Patents

Literature

103results about How to "Harmful emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

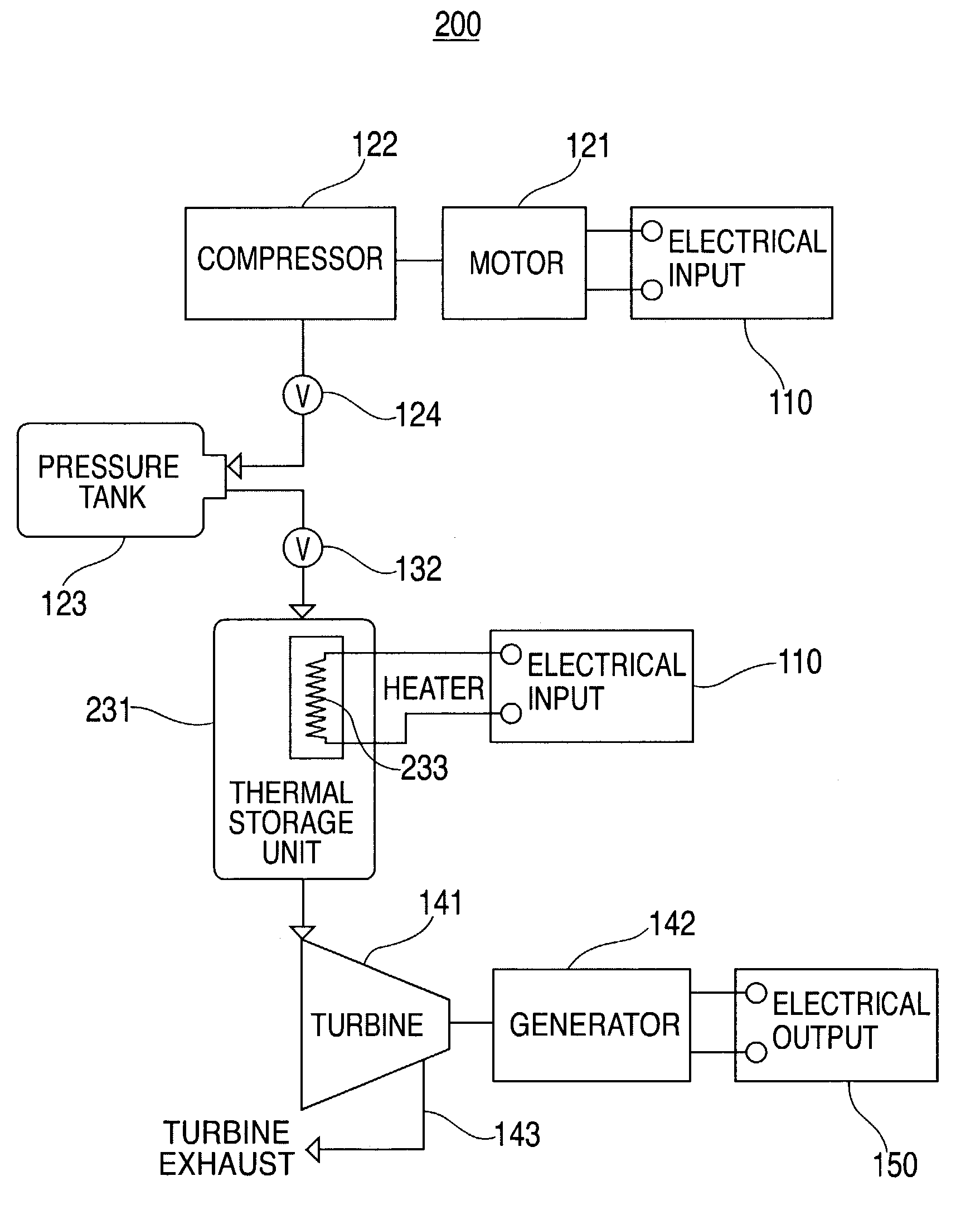

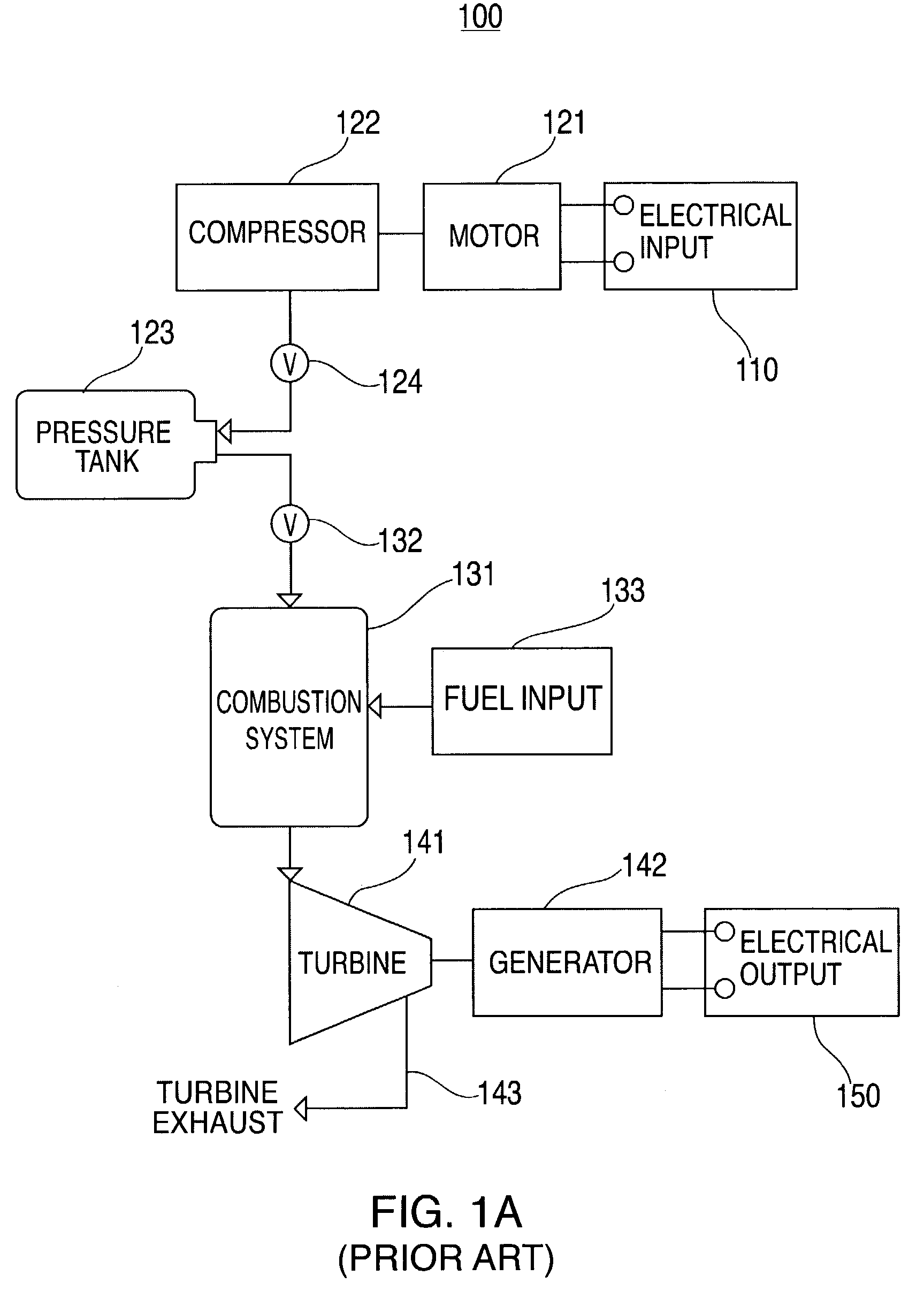

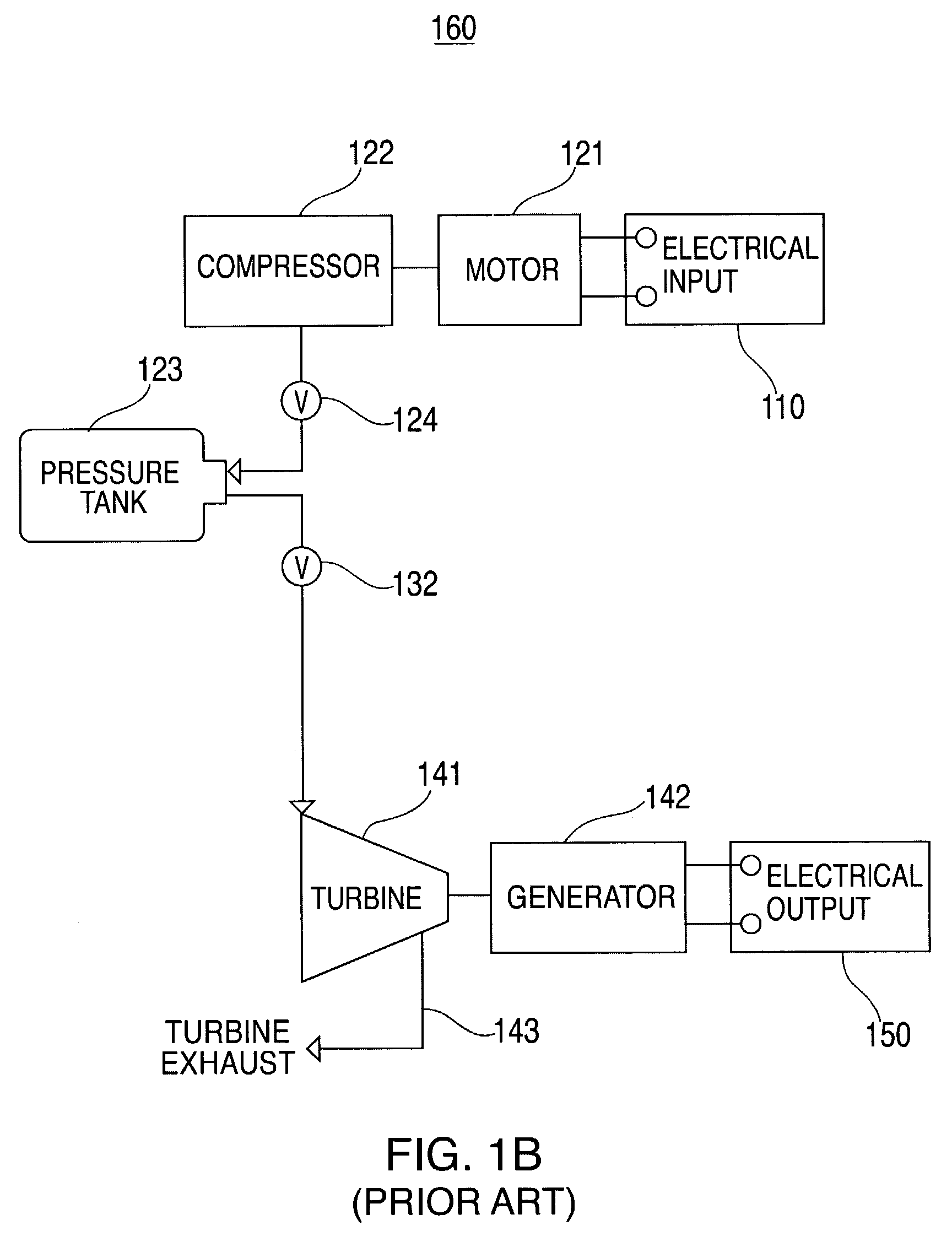

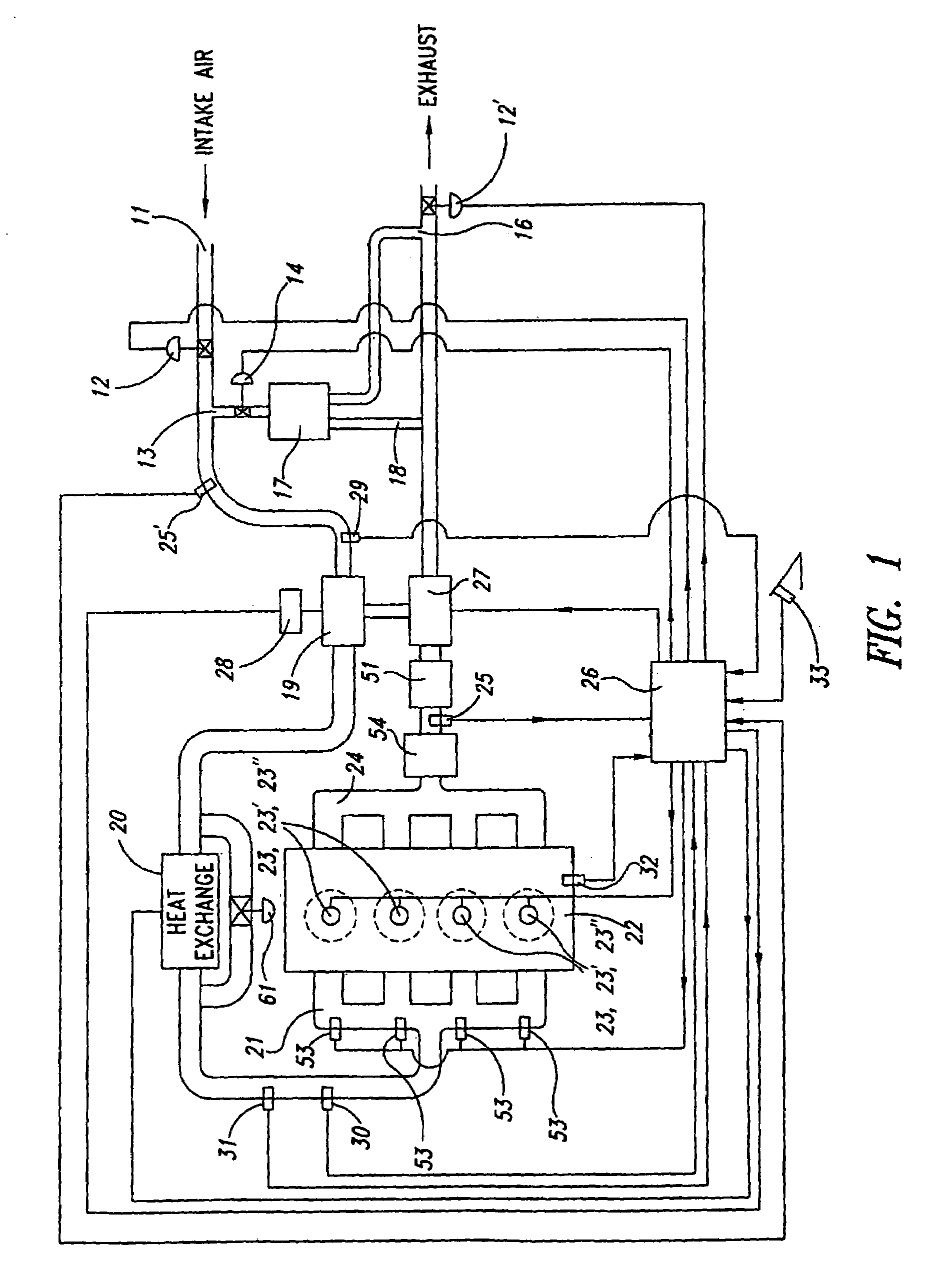

Thermal and compressed air storage system

InactiveUS7086231B2Improve efficiencyReduced point source pollutionHeat storage plantsSteam accumulatorsEngineeringTurbine

Combined thermal and compressed air storage systems are provided that utilize an exhaustless heater, such as a thermal storage unit, to provide power with enhanced efficiency. Compressed air is heated by the thermal storage unit prior to entering a turbine, which powers an electrical generator. In various embodiments, ambient air temperature, turbine exhaust or other types of waste heat are used to preheat the compressed air prior to the compressed air entering the thermal storage unit, thereby further increasing system efficiency.

Owner:P10 IND INC

Fuel additive composition and method for treatment of middle distillate fuels and gasoline

InactiveUS6923838B2Increase and improvement of performanceIncrease and improvement of and lubricityLiquid carbonaceous fuelsFuel additivesVegetable oilAntioxidant

A fuel additive for middle distillate fuels is a mixture of at least one methyl, ethyl, propyl or butyl ester of a vegetable oil or a C16-C18 fatty acid, at least one alkyl ether of propylene glycol, a surfactant, and an antioxidant. A fuel additive for gasoline is a mixture of ligroin or toluene / xylene, at least one alkyl ether of propylene glycol, a surfactant, and tertiary amyl methyl ether.

