A carbon/molybdenum dioxide/silicon/carbon composite material, a battery negative electrode containing it, and a lithium-ion battery

A carbon composite material, molybdenum dioxide technology, applied in molybdenum oxide/molybdenum hydroxide, battery electrodes, secondary batteries, etc., can solve the problems of high voltage platform, poor cycle stability and rate performance of silicon anode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

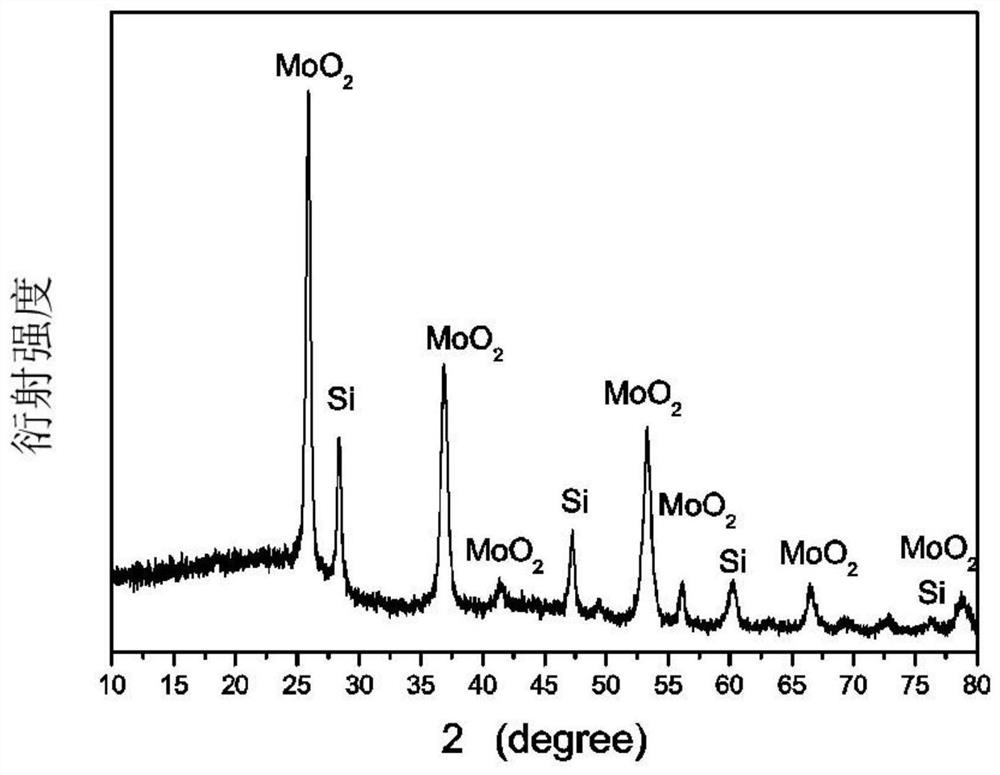

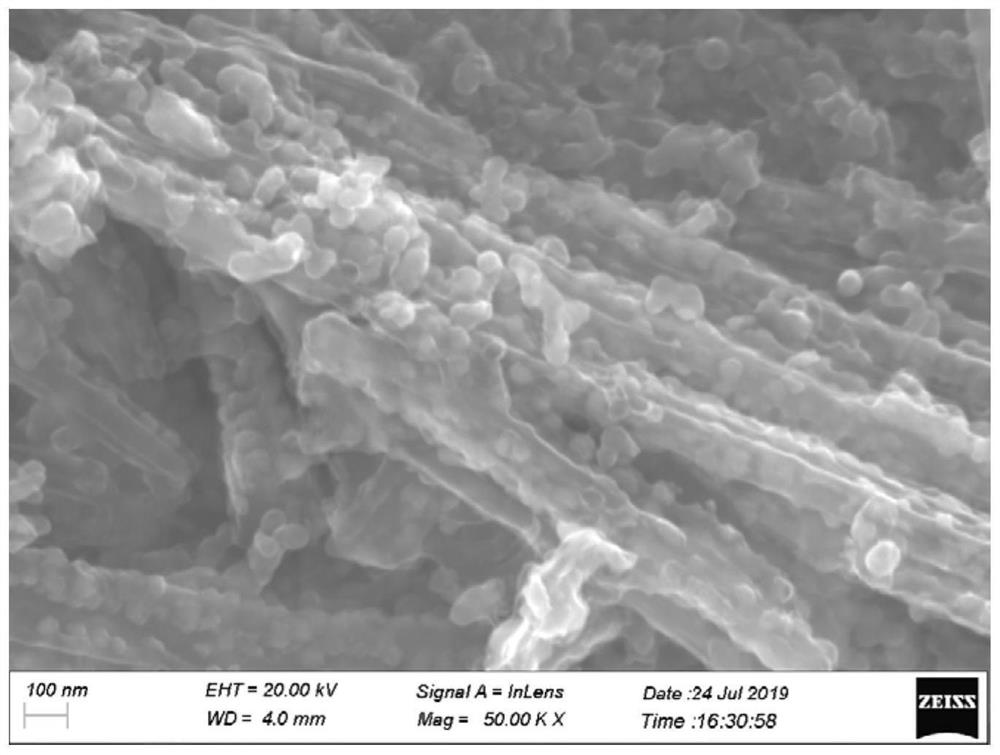

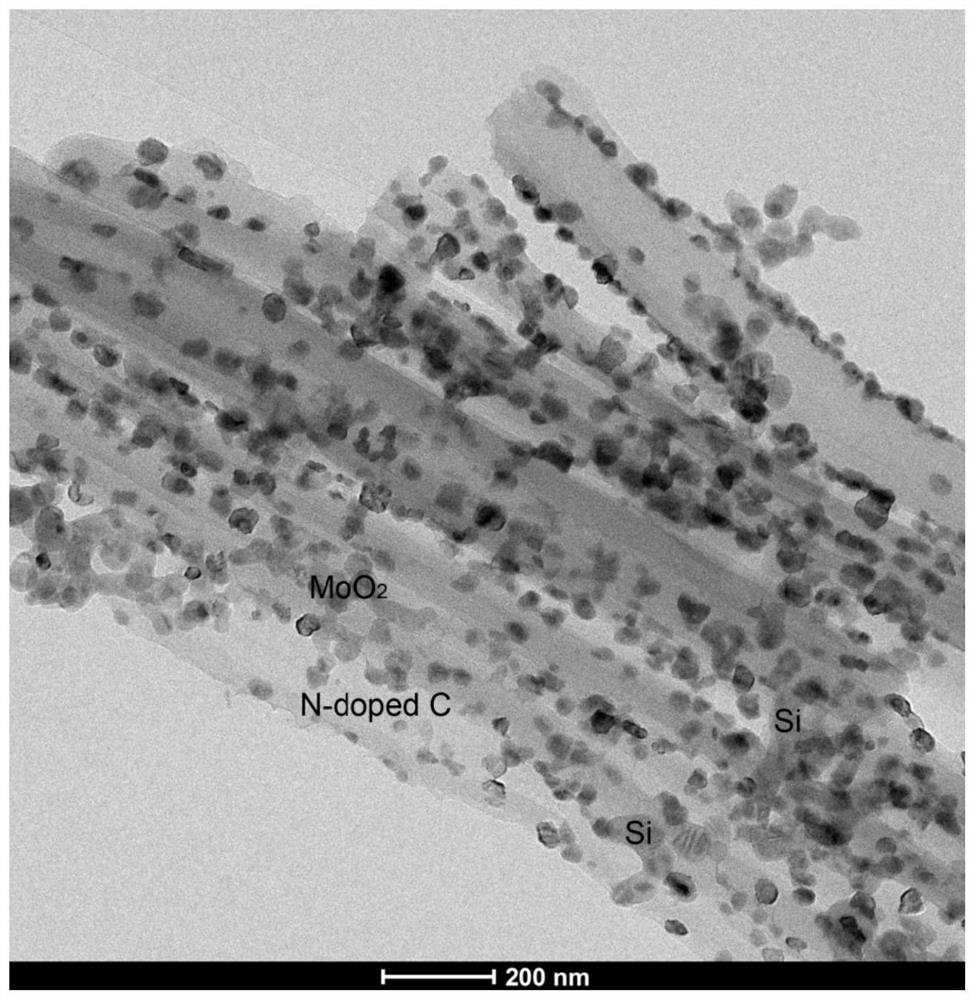

[0056] A preparation method of carbon / molybdenum dioxide / silicon / carbon composite material, comprising the steps of:

[0057] 1) Ultrasonic dispersion of 0.2g of nano silicon powder in 20ml of absolute ethanol to obtain solution A;

[0058] 2) Dissolve 2.48g of ammonium tetramolybdate tetrahydrate in 80ml of deionized water to obtain solution B;

[0059] 3) Under stirring conditions, add solution B to solution A, then add 3.4 g of aniline to the mixed solution, and then add 6 ml of dilute hydrochloric acid solution with a concentration of 1M to the mixed solution;

