Steam enhanced double piston cycle engine

a double-piston cycle engine and double-piston technology, applied in the direction of positive displacement engines, machines/engines, mechanical apparatus, etc., can solve the problems of inability to increase efficiencies, more than one-half of the potential fuel thermal energy created by conventional engines disperse through the engine structure without adding any useful mechanical work, etc., to facilitate efficient transfer of compressed gas, increase engine efficiency, and increase power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

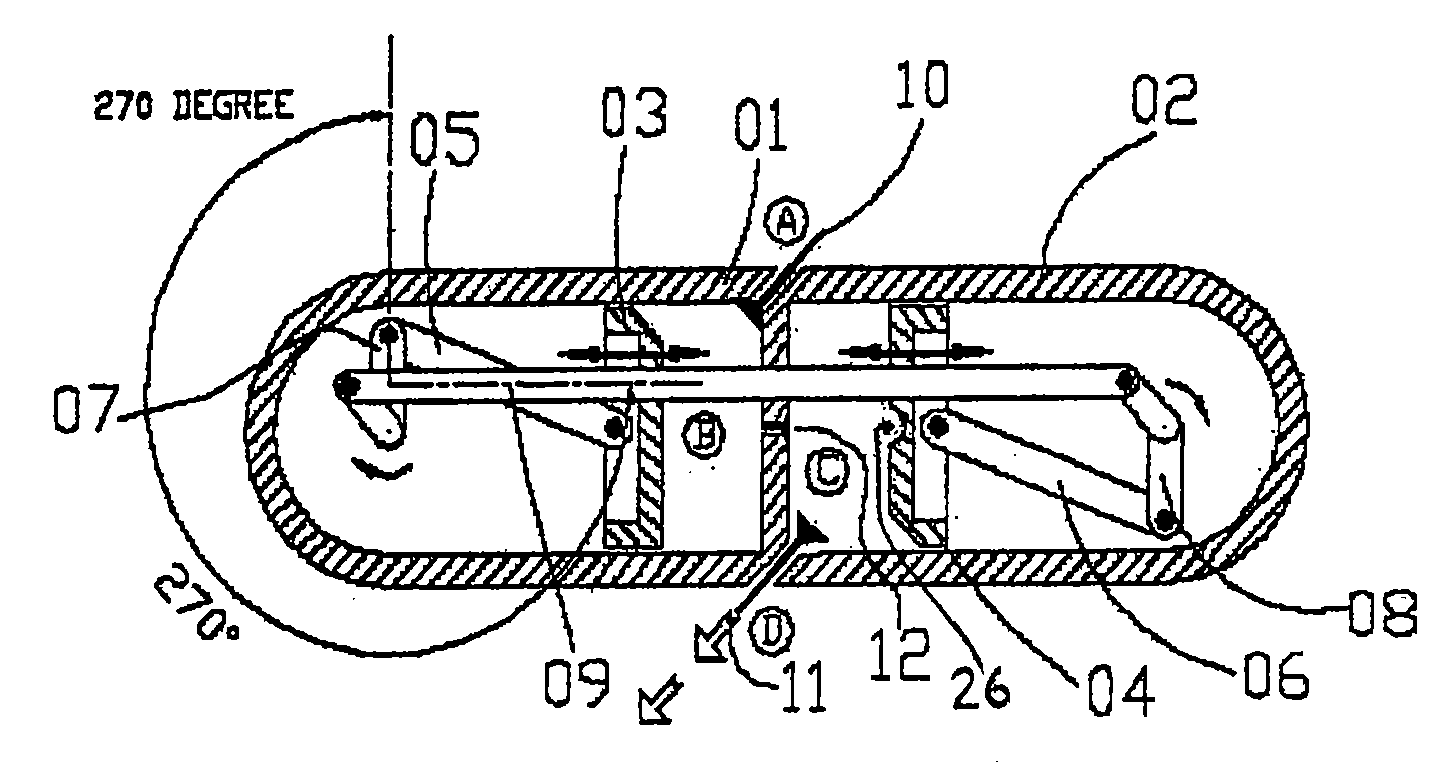

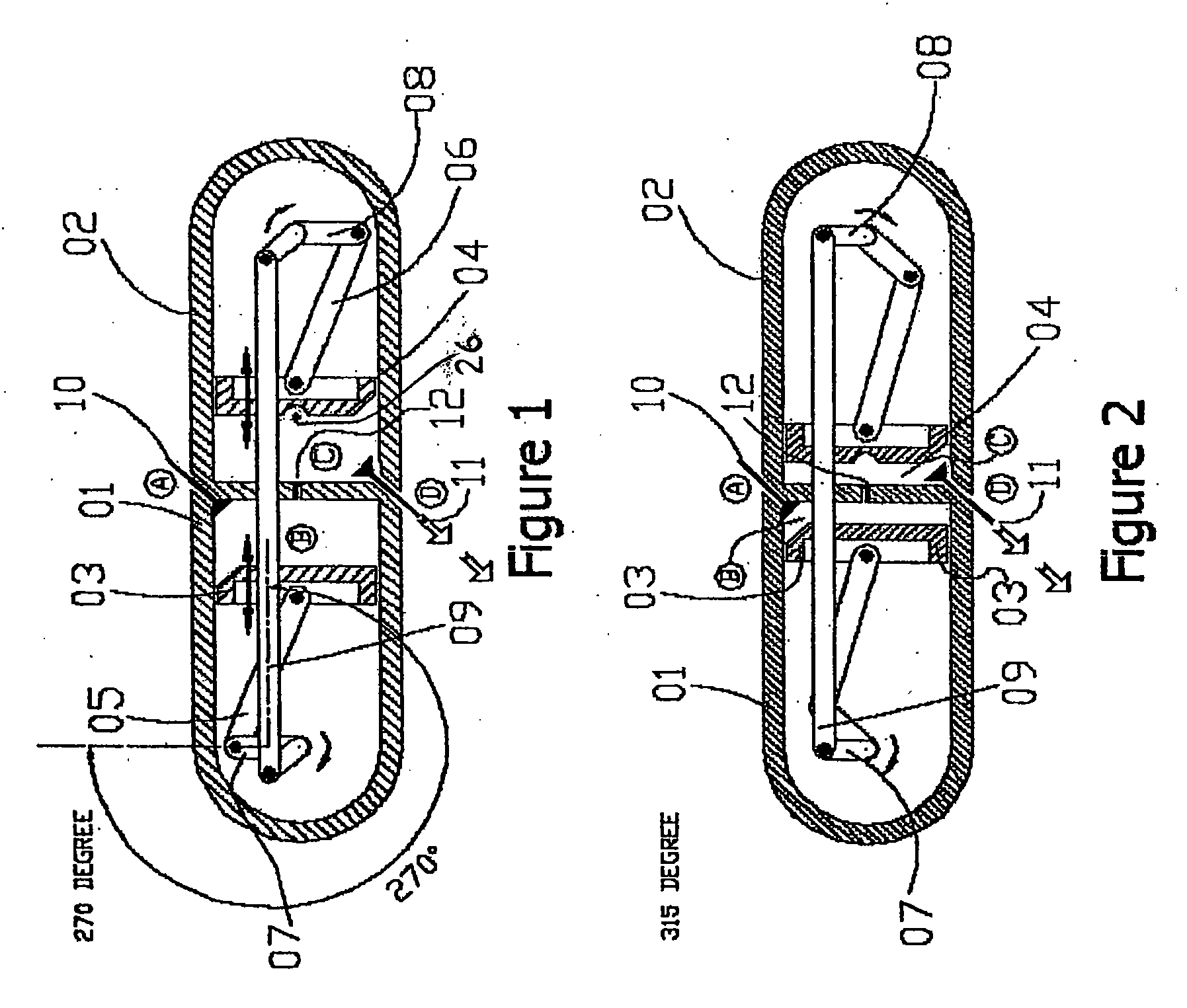

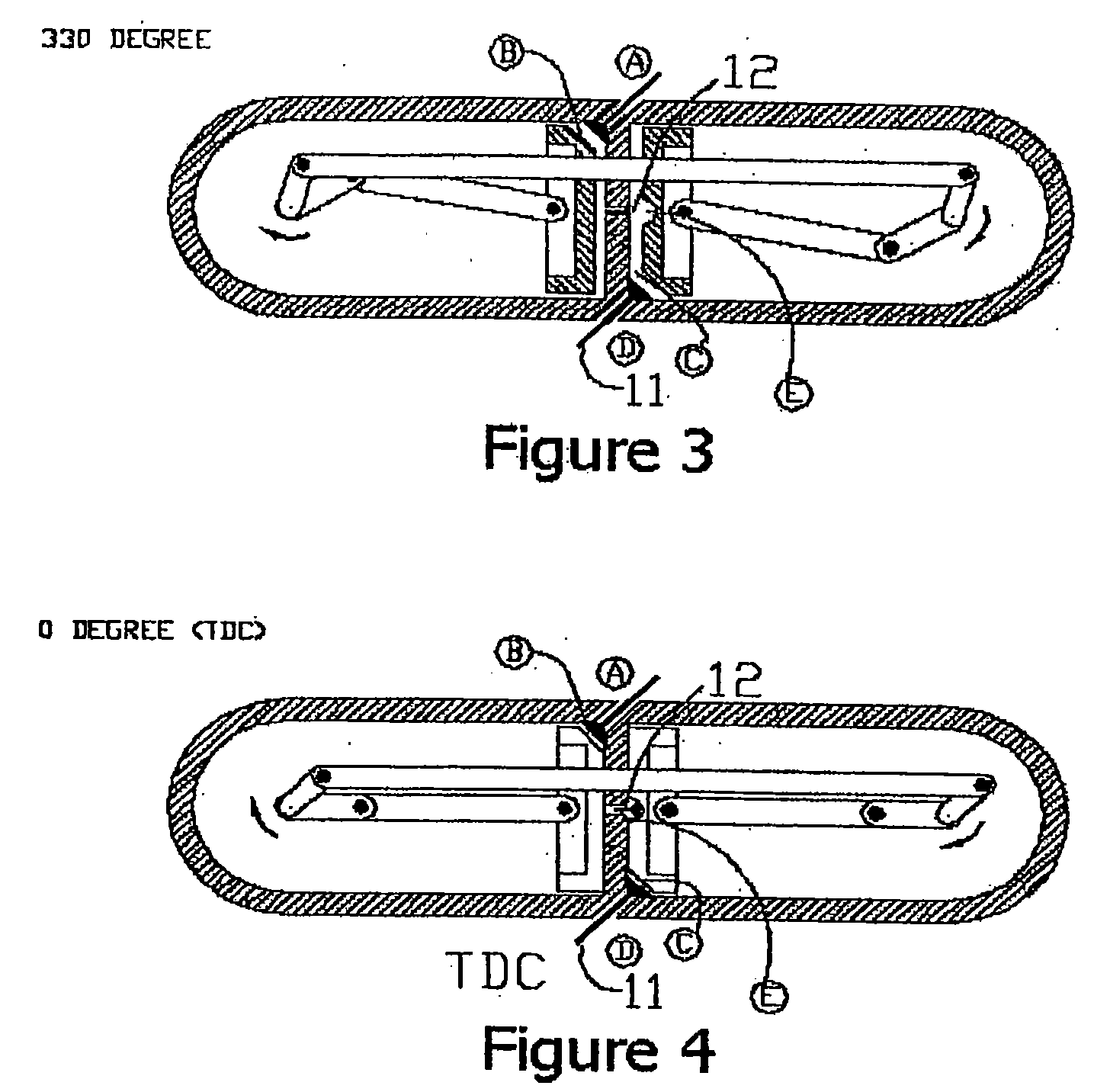

[0063] The invention is described in detail below with reference to the figures, wherein similar elements are referenced with similar numerals throughout. It is understood that the figures are not necessarily drawn to scale. Nor do they necessarily show all the details of the various exemplary embodiments illustrated. Rather, they merely show certain features and elements to provide an enabling description of the exemplary embodiments of the invention.

[0064] Referring to FIG. 1, in accordance with one embodiment of the invention, a DPCE cylinder includes: a compression cylinder 01, a power cylinder 02, a compression piston 03, a power piston 04, two respective piston connecting rods 05 and 06, a compression crankshaft 07, a power crankshaft 08, a crankshaft connecting rod 09, an intake valve 10, an exhaust valve 11 and an interstage valve 12. The compression cylinder 01 is a piston engine cylinder that houses the compression piston 03, the intake valve 10 and part of the interstage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com