Owner:ADVANCED COMBUSTION TECH

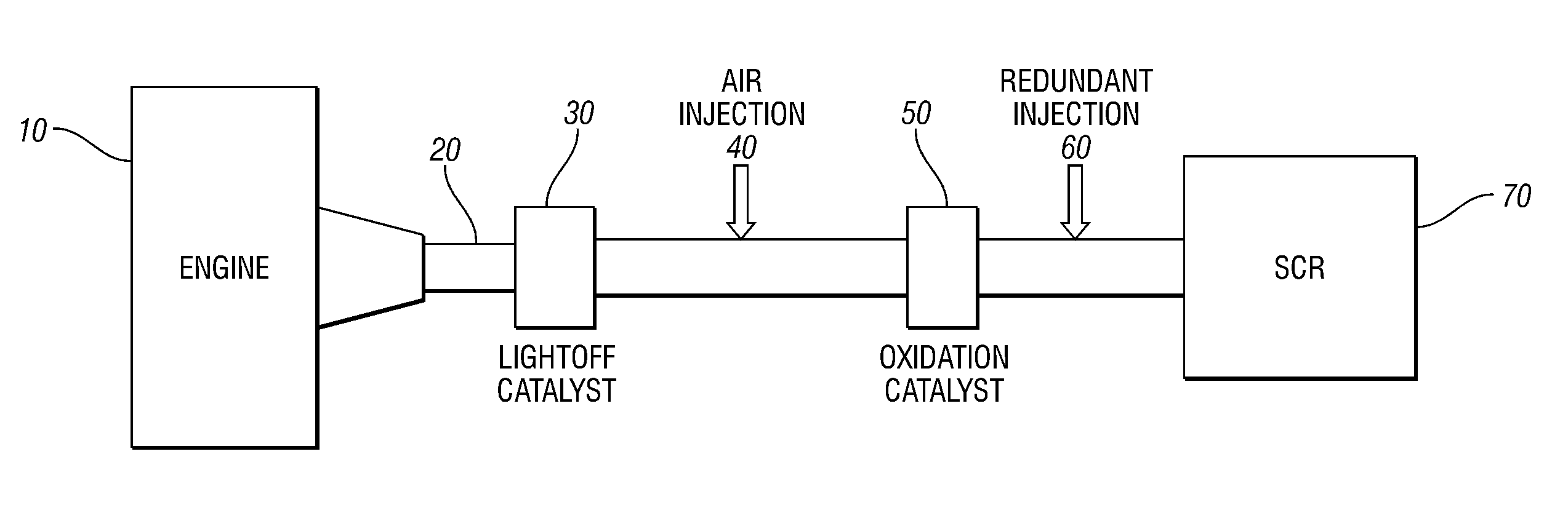

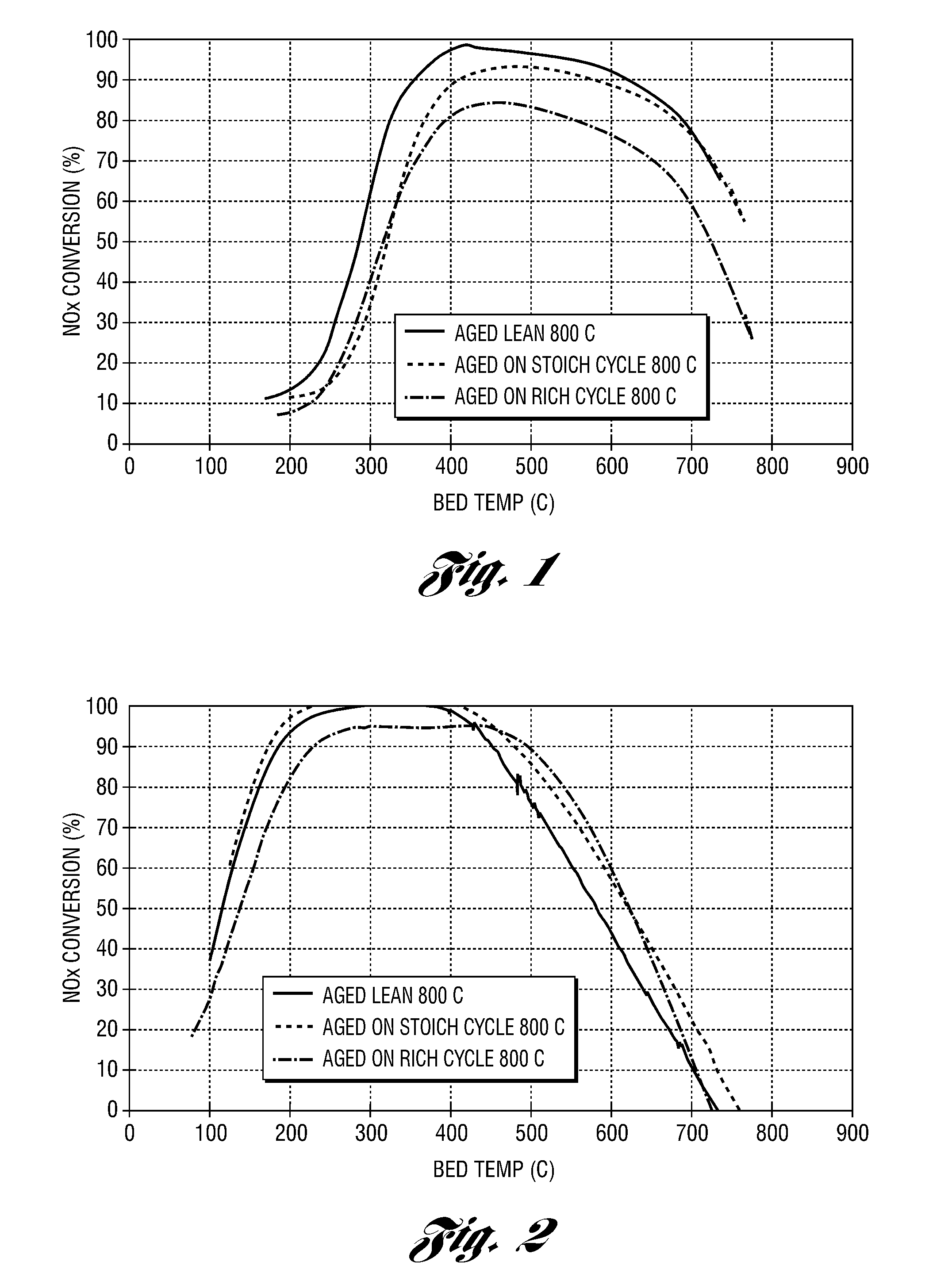

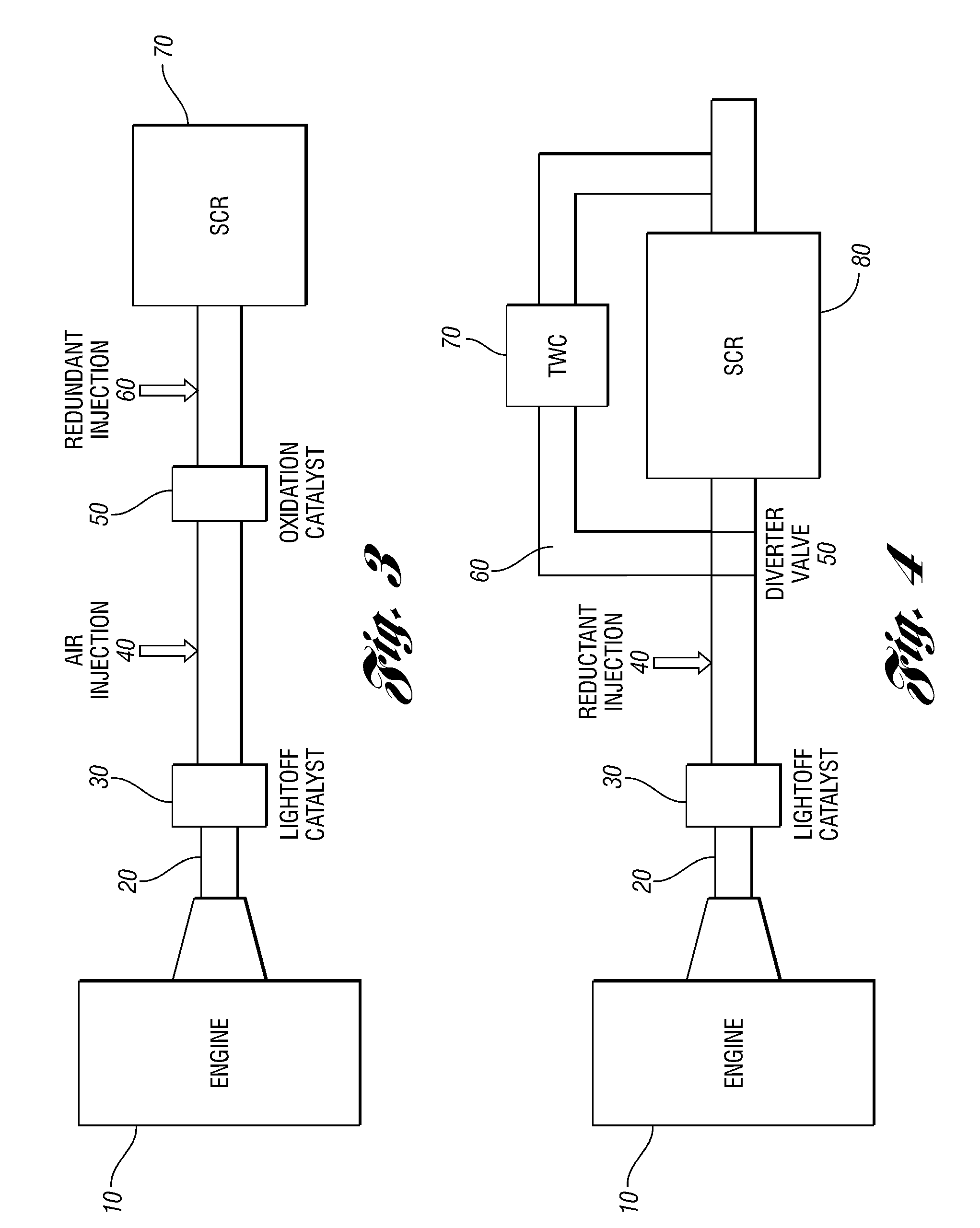

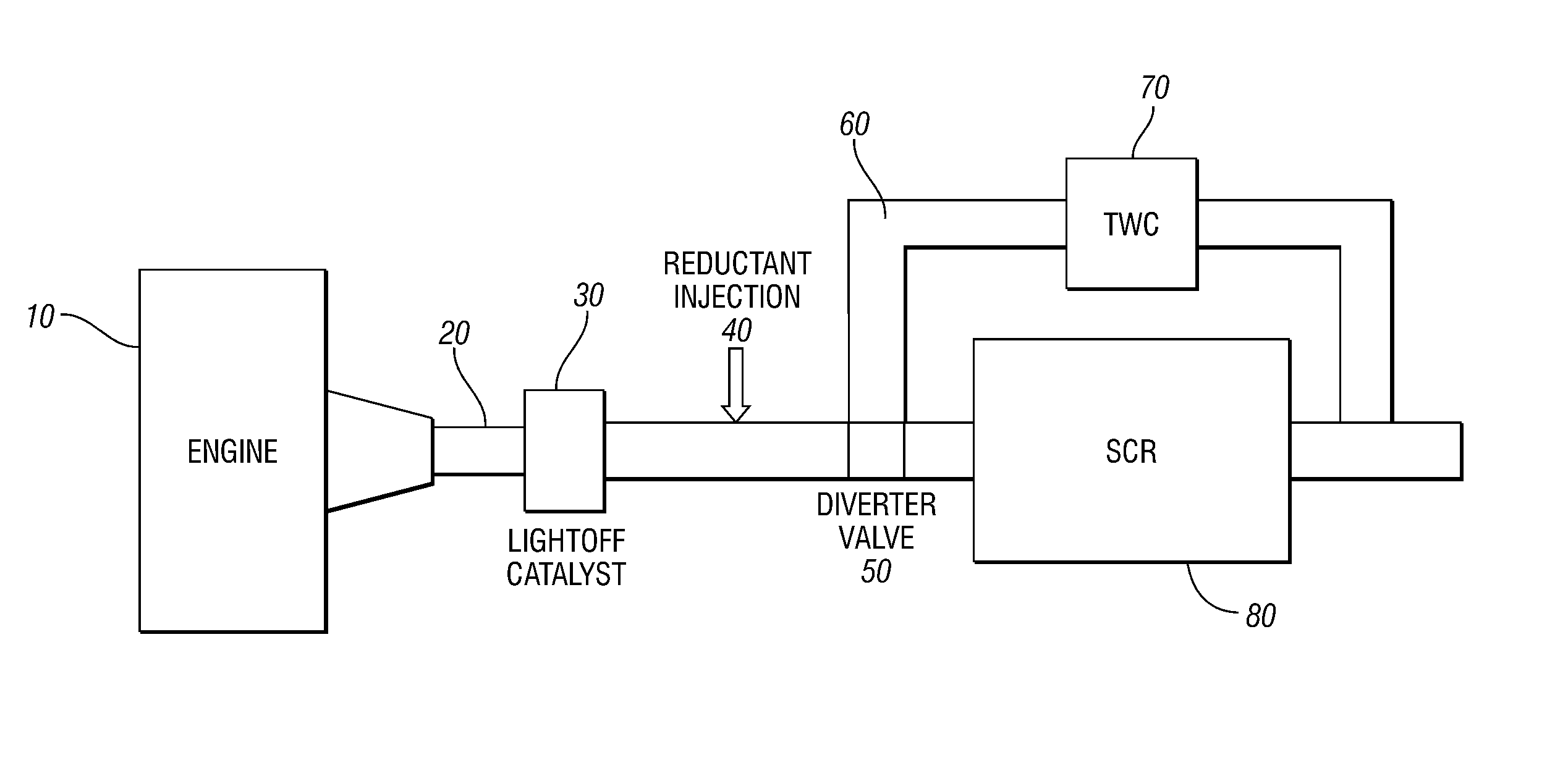

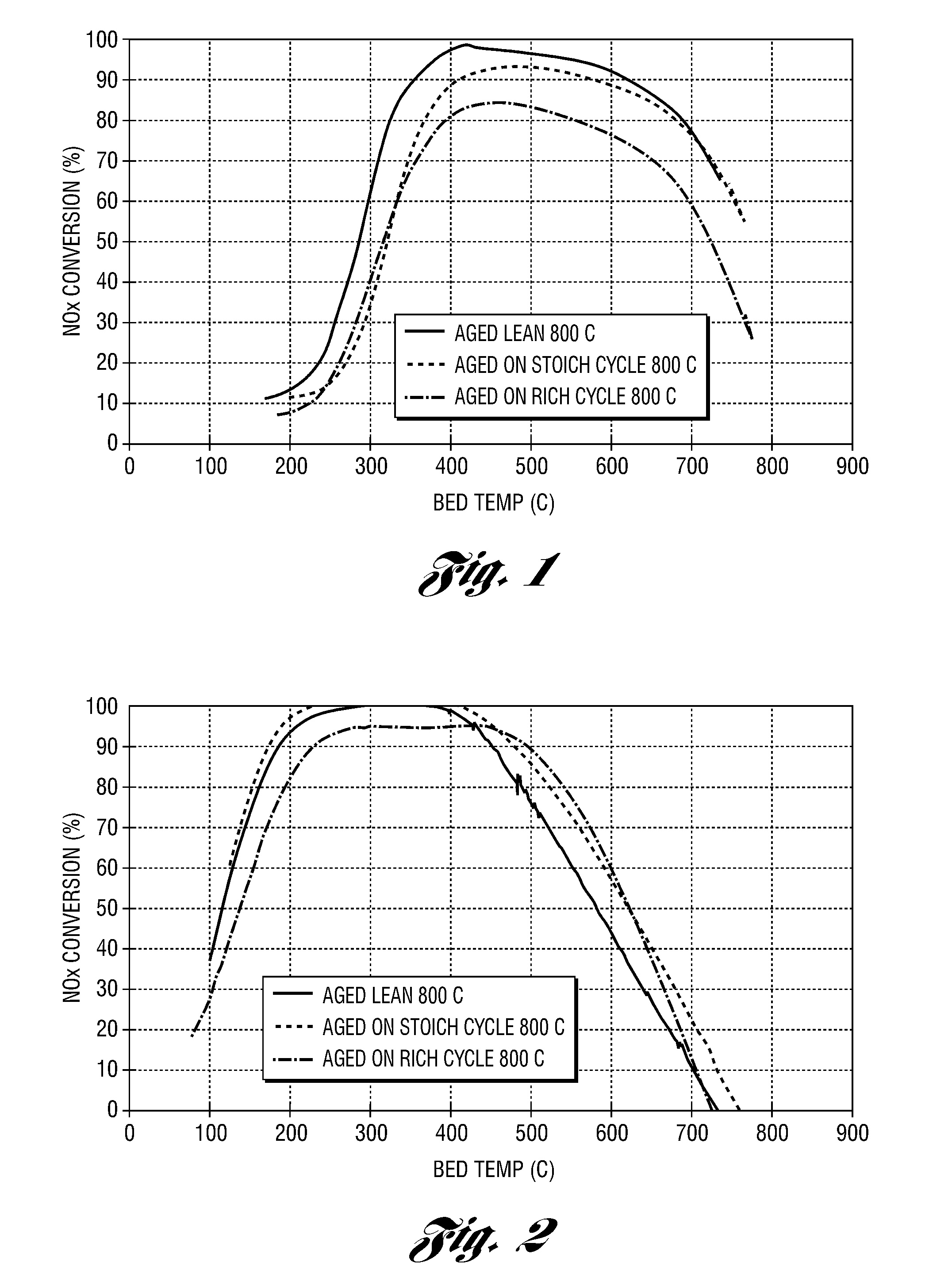

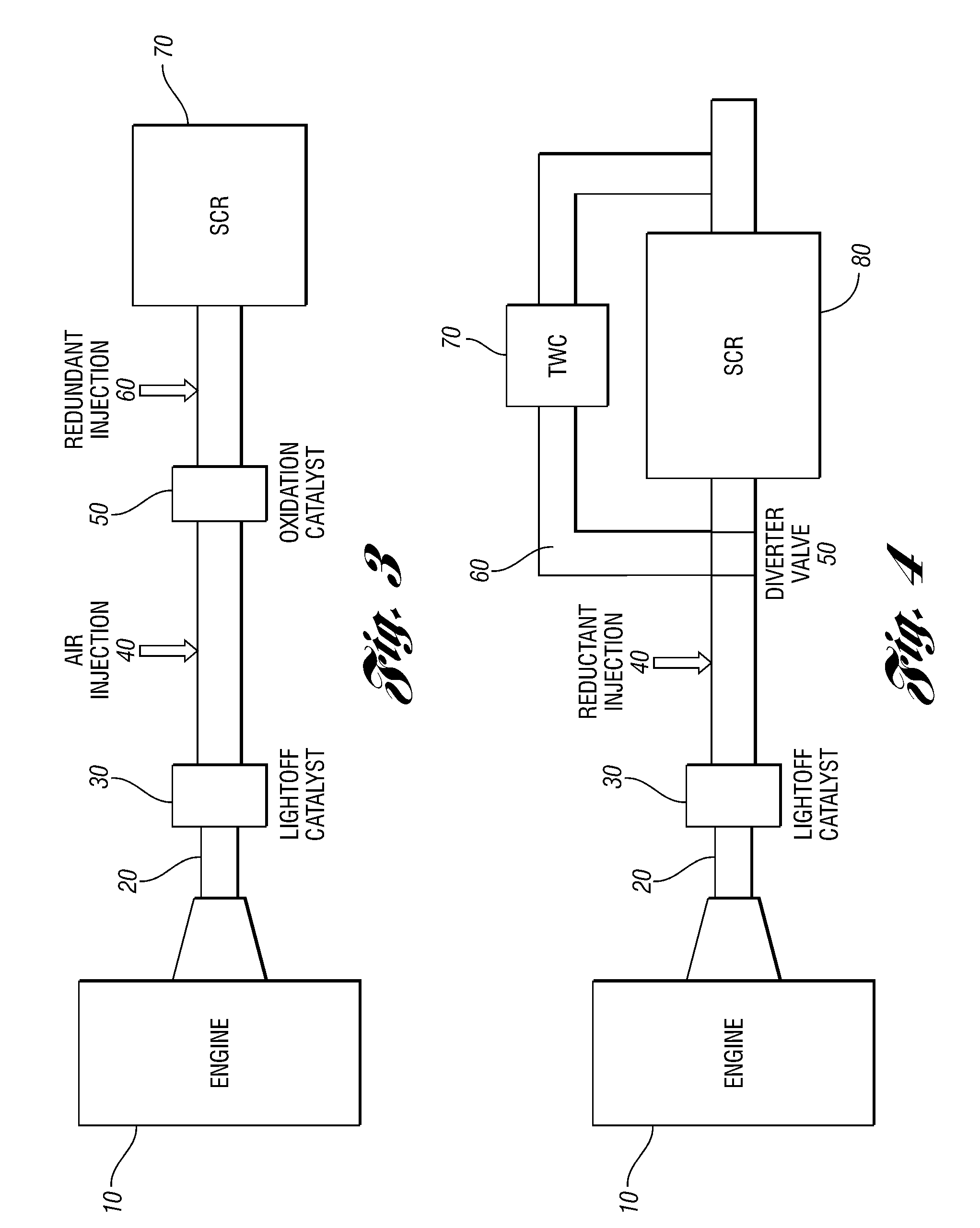

Air-injection system to improve effectiveness of selective catalytic reduction catalyst for gasoline engines

InactiveUS20090260349A1Increased durabilityHarmful emissionGas treatmentInternal combustion piston enginesGasolineEngineering

Embodiments are described to improve the durability of a lean NOx aftertreatment system. According to one embodiment of the present invention an air injection system is used to inject air continuously into the exhaust system between the upstream three-way catalyst and the downstream selective catalytic reduction (SCR) catalyst when the engine is operating at stoichiometric or rich air / fuel ratios and the exhaust temperatures are above a calibratible level (e.g., 700° C.). In another embodiment, an oxidation catalyst is positioned downstream of the air injection point to prevent exothermic reactions from occurring on the SCR. In another embodiment, the reductant for the SCR is generated in-situ. In yet another embodiment, a diverter valve with a reduction catalyst in a bypass arm is utilized to bypass the SCR during high load conditions.

Owner:FORD GLOBAL TECH LLC

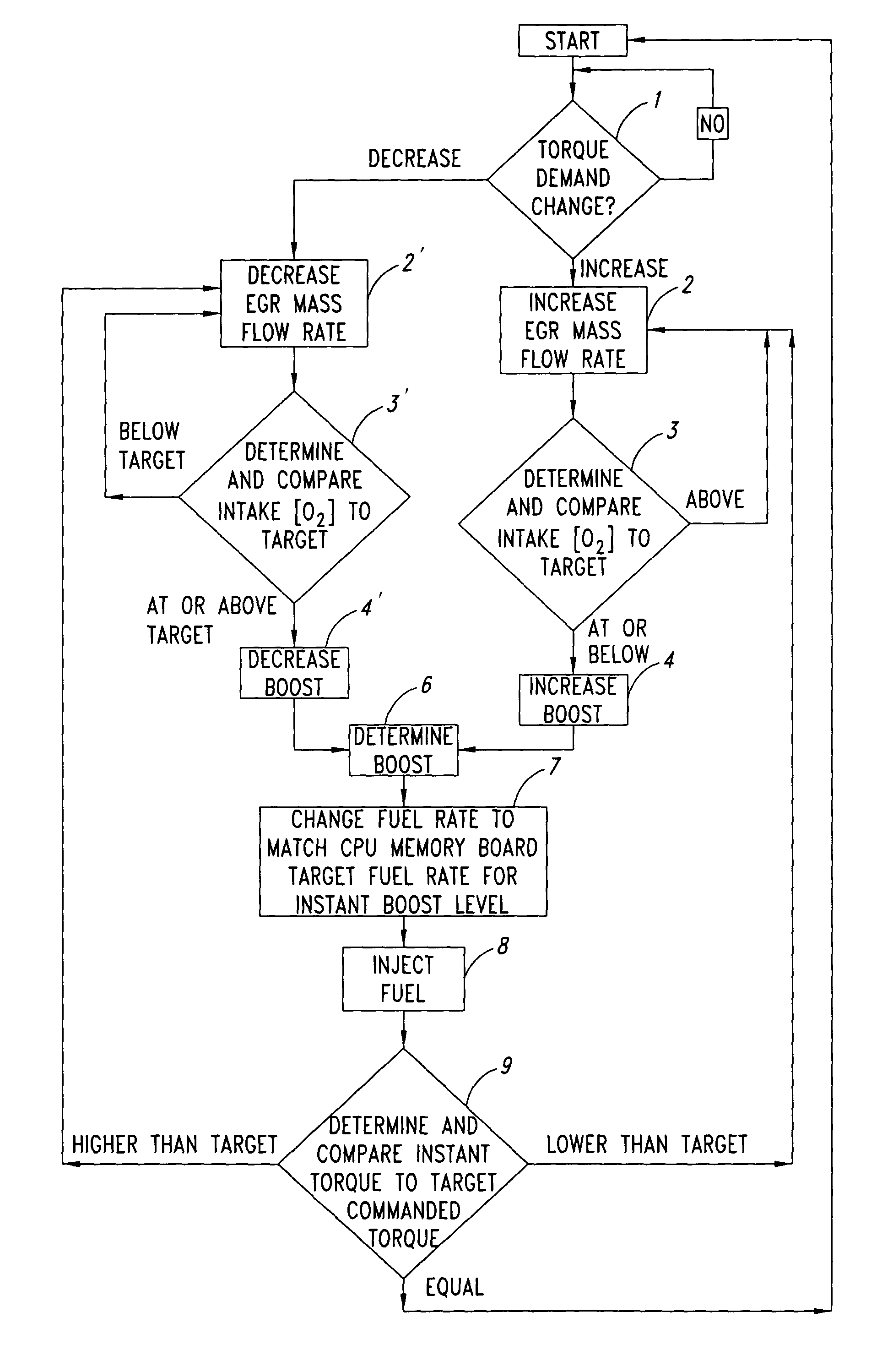

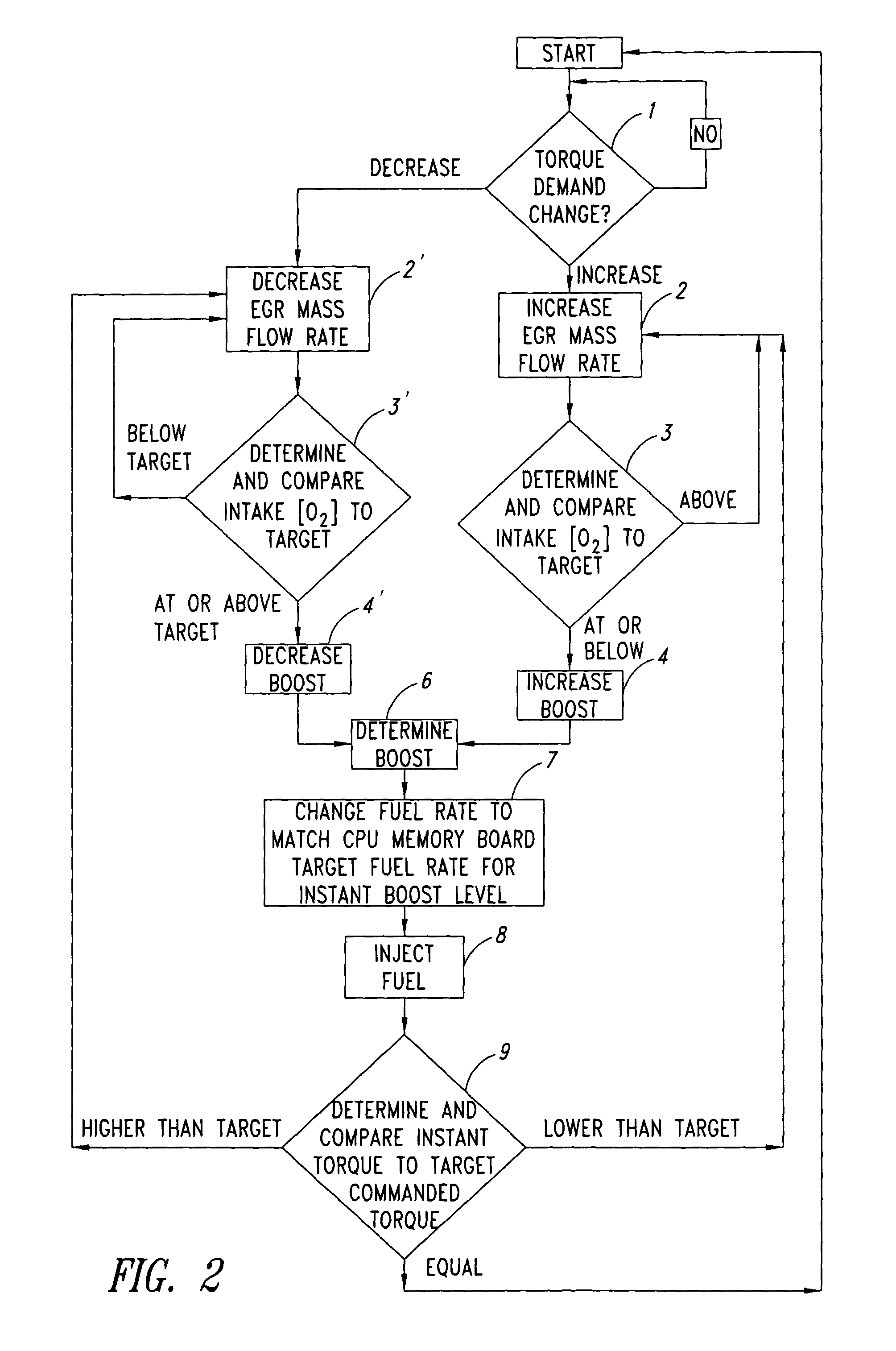

Methods for low emission, controlled temperature combustion in engines which utilize late direct cylinder injection of fuel

InactiveUS7047741B2Minimize harmful emissionImprove the level ofElectrical controlInternal combustion piston enginesCombustionClosed loop

A method is provided for close control and adjustment of in-cylinder oxygen concentration levels together with boost adjustments to minimize harmful emissions during transients in engines which utilize late direct cylinder injection of fuel. EGR flow rates are adjusted in a closed loop, linked fashion together with boost pressure changes during transients, to maintain intake charge-air oxygen concentration and boost levels within critical ranges for controlled temperature, low emission combustion. Changes in fuel feed into the cylinder are made to wait for or follow changes in the boost level of charge-air into the cylinder for combustion. Temporary fuel levels are not allowed to exceed desired fuel / oxygen ratios during transients, by controlling fuel feed responsive to the level of boost of charge-air being taken into the cylinder for combustion.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

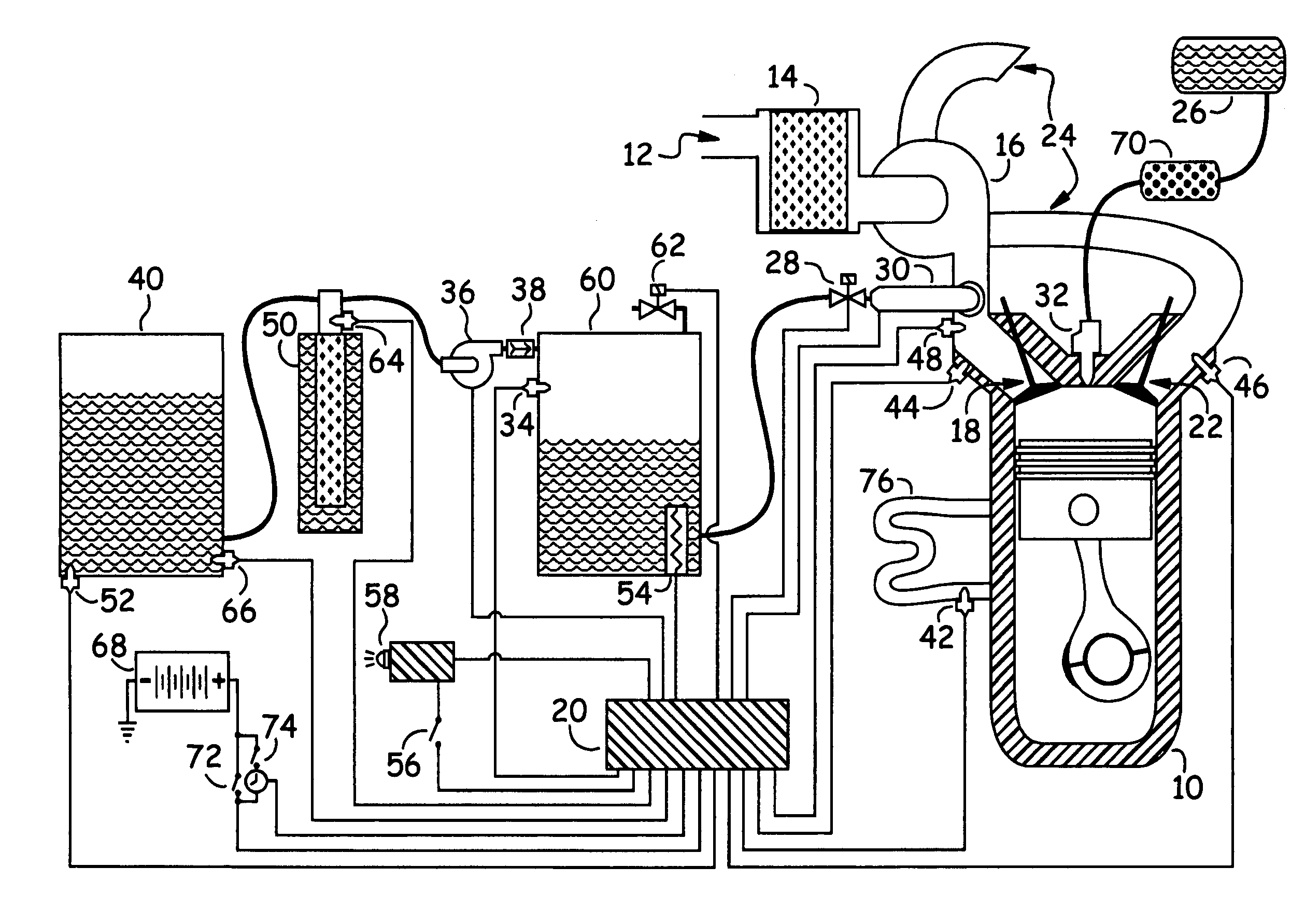

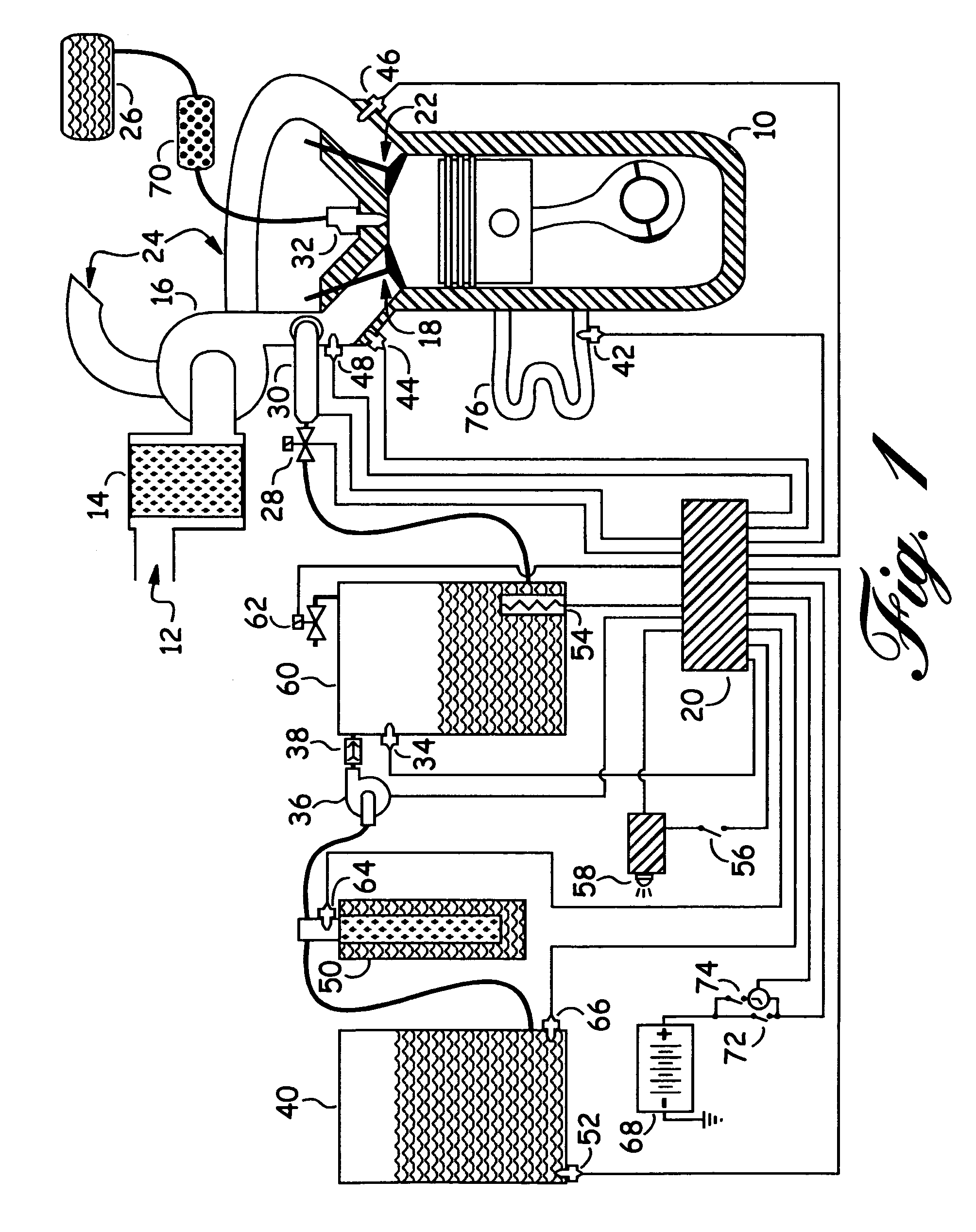

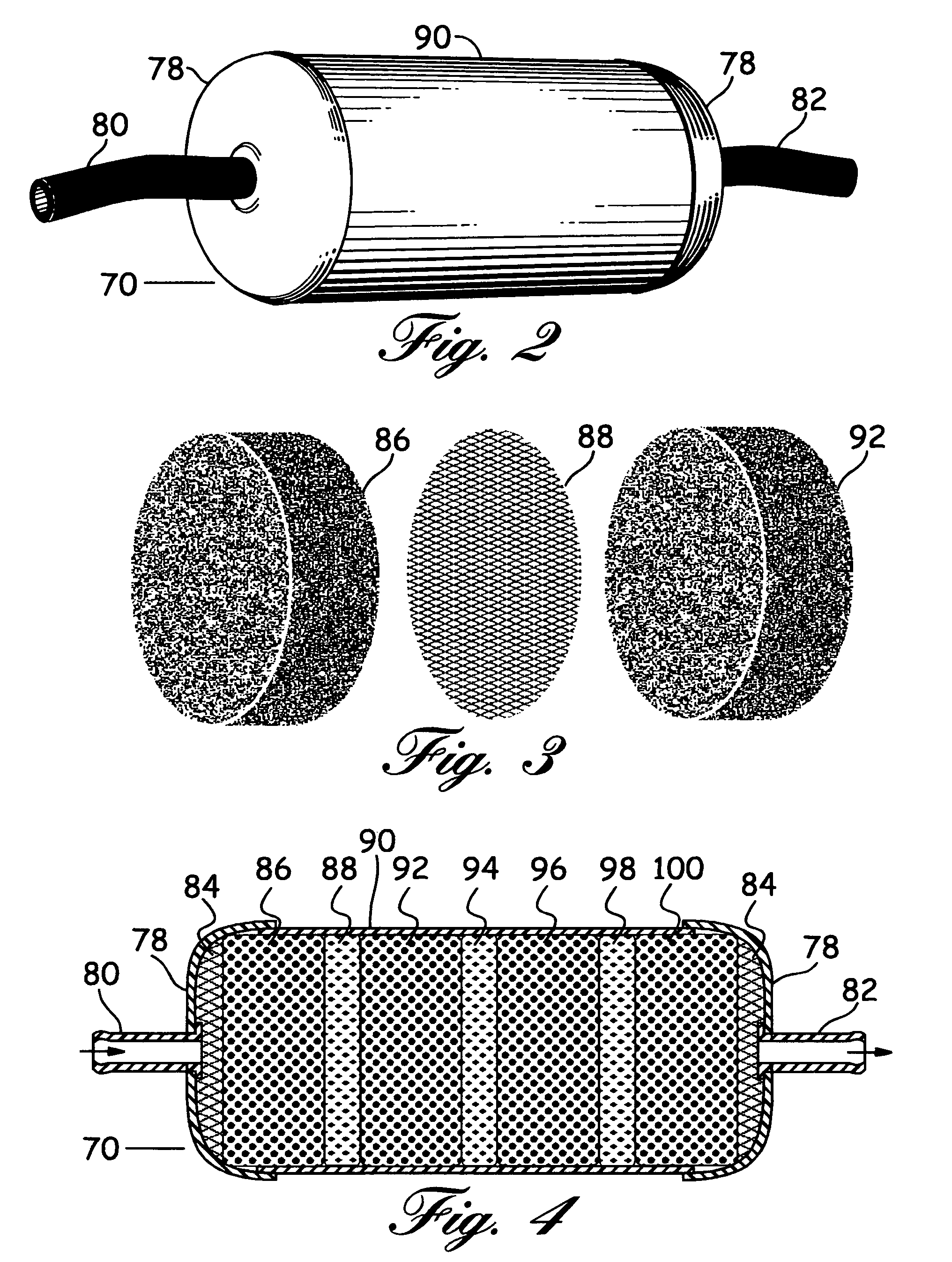

Emissions reduction system for an internal combustion engine

InactiveUS7013845B1Reduce harmful emissionsImprove performanceInternal combustion piston enginesNon-fuel substance addition to fuelPrime moverNitrogen oxides

A dual system for overall engine emissions control, including prevention of excessive formation of nitrogen oxides and carbon compounds 1) by cooling and humidifying intake air and 2) by restructuring and modifying hydrocarbon fuels, resulting in a more complete combustion, a significant reduction of the latent heat of combustion and increased combustion potency. The invention utilizes one or more ultrasonic devices to create an aqueous vapor from an ultra-pure water supply, said vapor varying in quantity according to engine size and load, having electronic sensors and controls for precision switching, metering and delivery. Simultaneously, while humidifying the intake air, the hydrocarbon fuel is passed from a fuel supply through a catalytic reactor to restructure the hydrocarbon molecules into a more homogeneous, more combustible and cleaner-burning fuel. Thus equipped, said internal combustion engine can be run as a fuel conserving, low emissions prime mover.

