Rotary hearth furnace

A technology of rotary hearth furnace and furnace width, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve problems such as disadvantage, reduced radiant energy space, and inability to radiate energy supply, etc., to promote combustion and improve heat generation. , the effect of shortening the uniform mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in more detail based on the embodiments shown in the drawings.

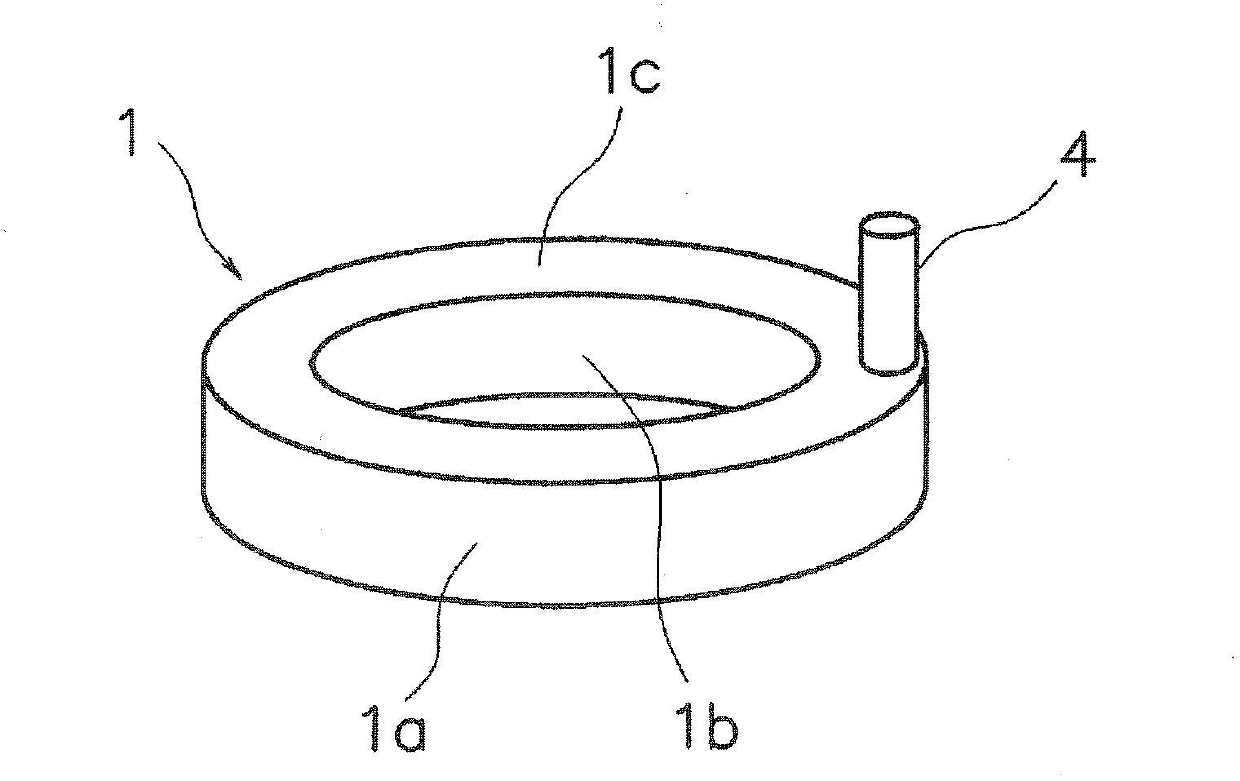

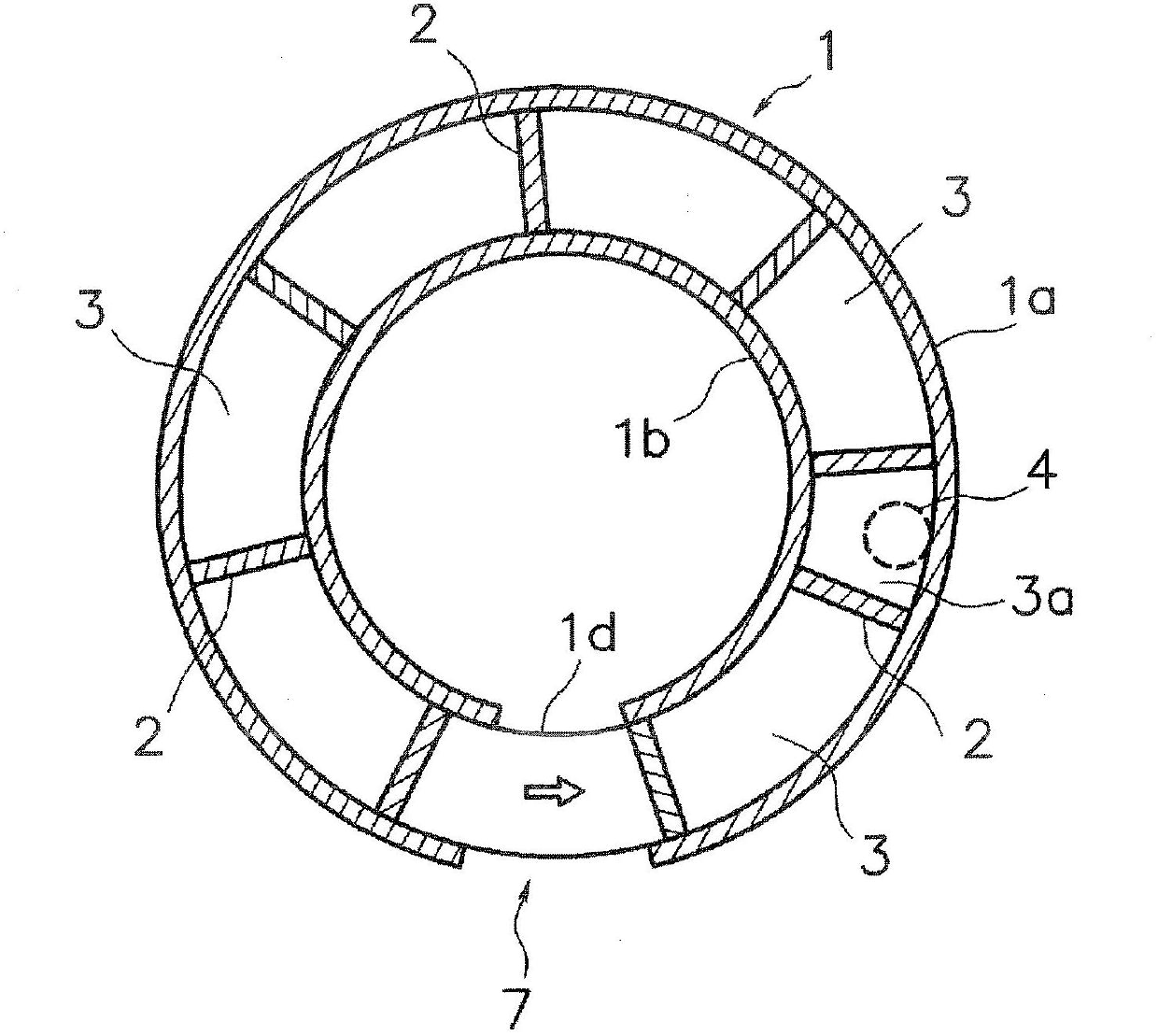

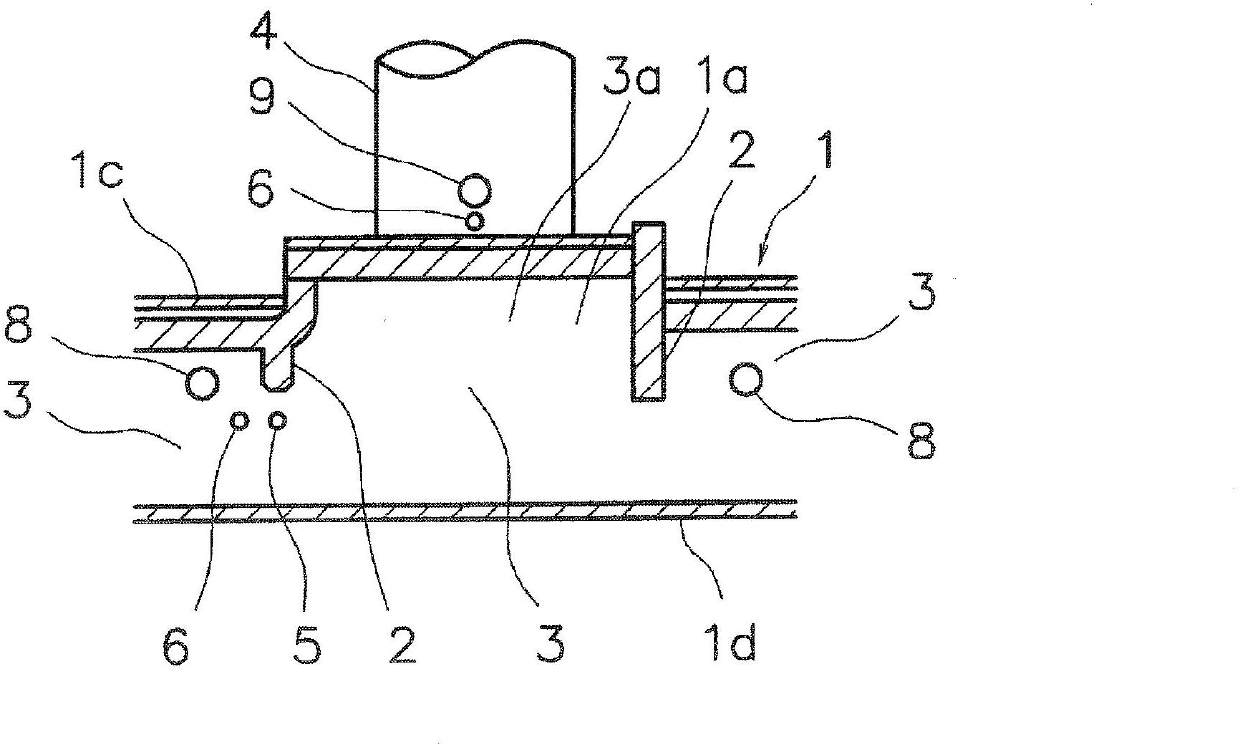

[0029] For example, if Figure 1 ~ Figure 3 As shown, the rotary hearth hearth furnace 1 of the present invention has a substantially rectangular longitudinal section and is formed in a hollow ring shape, including: an annular outer peripheral wall 1a; with a slightly smaller radius of curvature than the outer peripheral wall 1a An annular inner peripheral wall 1b; an annular plate-shaped top 1c arranged on the upper surface covering between the outer peripheral wall 1a and the inner peripheral wall 1b; The surface of the circular plate-shaped rotary hearth 1d. The rotary hearth furnace 1, especially the outer peripheral wall 1a, the inner peripheral wall 1b, and the ceiling 1c are formed of a refractory material having heat insulating properties.

[0030] In addition, a plurality of vertical walls 2 hang down from the lower surface of the annular plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com