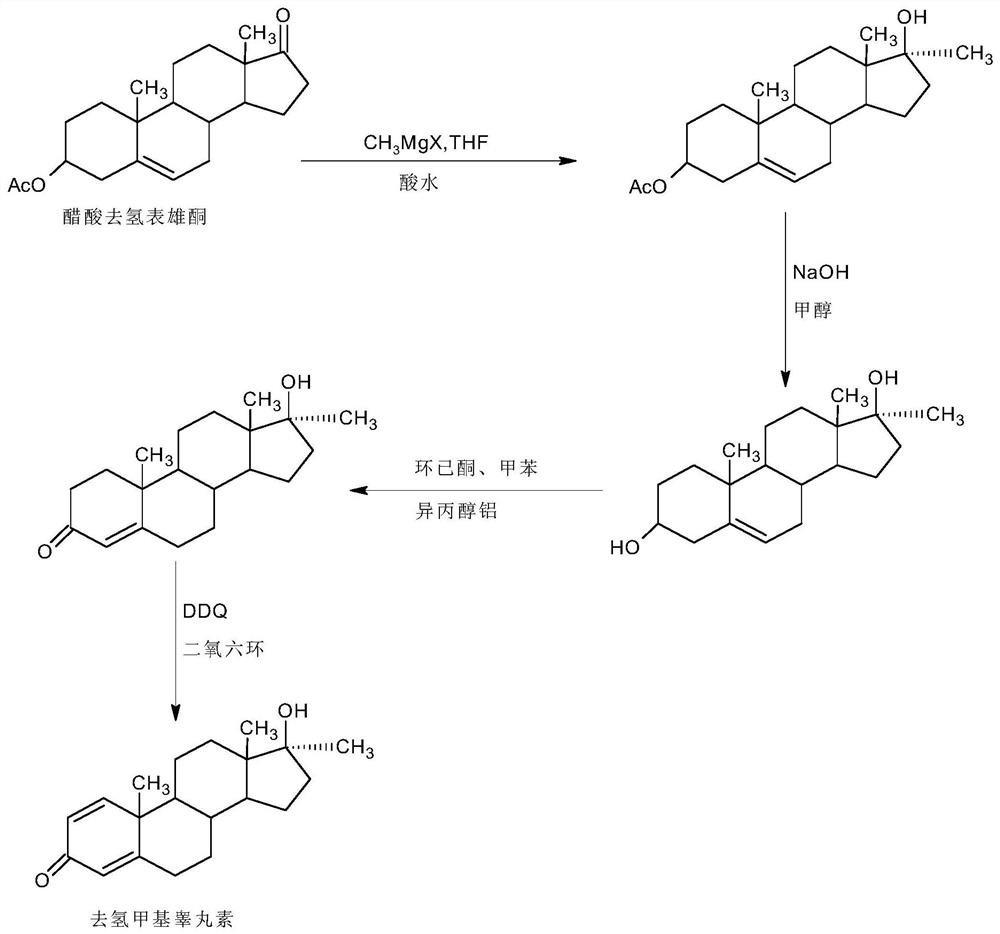

A kind of preparation method of dehydromethyl testosterone product

ActiveCN109456379BWide variety of sourcesProcess economy and environmental protectionSteroidsMethylmagnesium chlorideOrganosolv

The invention provides a preparation method of a metandienone product. The preparation method comprises the following steps that 1,4-androstenedione, namely IDD, is adopted as a raw material, in the presence of methylmagnesium chloride, an organic solvent and acid, alpha-CH3 and beta-OH are introduced at the 17 position, and metandienone is prepared; and then the obtained metandienone is heated byactivated carbon in acetone or lower alcohol below C4 for reflow discoloration and is recrystallized, and the metandienone product is obtained. According to the preparation method, the IDD serves asthe raw material to prepare the metandienone, compared with a traditional method adopting diosgenin as a raw material, the raw material source is wide, a process is economic and environmentally friendly, and the production cost is significantly lowered. Compared with a traditional production method, according to the preparation method, a synthesis route is short, the process is easy, convenient and environmentally friendly, the product yield is high, the quality is good, and the production raw material cost is lowered by 40-45% by calculating through the current raw material price.