Owner:CONTEGO MEDICAL INC

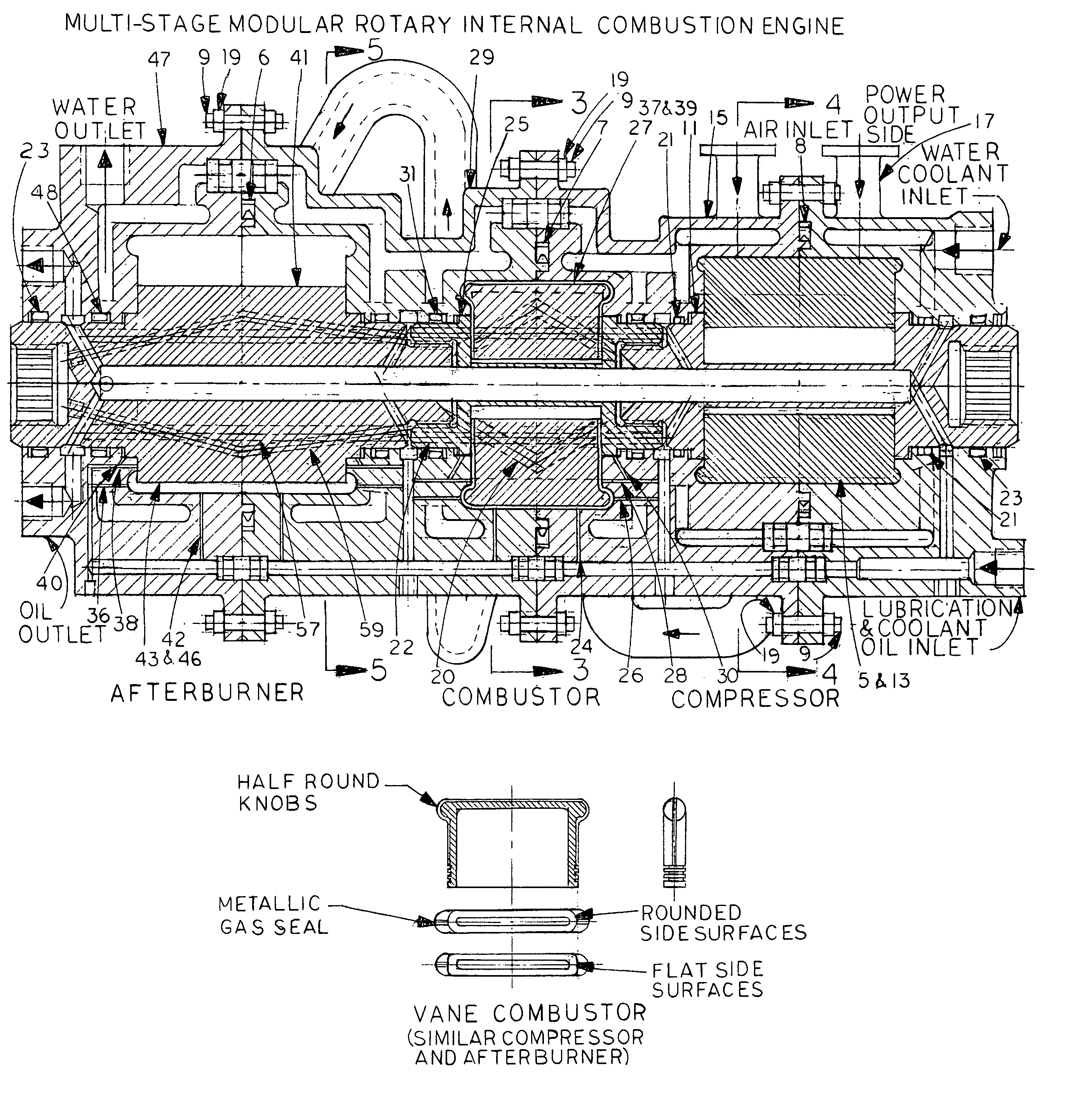

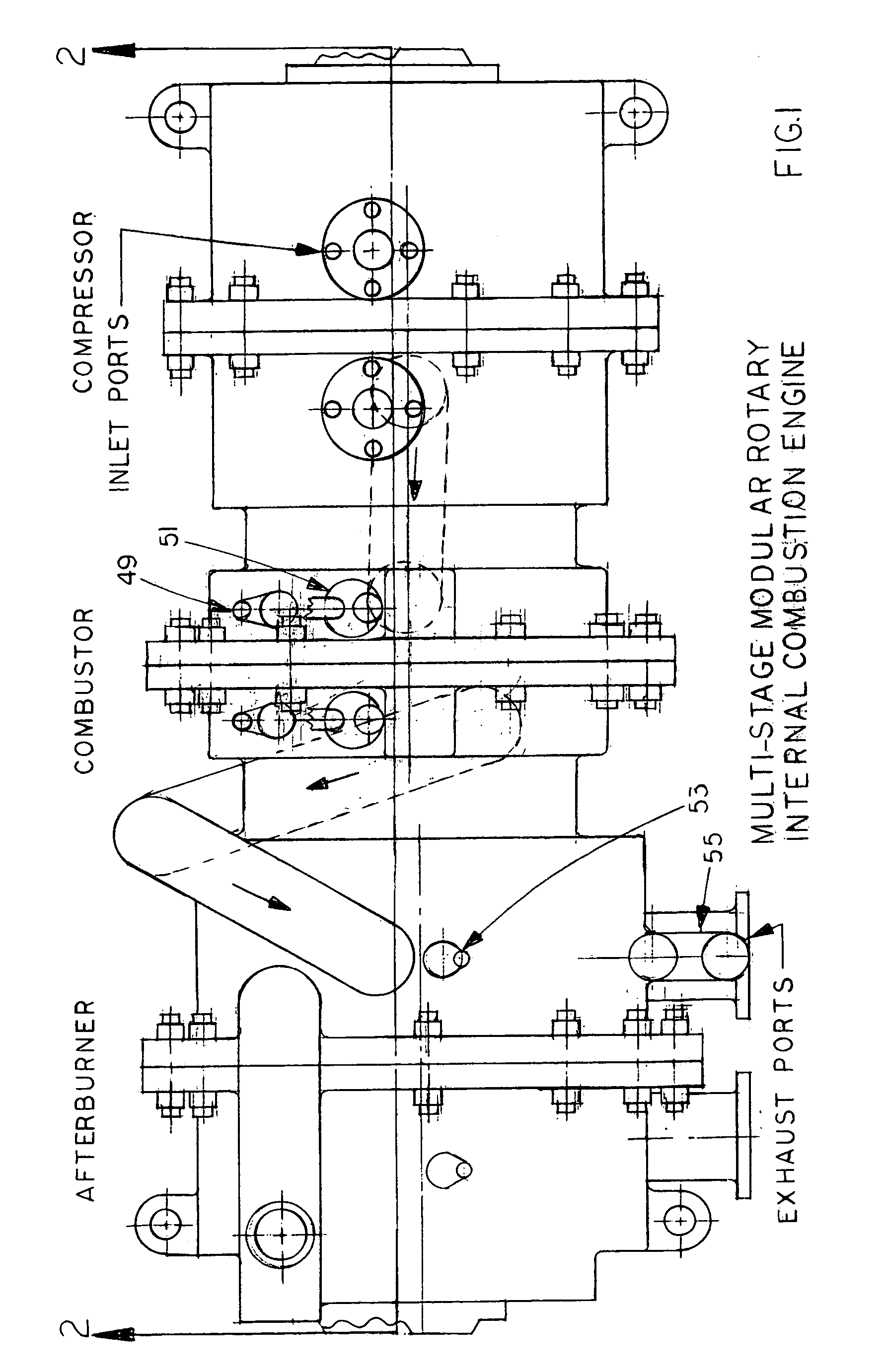

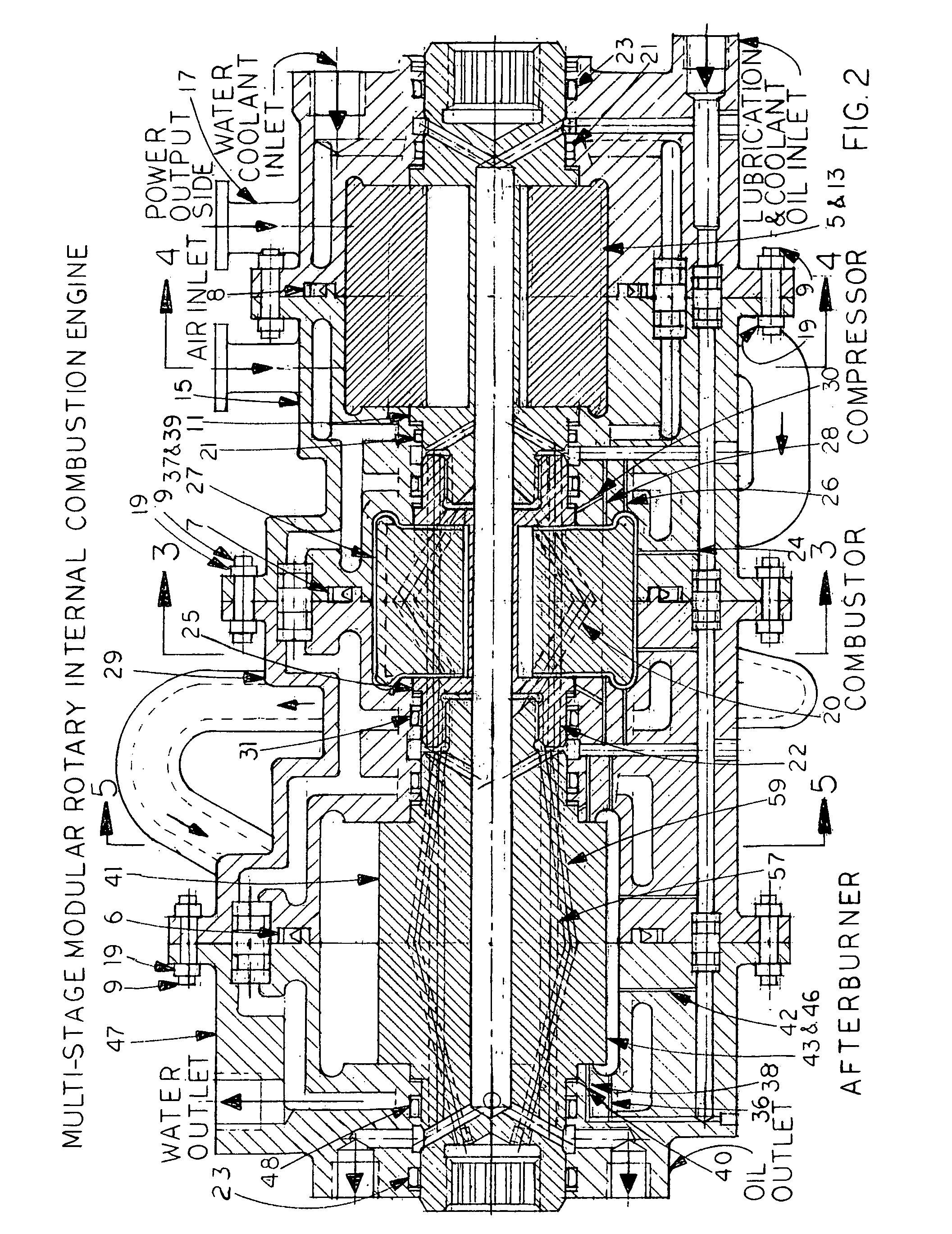

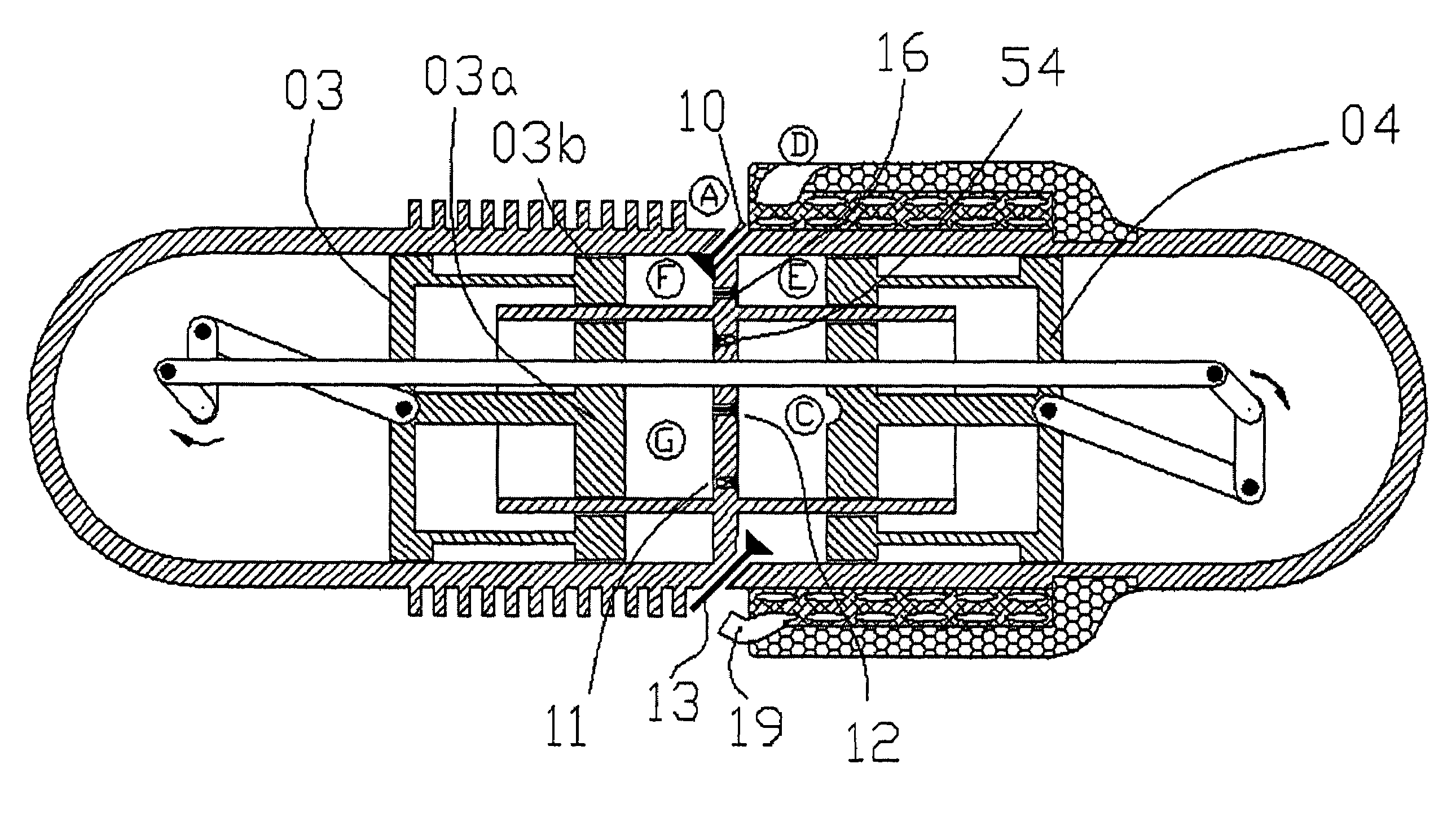

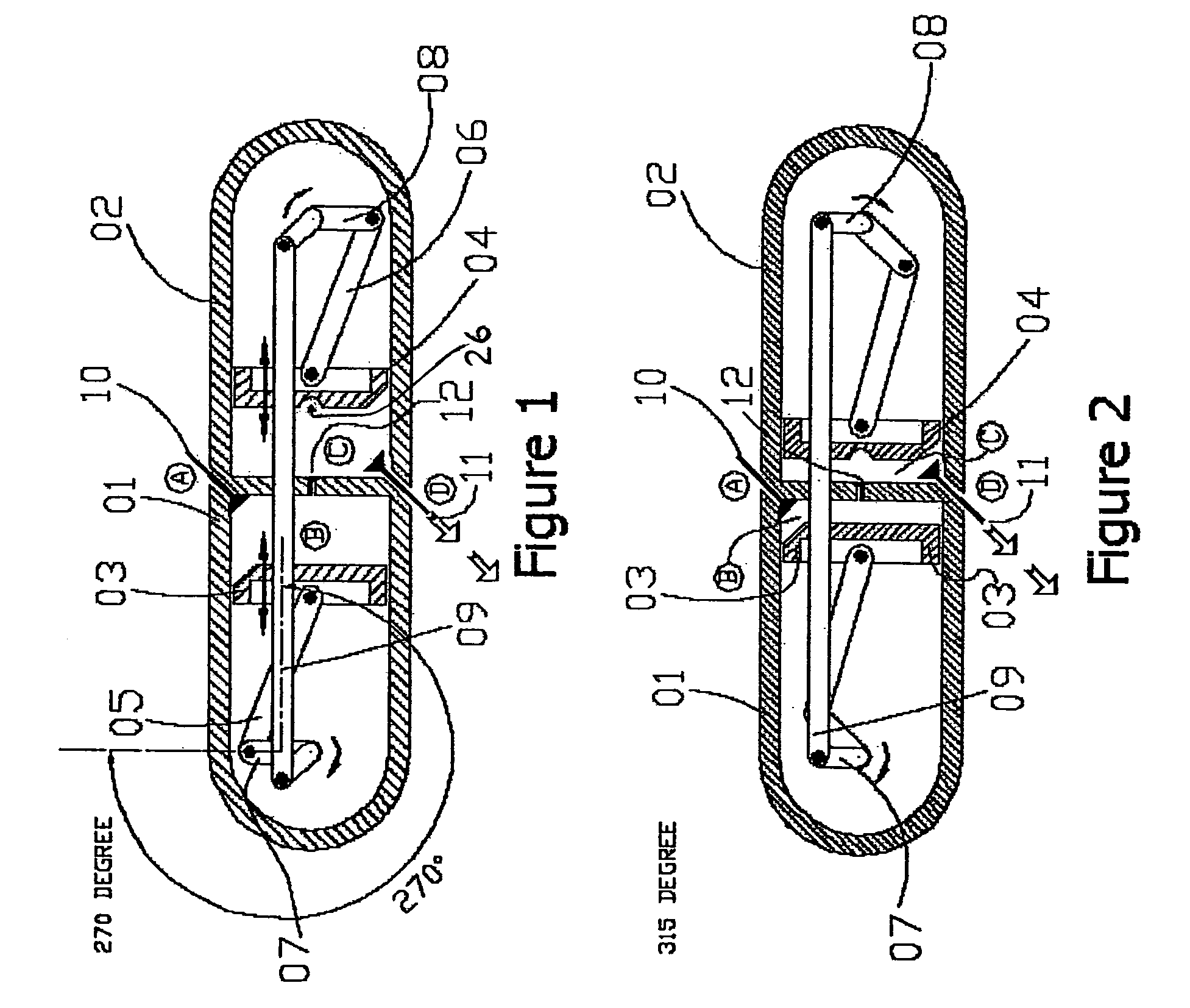

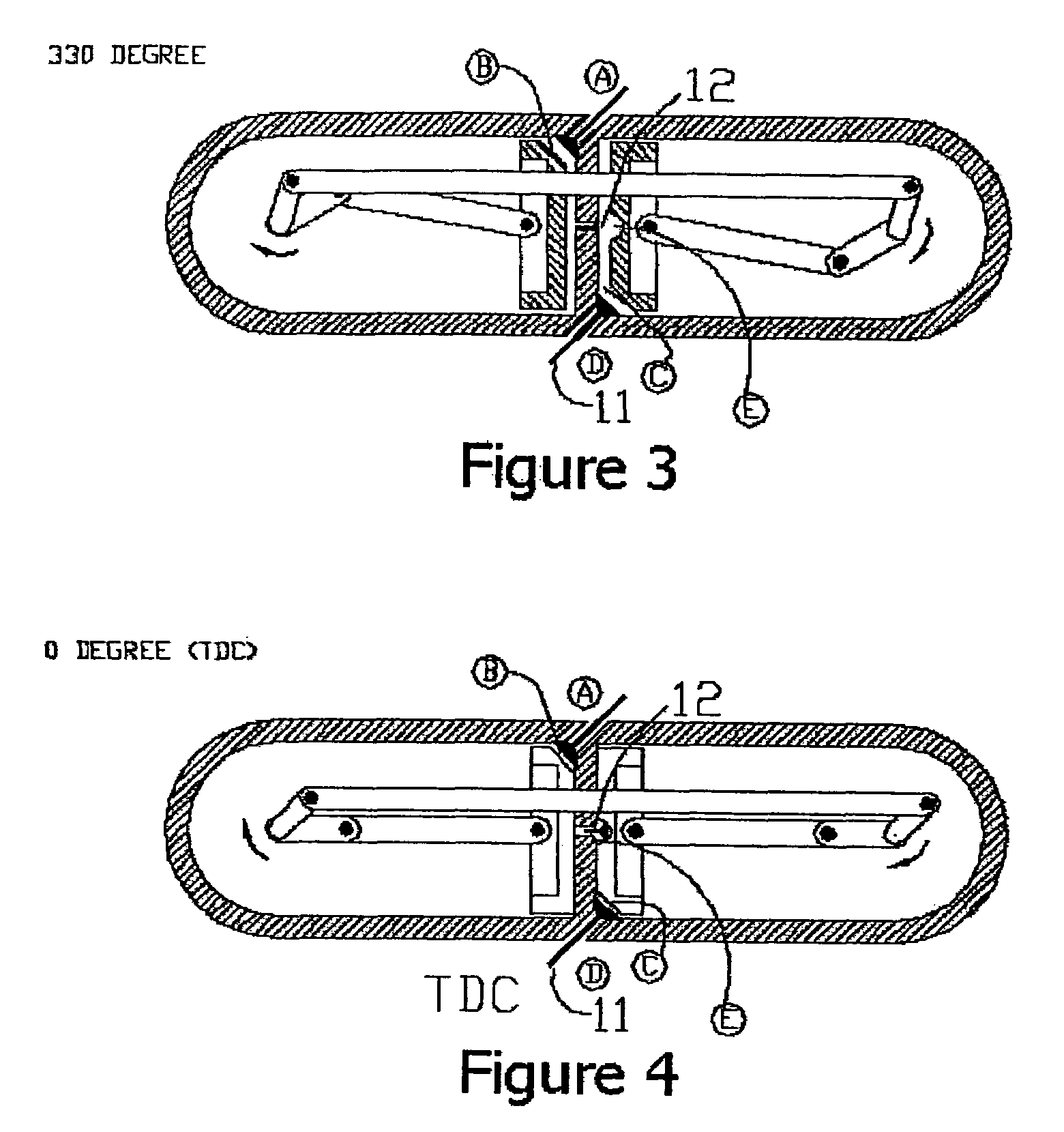

Multi-stage modular rotary internal combustion engine

ActiveUS7117839B2Easy constructionRobust designInternal combustion piston enginesOscillating piston enginesCombustorThree stage

A three-stage internal combustion rotary engine, comprised of: a compressor feeding compressed air to a combustor for compression, fuel injection, combustion, and expansion of gases which rotate the rotor. The combustor rotor generates torque and drives the compressor and afterburner rotors simultaneously. The afterburner receives the combusted gases and scavenged air from the combustor for secondary combustion and expels the exhaust gases. Each unit consists of a housing joined together on a common axis and a rotor with a shaft mounted in an eccentric position of the housing side-walls. The shafts are interconnected by splines. The rotors have radial blind slots which contain slidable, movable vanes fitted with half-round knobs on opposite sides, aligned with the top surface and fit in the hemispherical grooves on the interior side-walls of the housing. This maintains a permanent contact with the interior housing periphery, regardless of gas pressures and rotating speed.