[0060] 4) Stir the mixed solution obtained in step 3) at room temperature for 48 hours to make the in-situ polymerization reaction fully complete, then filter, wash with deionized water, and dry to obtain an organic precursor containing Mo-Si;

[0061] 5) The obtained Mo-Si-containing organic precursor was heat-treated at 650 °C for 2 h under the protection of an inert gas to obtain C-MoO 2 - Si composite materia...

Embodiment 2

[0078] A preparation method of carbon / molybdenum dioxide / silicon / carbon composite material, comprising the steps of:

[0079] 1) Ultrasonic dispersion of 0.1g of nano silicon powder in 30ml of absolute ethanol to obtain solution A;

[0080] 2) 1.24g of ammonium tetramolybdate heptahydrate was dissolved in 40ml of deionized water to obtain solution B;

[0081] 3) Under stirring conditions, add solution B to solution A, then add 1.7 g of aniline to the mixed solution, and then add dropwise 7 ml of dilute hydrochloric acid solution with a concentration of 0.8 M to the mixed solution;

[0082]4) Stir the mixed solution obtained in step 3) at room temperature for 25 hours to make the in-situ polymerization reaction fully complete, then filter, wash with deionized water, and dry to obtain an organic precursor containing Mo-Si;

[0083] 5) The obtained Mo-Si-containing organic precursor was heat-treated at 600 °C for 5 h under the protection of an inert gas to obtain C-MoO 2 - Si c...

Embodiment 3

[0094] A preparation method of carbon / molybdenum dioxide / silicon / carbon composite material, comprising the steps of:

[0095] 1) Ultrasonic dispersion of 0.3g of nano silicon powder in 30ml of absolute ethanol to obtain solution A;

[0096] 2) 2.48g ammonium tetramolybdate heptahydrate was dissolved in 80ml deionized water to obtain solution B;

[0097] 3) Under stirring conditions, add solution B to solution A, then add 3.4 g of aniline to the mixed solution, then add 8 ml of dilute hydrochloric acid solution with a concentration of 1M to the mixed solution;

[0098] 4) Stir the mixed solution obtained in step 3) at room temperature for 48 hours to make the in-situ polymerization reaction fully complete, then filter, wash with deionized water, and dry to obtain an organic precursor containing Mo-Si;

[0099] 5) The obtained Mo-Si-containing organic precursor was heat-treated at 800 °C for 1.5 h under the protection of an inert gas to obtain C-MoO 2 - Si composite material; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com