Method for producing calcium fluoride by utilizing high-fluorine-content industrial wastewater

A technology for industrial wastewater and calcium fluoride, applied in chemical instruments and methods, metallurgical wastewater treatment, calcium/strontium/barium fluoride, etc., can solve the problem of high material consumption and energy consumption, high cost of fluorine-containing wastewater treatment, and secondary pollution and other problems, to achieve the effect of high fluorine recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

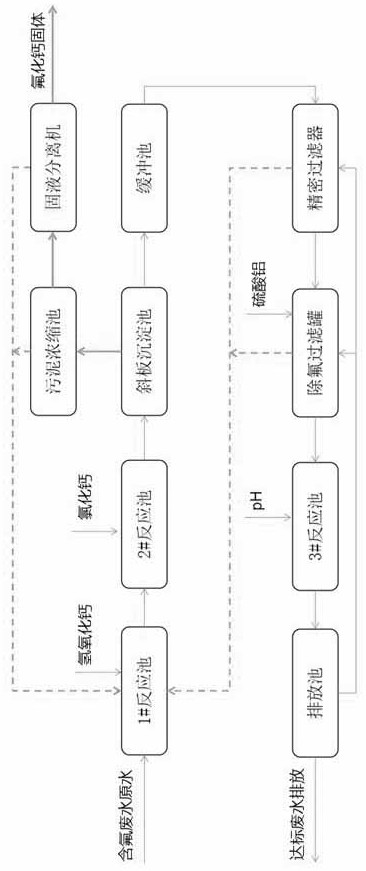

Image

Examples

Embodiment 1

[0024] A method for producing calcium fluoride by utilizing high fluorine-containing industrial waste water, comprising the following steps:

[0025] S1. Fluorine-containing waste water (fluoride ion concentration is 260mg / L) enters the 1# reaction tank, and calcium hydroxide is added to the 1# reaction tank, and the pH value is adjusted to 10, and stirred and mixed for 30 minutes; how much is the fluorine-containing waste water added? It doesn't matter, as long as the pH value is adjusted to 10 with calcium hydroxide;

[0026] S2. Introduce the upper layer waste water after the treatment of 1# reaction tank into 2# reaction tank, add calcium chloride in 2# reaction tank, adjust the chloride ion concentration to 400mg / L, stir for 30 minutes; as long as the chloride ion concentration is adjusted to 400mg / L L is enough;

[0027] S3. Introduce the upper-layer wastewater treated in the 2# reaction tank into the inclined plate settling tank, the supernatant of the inclined plate s...

Embodiment 2

[0034] A method for producing calcium fluoride by utilizing high fluorine-containing industrial waste water, comprising the following steps:

[0035] S1. Fluorine-containing waste water (fluorine ion concentration is 163mg / L) enters the 1# reaction tank, and calcium hydroxide is added to the 1# reaction tank, the pH value is adjusted to 9.3, and the mixture is stirred for 30 minutes;

[0036] S2. introduce the upper strata waste water after the 1# reaction tank treatment into the 2# reaction tank, add calcium chloride in the 2# reaction tank, adjust the chloride ion concentration to 320mg / L, and stir for 30 minutes;

[0037] S3. Introduce the upper-layer wastewater treated in the 2# reaction tank into the inclined plate settling tank, the supernatant of the inclined plate settling tank is introduced into the buffer tank, and the sludge produced in the inclined plate settling tank is discharged into the sludge thickening tank;

[0038] S4. Pump the wastewater from the buffer po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com