Owner:HORSTIN ABRAHAM H

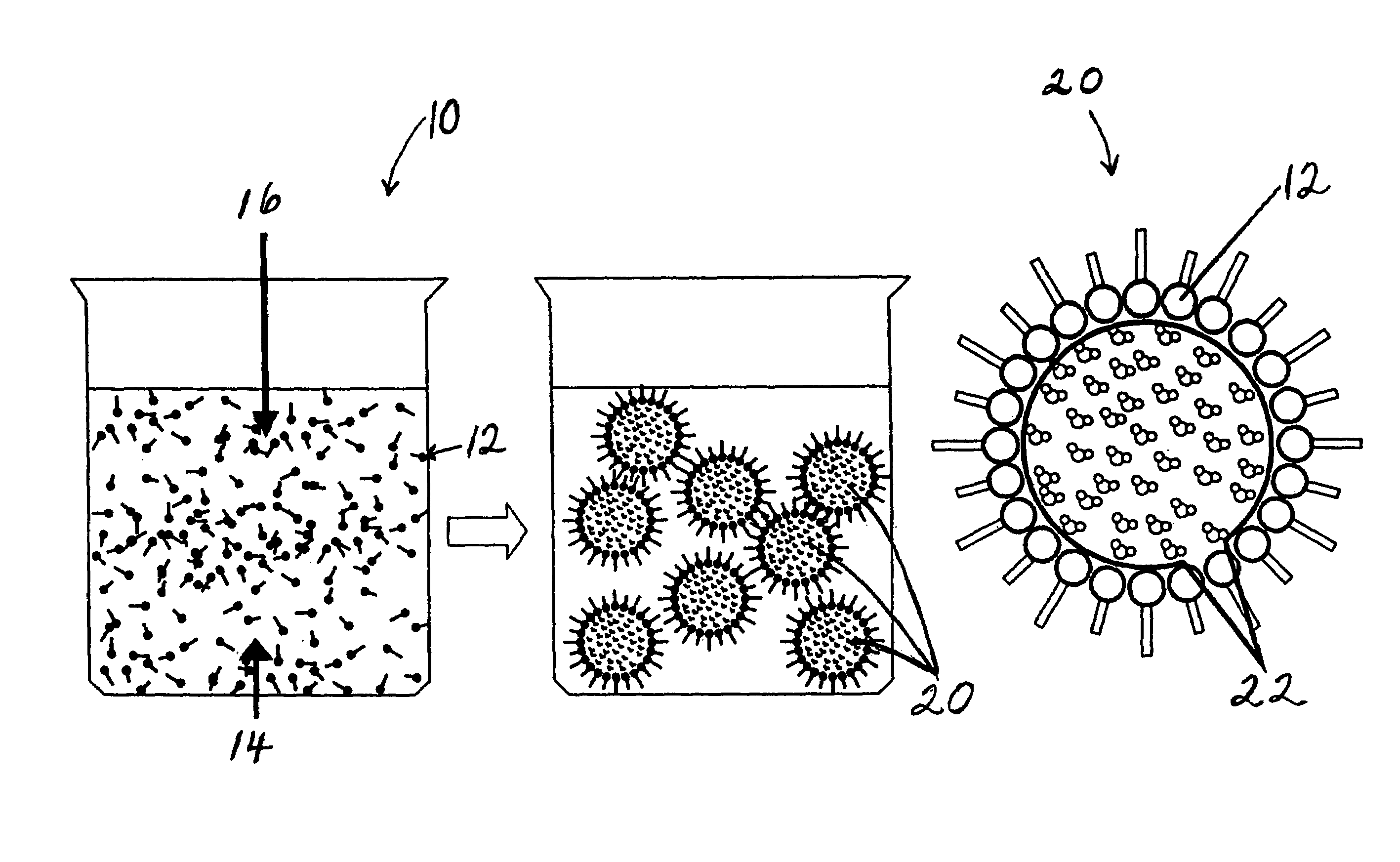

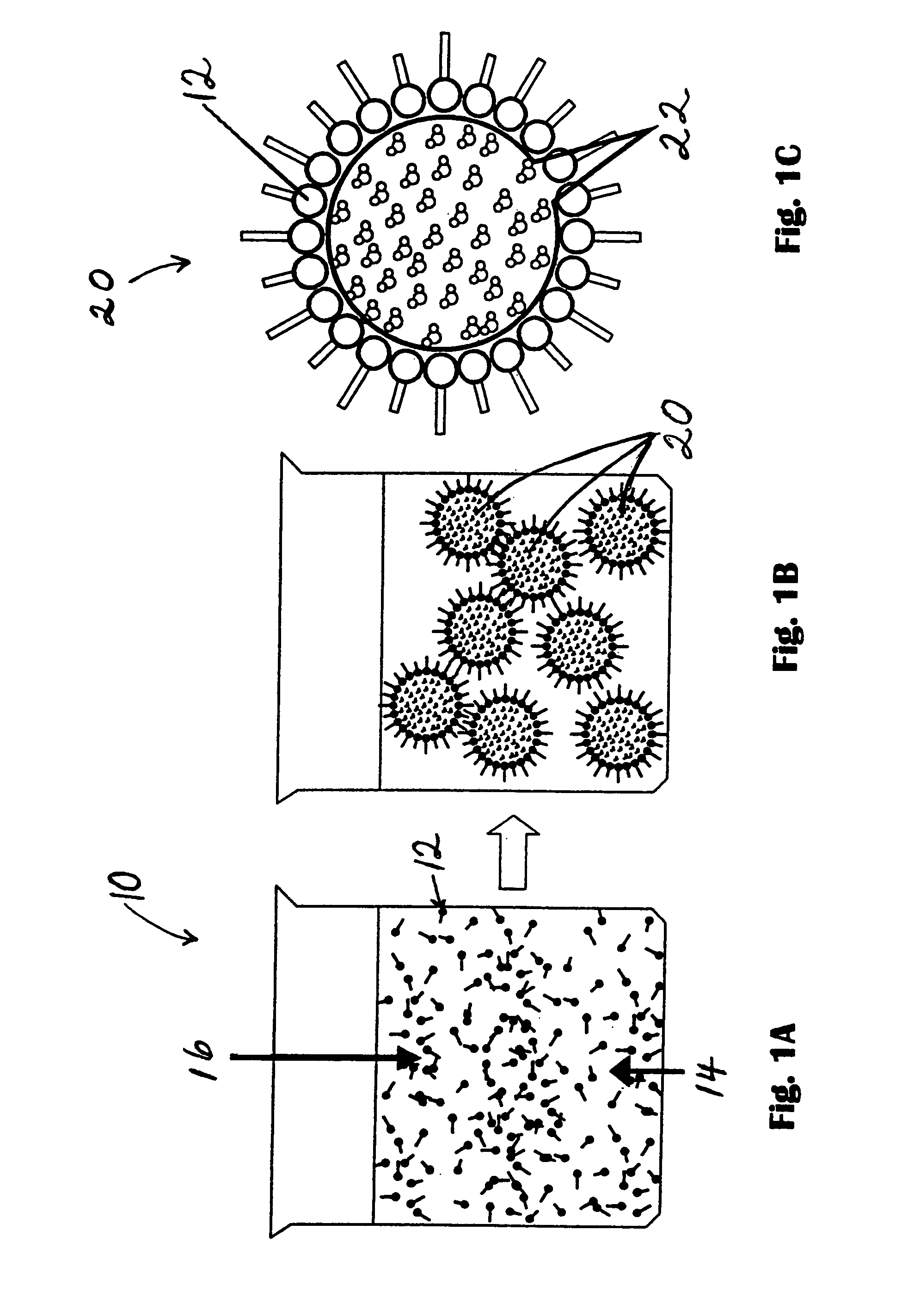

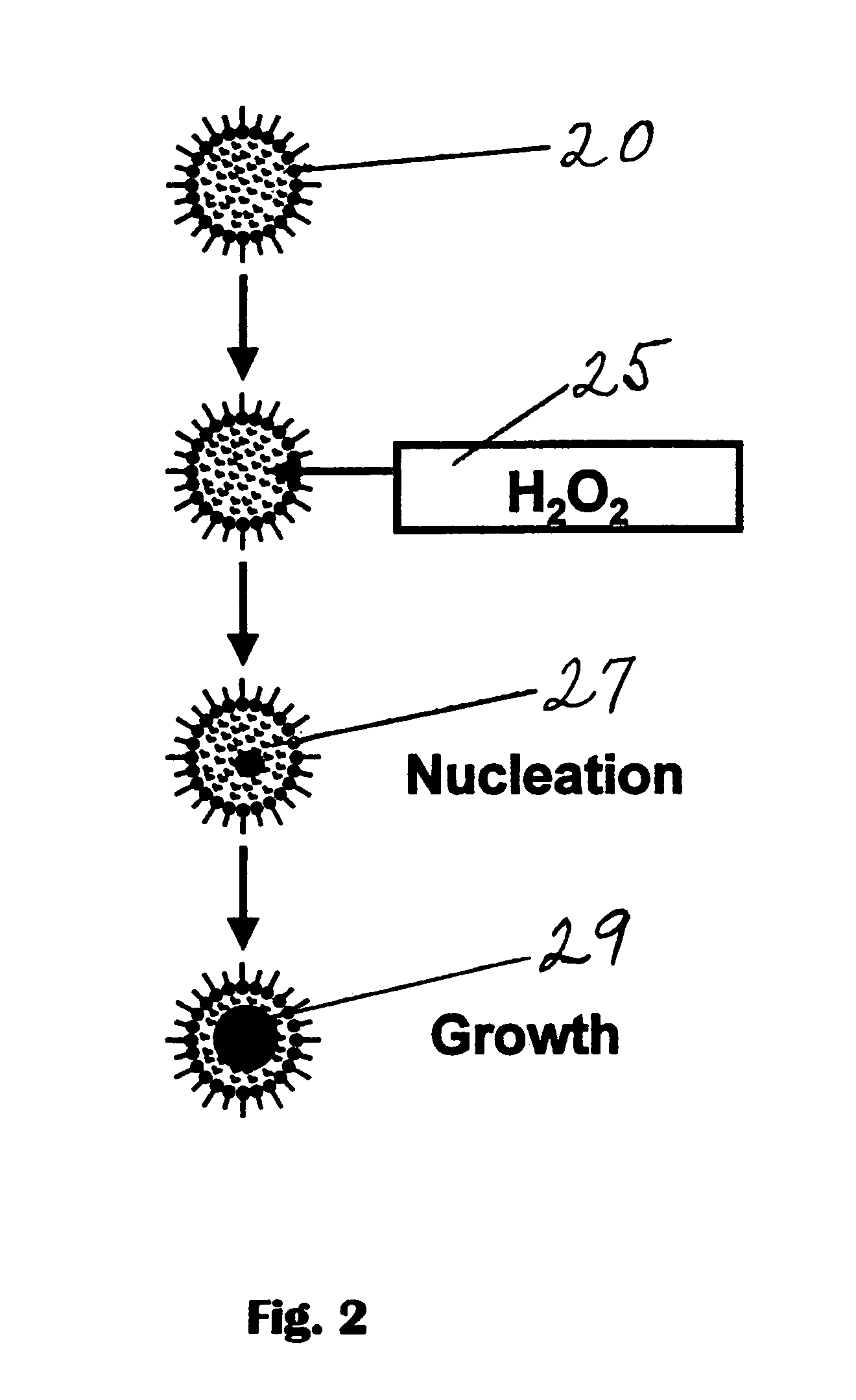

Use of oxide nanoparticles in soot reduction

InactiveUS7419516B1Reduce formation/emissionsReduce soot formation/emissionsMaterial nanotechnologyLiquid fuel feeder/distributionOxygen vacancyEngineered Nanoparticle

Novel nano-sized rare earth metal oxide prepared from aqueous reverse micelles is provided. The engineered nanoparticles have large surface area to volume ratios, and sufficient oxygen vacancies on the surface of each particle, so that when mixed with carbon-containing combustible fuels, the particles remain suspended indefinitely; there is a significant reduction in soot and other by-products of combustion, an increase in engine efficiency and less fuel consumed per mile traveled in various vehicles, such as, but not limited to, automobiles, defense vehicles, airplanes, ships and other surface or air-bearing vehicles.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

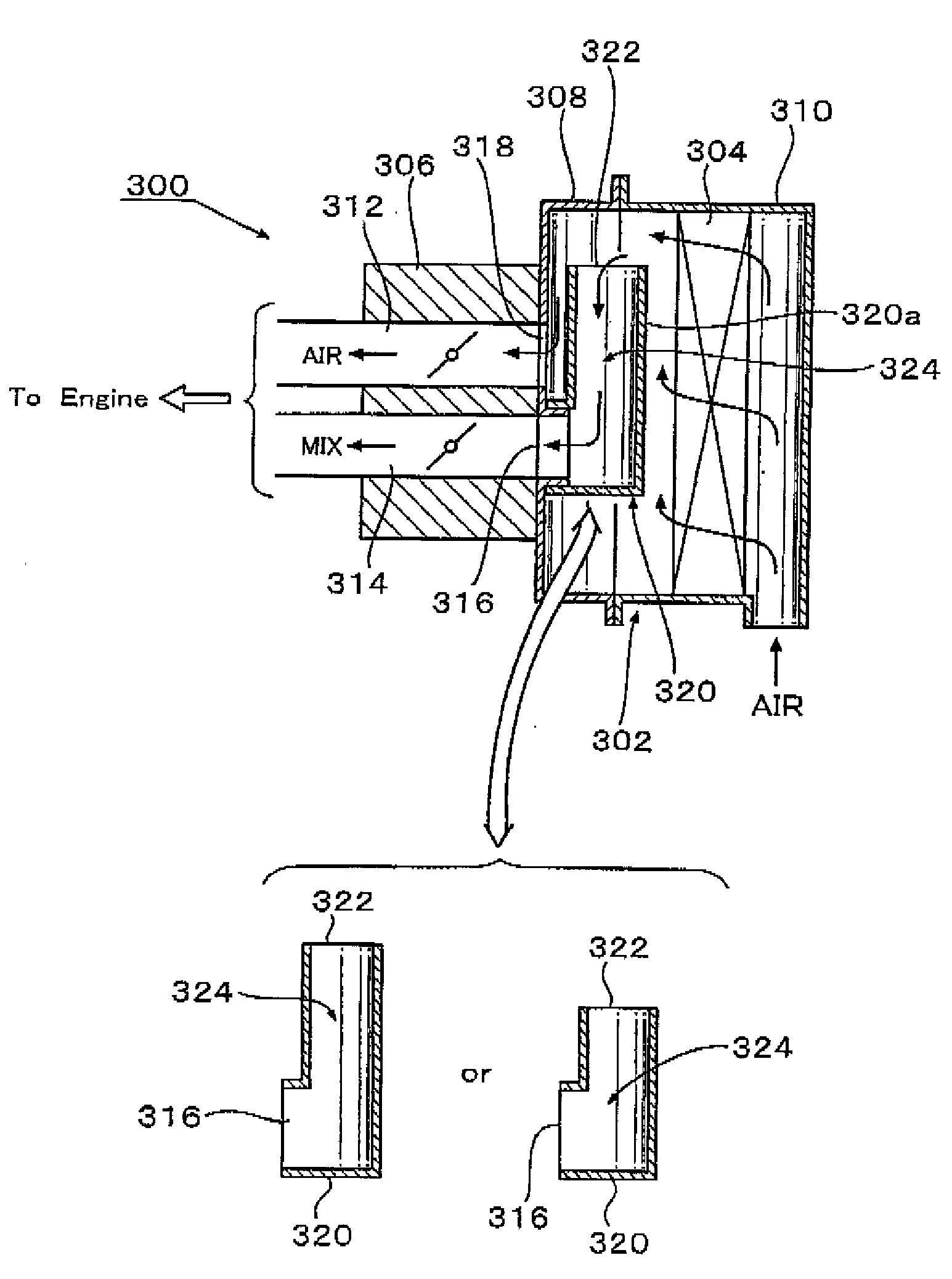

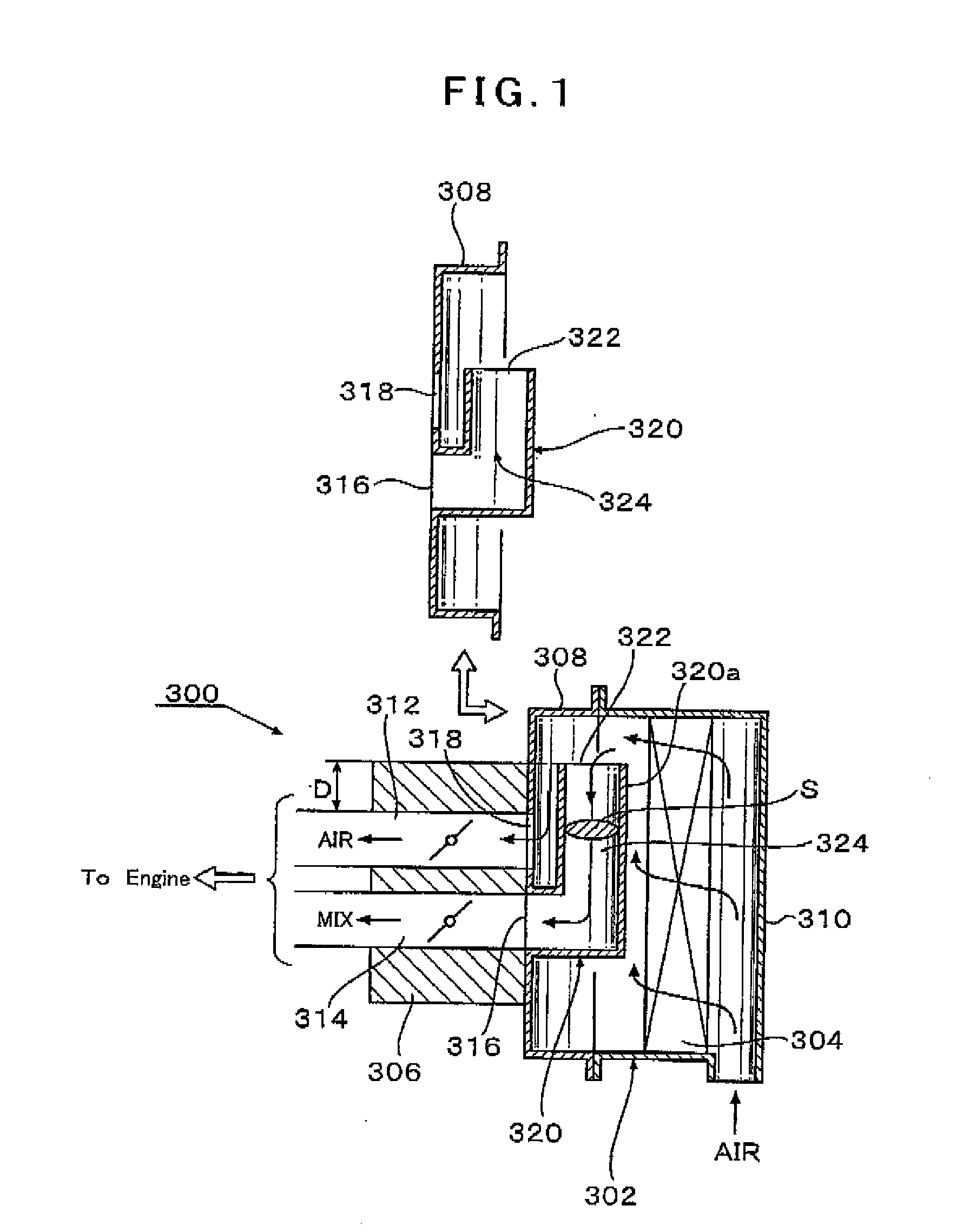

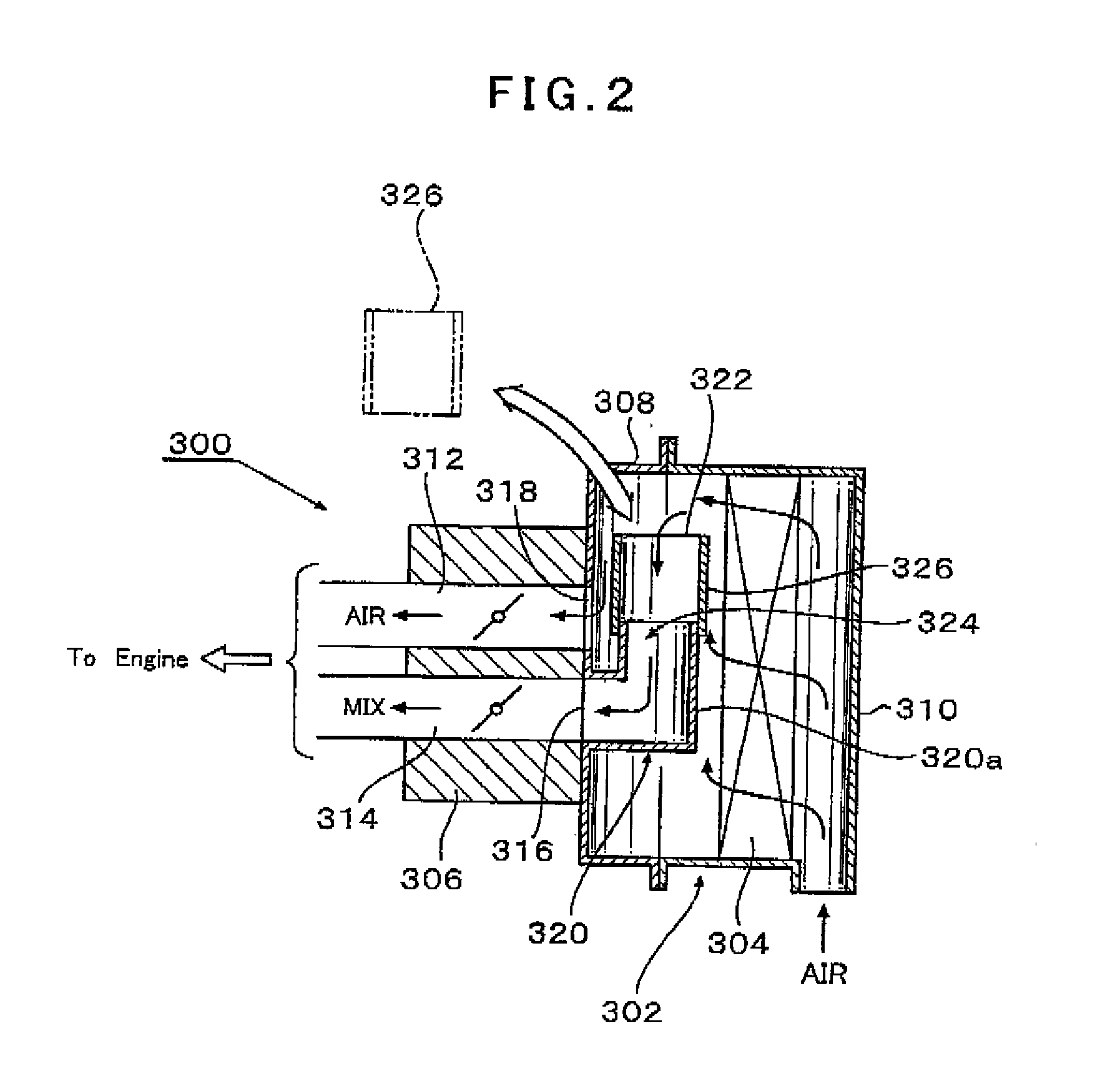

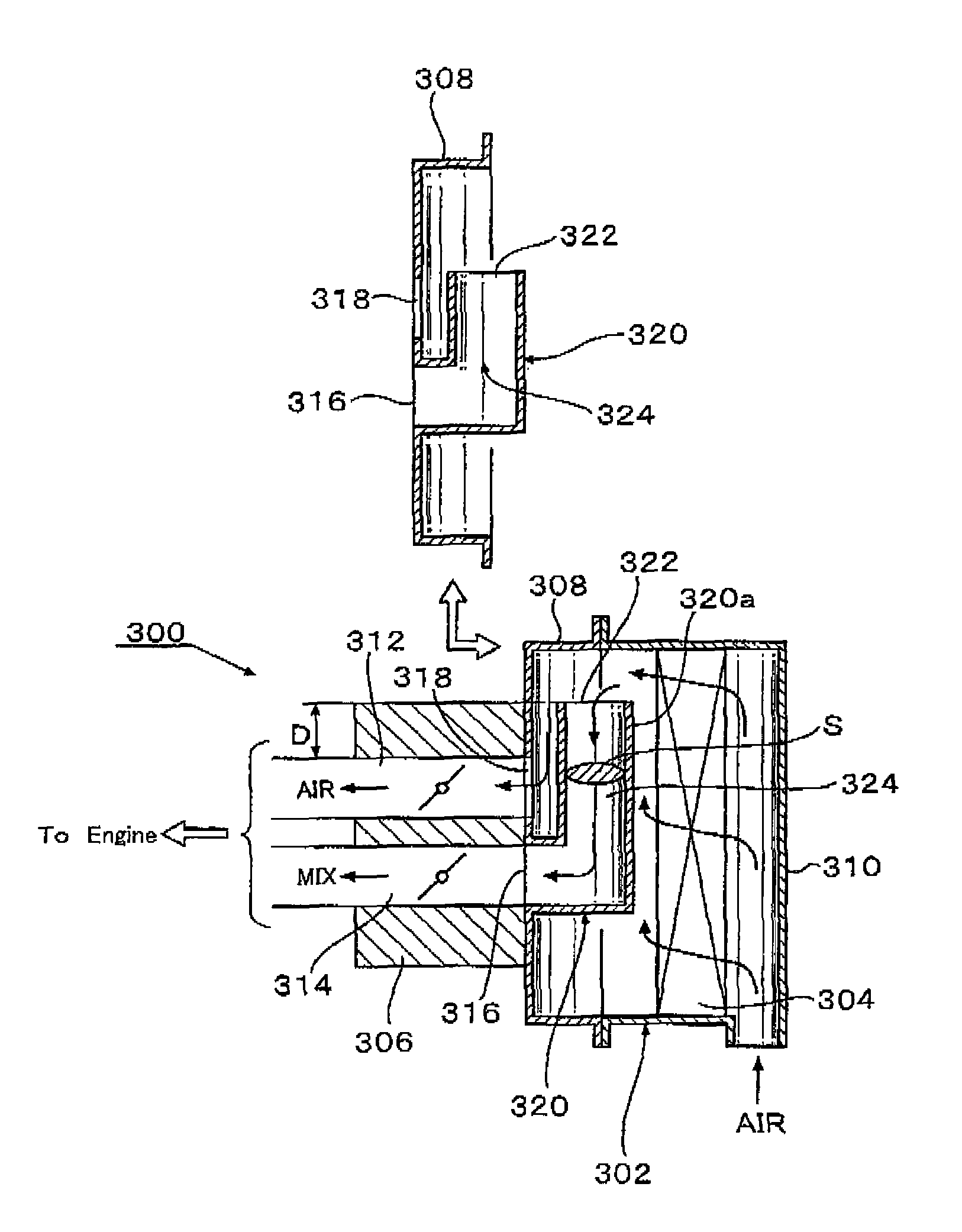

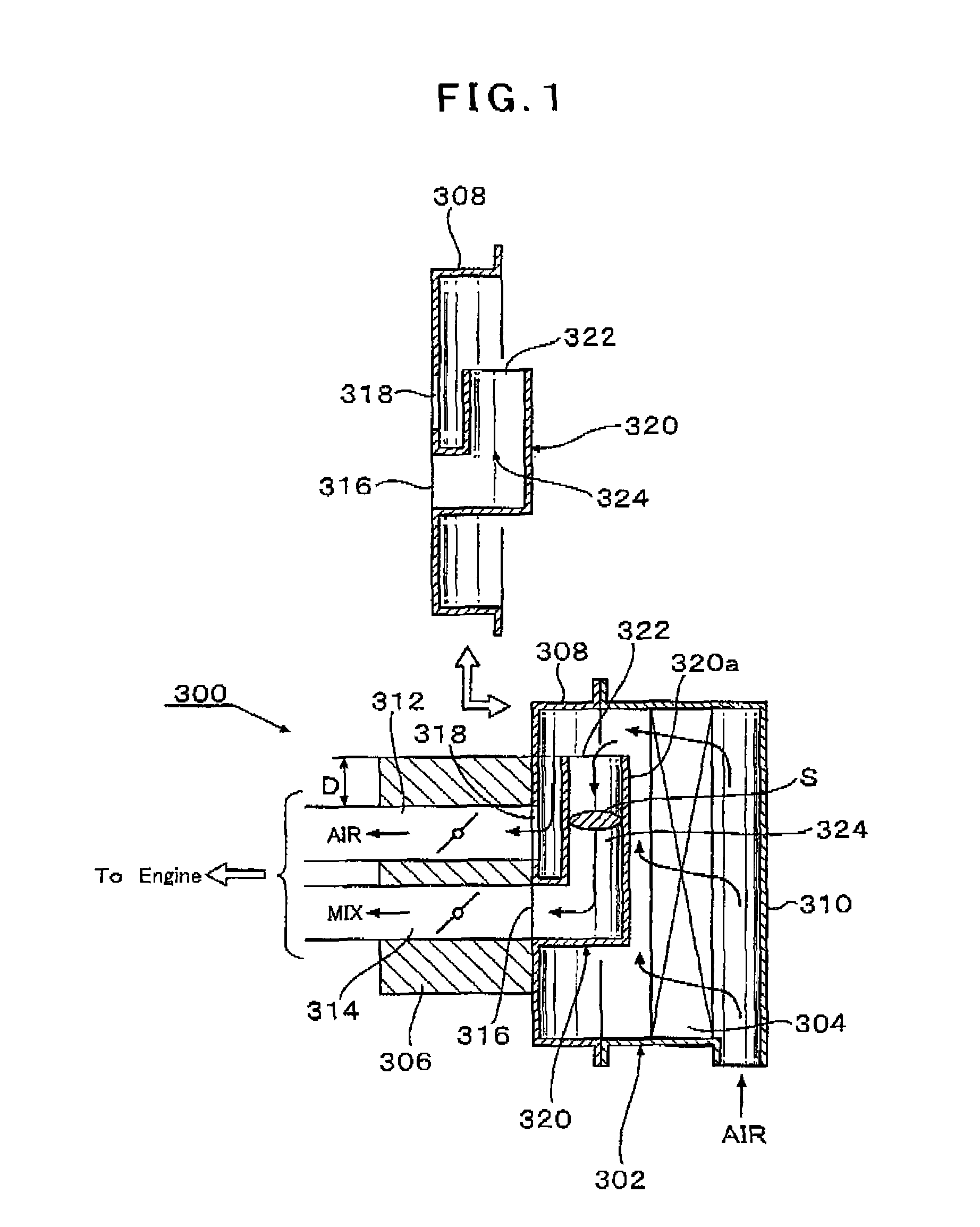

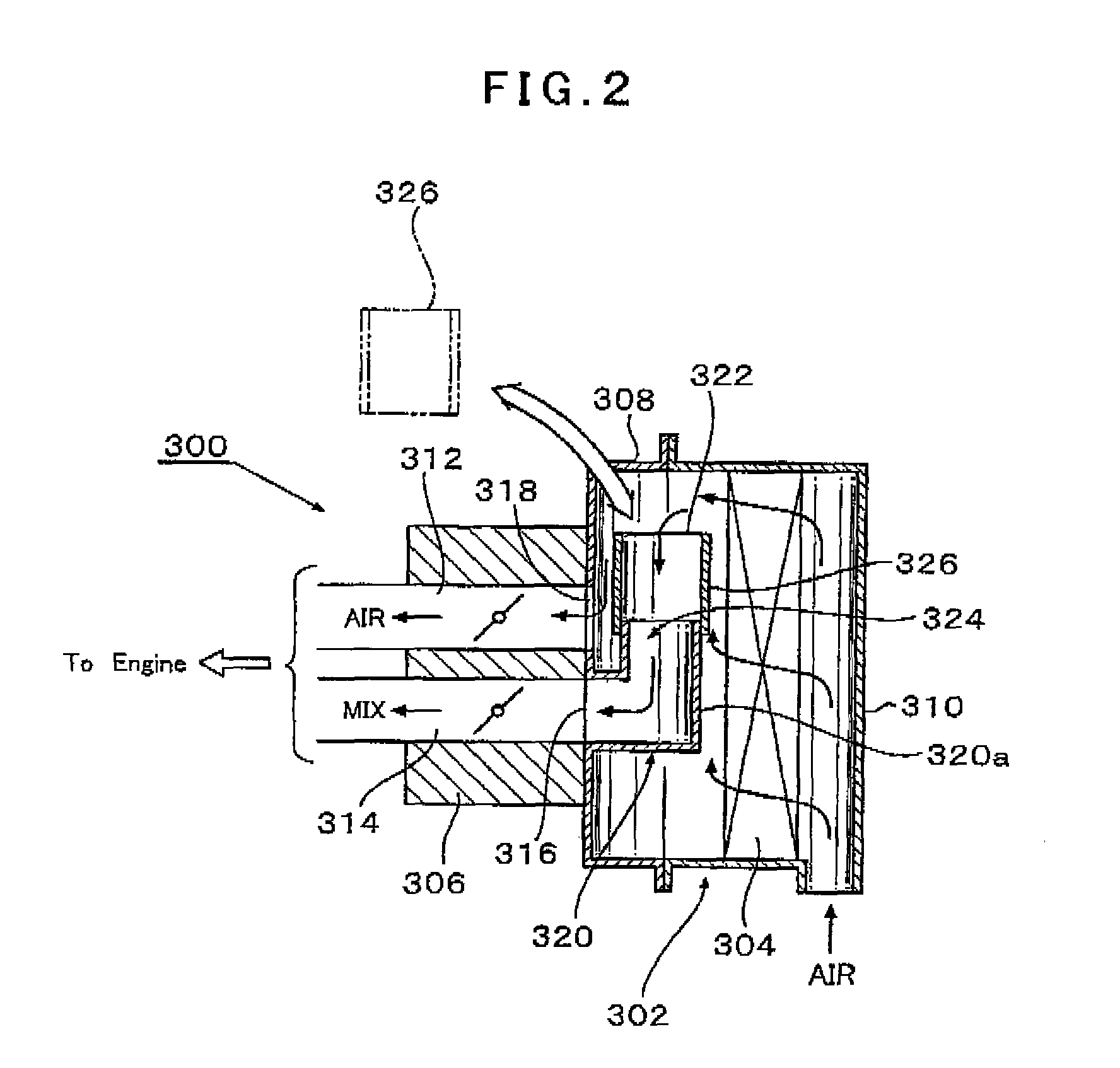

Air cleaner for two-stroke internal combustion engine and method of tuning the length of air-fuel mixture passage by using the air cleaner

InactiveUS20080120951A1Reduce harmful emissionsChange the engine characteristicsCombination devicesGas treatmentExternal combustion engineFresh air

An air cleaner is used in a two-stroke internal combustion engine to supply an air-fuel mixture passage and a fresh air passage in a carburetor with air cleaned by an air cleaner element. The air cleaner includes an air cleaner base having an air-fuel mixture opening communicating with the air-fuel mixture passage and a fresh air opening communicating with the fresh air passage, and an air guide member provided at the air-fuel mixture opening. The air guide member is configured to curve near the air-fuel mixture opening and extend from there along the air cleaner base, and has a cross section surrounded by a peripheral wall. The air guide member defines a mixture-use air extension passage for air to be added to prepare an air-fuel mixture air-fuel mixture, which extends from a first clean air intake to the air-fuel mixture opening. Blown-back gas from the air-fuel mixture passage hits against the inner wall of the curved portion of the air guide member, and is therefore restricted to flow out of the first clean air intake and leak into the air cleaner. Thereby, harmful emissions in the exhaust gas from the two-stroke internal engine can be reduced.

