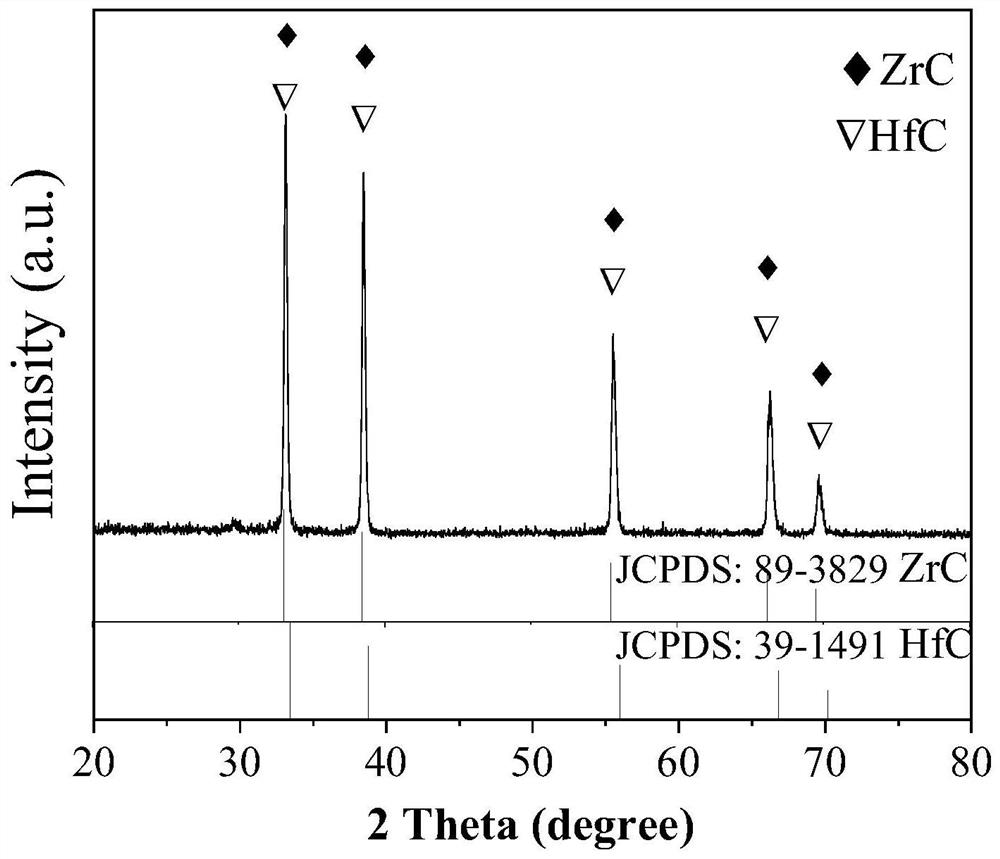

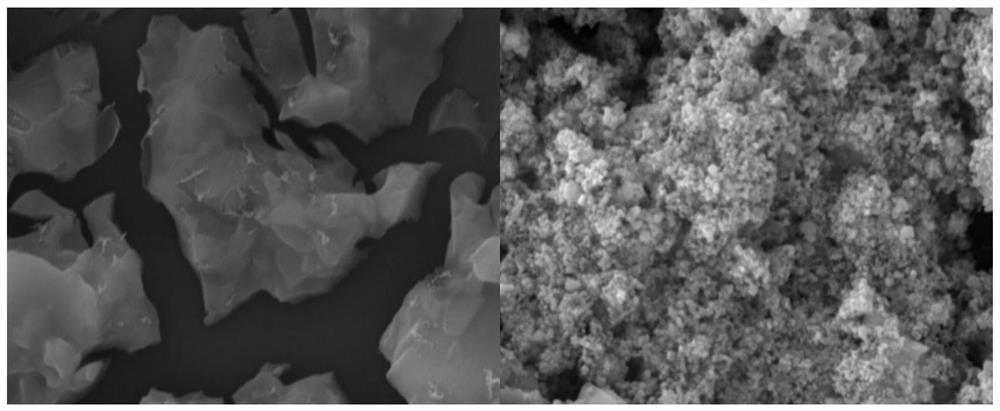

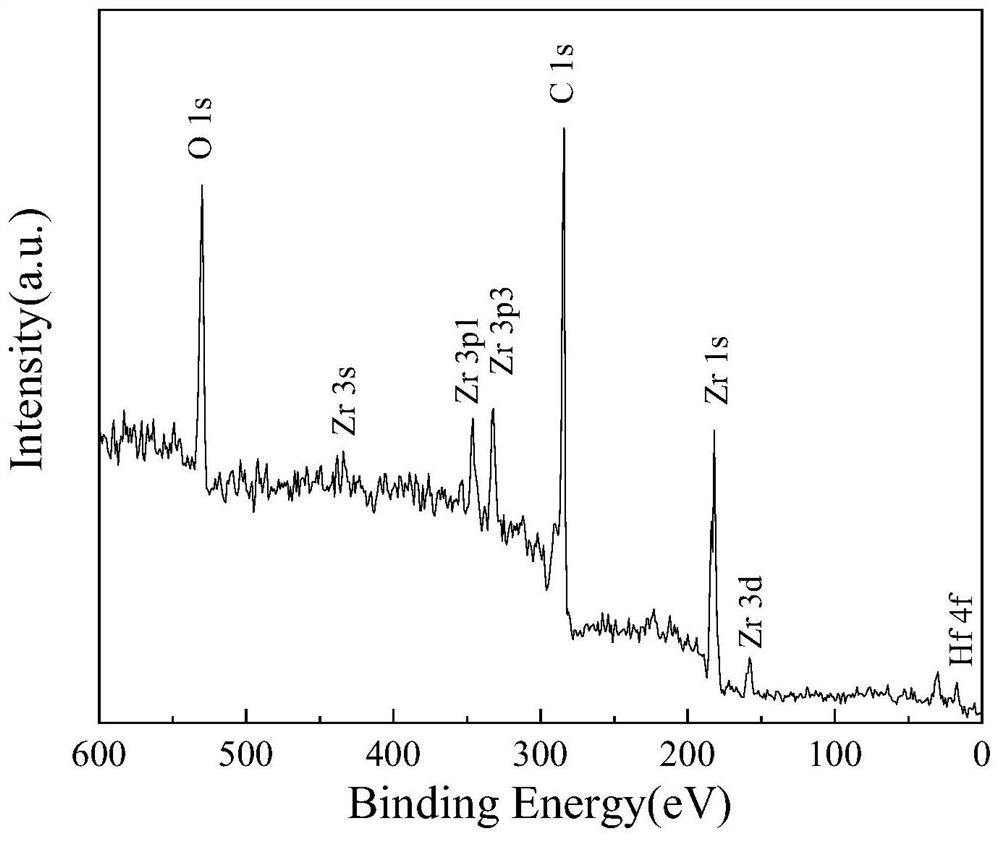

Preparation method of zirconium carbide/hafnium carbide nano composite particles

A nanocomposite, zirconium carbide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of large environmental pollution of intermediate products, complicated preparation process, etc., and achieve low cost and process. Simple, simple process and environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing zirconium carbide / hafnium carbide nanocomposite particles, specifically implemented according to the following steps:

[0034] Step 1, weigh 6.5g of ZrOCl 2 ·8H 2 O, add 20mL of deionized water, stir until completely dissolved to obtain a colorless transparent solution, and add 2.0g of glucose and 3.60g of HfOCl in turn to the colorless and transparent solution 2 Suspension, HfOCl 2 When adding the suspension, add it drop by drop, and get a white suspension solution 1 after stirring evenly;

[0035] Step 2. Weigh tartaric acid with a mass of 0.75 g, add 5 mL of deionized water, and stir until completely dissolved to obtain a colorless and transparent solution 2;

[0036] Step 3. Add the colorless and transparent solution 2 obtained in step 2 to the white suspension solution 1 obtained in step 1, and continue to stir for 30 minutes until the mixture is uniform, and obtain the white suspension solution 2;

[0037] Step 4. Perform rotary evaporat...

Embodiment 2

[0040] A method for preparing zirconium carbide / hafnium carbide nanocomposite particles, specifically implemented according to the following steps:

[0041] Step 1, weigh 8g of ZrOCl 2 ·8H 2 O, add 20mL deionized water, stir until completely dissolved to obtain a colorless and transparent solution, add 2.5g of glucose and 4.20g of HfOCl in turn to the colorless and transparent solution 2 Suspension, HfOCl 2 When adding the suspension, add it drop by drop, and get a white suspension solution 1 after stirring evenly;

[0042] Step 2. Weigh 1.00 g of tartaric acid, add 6 mL of deionized water, and stir until completely dissolved to obtain a colorless and transparent solution 2;

[0043] Step 3. Add the colorless and transparent solution 2 obtained in step 2 to the white suspension solution 1 obtained in step 1, and continue to stir for 30 minutes until the mixture is uniform, and obtain the white suspension solution 2;

[0044] Step 4. Rotate the white suspension solution 2 o...

Embodiment 3

[0047] A method for preparing zirconium carbide / hafnium carbide nanocomposite particles, specifically implemented according to the following steps:

[0048] Step 1, weigh 9.0g of ZrOCl 2 ·8H 2 O, add 25mL of deionized water, stir until completely dissolved to obtain a colorless transparent solution, and add 3.0g of glucose and 4.80g of HfOCl in turn to the colorless and transparent solution 2 Suspension, HfOCl 2 When adding the suspension, add it drop by drop, and get a white suspension solution 1 after stirring evenly;

[0049] Step 2. Weigh 1.25 g of tartaric acid, add 7 mL of deionized water, and stir until completely dissolved to obtain a colorless and transparent solution 2;

[0050] Step 3. Add the colorless and transparent solution 2 obtained in step 2 to the white suspension solution 1 obtained in step 1, and continue to stir for 30 minutes until the mixture is uniform, and obtain the white suspension solution 2;

[0051] Step 4. Perform rotary evaporation on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com