Owner:HUNAN KEREY BIOTECH

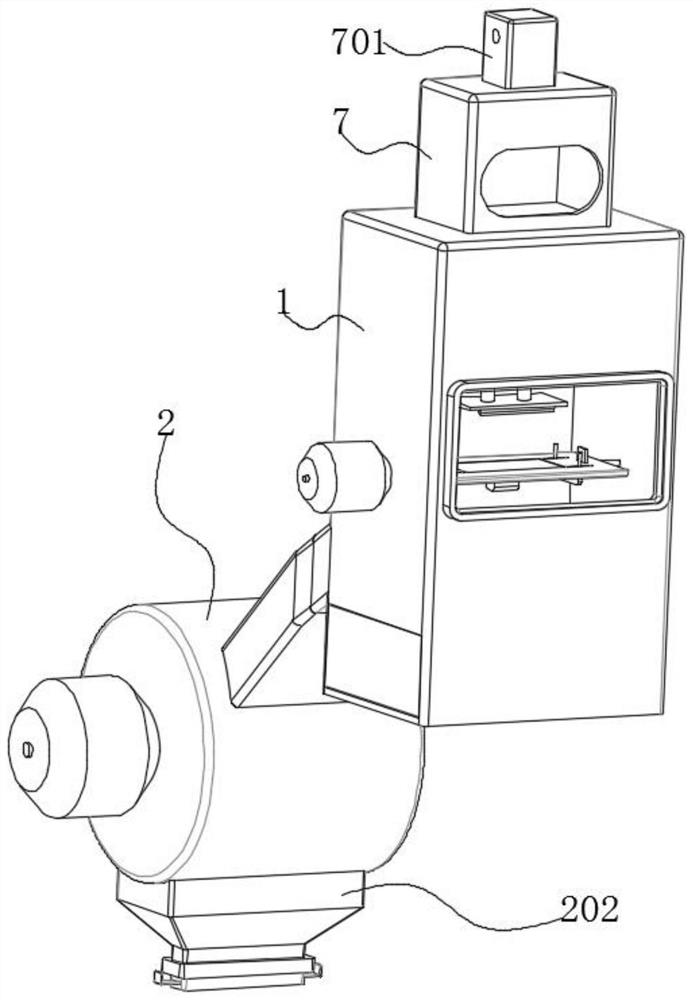

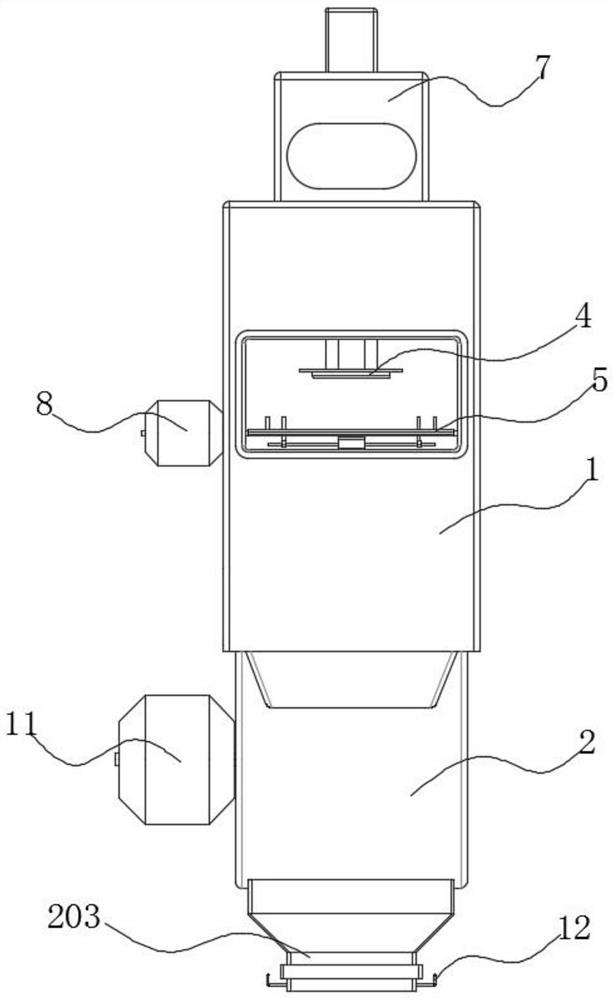

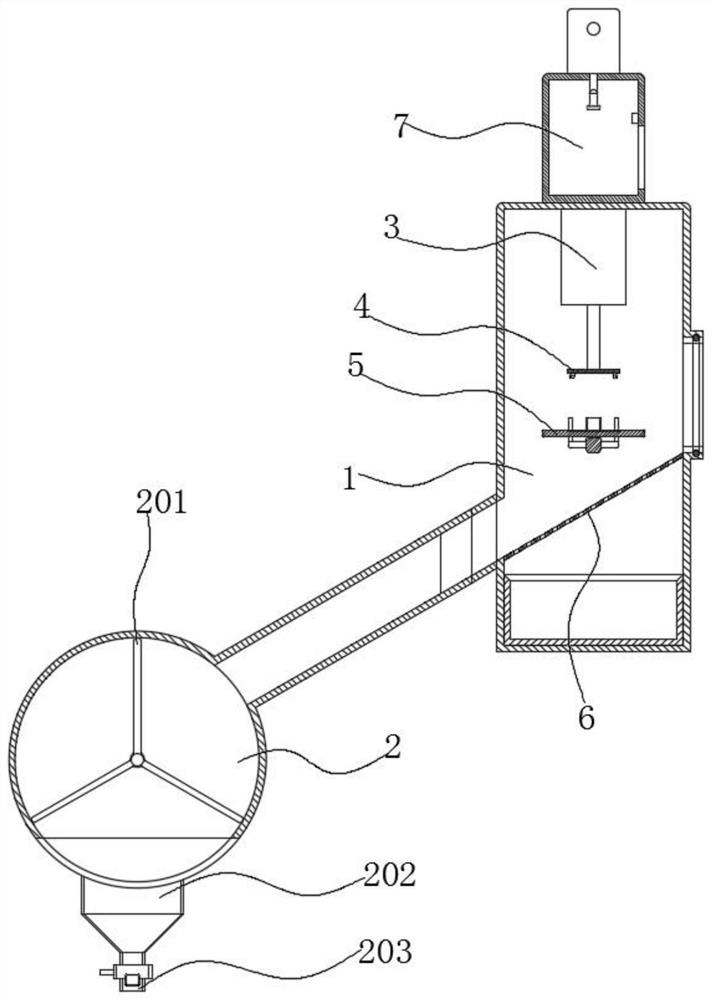

A waste mask processing device based on environmental protection

ActiveCN111957717BGuaranteed placementEasy to separateSolid waste disposalMedical waste disposalEngineeringStructural engineering

The invention discloses an environmental protection-based waste mask processing device, which relates to the technical field of environmental protection equipment. The invention comprises a cutting box and a crushing barrel connected to each other, the inner top of the cutting box is connected with a knife seat through a cylinder; the middle part of the inner wall of the cutting box is rotated and matched with a mask supporting plate, and two symmetrical limiting plates and Two sets of limit rods symmetrical about the limit plate; an inclined filter plate is fixed on the inner bottom of the cutting box; a spray disinfection box is fixed on the top of the cutting box. The present invention fixes the mask on the mask supporting plate through the limiting plate and the limiting rod, and cuts the edge of the mask nose clip strip through the cooperation of the mask supporting plate and the knife seat, and makes the nose clip strip fall off and slide in by rotating the mask supporting plate. Cutting the box, and then loosen the limit lever to make the mask fall off, and finally slide into the crushing barrel for crushing; through the cooperation of the cutting box and the crushing barrel, the mask fabric and the nose clip strips are separated and processed separately to protect the environment.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