Owner:YAMABIKO CORP

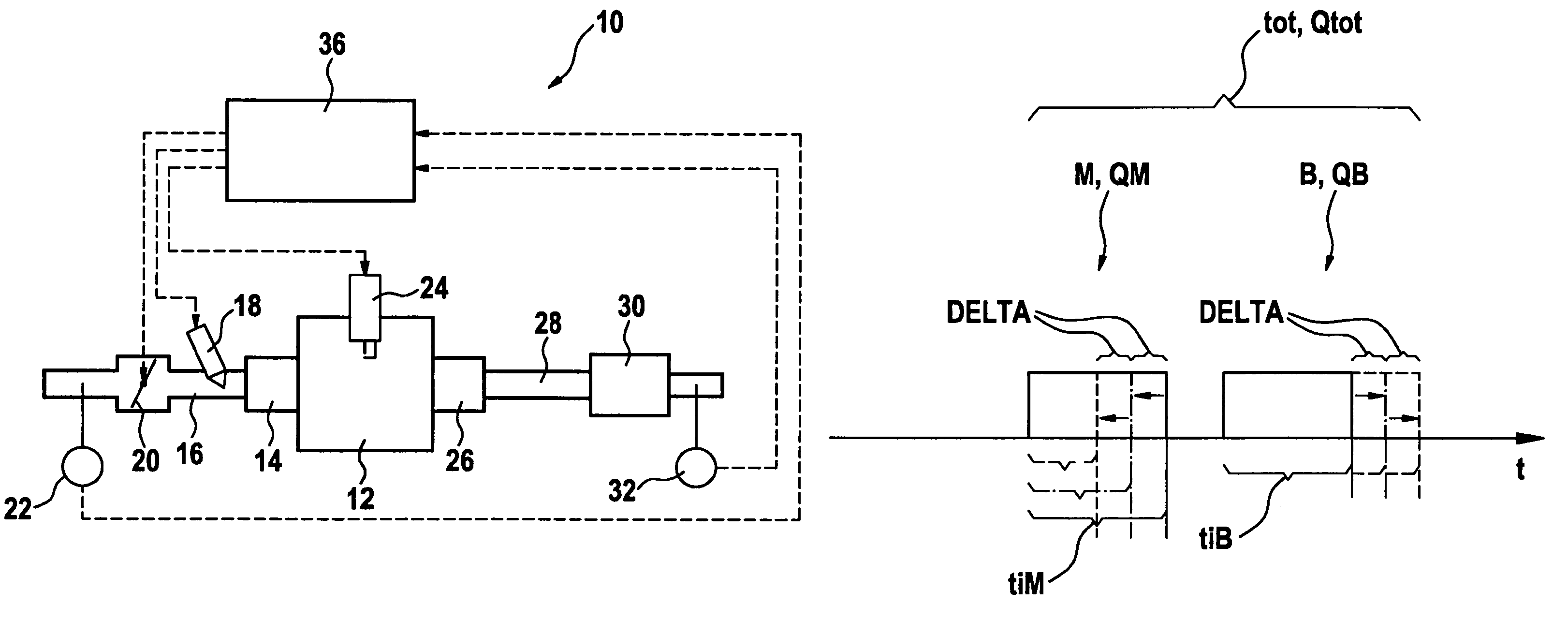

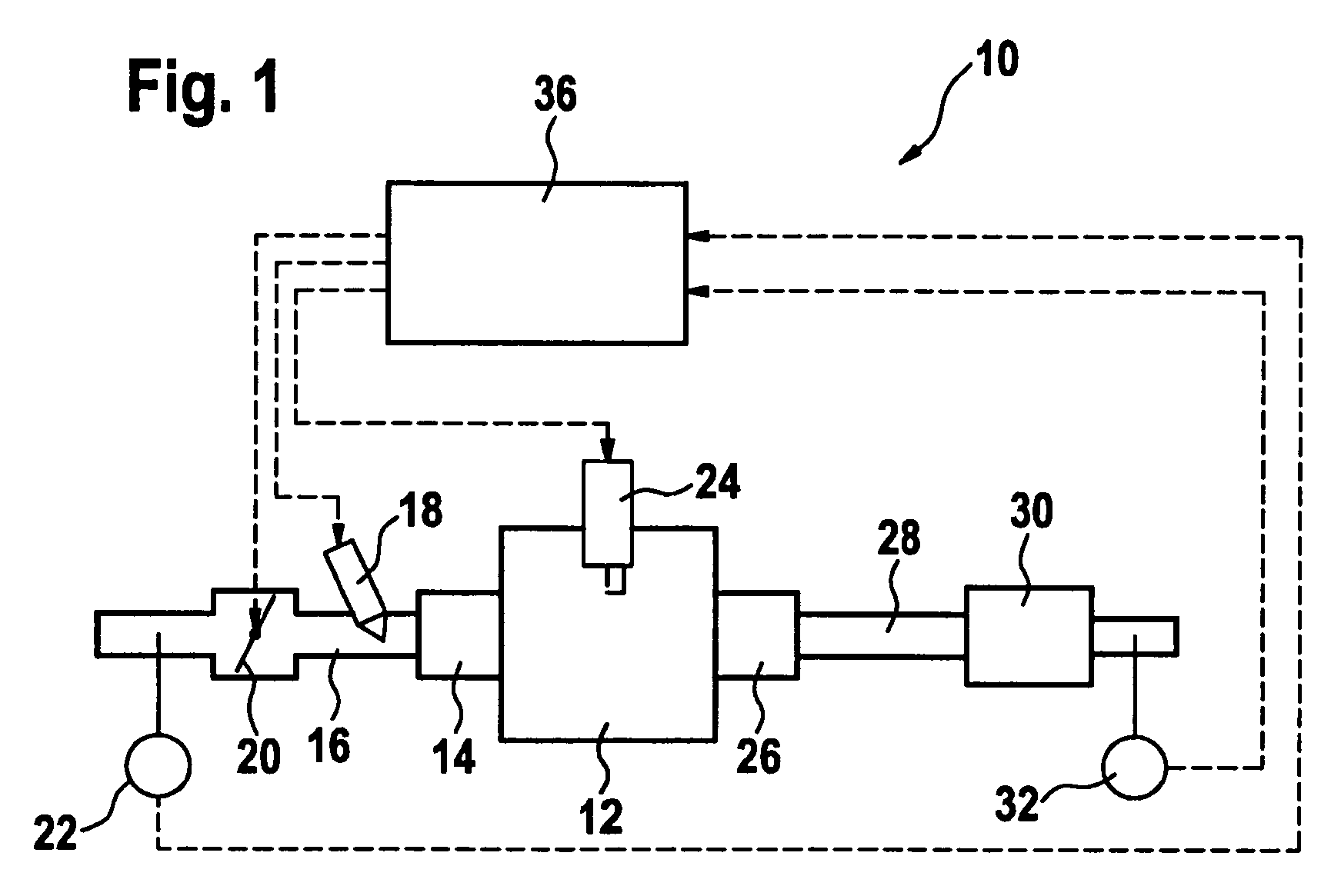

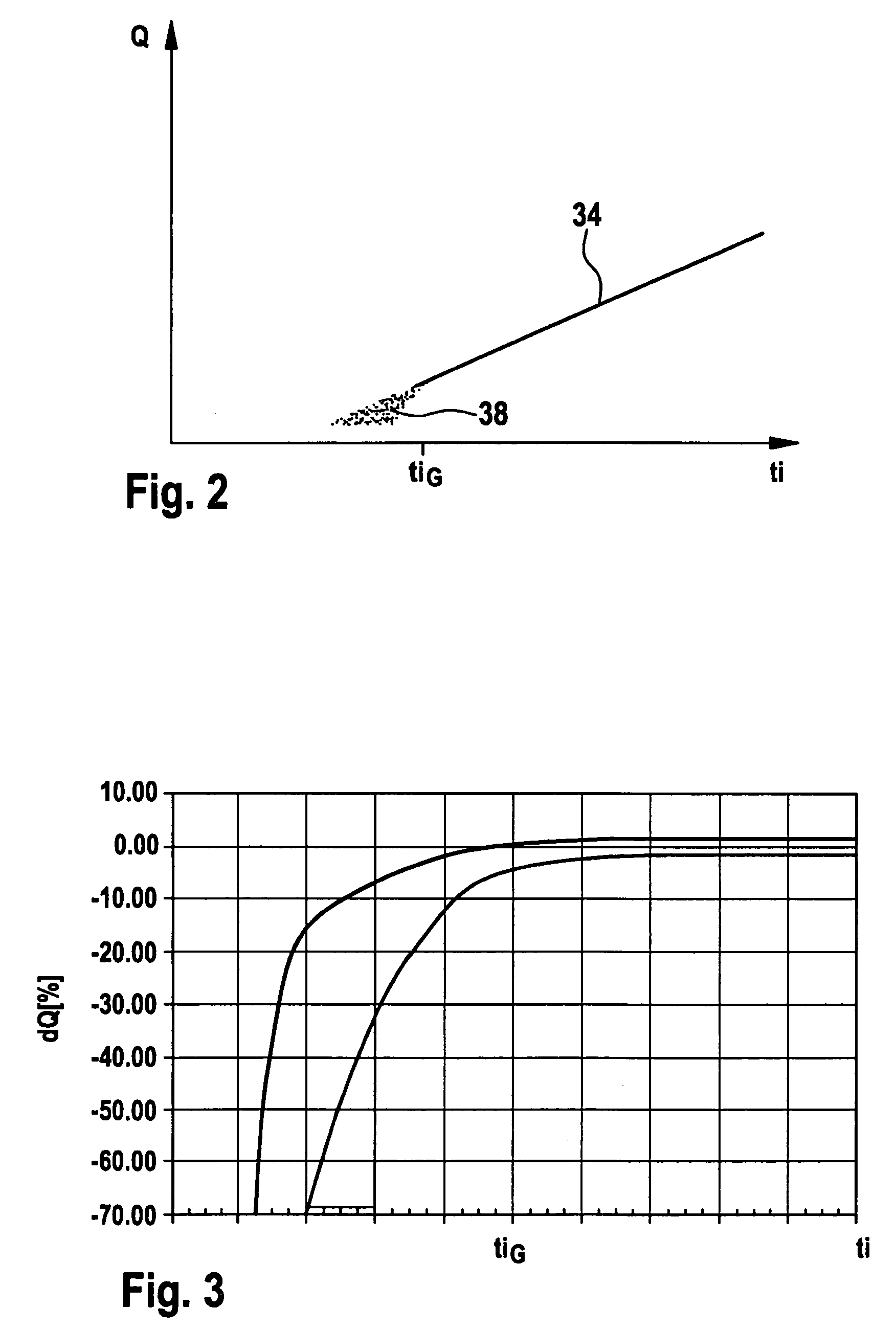

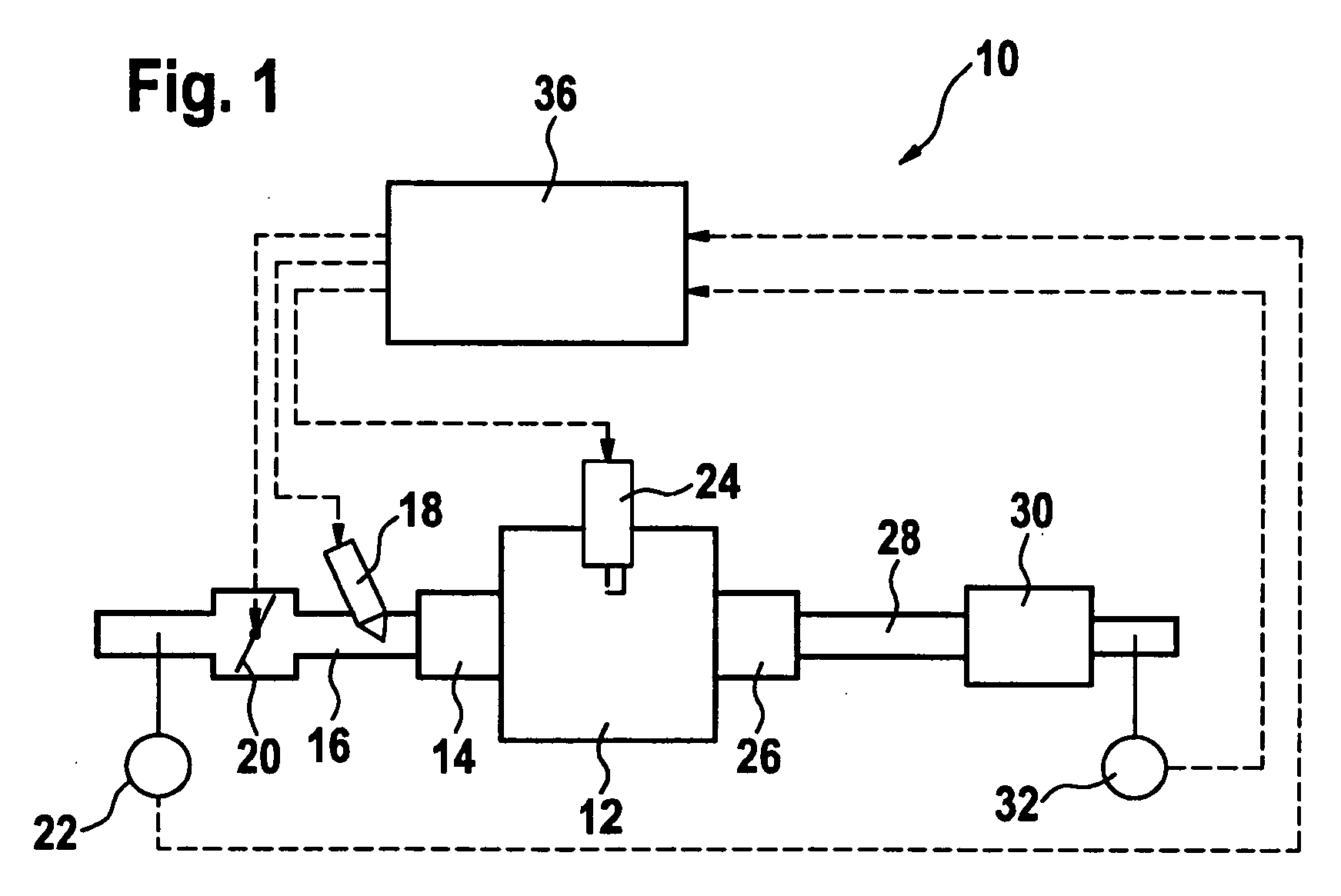

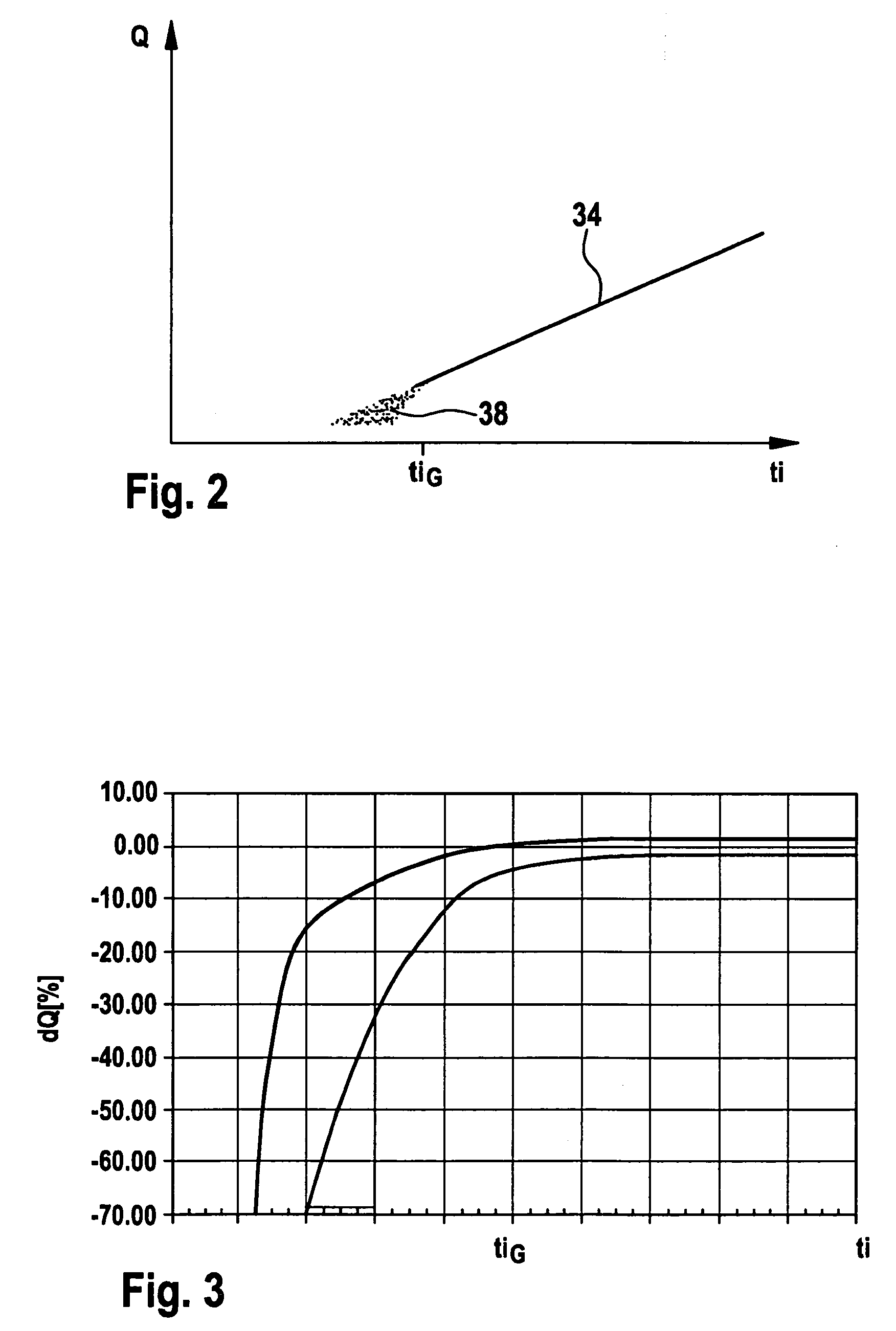

Method for operating an internal combustion engine

InactiveUS7881857B2Guaranteed uptimeTorque and running smoothnessElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

In a method for operating an internal combustion engine, the fuel is supplied to at least one combustion chamber via at least one injector, which method includes the following steps: a) a total injection is divided into a basic injection and at least one measured injection; b) the injection time of the measured injection is successively decreased and the injection time of the basic injection is successively increased so that a total injection quantity ascertained from a valve characteristic curve remains the same.

Owner:ROBERT BOSCH GMBH

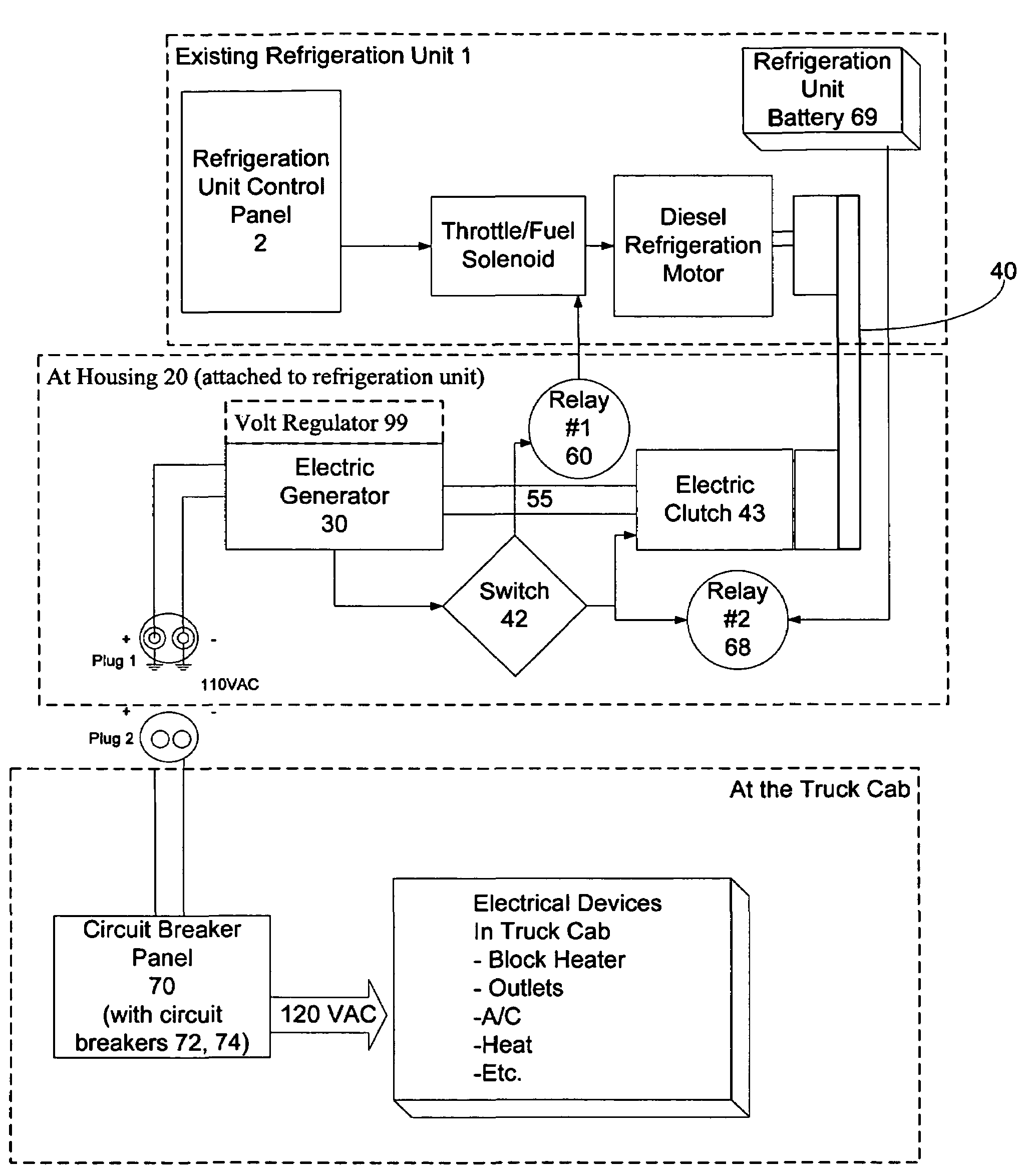

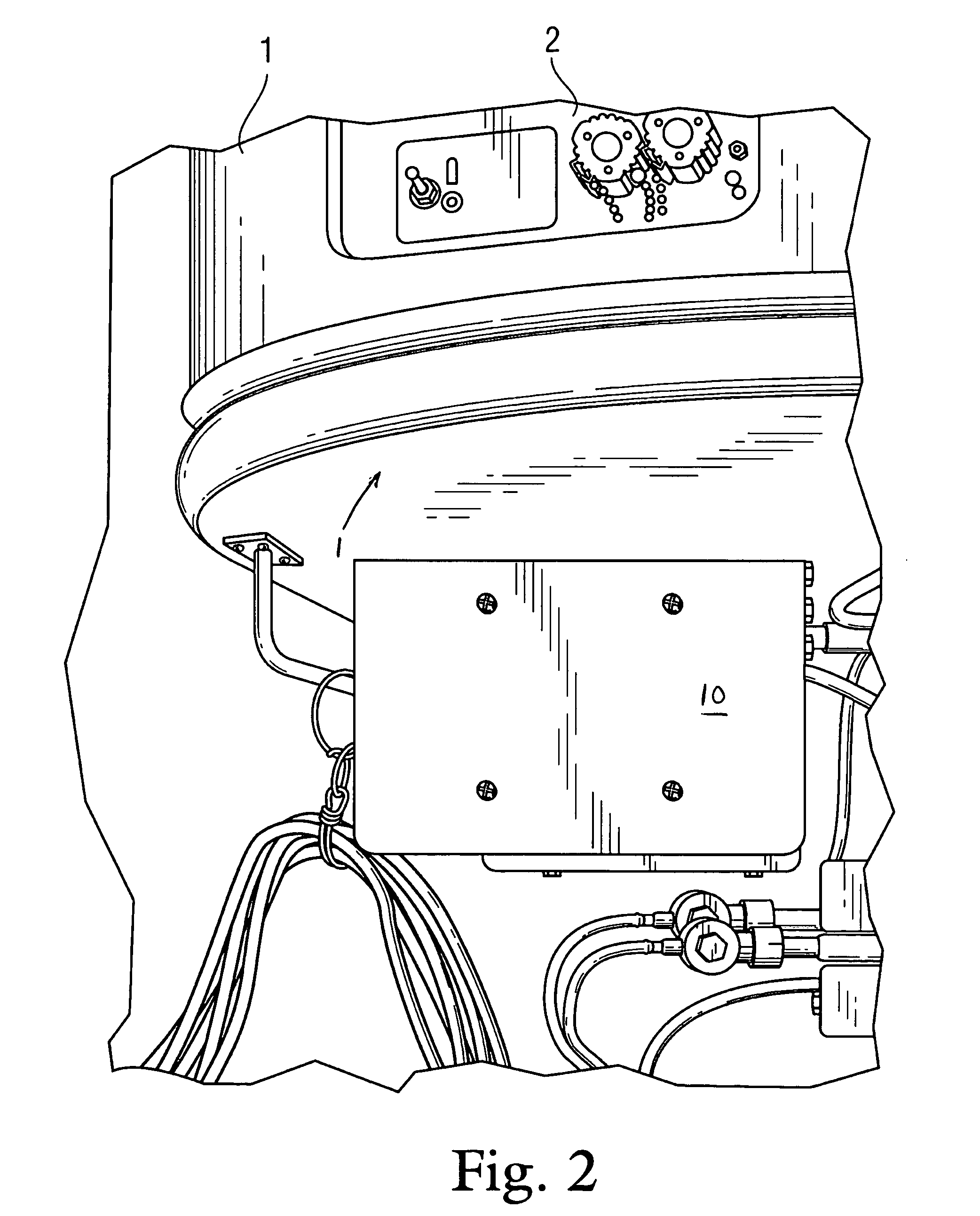

Auxiliary power device for refrigerated trucks

InactiveUS7673466B2Save fuelHarmful emissionAir-treating devicesRefrigerated goods vehicleElectrical batteryDrive shaft

An auxiliary power device for attachment to an existing refrigeration unit of a refrigerated trailer to serve as a power source to a truck cab, thereby allow operation of electrical devices in said cab without idling of the truck's engine. The auxiliary power device comprises a housing attached beneath the existing refrigeration unit, an electric generator enclosed within the housing, and a pulley assembly mounted in the housing and connected by drive shaft to the generator. The pulley assembly is connected via drive belt to the diesel motor in the existing refrigeration unit. When the generator is activated a first relay governs the speed of the diesel motor in the refrigeration unit, which turns the generator to generate power, and a second relay prevents drainage of the refrigeration unit battery. The power from the generator is routed through a breaker panel mounted in the cab of the truck for distributing and regulating power from the battery and / or generator into the truck cab. Thus, the driver can power electric devices in the cab from the auxiliary power generation device without idling the truck's main engine, thereby reducing fuel consumption, harmful emissions, and prolonging engine life.

