Method for preparing sweetening agent sucralose by one-pot process

A technology of sucralose and sucrose, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of difficult intermediate product purification, complicated operation process, and inconvenient operation, and achieve the improvement of industrial production level, The process is simple and environmentally friendly, and the effect of reducing wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

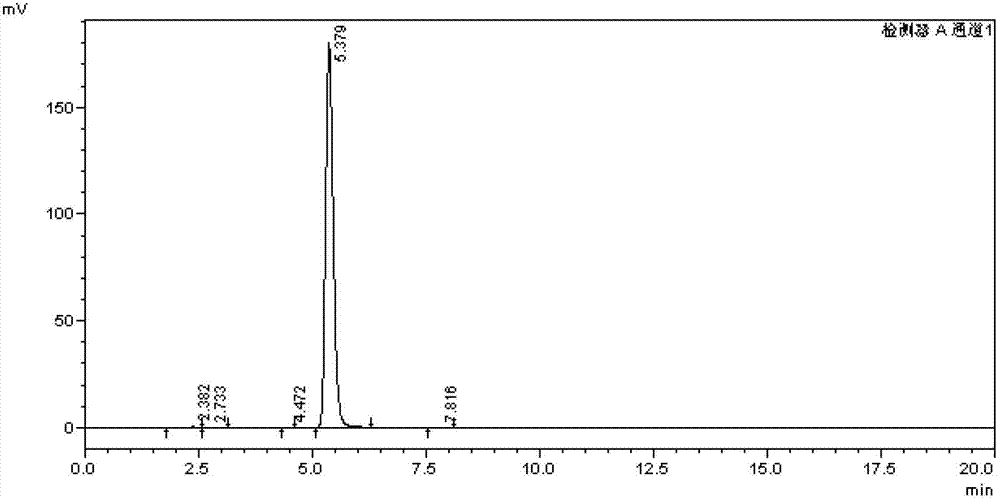

[0043] Under nitrogen protection, 200 g of N,N-dimethylformamide, 34.2 g (0.1 mol) of sucrose, and 0.14 g of p-toluenesulfonic acid were sequentially added to a dry 1000 ml glass flask. Keep at 0°C-10°C, add 2.31g (0.034mol) boric anhydride in batches, keep warm at 10°C-20°C for 3 hours, liquid phase detection of sucrose conversion is complete; then cool in ice water, keep at 0°C-10°C, add dropwise 39.3 grams (0.33 moles) of thionyl chloride, after dropping, the reaction was heated up in stages, stirred at 20°C to 30°C for 2 hours, 70°C to 90°C for 2 hours, 120°C to 150°C for 3 hours, About 150 g of solvent was recovered by distillation under reduced pressure, and cooled to room temperature. Add 120 grams of saturated sodium chloride aqueous solution, stir and hydrolyze at room temperature for 3 hours; add ethyl acetate for extraction three times, share 130 grams of ethyl acetate, combine the organic phases, wash twice with 30 grams of saturated sodium chloride aqueous solutio...

Embodiment 2

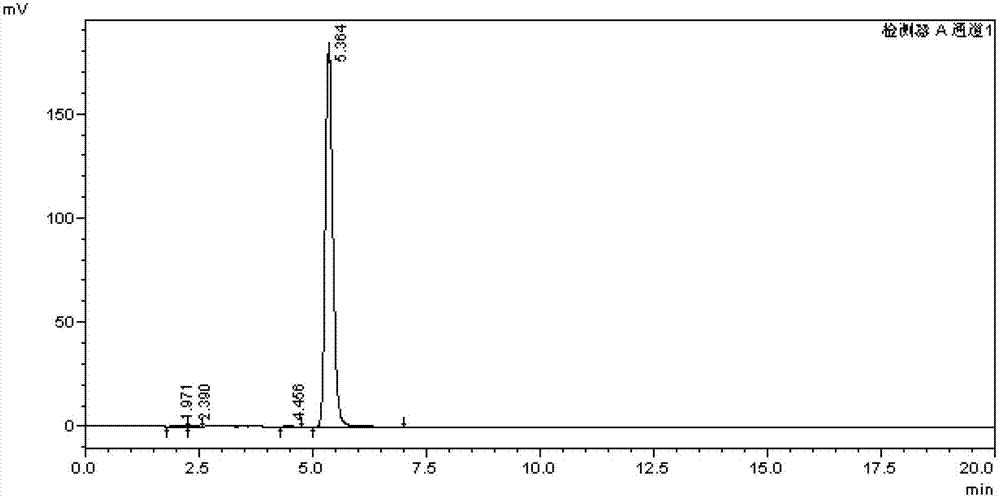

[0045] As described in Example 1, the difference is that the acid catalyst is selected from methanesulfonic acid, and 80 mg of methanesulfonic acid is used to replace 0.14 gram of p-toluenesulfonic acid in Example 1 to react, and the preparation steps and conditions are the same as in the implementation Example 1, the resulting product purity and yield are shown in Table 1.

Embodiment 3

[0047] As described in Example 1, the difference is that the acidic catalyst is selected from 98% vitriol oil, and 80 mg of 98% vitriol oil is used to replace 0.14 gram of p-toluenesulfonic acid in Example 1 to react, and the preparation steps and conditions are the same as in the implementation Example 1, the resulting product purity and yield are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com