A preparation method of modified granite waste rock powder crystalline glaze

The invention discloses a preparation method of modified granite waste rock powder crystalline glaze, which belongs to the technical field of ceramics. The raw material composition of the granite waste stone powder crystal glaze: 80-95 parts of modified granite powder, 1-15 parts of crystal nucleus agent, 1-5 parts of sintering aid, and 1-2 parts of dispersant. After the raw materials are prepared, water is added and mixed uniformly by ball milling to obtain a glaze, which is sprayed, dried and sintered to prepare a crystalline glaze. The invention has the characteristics of high utilization rate of granite waste rock powder, environmental protection process, rich glaze pattern, low cost, etc., and can realize large-scale high value-added utilization of granite waste rock powder.

Owner:NANCHANG HANGKONG UNIVERSITY

A kind of preparation method of dehydromethyl testosterone

Owner:HUNAN KEREY BIOTECH

A kind of method for preparing dehydromethyltestosterone product

ActiveCN109456378BWide variety of sourcesProcess economy and environmental protectionSteroidsBiotechnologyPlant sterol

Owner:HUNAN KEREY BIOTECH

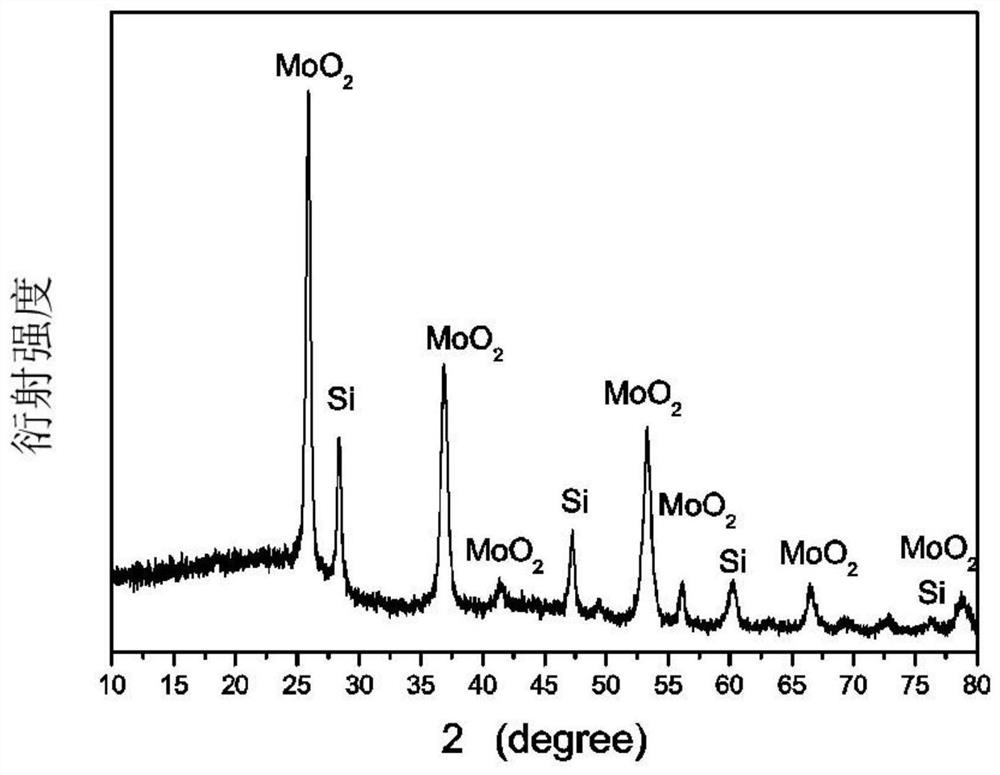

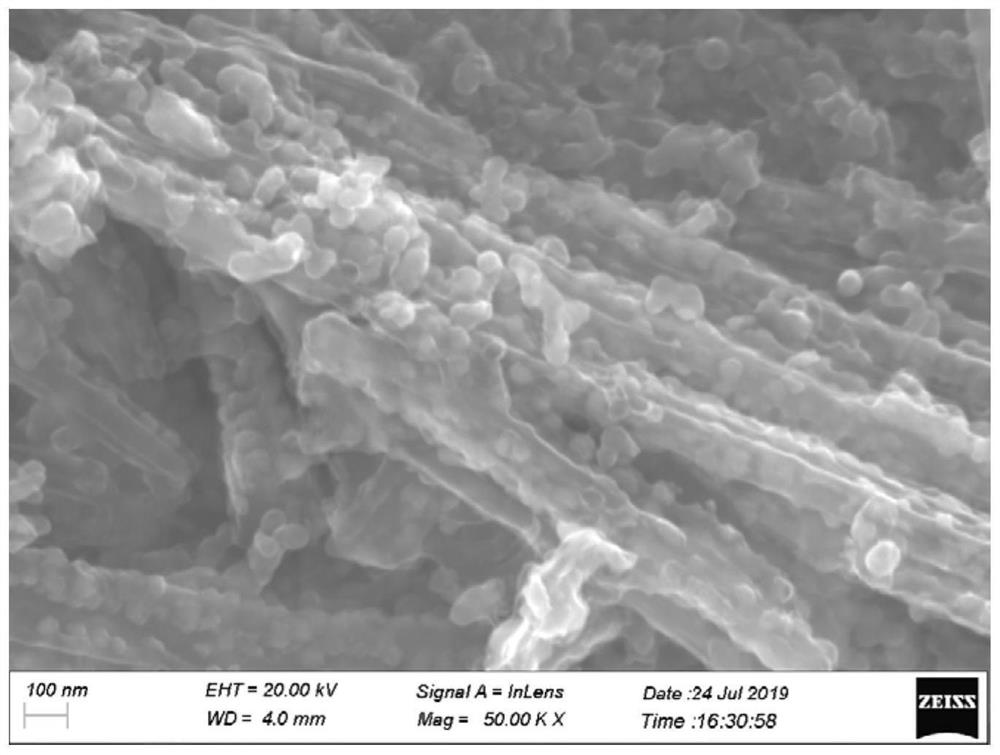

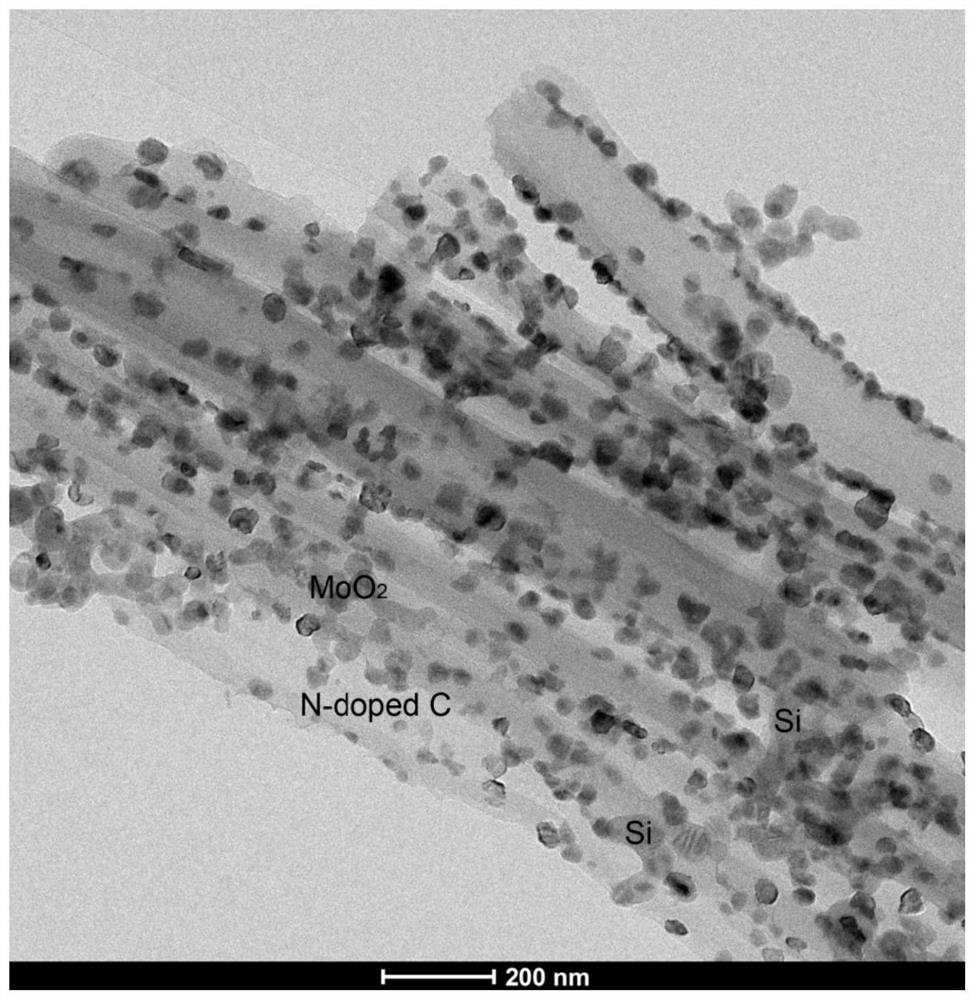

A carbon/molybdenum dioxide/silicon/carbon composite material, a battery negative electrode containing it, and a lithium-ion battery

ActiveCN111180714BExcellent negative electrode lithium storage performanceImprove cycle stabilitySiliconSecondary cellsCarbon compositesCarbon layer

The invention relates to a carbon / molybdenum dioxide / silicon / carbon composite material, a battery negative electrode containing the same and a lithium-ion battery. The carbon / molybdenum dioxide / silicon / carbon composite material is nano-molybdenum dioxide evenly loaded on nano-carbon fibers And nano-silicon particles, the outermost layer is coated with carbon layer. The battery negative electrode comprising the carbon / molybdenum dioxide / silicon / carbon composite material is used to make a lithium ion battery, and the discharge specific capacity at 0.1A / g is not less than 750mAh / g, and the discharge specific capacity at 3A / g reaches at least 250mAh / g, after 500 cycles at a rate of 0.5A / g, the discharge specific capacity still remains at 480mAh / g and above, which has good cycle performance and rate performance.