Owner:PACY DAVID H

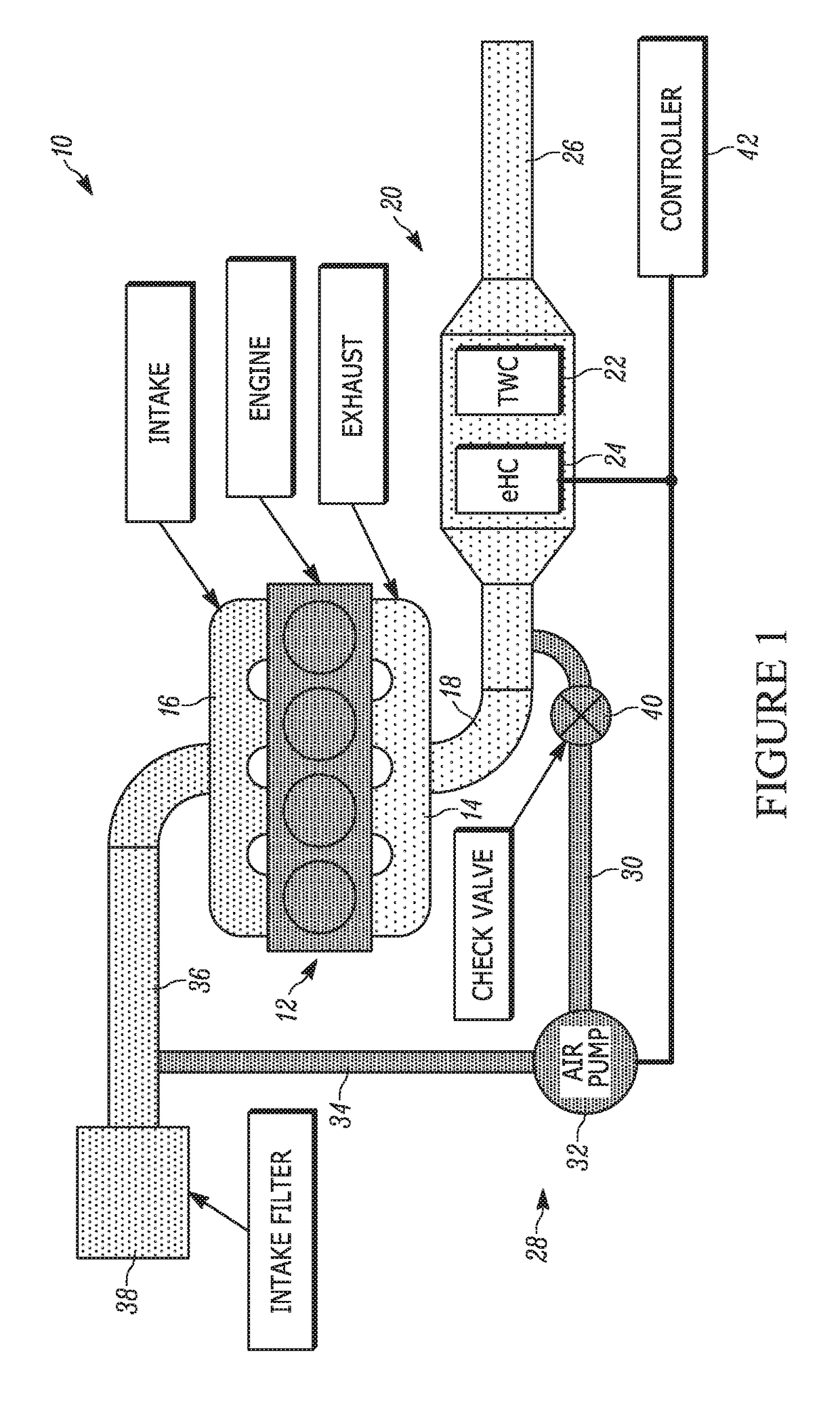

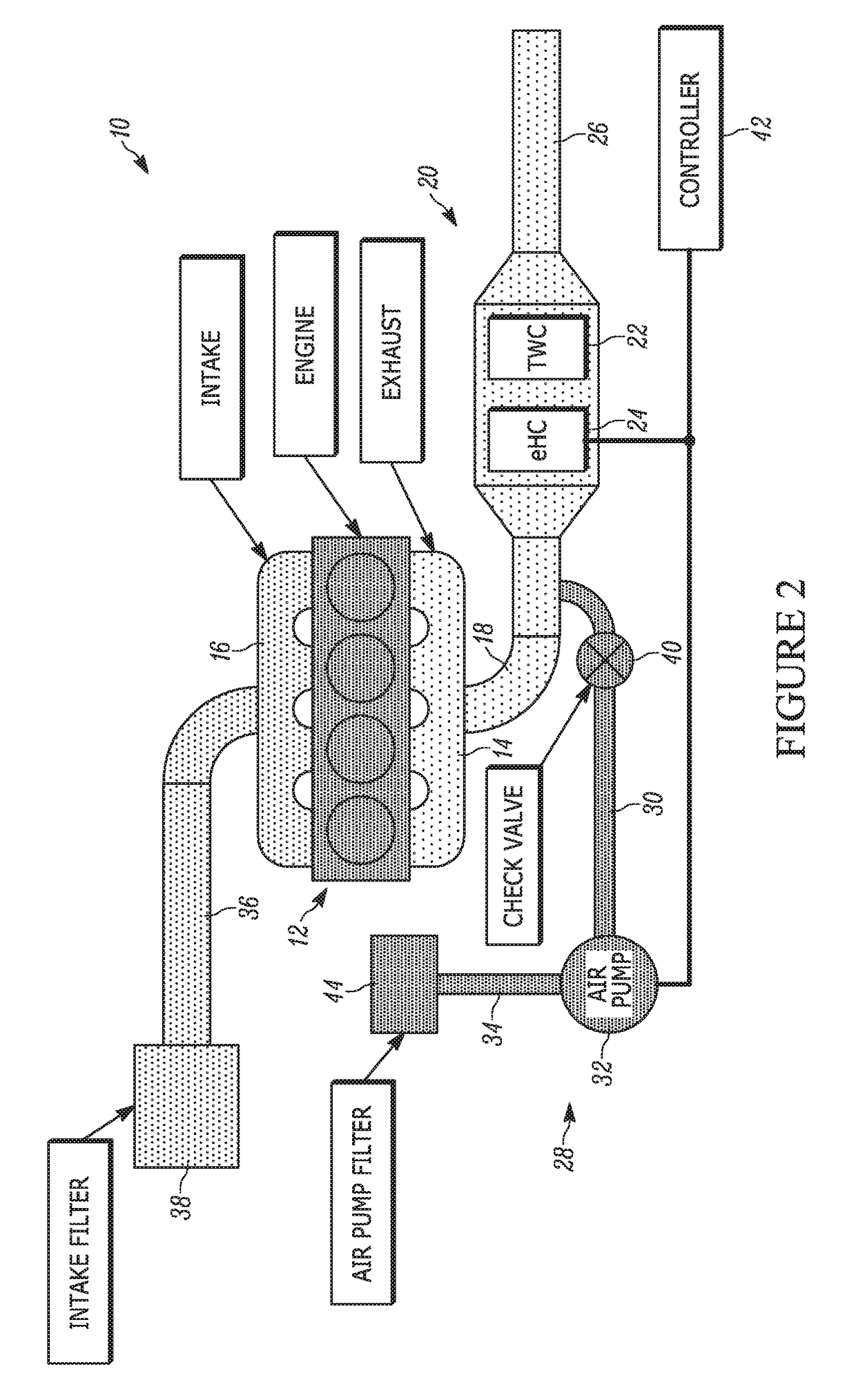

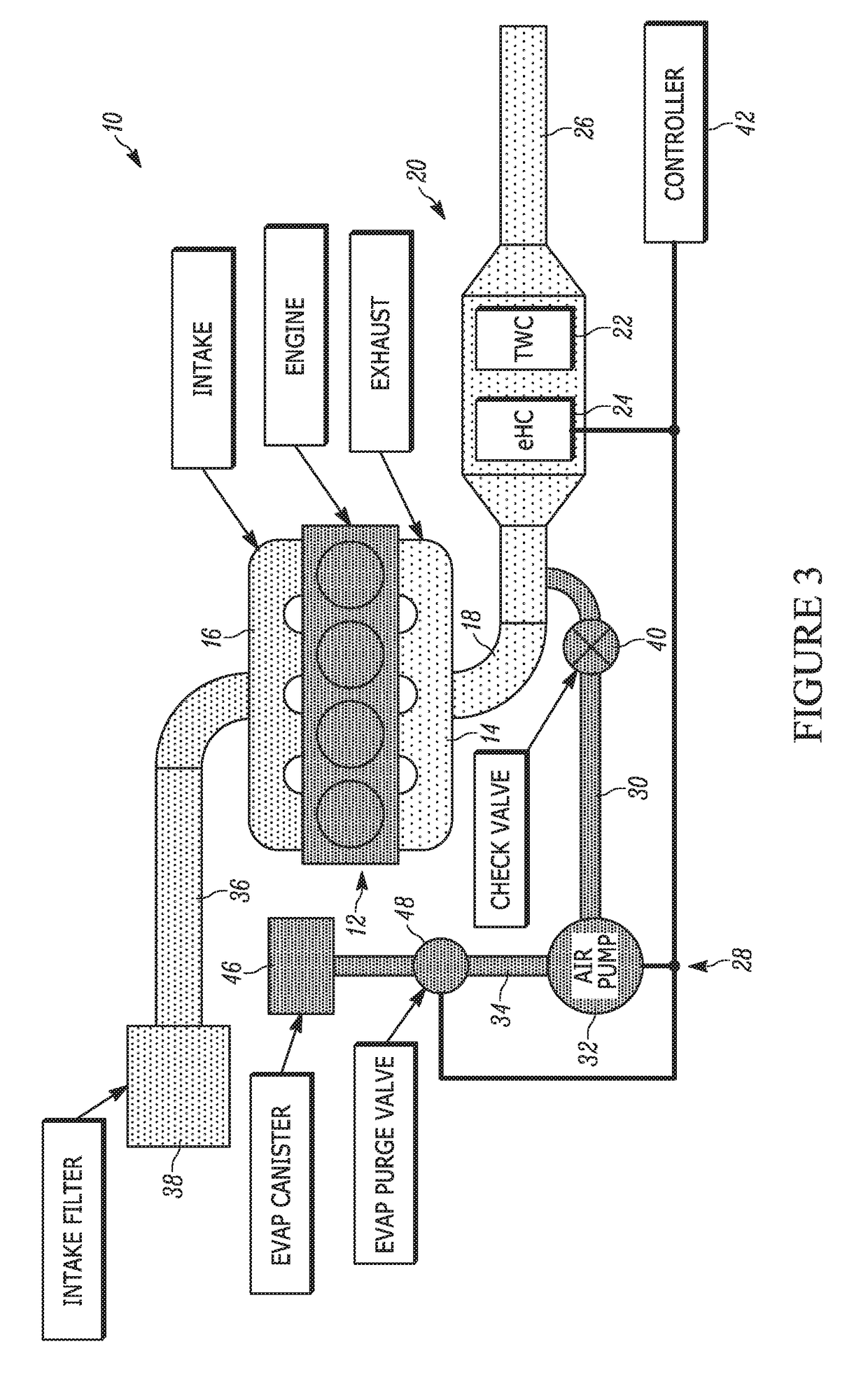

Proactive catalyst heating

ActiveUS20190063352A1Harmful emissionReduce processElectrical controlNon-fuel substance addition to fuelEngineeringInternal combustion engine

A proactive heating system for a vehicle, which is used to increase the temperature of an exhaust catalyst prior to ignition of an engine to reduce emissions. The proactive heating system is part of an exhaust system for a vehicle, and includes an electrically heated catalyst and an air pump, which are activated prior to engine ignition, to increase the temperature of a three-way catalyst such that the three-way catalyst is at the desired target threshold temperature, or light-off temperature, prior to engine ignition, eliminating the delay in emissions treatment after cold-start of the engine. The proactive heating system addresses the high level of untreated emissions emitted from an internal combustion engine before the catalytic emissions system reaches the light-off temperature. The proactive heating system provides heating of a catalyst to light-off temperature without combusting hydrocarbon fuel, which leads to engine out emissions.

Owner:VITESCO TECH USA LLC

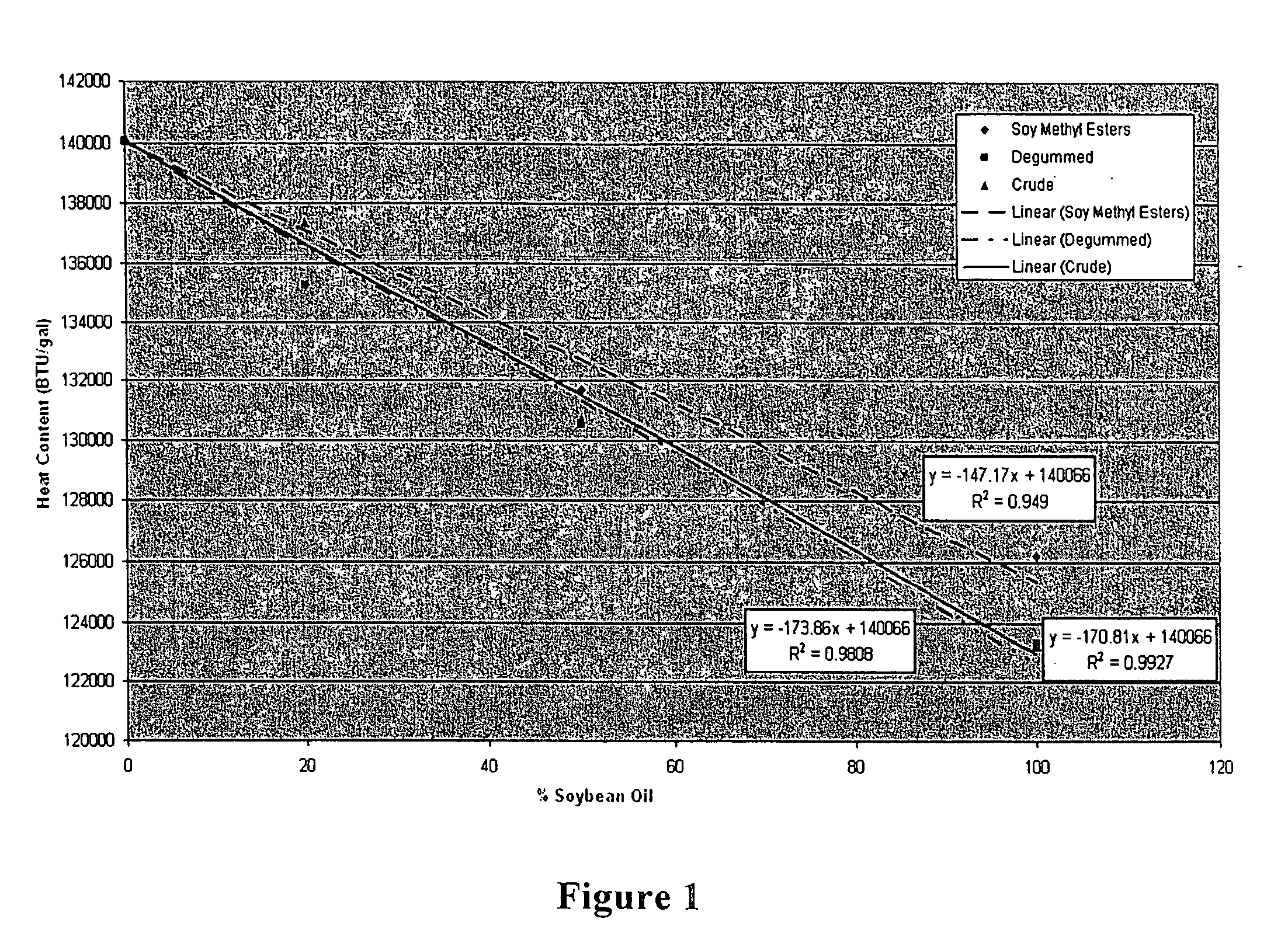

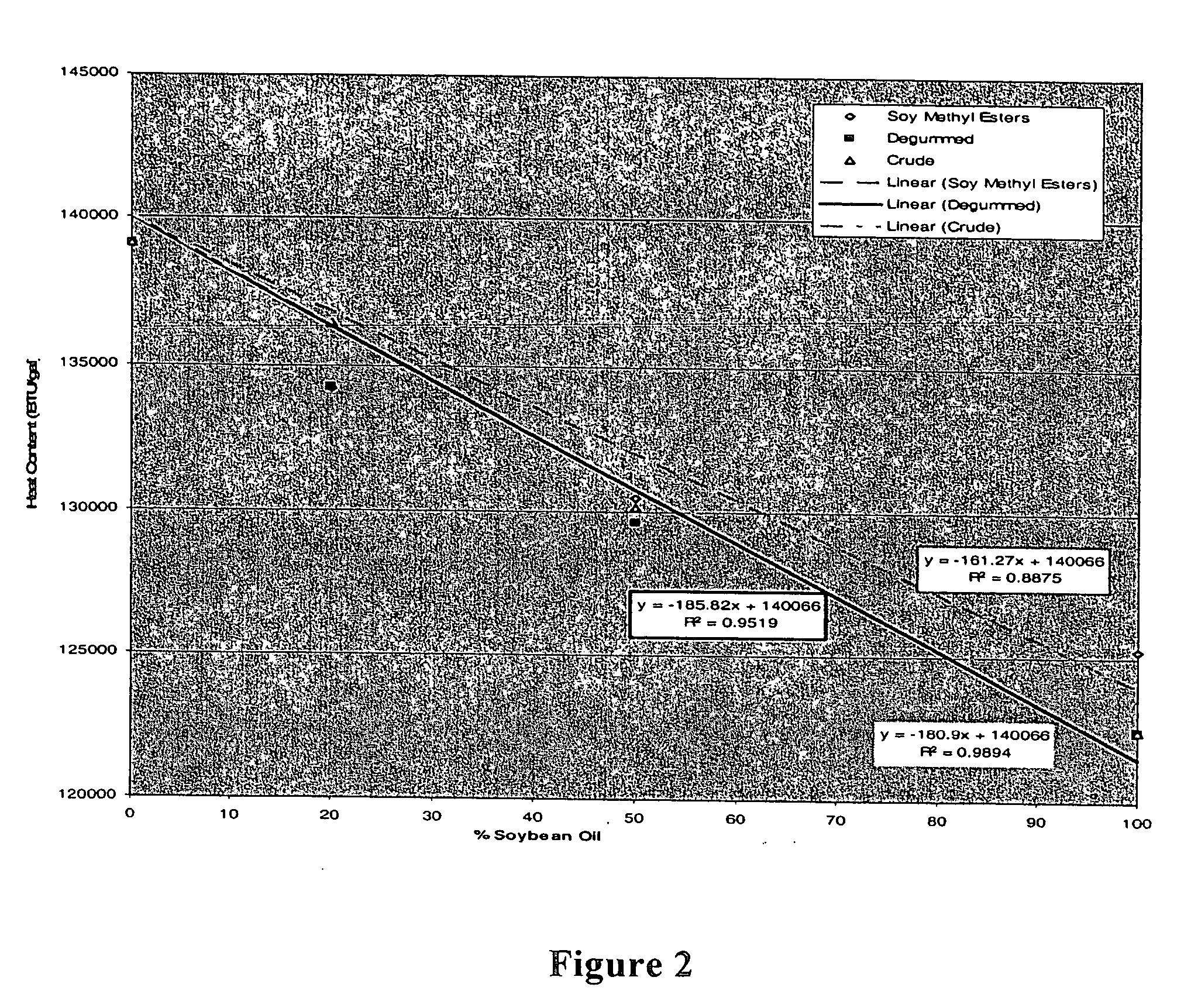

Heating fuel blend

An embodiment of the invention provides a heating fuel blend comprising a petroleum based fuel and a vegetable oil. The petroleum based fuel can be selected from diesel fuel, fuel oil, and kerosene. The vegetable oil may be crude oil, degummed oil, or a mixture of crude and degummed oil and is selected from the group consisting of soybean oil, cottenseed oil, rapeseed oil, corn oil, peanut oil, sunflowerseed oil, palm kernel oil, copra oil and other oils of similar composition produced by plants. In a preferred embodiment, the vegetable oil is present in an amount greater than zero and up to about 50% by volume, in a more preferred embodiment the vegetable oil is present in an amount greater than zero and up to about 20% by volume. A preferred embodiment of the invention comprises a petroleum based fuel and a soybean oil, where the soybean oil is present in an amount greater than zero and up to about 20% by volume. The invention also involves a method of making the heating fuel blend and a method of heating a building with the heating fuel blend.

Owner:PURDUE RES FOUND INC

Steam enhanced double piston cycle engine

ActiveUS7273023B2Improve engine efficiencyReduce the temperatureInternal combustion piston enginesGas pressure propulsion mountingEngineeringPiston

A steam enhanced dual piston cycle engine utilizes a unique dual piston apparatus that includes: a first cylinder housing a first piston therein, wherein the first piston performs only intake and compression strokes; a second cylinder housing an inner power piston that forms an inner internal chamber of the second cylinder, and either a ring-shaped outer power piston surrounding the inner power piston, wherein the outer power piston forms an outer internal chamber of the second cylinder and is configured to convert engine heat into additional work, and / or an outer boiler which is configured to produce steam to be converted into additional work.

