Method for recovering tin metal from tin-containing waste bricks

A technology of tin metal and waste brick slag, applied in the field of non-ferrous metal smelting, can solve the problems of air, water and soil pollution, waste of tin resources, etc., achieve simple and environmentally friendly procedures, low energy consumption, and solve the effects of environmental pollution and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

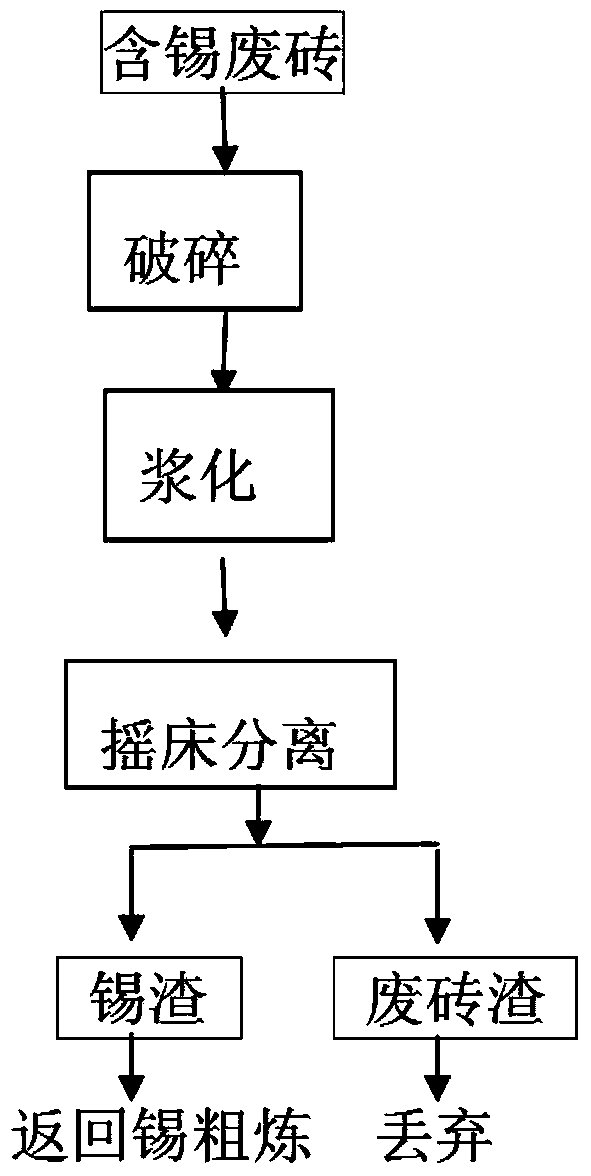

Image

Examples

Embodiment 1

[0019] The method for reclaiming tin metal from tin-containing waste bricks of the present invention, comprises the steps:

[0020] 1. Mineral raw material composition and content

[0021] In tin metal smelters, tin waste bricks contain 15% tin, and the rest are impurities such as alumina and quartz.

[0022] 2. The operation process includes the following steps:

[0023] (1) Put the refractory bricks of the reverberatory furnace, electric furnace or Ausmelt furnace in the tin metal smelting plant into the crusher for crushing to obtain fragments with a particle size of 6 mm to 15 mm;

[0024] (2) hoist the fragments into a ball mill with a gourd crane for fine grinding to obtain coarse sand with a particle size less than 2mm;

[0025] (3) Put the coarse sand into the pulping tank, inject water into the slurrying tank according to the weight ratio coarse sand: water = 1:3-4, and stir for 0.5-1 hour to obtain the pulp;

[0026] (4) The slurried pulp is pumped to the shaking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com