Owner:XIAMEN UNIV OF TECH

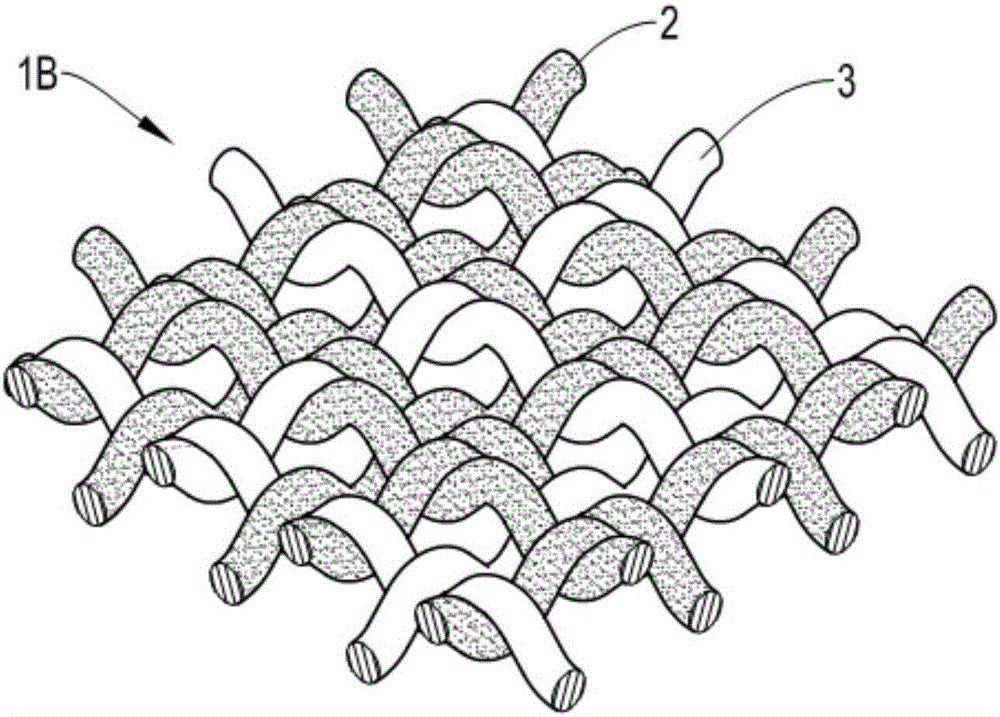

Composite reinforced fabric and its preparation method

ActiveCN107523920BHigh strengthHigh tensile strengthWeft knittingHeating/cooling textile fabricsYarnElastomer

The invention provides a composite reinforced fabric and a preparation method thereof. The composite reinforced fabric includes high-hardness thermoplastic elastomer yarns and low-hardness thermoplastic elastomer yarns, and the surface of the low-hardness thermoplastic elastomer yarns is slightly fused to adhere to the surface of the high-hardness thermoplastic elastomer yarns. The preparation method of the composite reinforced fabric comprises: weaving high-hardness thermoplastic elastomer yarns and low-hardness thermoplastic elastomer yarns into fabrics, and the melting point of the low-hardness thermoplastic elastomer yarns is 50°C to 150°C; , hot pressing the fabric to obtain a composite reinforced fabric, the hot pressing temperature is greater than or equal to the melting point of the low-hardness thermoplastic elastomer yarn and lower than the melting point of the high-hardness thermoplastic elastomer yarn. Through the above-mentioned technical means, a composite reinforced fabric with strong tensile strength and strong impact resistance can be produced in a relatively simple and environmentally friendly process.

Owner:SHUN YI MATERIALS CO LTD

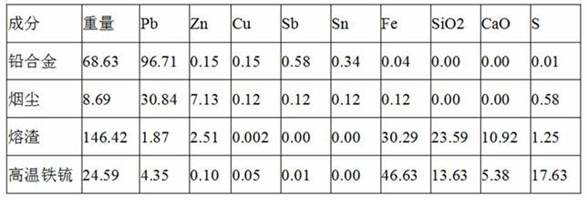

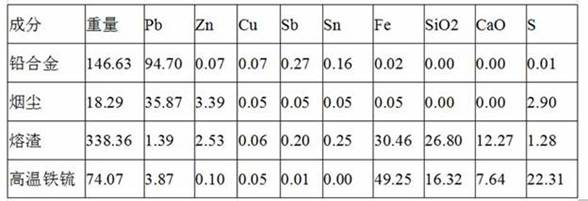

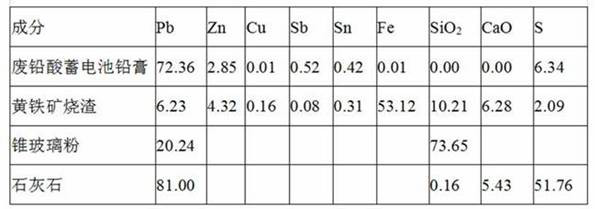

A process for recycling valuable metals in waste lead-acid battery lead paste by using iron powder and cone glass

ActiveCN110343865BEmission reductionThe process is simple and environmentally friendlyCeramic shaping apparatusWaste accumulators reclaimingIron powderSlag

The invention discloses a process method for recovering valuable metals in lead paste of waste lead-acid batteries by using iron powder and cone glass, and belongs to the technical field of lead paste recovery and treatment. The method is to mix conical glass, iron powder and lead-acid battery lead paste with auxiliary materials, use the sulfur in the lead sulfate paste and the iron in the iron powder to carry out fermentation and solidification reaction, and then make billets, solidify and use fire smelting to produce lead Alloy, iron columbine, soot and slag, not only achieve the purpose of comprehensive recovery of valuable metals, but also reduce the emission of sulfur dioxide. The process is simple and environmentally friendly, with low cost and high recycling efficiency.