Owner:TOUR ENGINE INC

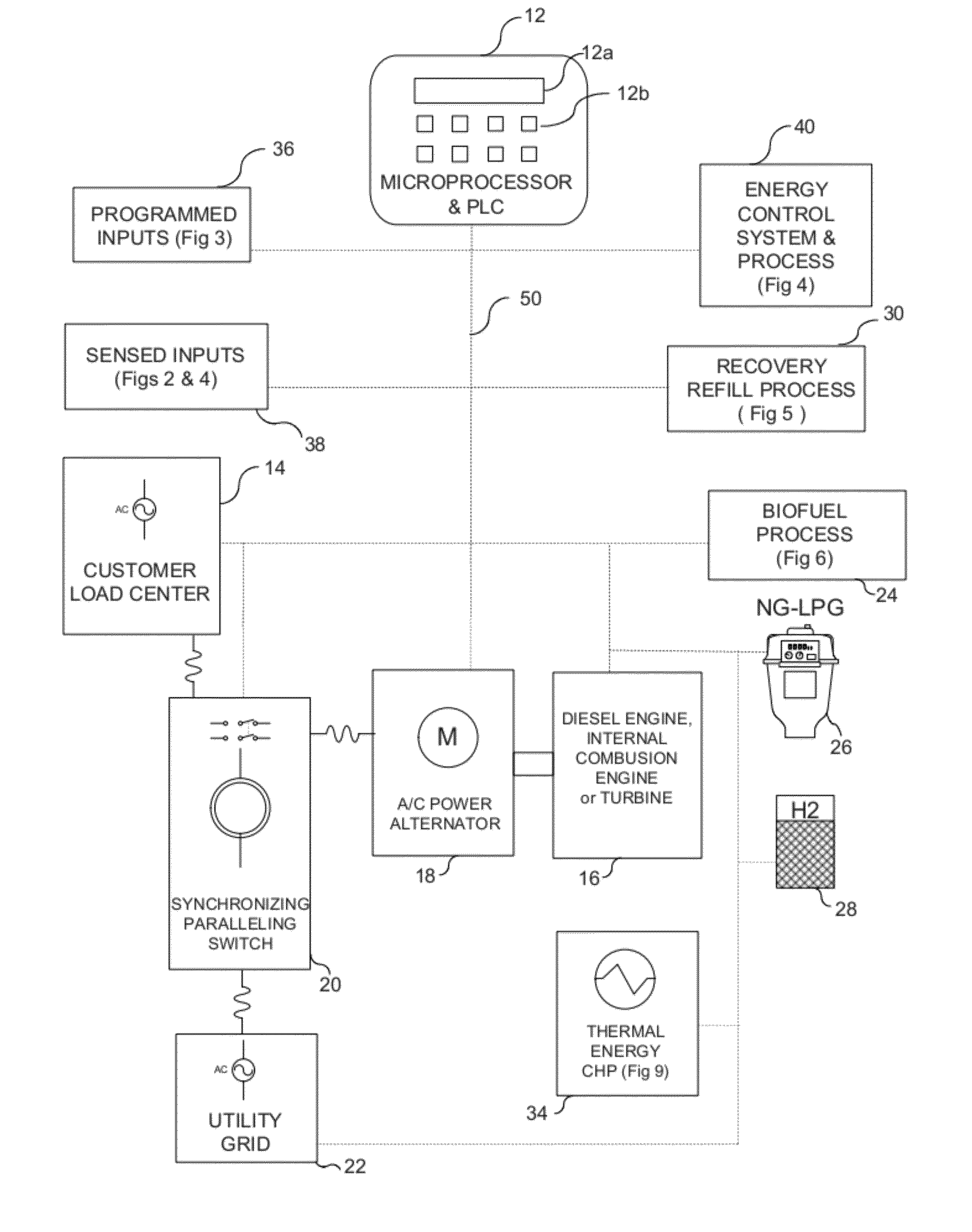

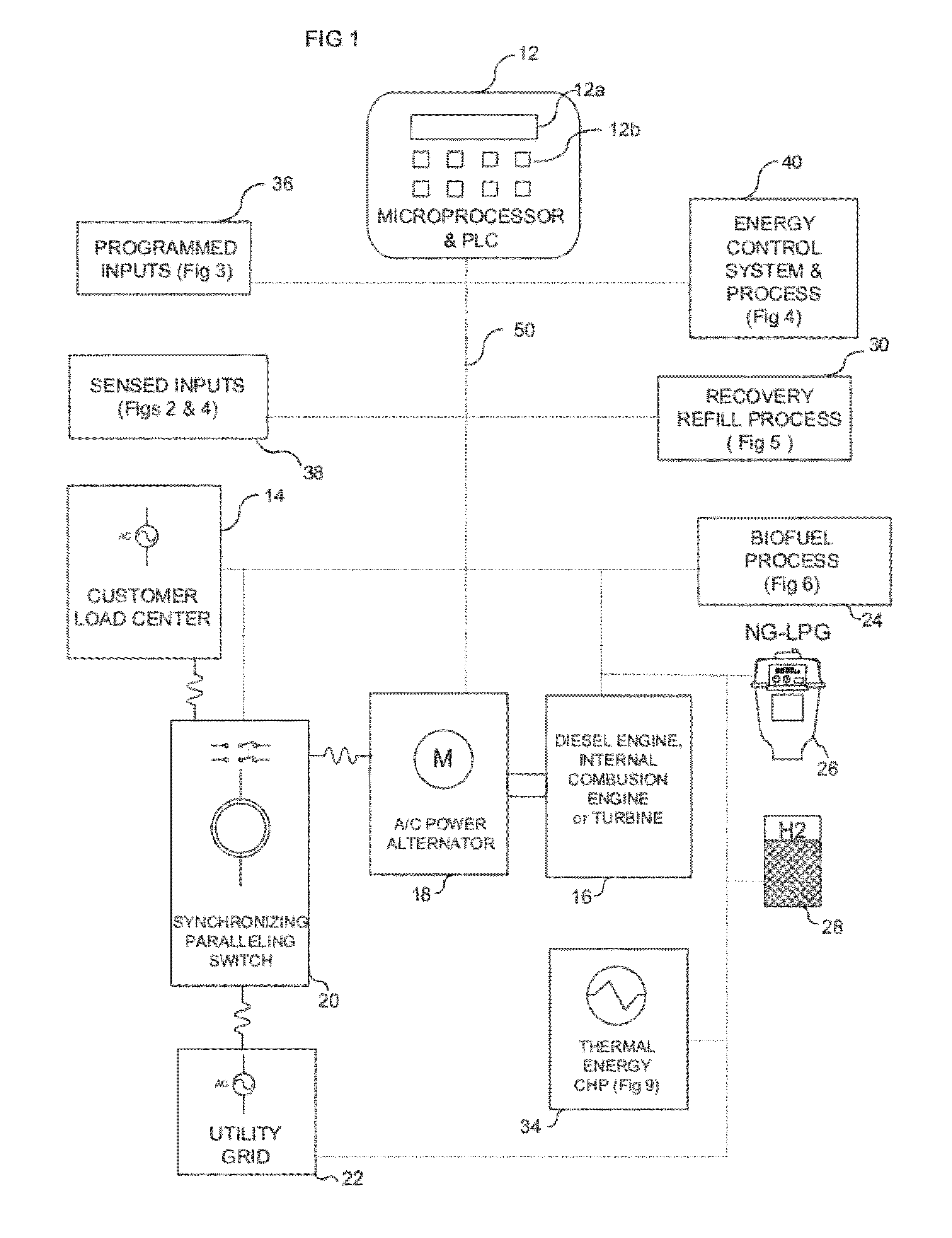

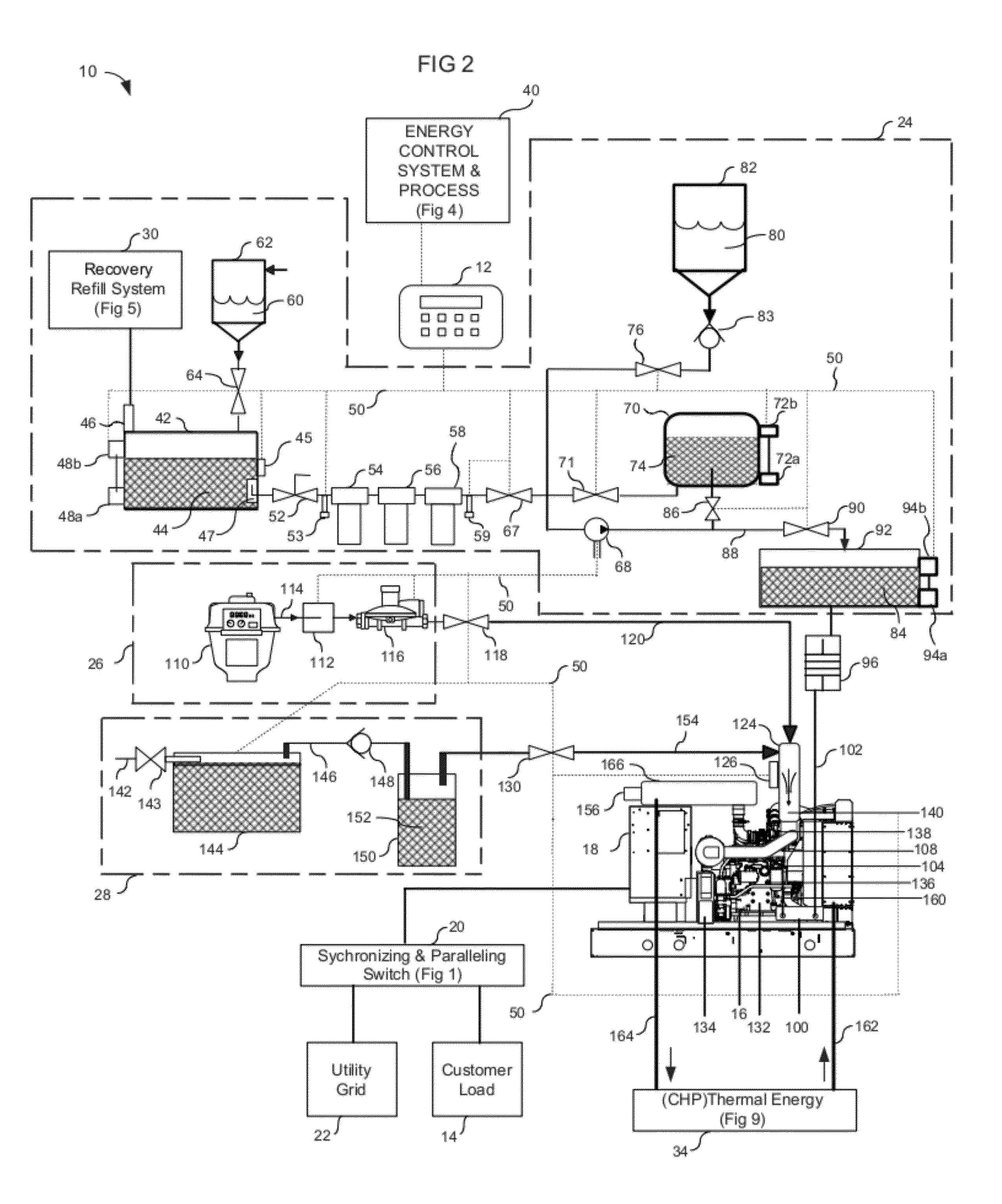

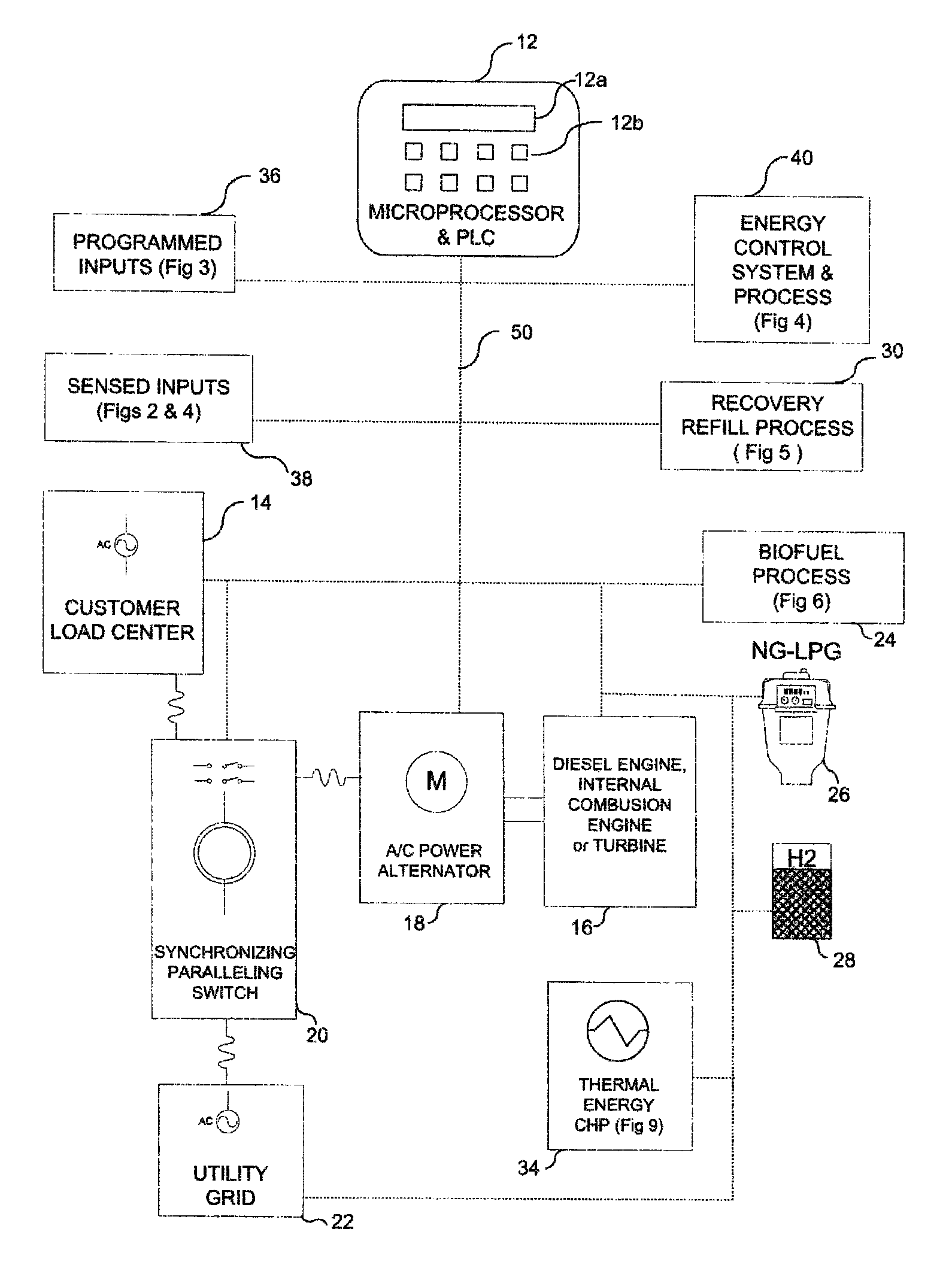

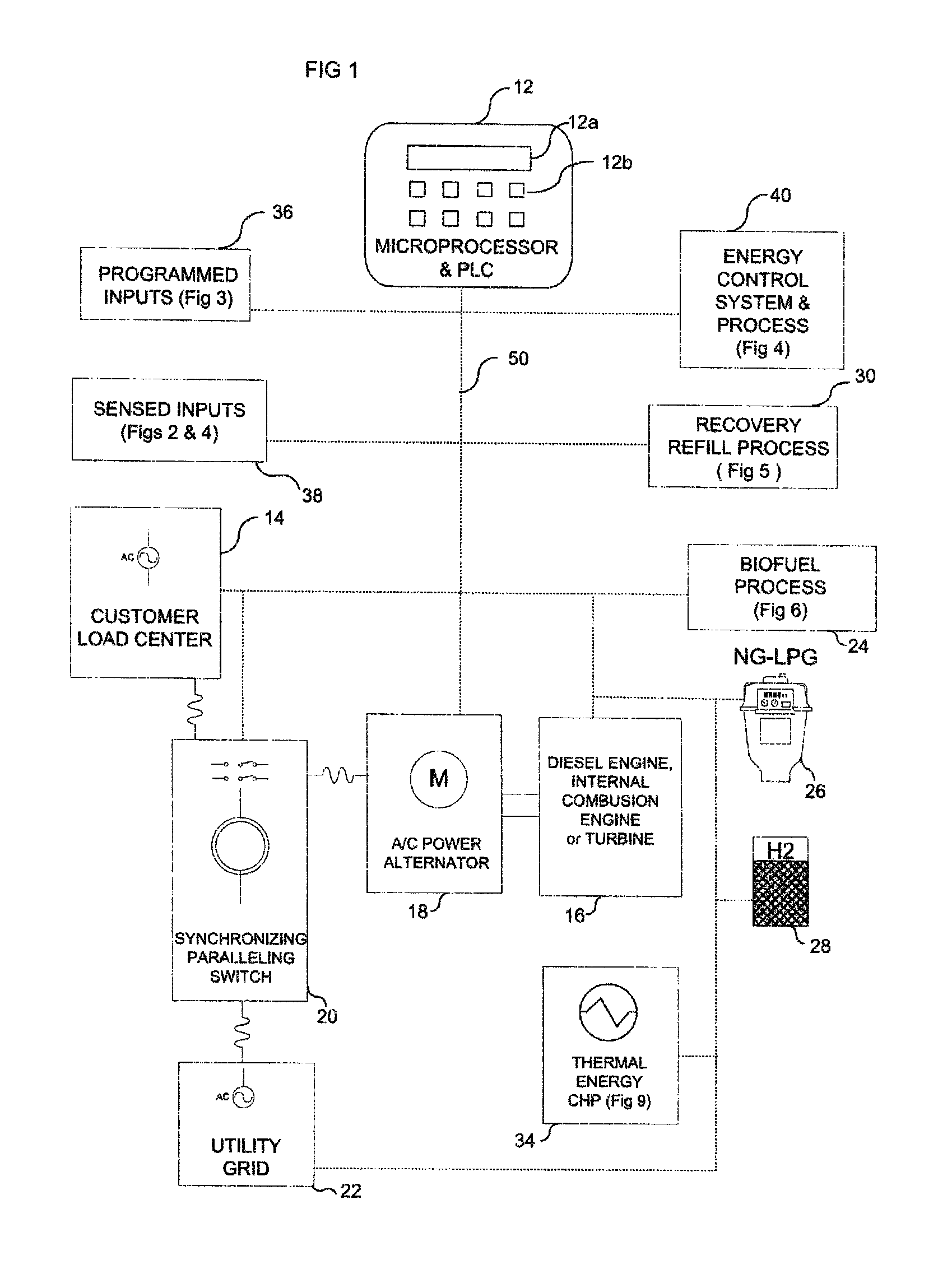

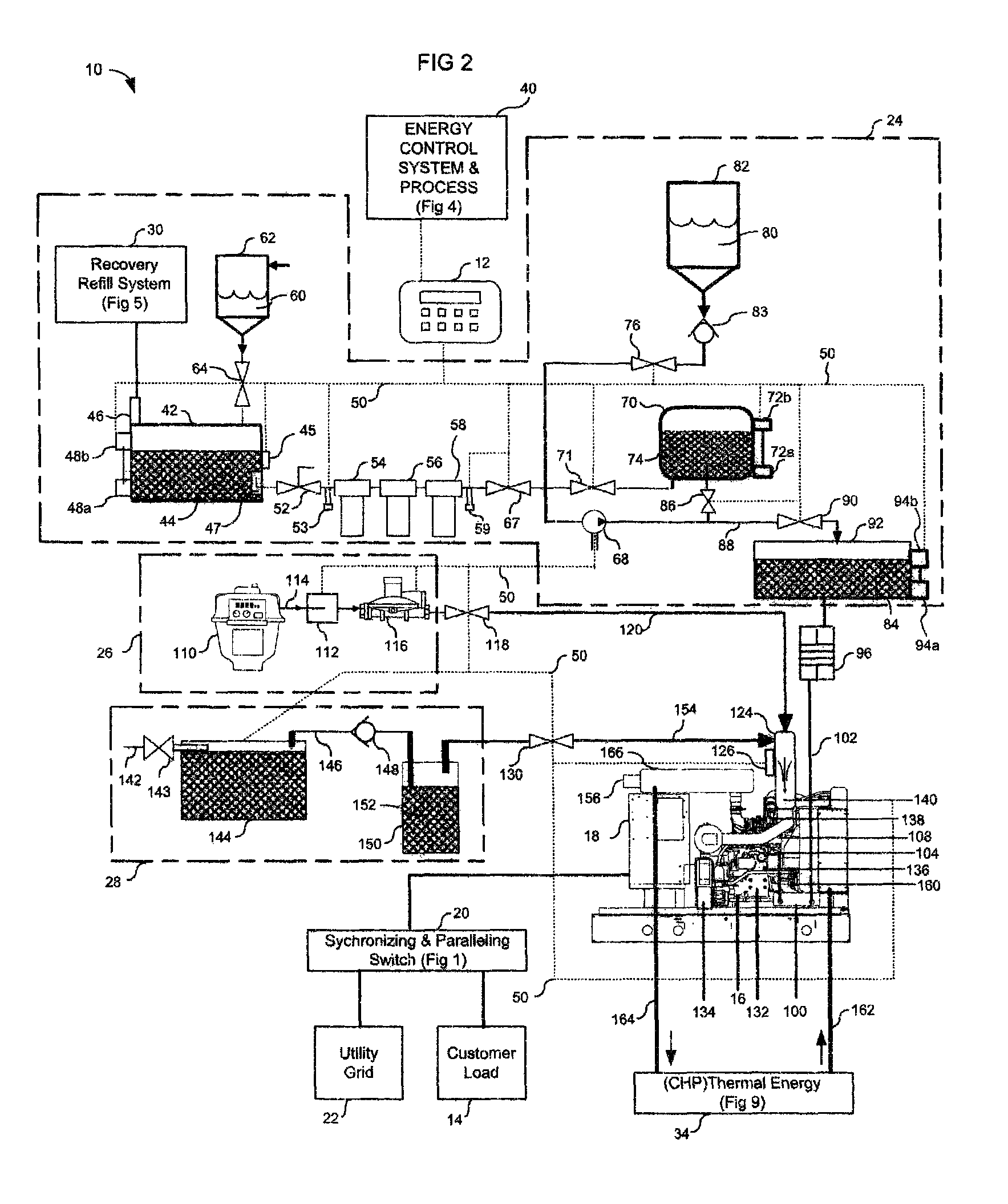

Microprocessor controlled automated mixing system, cogeneration system and adaptive/predictive control for use therewith

InactiveUS8301359B1Improve fuel efficiencyReduce harmful emissionsAnalogue computers for vehiclesDigital data processing detailsHybrid systemCogeneration

A microprocessor controlled automated, multi-fuel apparatus to blend hydrogen, bio-fuel and / or natural or propane gases. This novel multi-stage apparatus first converts cooking oils into bio-fuel. The system automatically blends the bio-fuel with at least one of or both hydrogen gas, generated by a self-contained on-board hydrogen electrolyzer, and / or natural or propane gases. This blended “Hyenrich” gaseous fuel drives various processes including, but not limited to, cogeneration systems and electrical generators to produce “green” electricity by utilizing an adaptive and predictive learning algorithms to significantly reduce cost per kilowatt and lessen dependency on the over taxed utility grid, while simultaneously reducing emissions of CO, CO2 and NOx, making the method and apparatus an environmentally-friendly energy device.

