VO2/g-C3N4 composite photocatalyst as well as preparation method and application thereof

A g-c3n4, VO2 technology, applied in physical/chemical process catalysts, chemical instruments and methods, oxidation preparation of carbonyl compounds, etc., can solve problems such as unsatisfactory photocatalytic performance, improve conversion rate and selectivity, and simplify the process. Environmental protection and strong catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

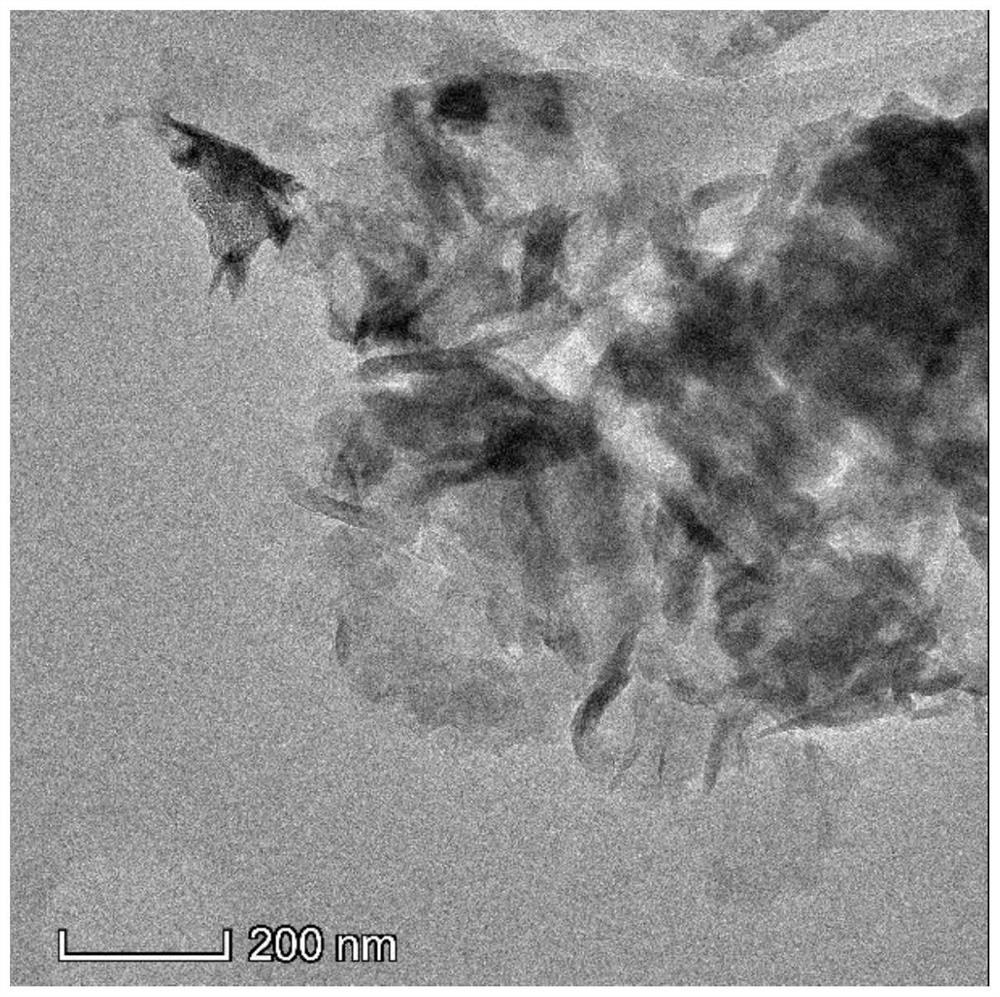

[0029] The present invention provides VO 2 / g -C 3 N 4 The preparation method of composite catalyst comprises the following steps: first, prepare g-C 3 N 4 : Put the urea in a crucible wrapped in aluminum foil and use a muffle furnace to heat up to 500-600°C for 1.5-2.5 hours, then put it in a crucible with a cover, raise the temperature to 500-600°C in the muffle furnace, and refire. Keep warm for 1.5-2.5h to get g-C 3 N 4 .

[0030] Then, VO was prepared by ultrasound-assisted method under different pH environments. 2 VO with different mass proportions 2 / g -C 3 N 4 Composite photocatalyst:

[0031] Pour an appropriate amount of ultrapure water or ethanol aqueous solution into a beaker, and weigh g-C according to the mass ratio 3 N 4 Add it into a beaker and ultrasonically stir for 1h, take an appropriate amount of ultrapure water or ethanol aqueous solution and pour it into another beaker, and weigh VO according to the mass ratio 2 In a beaker, stir magneticall...