Owner:四川正祥环保技术有限公司

Square winding structure lead-acid battery and manufacturing method thereof

ActiveCN106159128BReduce weightIncreased energy-to-weight ratioFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryInternal resistance

The present invention is a lead-acid storage battery with a square winding structure and its manufacturing method. The positive and negative active materials are respectively coated on the flexible grid obtained by expansion, punching, continuous casting or other forms to make positive and negative plates. Plate, separator, and negative plate are wound on the same core plate to form a battery core, and the battery core is placed in a battery tank with a circular arc transition at both ends and a straight line in the middle. After drying by a special process, casting welding, sealing, and filling are completed. A series of physical and electrochemical processes such as acid and chemical formation, and finally, it becomes a lead-acid battery that can be used repeatedly for charging and discharging. The invention combines the advantages of cylindrical winding batteries and traditional square flat batteries. It not only has the characteristics of low internal resistance, high specific power and long life of winding batteries, but also has the characteristics of high volume utilization rate and wide application range of traditional batteries. It breaks through It overcomes the limitation that the cylindrical winding battery is only suitable for small and medium capacity batteries, and has broad application prospects.

Owner:山东超威磁窑电源有限公司

Quasi-two-pole winding-structure lead-acid battery and making method

InactiveCN100350666CIncrease specific energyImprove connection reliabilityFinal product manufactureLead-acid accumulators constructionInternal resistanceElectrical polarity

Positive active material and negative active material separated by lead wires are coated on two sides of composite slab lattice so as to constitute bipolar plate. The said lead wires can be cut into certainshape to become positive pole plate or negative pole plate with single pole. Single adjacent batteries separated by lead wires can be connected in series. Positive pole plate, diaphragm, and negative pole plate of single battery are winded on same core axle. Winded pole plates and diaphragm fixed by plastic fixture becomes battery core. Dried battery core is installed inside cylindrical battery box so as to complete electrochemical procedure. Then, firming agent is filled into the box. The invention combines advantages of both of quasi-bipolar battery and cylindrical winded battery, possessing features of low internal resistance, high specific energy, high specific power, and long service life.

Owner:李向秀

Color building external wall waterproof coating

InactiveCN107418320ALow costThe process is simple and environmentally friendlyMulticolor effect coatingsEnvironmental resistanceSocial benefits

The invention provides a color building external wall waterproof coating comprising, by weight, 10-15 parts of water, 25-30 parts of talcum powder and the like. The coating, compared with similar building external wall waterproof coatings, has the following advantages: the raw materials are easy to obtain and low in cost and a process is simple and environment-friendly; the coating is convenient to construct, has high adhesion force and good anti-tearing capability, has multiple and adjustable colors and is free of discoloring, and also has significant economic and social benefits.

Owner:白克雯

A method for preparing dehydromethyltestosterone

ActiveCN109369760BWide variety of sourcesProcess economy and environmental protectionSteroidsBiotechnologyPlant sterol

The invention provides a method for preparing metandienone, the method comprises firstly using a nutrient medium and one or more microbial strains, performing microbial fermentation on phytosterol toprepare 1,4-androstenedione, namely IDD, then using the IDD as the raw material, introducing alpha-CH3 and beta-OH into a 17 site with the existence of methyl magnesium halide, an organic solvent andan acid, and preparing the metandienone. The method uses the IDD as the raw material to prepare the metandienone, compared with the traditional method taking diosgenin as the raw material, the sourceof the raw material is wide, the process is economical and environmentally friendly, and the production cost is greatly reduced. Compared with the traditional production method, the synthesis route isshort, the process is simple, convenient and environmentally friendly, the yield of a product is high, the quality is high, and the cost of the raw material for production is reduced by 40-45% according to the current price of the raw material.

Owner:HUNAN KEREY BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com