Oxygen carrier of chemical-looping combustion and preparation method and application thereof

A technology of chemical chain combustion and oxygen carrier, which is used in fuels, fuel additives, petroleum industry and other directions, can solve the problems of low dispersion of metal oxides, large pressure drop in the reaction bed, and low cyclic reactivity, etc. The method is simple and easy to implement, improves the utilization rate, and improves the effect of circulating oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 20ml of styrene, add dropwise to 110mL of deionized water and 60mL of anhydrous ethanol solution, stir while adding dropwise, after uniform, add 10mL of initiator, the concentration of sodium persulfate in the initiator is 0.068mol / L. After stirring at 70°C for 24 hours, it was placed in a drying oven to dry for 12 hours. The template was heat-treated at 110 °C for 10 minutes to enhance the mechanical strength of the template.

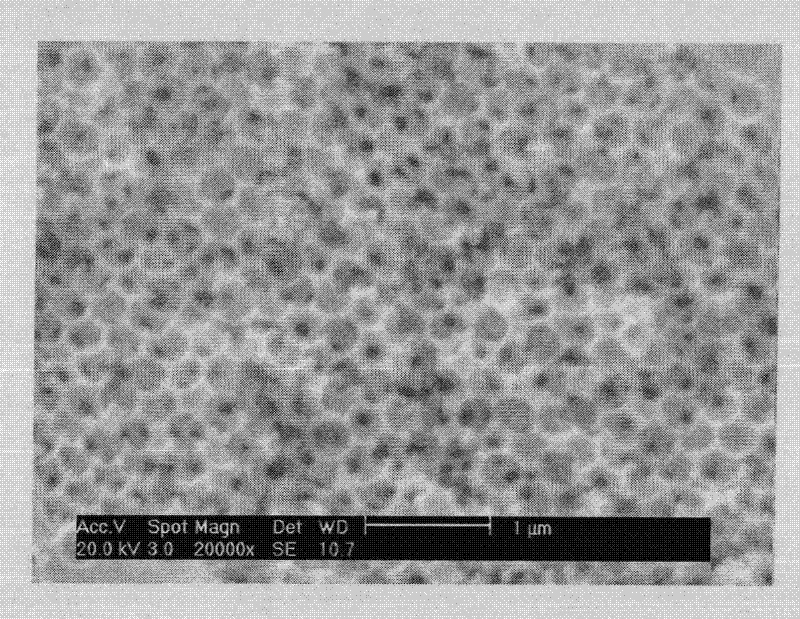

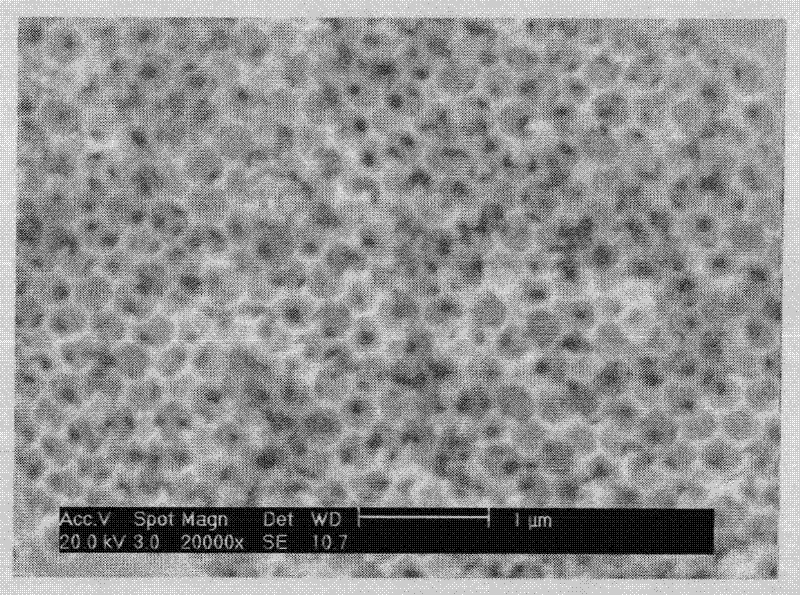

[0024] Take 18.31gCe (NO 3 ) 3 ·6H 2 O, added to 40 mL of absolute ethanol, then added 4.4 g of citric acid, and stirred until a transparent color was obtained. The polystyrene template was immersed in the solution, vacuumed after 5 minutes, and dried in a drying oven at 70°C for 2 hours. Then repeat the above impregnation-pumping rate-drying process 4 times, and then program the temperature to 800°C at 2°C / min in a tubular muffle furnace, and calcinate at a constant temperature for 4 hours to obtain three-dimensional ordered macroporou...

Embodiment 2

[0028] According to the preparation steps in Example 1, the concentration of iron nitrate was changed to 1 mol / L, and the mass content of iron oxide was 11.6 wt%. The chemical chain combustion reaction performance test was carried out with this catalyst, and the test conditions were the same as those in Example 1. H 2 The conversion was 99% and the CO conversion was 96%.

Embodiment 3

[0030] According to the preparation steps in Example 1, the concentration of iron nitrate was changed to 2 mol / L, and the mass content of iron oxide was 20.9 wt%. The chemical chain combustion reaction performance test was carried out with this catalyst, and the test conditions were the same as those in Example 1. H 2 The conversion was 98% and the CO conversion was 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com