Composite reinforced fabric and its preparation method

A fabric and manufacturing technology, applied in the field of composite reinforced fabric and composite reinforced fabric manufacturing method, can solve the problems of loss of high strength, aging of hot melt adhesive layer, peeling of reinforced film from fabric, etc., and achieve the effect of complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

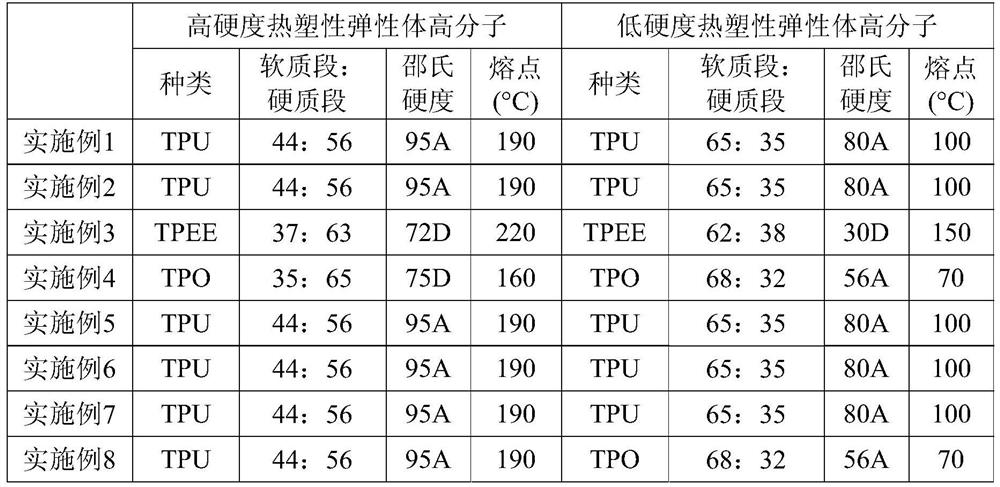

[0046] Embodiment 1 uses thermoplastic polyurethane (TPU) macromolecule as raw material, wherein a kind of raw material uses polyol (polyol) as soft segment, diisocyanate (diisocyanate) as hard segment, the soft segment of this raw material is relative to the hard segment The ratio is 44:56. Use this raw material to make high-hardness thermoplastic elastomer yarn (150D / 72F). The high-hardness thermoplastic elastomer yarn has a Shore hardness of 95A and a melting point of 190°C. In addition, another raw material uses polyol as the soft segment and diisocyanate as the hard segment. The ratio of the soft segment to the hard segment of this raw material is 65:35, and then the raw material is used to make low hardness thermoplastic Elastomer yarn (150D / 72F), the low-hardness thermoplastic elastomer yarn has a Shore hardness of 80A and a melting point of 100°C.

