Corrosion inhibitor for pickling of copper and alloys thereof and preparation method of corrosion inhibitor

A technology of alloy acid and corrosion inhibitor, which is applied in the field of corrosion inhibitor for copper and copper alloy pickling and its preparation, can solve the problems that are difficult to meet environmental protection, low toxicity and low cost, difficult to achieve the corrosion inhibition effect of pickling, difficult Solved organic matter instability and other problems, to achieve the effect of low cost, good corrosion inhibition effect, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

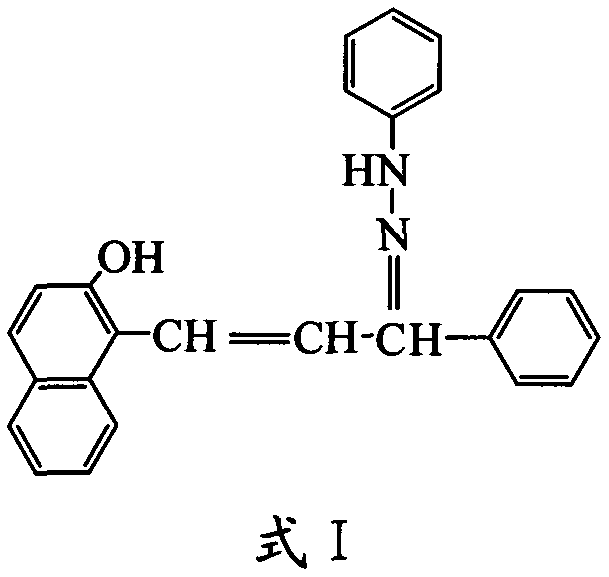

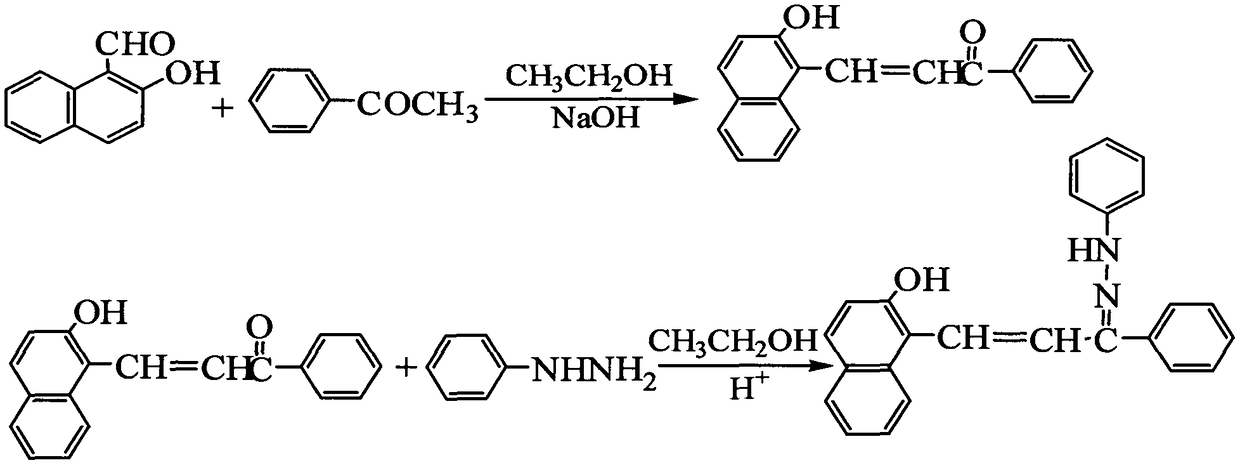

[0028]A phenylhydrazone Schiff base is a corrosion inhibitor for pickling copper and its alloys, which is a core corrosion inhibitor component, and is composed of the following species by weight percentage (w%): acetophenone and 2-hydroxyl-1-naphthaldehyde condensate 2.0% of phenylhydrazone derivatives, 2.5% of citric acid, 0.5% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), and 95.0% of water.

[0029] This phenylhydrazone Schiff base is the preparation method of corrosion inhibitor for copper and its alloy pickling with the core corrosion inhibition component as follows: at room temperature, take 25g of citric acid according to the above ratio and add it to a mixing tank, stirring tank or tank, and then add 250g water, stirred to make it completely dissolved, then weighed 20 g of phenylhydrazone derivatives of acetophenone and 2-hydroxyl-1-naphthaldehyde condensate and added to the above-mentioned aqueous solution of citric acid, and finally added 5 g of AES and...

Embodiment 2

[0032] A phenylhydrazone Schiff base is a corrosion inhibitor for pickling copper and its alloys, which is a core corrosion inhibitor component, and is composed of the following species by weight percentage (w%): acetophenone and 2-hydroxyl-1-naphthaldehyde condensate 3.0% of phenylhydrazone derivatives, 1.5% of acetic acid, 0.5% of sodium lauryl sulfate (K12), and 95.0% of water.

[0033] The phenylhydrazone Schiff base is the preparation method of copper and its alloy pickling corrosion inhibitor of the core corrosion inhibition component as follows: at room temperature, take by weighing 15g acetic acid according to the above ratio and add it to a mixing kettle, a stirring tank or a tank, add 200g water, Stir and miscible, then weigh 30g of the phenylhydrazone derivative of the condensate of acetophenone and 2-hydroxy-1-naphthaldehyde and add it to the above-mentioned aqueous solution of acetic acid, then add 5g of sodium lauryl sulfate (K12) and the remaining Water 750g, st...

Embodiment 3

[0036] A phenylhydrazone Schiff base is a corrosion inhibitor for pickling copper and its alloys, which is a core corrosion inhibitor component, and is composed of the following species by weight percentage (w%): acetophenone and 2-hydroxyl-1-naphthaldehyde condensate 3.2% of phenylhydrazone derivatives, 5.0% of ethanol, 0.8% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), and 91.0% of water.

[0037] The phenylhydrazone Schiff base is the preparation method of the copper and its alloy pickling corrosion inhibitor of the core corrosion inhibition component as follows: at room temperature, take 50g of ethanol according to the above ratio and add it to a mixing tank, stirring tank or tank, add 300g of water, Stir to dissolve it completely, then weigh 32Kg of the phenylhydrazone derivative of the condensate of acetophenone and 2-hydroxy-1-naphthaldehyde, add it to the above aqueous solution of citric acid, then add 8g of AES and the remaining water 610g, and stir even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com