Embodiment 1

[0036] (1) g-C 3 N 4 Preparation of:

[0037] Take 5g of urea and place it in a crucible wrapped in aluminum foil, place the crucible in a muffle furnace, raise the temperature to 550°C at a rate of 10°C per minute, and keep it warm for 2h. Reburn the preliminarily fired urea, put it in a covered crucible, raise the temperature to 550°C at a rate of 5°C per minute, and keep it warm for 2 hours to obtain g-C 3 N 4 .

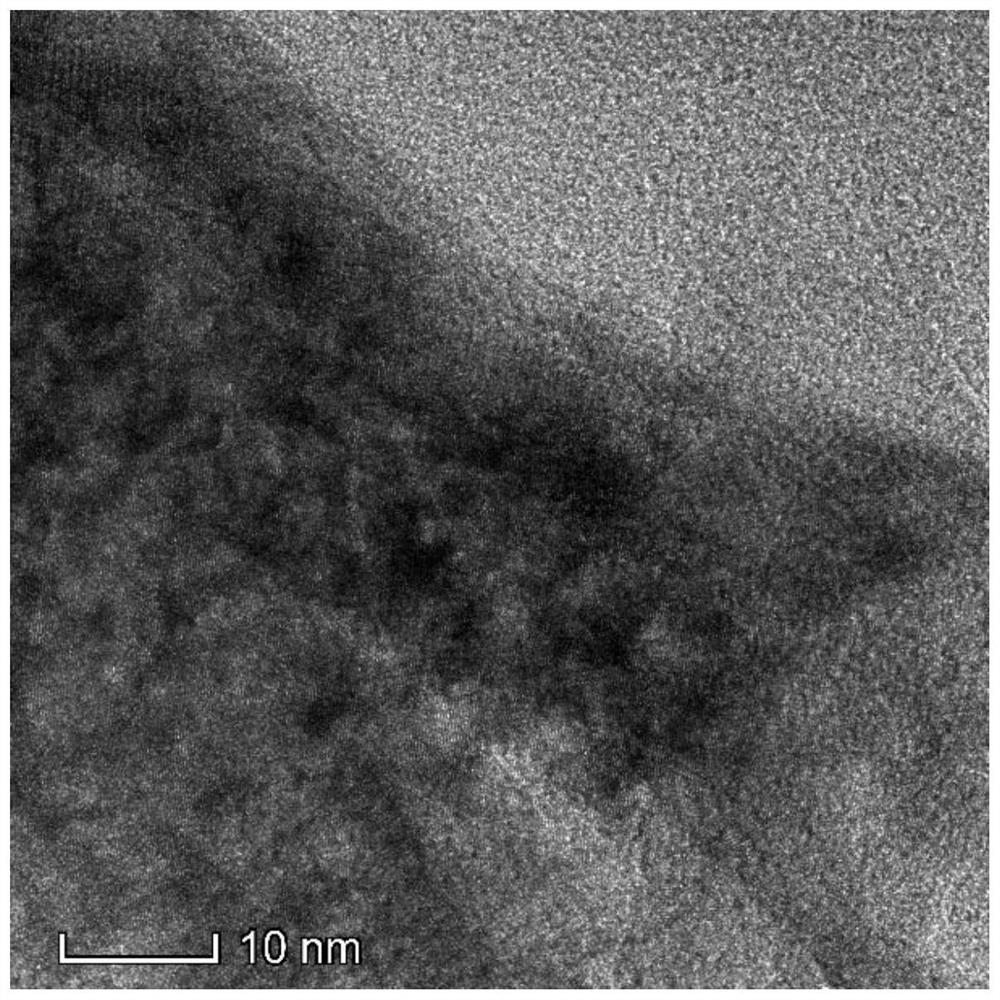

[0038] (2) In pH=7 solution, W7-VO 2 / g -C 3 N 4 Preparation of composite photocatalyst:

[0039] Take 20mL ultrapure water in a beaker, weigh 0.9g g-C 3 N 4 Add it into a beaker and ultrasonically stir for 1h, take 20mL of ultrapure water in another beaker, and weigh 0.1gVO 2 In a beaker and stirred until completely dissolved, the dissolved VO 2 Add the solution to the above g-C 3 N 4 In the solution, sonicate for 1h, then stir and evaporate at 80°C until the solution becomes a paste, put the beaker in an oven and dry at 80°C for 12h, and grind it wi...