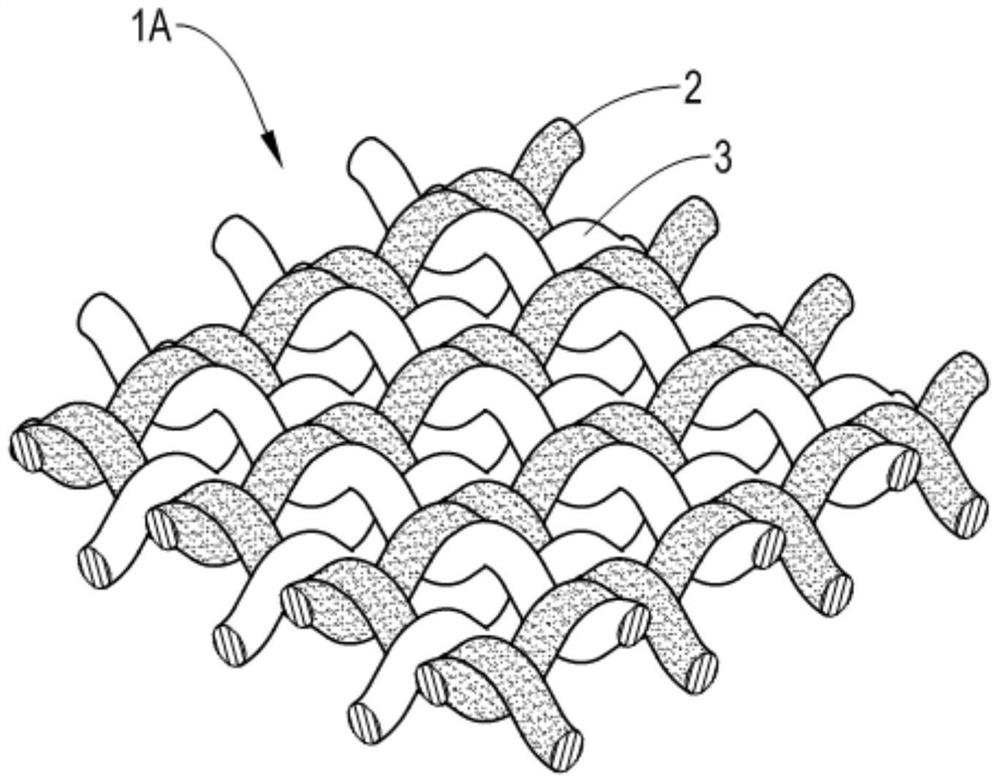

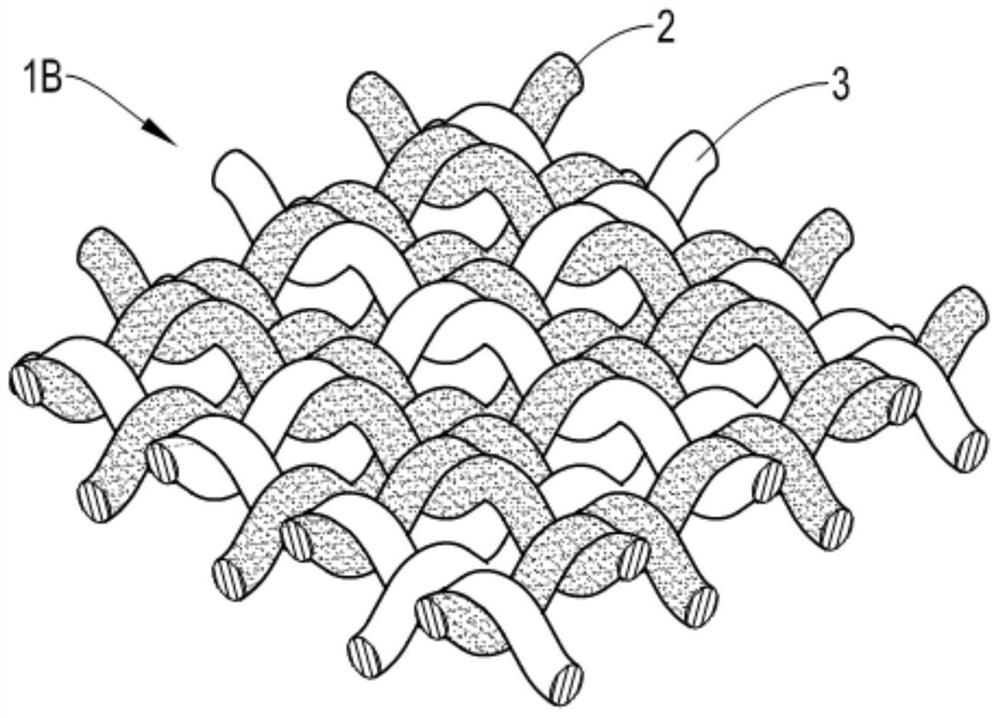

[0047] Next, use the above-mentioned high and low hardness thermoplastic elastomer yarns to weave into a fabric with a si...

Embodiment 2

[0051] Example 2 uses thermoplastic polyurethane (TPU) polymers as raw materials, one of which uses polyol as the soft segment and diisocyanate as the hard segment, and the ratio of the soft segment to the hard segment of the raw material is 44:56 , use this raw material to make high-hardness thermoplastic elastomer yarn (150D / 72F), the Shore hardness of this high-hardness thermoplastic elastomer yarn is 95A, and the melting point is 190°C. In addition, another raw material uses polyol as the soft segment and diisocyanate as the hard segment. The ratio of the soft segment to the hard segment of this raw material is 65:35, and then the raw material is used to make low hardness thermoplastic Elastomer yarn (150D / 72F), the low-hardness thermoplastic elastomer yarn has a Shore hardness of 80A and a melting point of 100°C.

[0052] Next, use the above-mentioned high and low hardness thermoplastic elastomer yarns to weave into a fabric with a size of 21cm×30cm at a ratio of 2:1. The...

Embodiment 3

[0056] Embodiment 3 uses thermoplastic polyester polyether elastomer (TPEE) macromolecule as raw material, wherein a kind of raw material uses aliphatic polyester as soft segment, aromatic crystalline polyester as hard segment, the soft segment of this raw material The ratio of segment to hard segment is 37:63. Use this raw material to make high-hardness thermoplastic elastomer yarn (150D / 72F). The Shore hardness of this high-hardness thermoplastic elastomer yarn is 72D and the melting point is 220°C. In addition, another raw material uses aliphatic polyester as the soft segment and aromatic crystalline polyester as the hard segment. The ratio of the soft segment to the hard segment of this raw material is 62:38. The filaments were made into a low-hardness thermoplastic elastomer yarn (150D / 72F). The low-hardness thermoplastic elastomer yarn had a Shore hardness of 30D and a melting point of 150°C.

[0057] Next, use the above-mentioned high and low hardness thermoplastic ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com