A process for recycling valuable metals in waste lead-acid battery lead paste by using iron powder and cone glass

A technology for waste lead-acid batteries and valuable metals, applied in the field of lead paste recycling and treatment, can solve the problems of long process flow, sulfur pollution, large investment, etc., and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

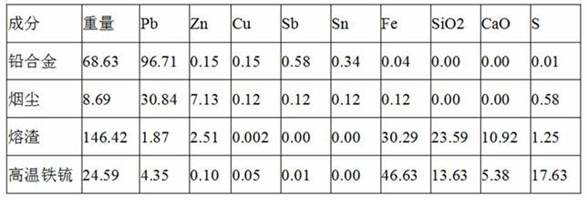

Embodiment 1

[0044] A process for recycling valuable metals in waste lead-acid storage battery lead paste by utilizing iron powder and cone glass, comprising the following steps:

[0045] S1. Material crushing: crush the conical glass in a pulverizer to obtain conical glass powder;

[0046] S2. Material mixing: Take the lead paste of waste lead-acid batteries from a battery dismantling factory in Ganluo, add goethite slag, cone glass powder, and limestone, mix them with a double-girder grab bridge crane, ferment and solidify for more than 24 hours, and get curing material;

[0047] S3. Press bricks to make blanks: After stirring the solidified materials in a double-shaft mixer, put them into a fully automatic forming static press to pressurize 8000kN to press bricks to make blanks, and then put them into a fully automatic palletizing conveyor for palletizing , stacked at room temperature for 3 days to carry out the brick curing reaction to obtain bricks;

[0048]S4. Reduction smelting in...

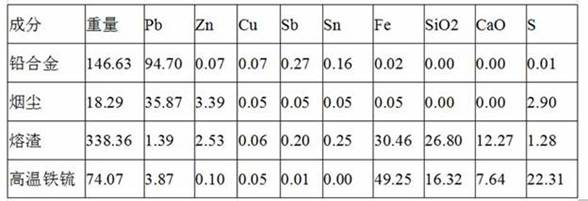

Embodiment 2

[0051] A process for recycling valuable metals in waste lead-acid storage battery lead paste by utilizing iron powder and cone glass, comprising the following steps:

[0052] S1. Material crushing: crush the conical glass in a pulverizer to obtain conical glass powder;

[0053] S2. Material mixing: Take the waste lead-acid battery lead paste from a battery dismantling factory in Ganluo, add goethite slag, cone glass powder, and limestone, mix it with a double-girder grab bridge crane, ferment and solidify for more than 24 hours, and get curing material;

[0054] S3. Press bricks to make blanks: After stirring the solidified materials in a double-shaft mixer, put them into a fully automatic forming static press and pressurize them at 9000kN to press bricks to make blanks, and then put them into a fully automatic palletizing conveyor for palletizing , stacked at room temperature for 5 days to carry out the brick curing reaction to obtain bricks;

[0055] S4. Reduction smelting...

Embodiment 3

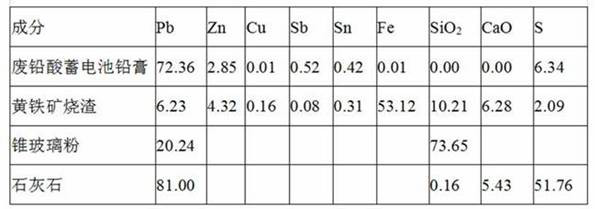

[0058] A process for recycling valuable metals in waste lead-acid storage battery lead paste by utilizing iron powder and cone glass, comprising the following steps:

[0059] S1. Material crushing: crush the conical glass in a pulverizer to obtain conical glass powder;

[0060] S2. Material mixing: Take the waste lead-acid battery lead paste from a battery dismantling factory in Ganluo, add pyrite slag, cone glass powder, and limestone, mix with a double-girder grab bridge crane, ferment and solidify for more than 24 hours, obtain solidified material;

[0061] S3. Brick making: After stirring the solidified material in a twin-shaft mixer, put it into a fully automatic forming static press and pressurize it to 10,000kN to make bricks, and then put it into a fully automatic palletizing conveyor for palletizing , stacked at room temperature for 7 days to carry out the brick curing reaction to obtain bricks;

[0062] S4. Reduction smelting in the sulfur-fixing furnace: put the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com