Embodiment 2

[0045] (1) g-C 3 N 4 Preparation of:

[0046] Take 5g of urea and put it in a crucible wrapped in aluminum foil, place the crucible in a muffle furnace, raise the temperature by 10°C per minute to 550°C, and keep it warm for 2h. Reburn the preliminarily fired urea, put it in a covered crucible, raise the temperature to 550°C at 5°C per minute, and keep it warm for 2 hours to obtain g-C 3 N 4 .

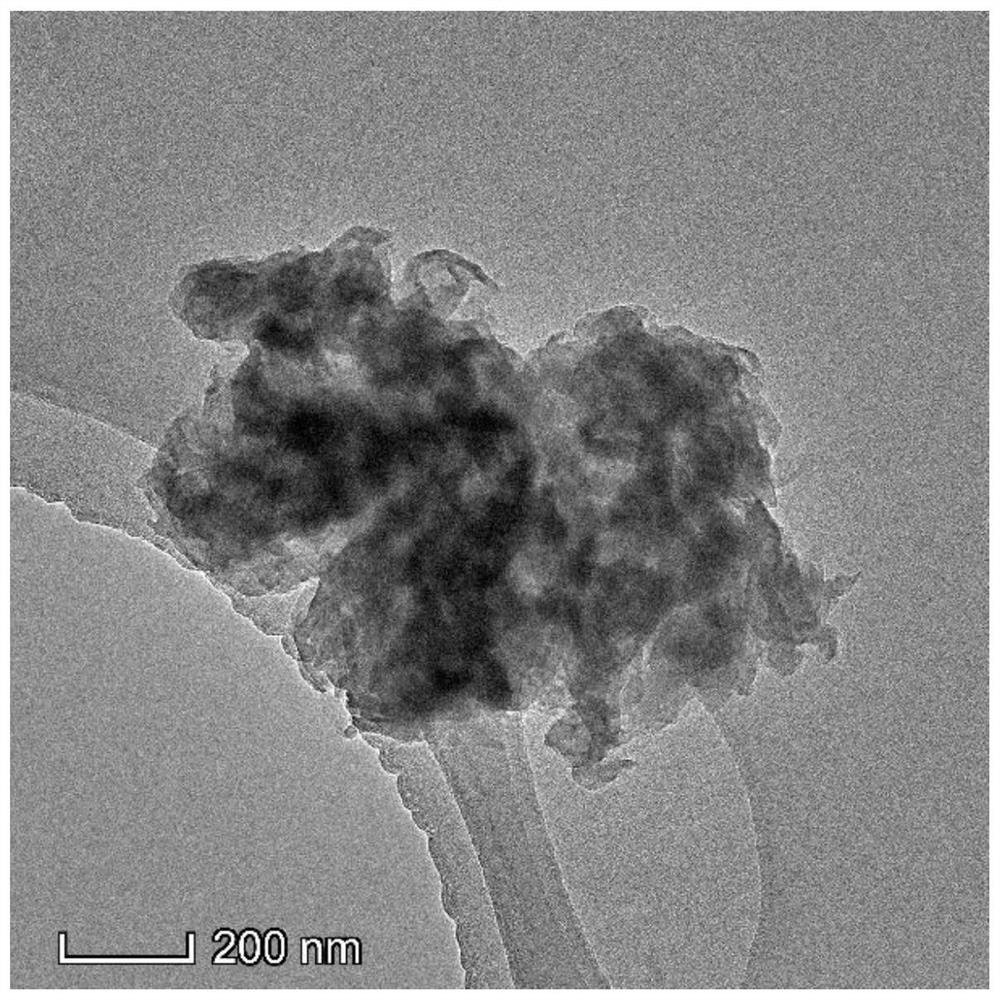

[0047] (2) In pH=1 solution, W7-VO 2 / g -C 3 N 4 Preparation of composite photocatalyst:

[0048] Take 20mL ultrapure water in a beaker, weigh 0.9g g-C 3 N 4 Add it into a beaker and ultrasonically stir for 1h, take 20mL of ultrapure water in another beaker, and weigh 0.1gVO 2 In a beaker and stirred until completely dissolved, the dissolved VO 2 Add the solution to the above g-C 3 N 4 Add oxalic acid to the solution to adjust the pH of the solution to 1, sonicate for 1h, then stir and evaporate at 80°C until the solution becomes a paste, put the beaker in an oven and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com