Two-half type splicing water meter casing and processing method thereof

A shell and water meter technology, applied in measuring devices, liquid/fluid solid measurement, instruments, etc., can solve the problems affecting the appearance and product quality of water meter products, poor surface roughness of product appearance, and low yield of blanks, etc. The appearance is novel and bright, the surface of the product is as smooth as a mirror, and the process is simple and environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

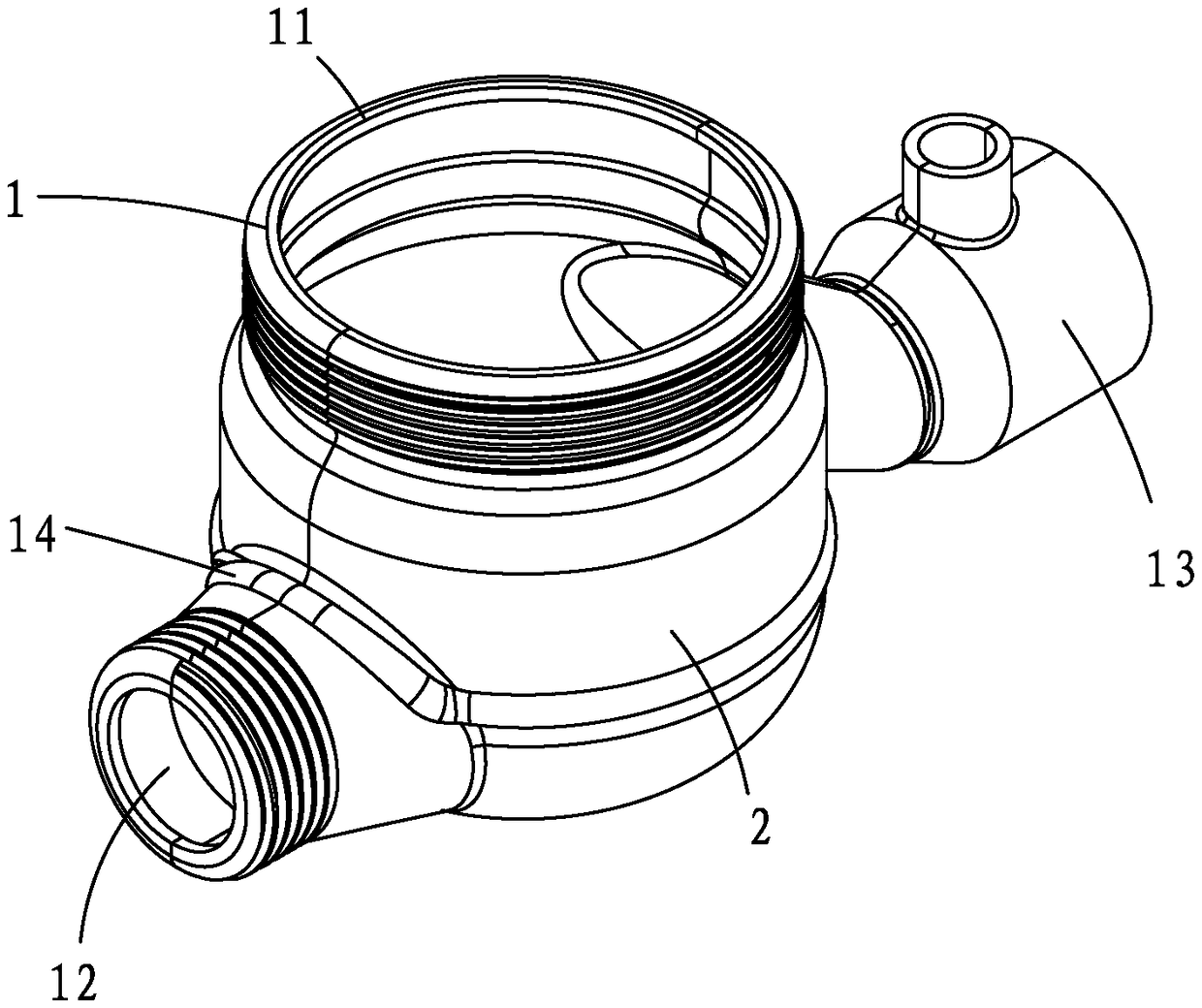

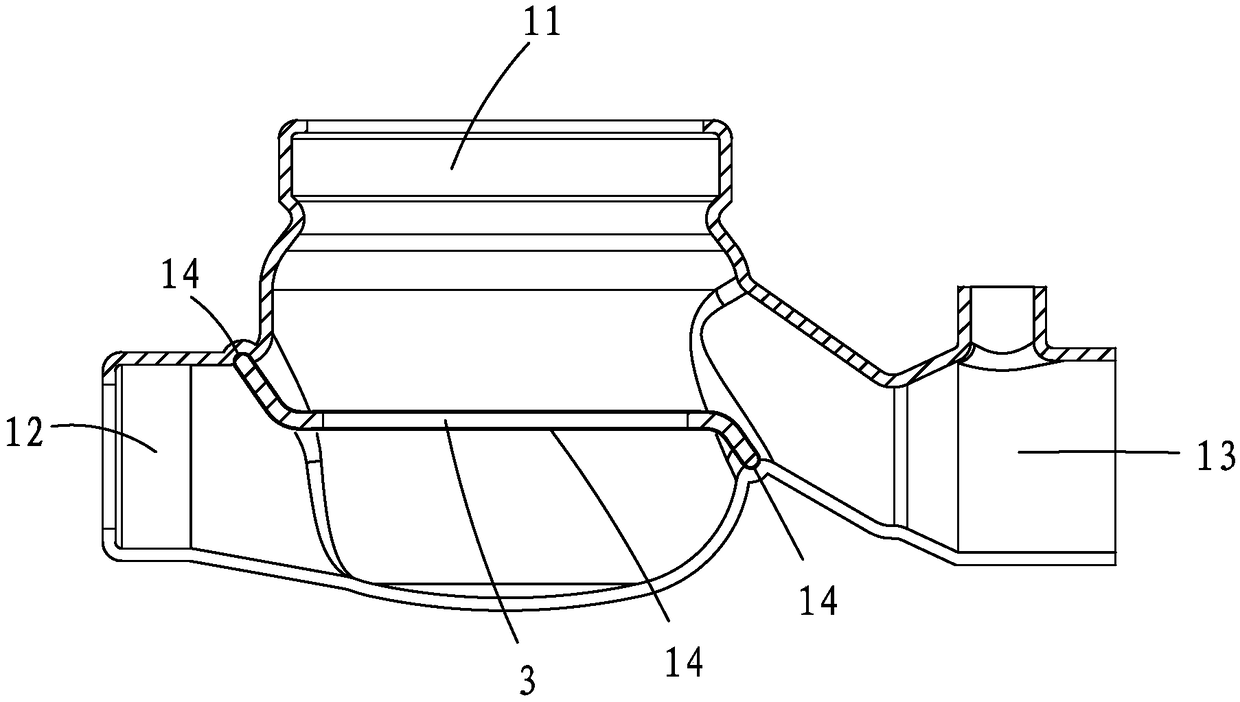

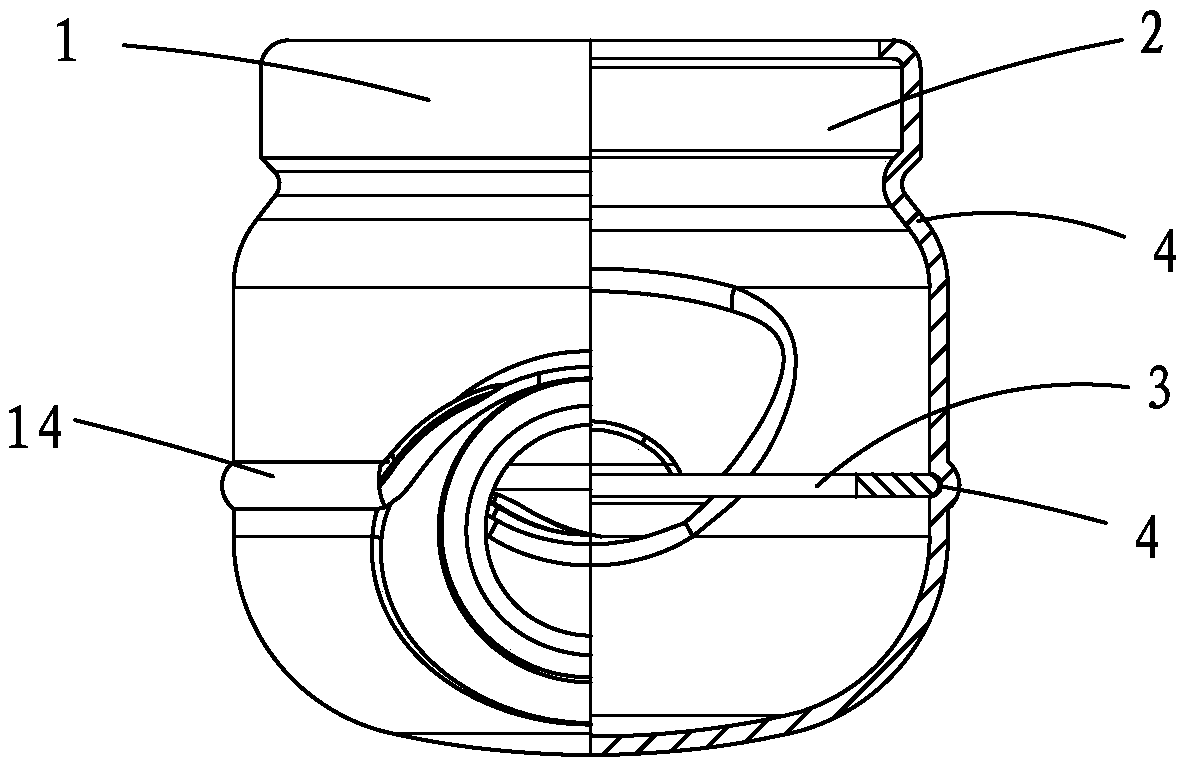

[0026] Take the valve-controlled water meter housing as an example, such as figure 1 - Figure 5 As shown, a two-half assembled water meter housing includes a left cavity 1, a right cavity 2 and a water baffle 3. The left cavity 1 and the right cavity 2 are matched with each other, and both include integrally formed The middle shell 11, the water inlet 12 and the water outlet 13; the inner walls of the left cavity 1 and the right cavity 2 are provided with matching baffle positioning grooves 14, when the left cavity 1 1. When the right cavity 2 and the water baffle 3 are assembled, all the edges of the water baffle 3 are engaged in the positioning groove 14 of the water baffle, so that the water baffle 3 is sealed and installed In the casing; the water baffle 3 separates the entire water meter casing into upper and lower chambers, so that water can only enter the lower chamber through the water inlet 12 to flow upward, and then flow out through the water outlet 13 .

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com