Owner:HYCOGEN POWER

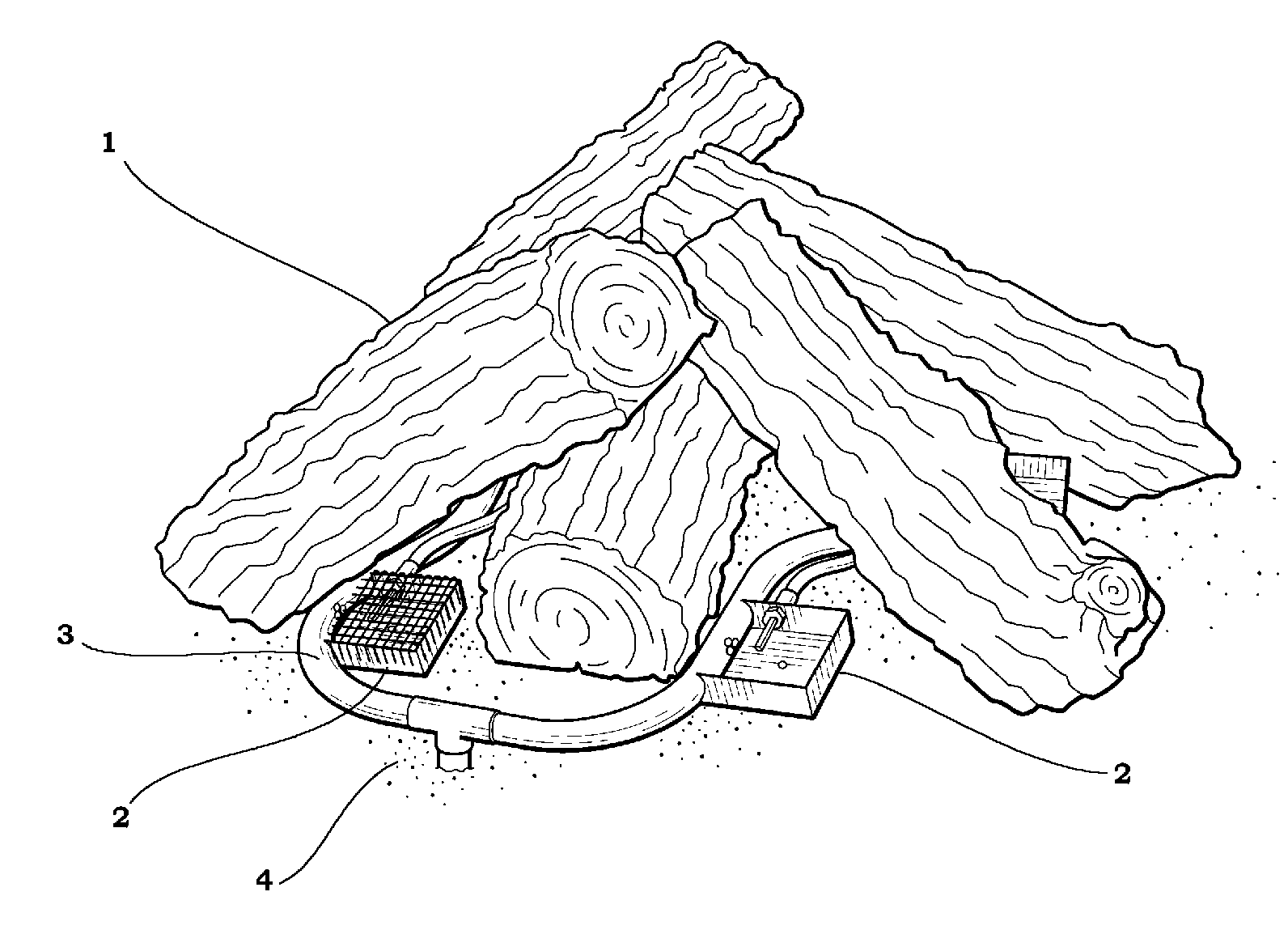

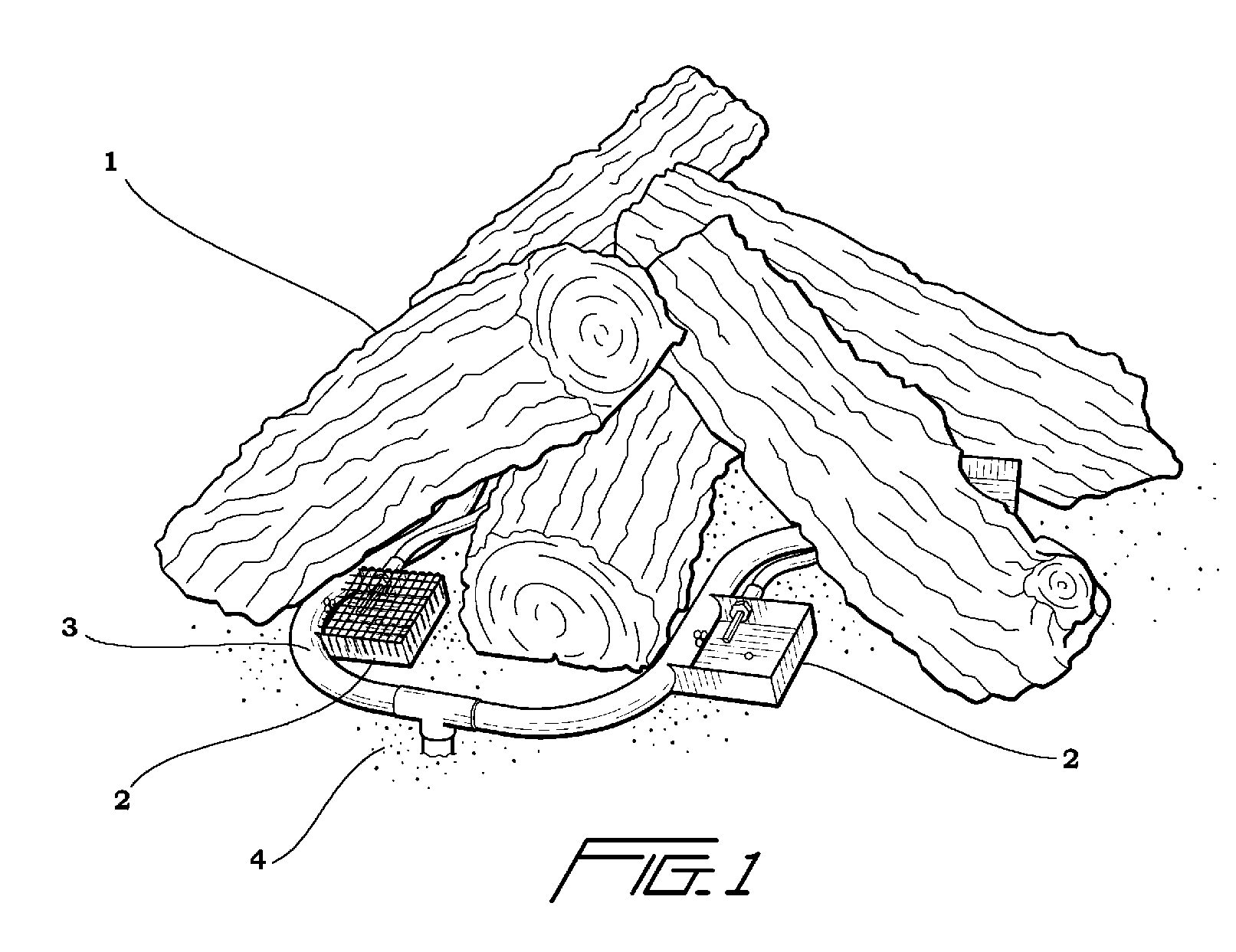

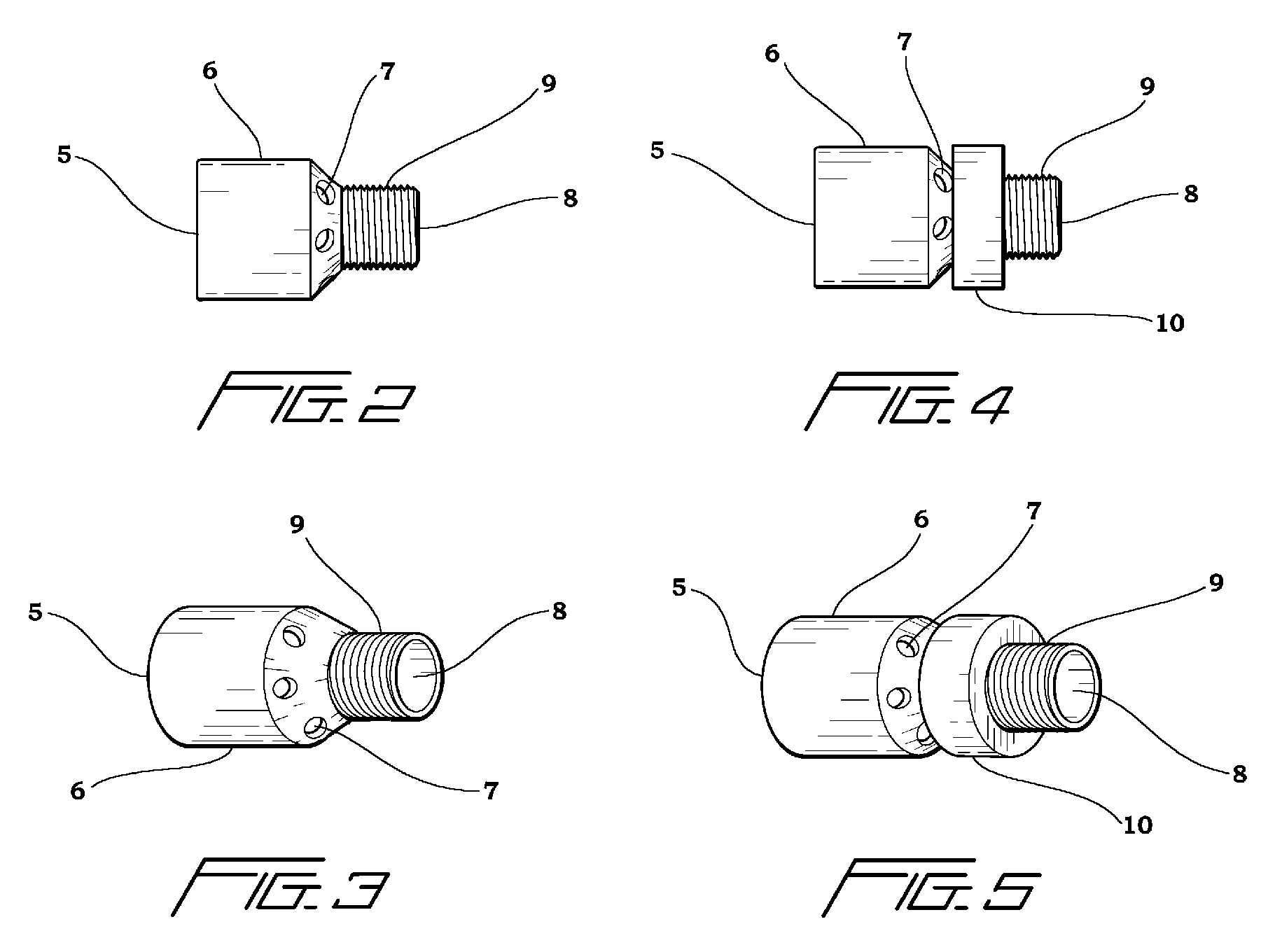

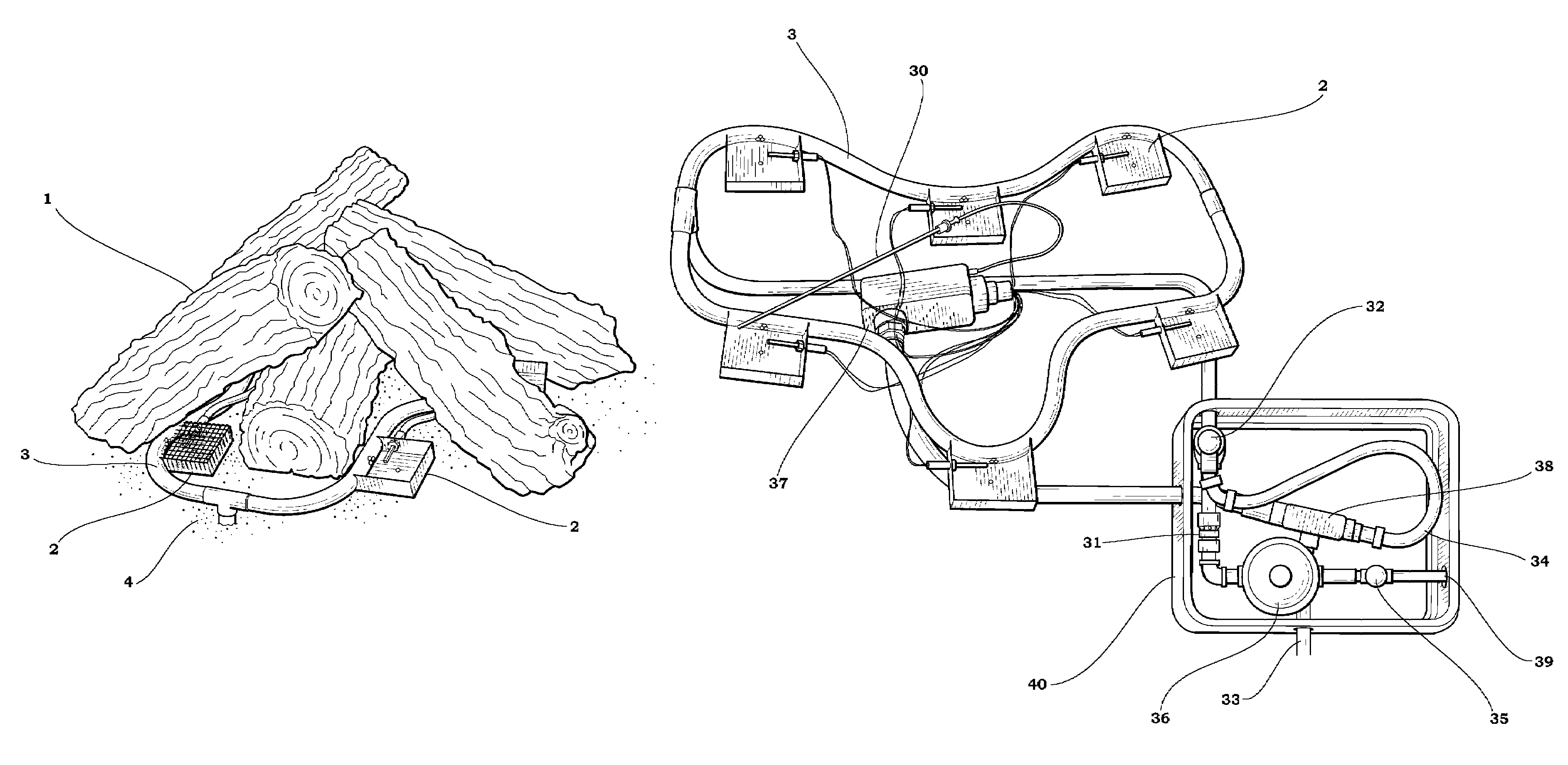

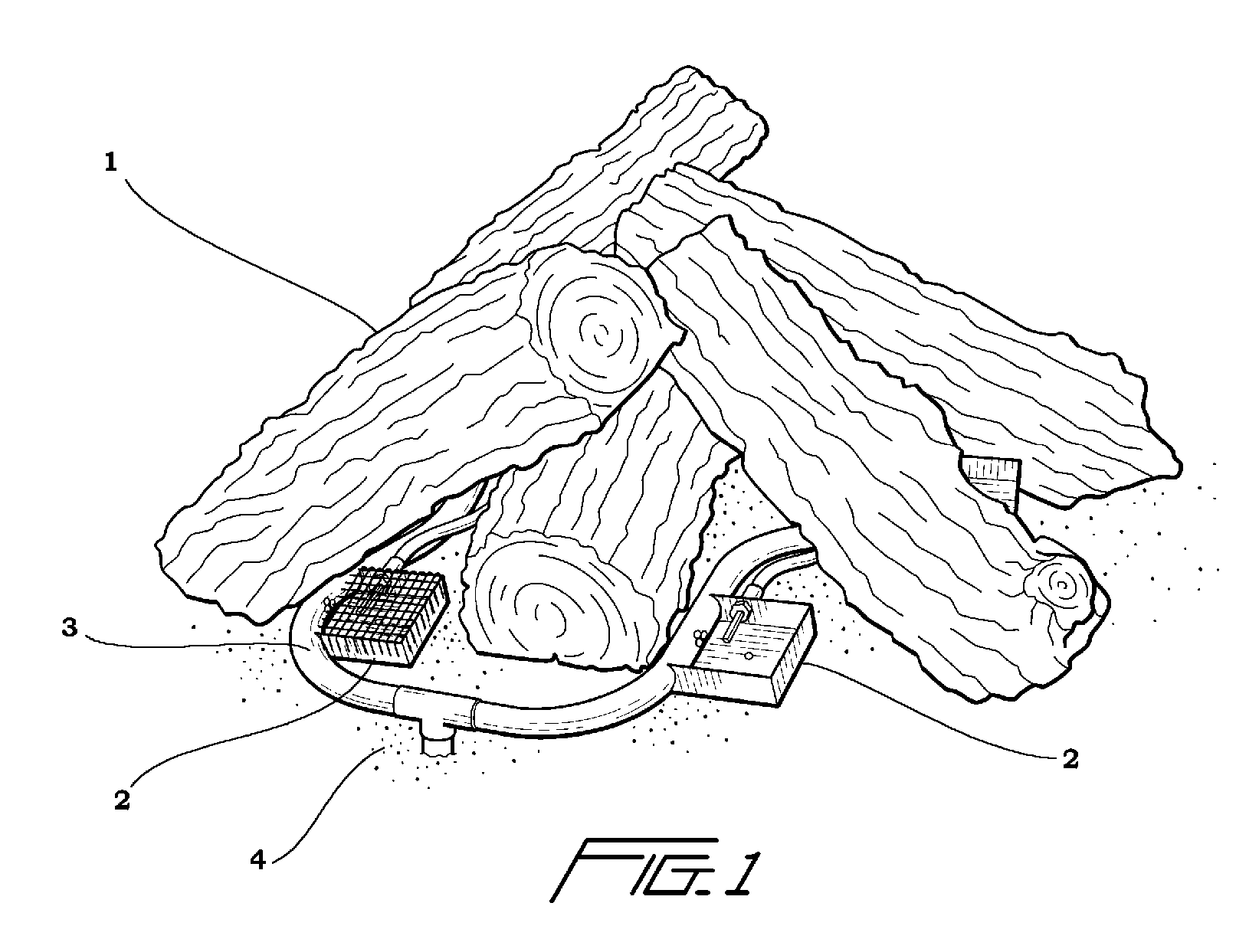

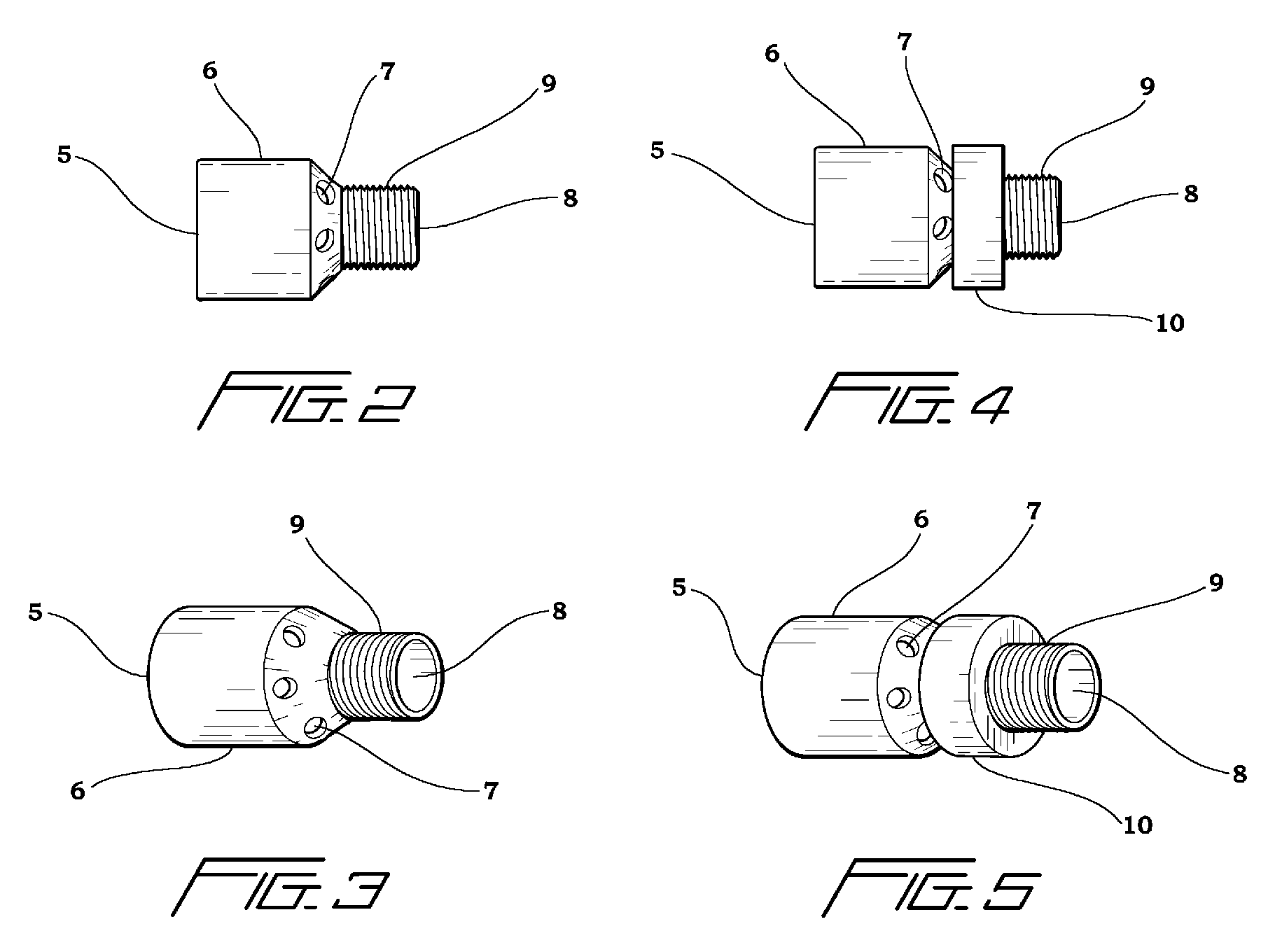

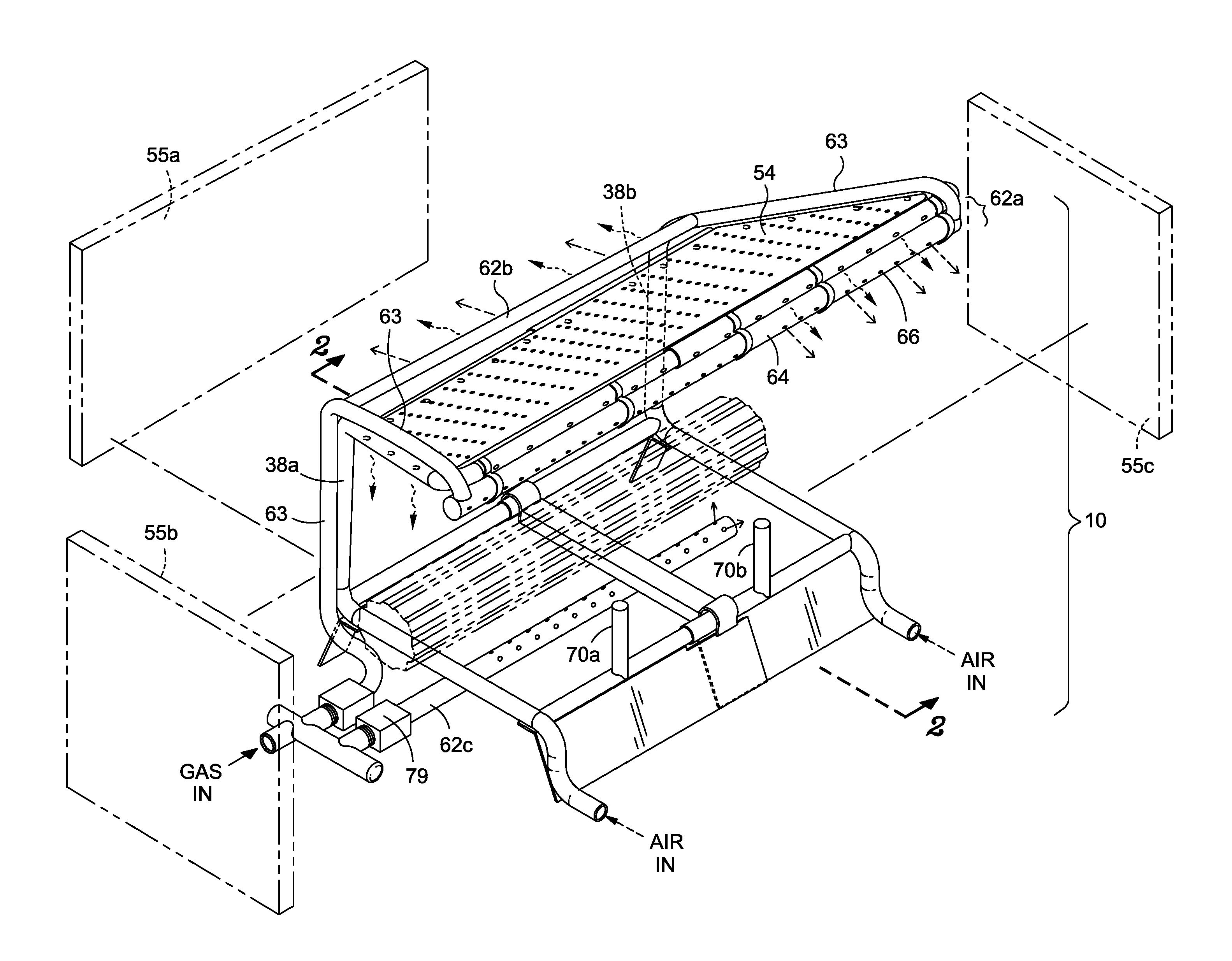

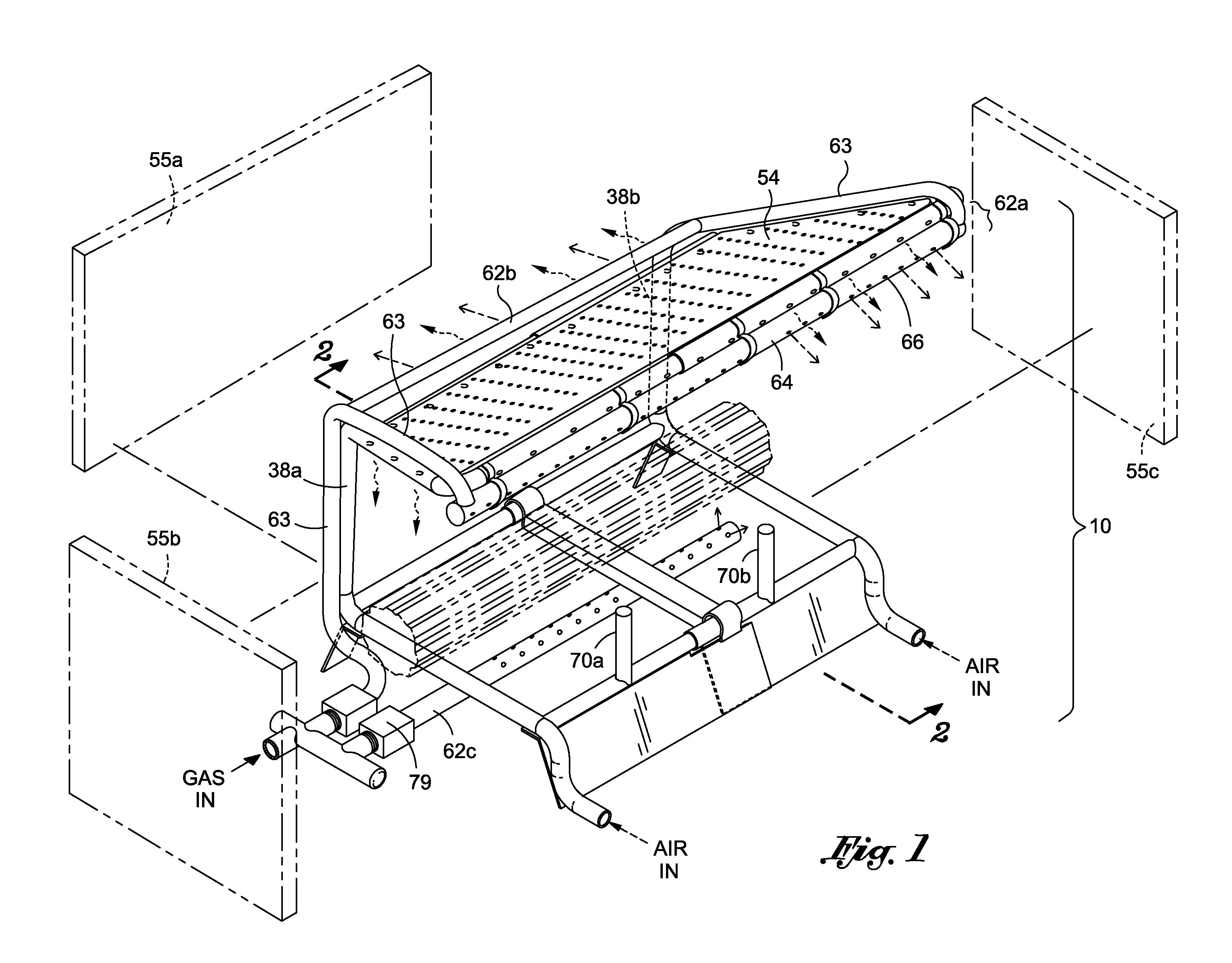

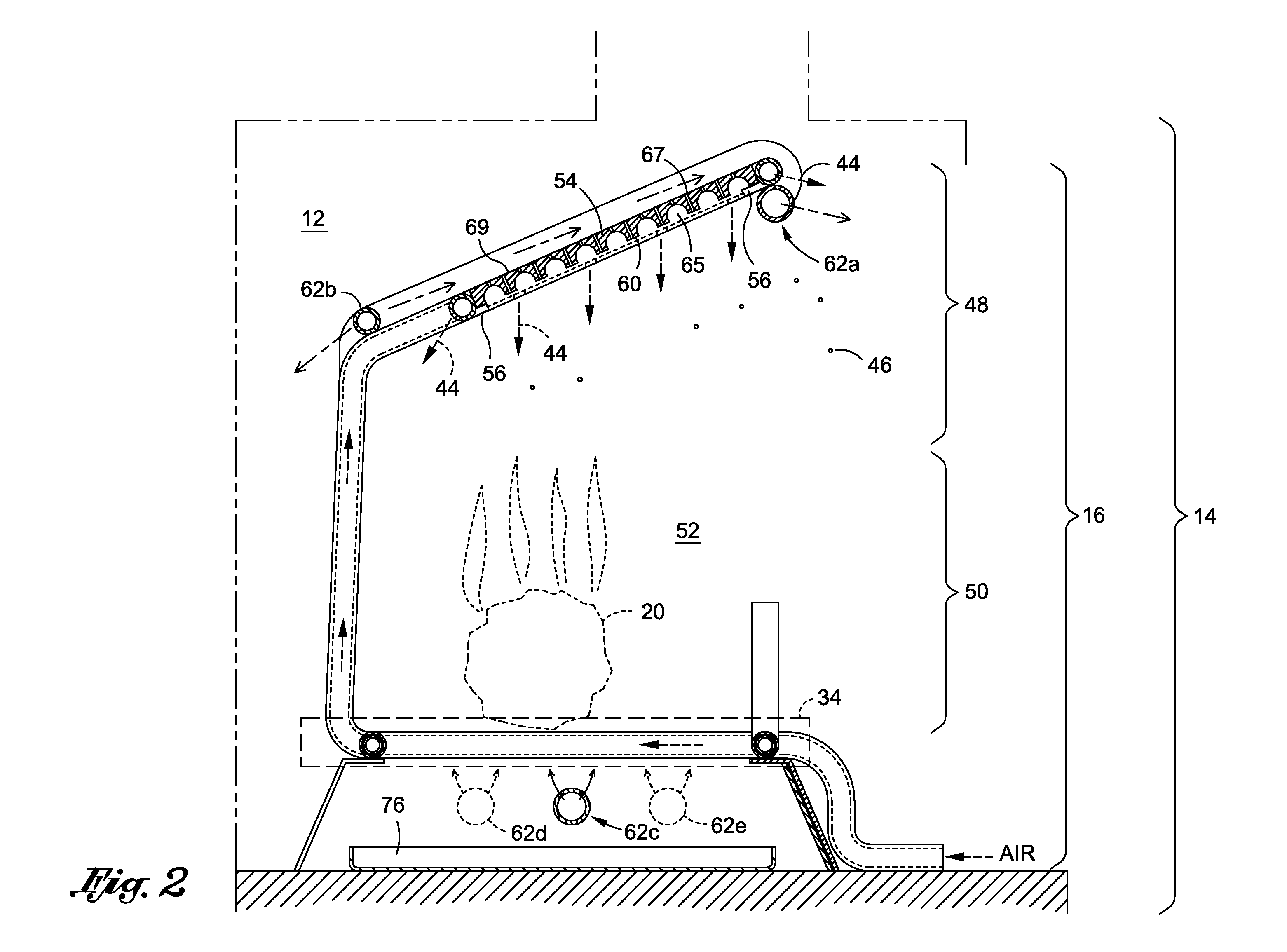

Burner Apparatus

InactiveUS20070128562A1Reduce harmful emissionHarmful emissionDomestic stoves or rangesLiquid heating fuelNatural gas fuelProcess engineering

A burner apparatus for an indoor or outdoor fireplace, fire pit, stove or oven is shown. The burner apparatus operates to produce natural gas fueled or liquid petroleum fueled amber flames among artificial logs, coals or a combination of artificial logs and coals, simulating a natural fire. One embodiment of the burner apparatus comprises a burner tube loop for the distribution of fuel, a fuel / air mixing valve for mixing the fuel and air before ignition of the resulting fuel / air mixture, metal cups for the dissipation of the fuel / air mixture and flames, an ignition system for igniting the fuel / air mixture, a control system for monitoring and controlling the ignition of the fuel and for regulating the flow of fuel, and artificial logs, coals or a combination of logs and coals placed around the burner tube loop to provide for an aesthetically pleasing and natural looking display.

Owner:THOMAS PAUL DAVID

Burner apparatus

InactiveUS7479008B2Harmful emissionDomestic stoves or rangesLiquid heating fuelCombustorControl system

A burner apparatus for an indoor or outdoor fireplace, fire pit, stove or oven is shown. The burner apparatus operates to produce natural gas fueled or liquid petroleum fueled amber flames among artificial logs, coals or a combination of artificial logs and coals, simulating a natural fire. One embodiment of the burner apparatus comprises a burner tube loop for the distribution of fuel, a fuel / air mixing valve for mixing the fuel and air before ignition of the resulting fuel / air mixture, metal cups for the dissipation of the fuel / air mixture and flames, an ignition system for igniting the fuel / air mixture, a control system for monitoring and controlling the ignition of the fuel and for regulating the flow of fuel, and artificial logs, coals or a combination of logs and coals placed around the burner tube loop to provide for an aesthetically pleasing and natural looking display.

Owner:THOMAS PAUL DAVID

Air-injection system to improve effectiveness of selective catalytic reduction catalyst for gasoline engines

InactiveUS8776498B2Increased durabilityHarmful emissionGas treatmentInternal combustion piston enginesGasolineEngineering

Embodiments are described to improve the durability of a lean NOx aftertreatment system. According to one embodiment of the present invention an air injection system is used to inject air continuously into the exhaust system between the upstream three-way catalyst and the downstream selective catalytic reduction (SCR) catalyst when the engine is operating at stoichiometric or rich air / fuel ratios and the exhaust temperatures are above a calibratible level (e.g., 700° C.). In another embodiment, an oxidation catalyst is positioned downstream of the air injection point to prevent exothermic reactions from occurring on the SCR. In another embodiment, the reductant for the SCR is generated in-situ. In yet another embodiment, a diverter valve with a reduction catalyst in a bypass arm is utilized to bypass the SCR during high load conditions.

Owner:FORD GLOBAL TECH LLC

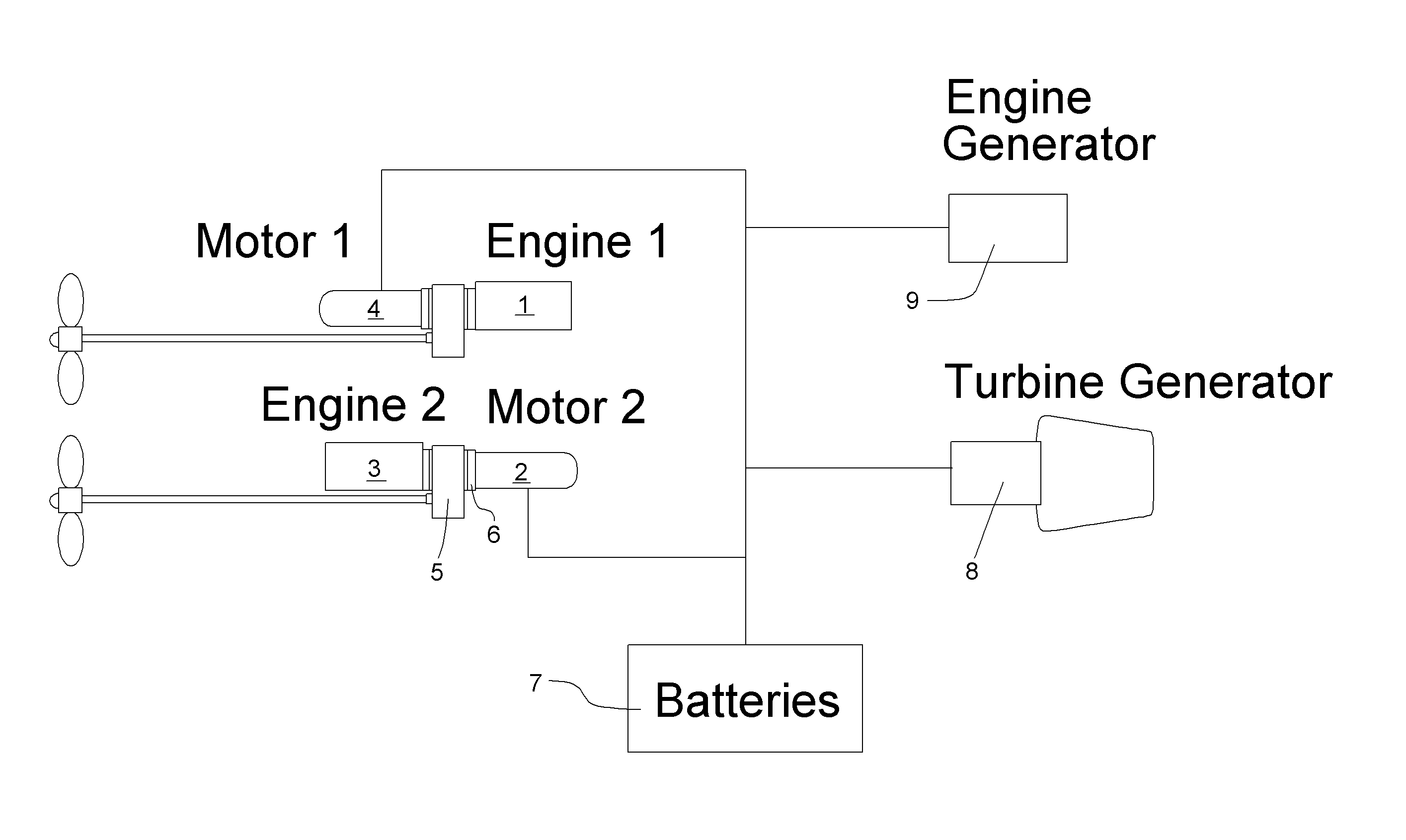

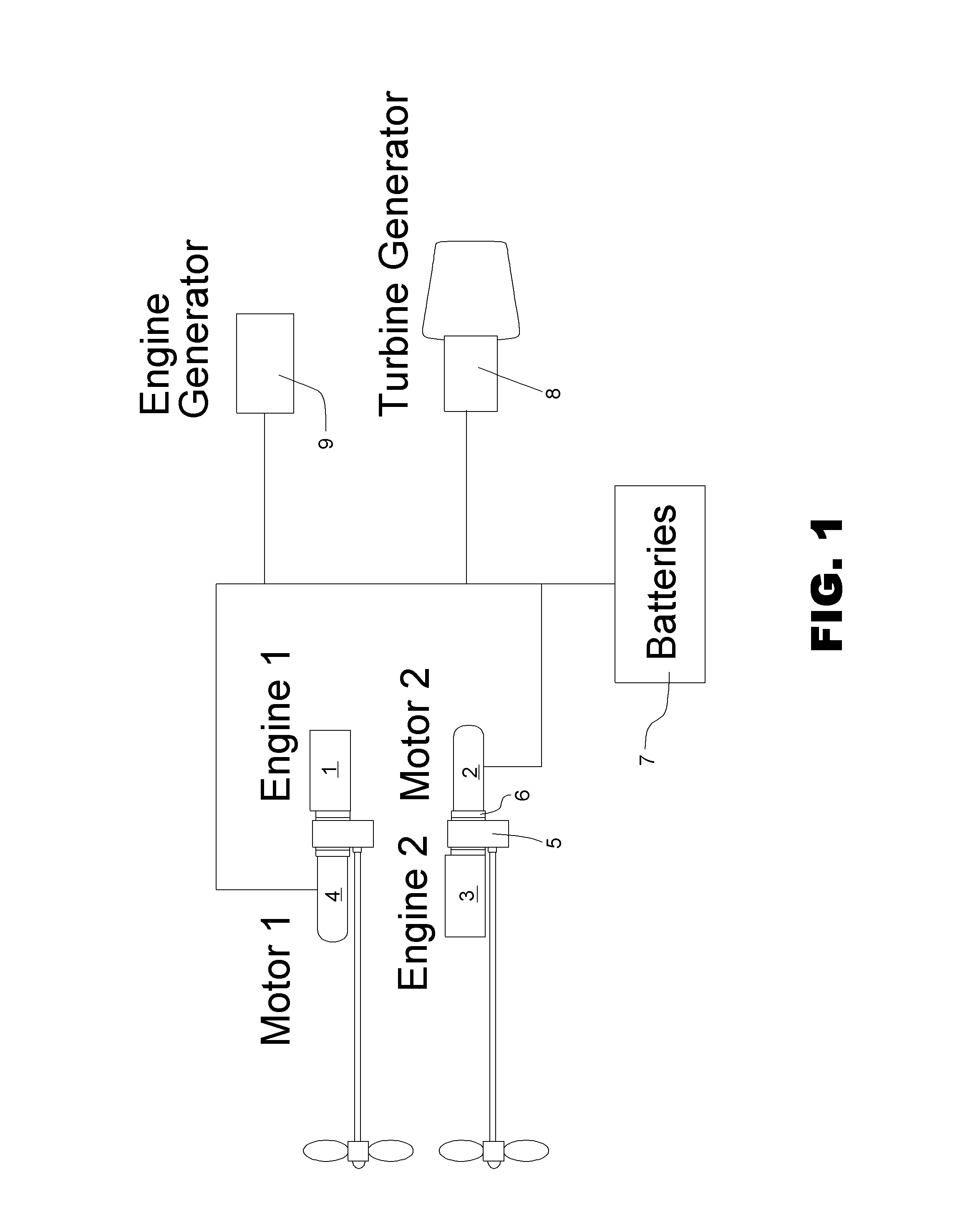

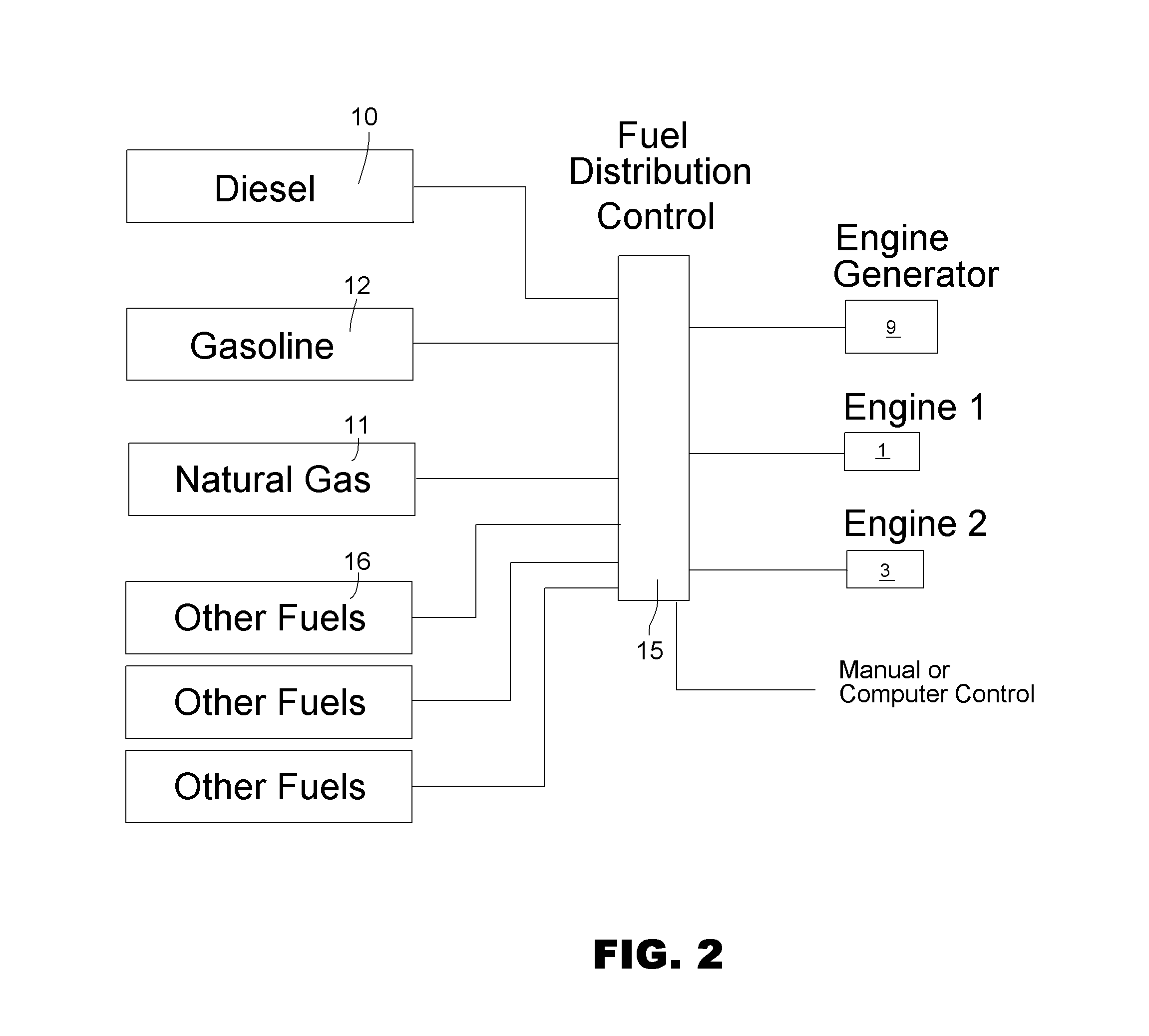

Multi-Propulsion, Multi-Fuel Marine Power System

InactiveUS20140102104A1Improve efficiencyReduce operating costsReciprocating combination enginesPropulsion based emission reductionMarine propulsionControl system

A marine propulsion and power supply for maritime vessels that includes an arrangement of modules that can be internal combustion engines, regenerative electric motors, engine generators, turbine generators and / or battery banks. These components can be arranged in such a way as to work together to increase efficiency and to utilize various fuel combinations to achieve the lowest overall operating cost or other goals whilst minimizing harmful emissions. Sensors can be used monitor various power parameters and can be coupled to a closed-loop in a control system to achieve vessel operating goals.

Owner:READ BRIAN L

Air cleaner for two-stroke internal combustion engine and method of tuning the length of air-fuel mixture passage by using the air cleaner

InactiveUS7857881B2Reduce harmful emissionsChange the engine characteristicsCombination devicesAuxillary pretreatmentExternal combustion engineFresh air

Owner:YAMABIKO CORP

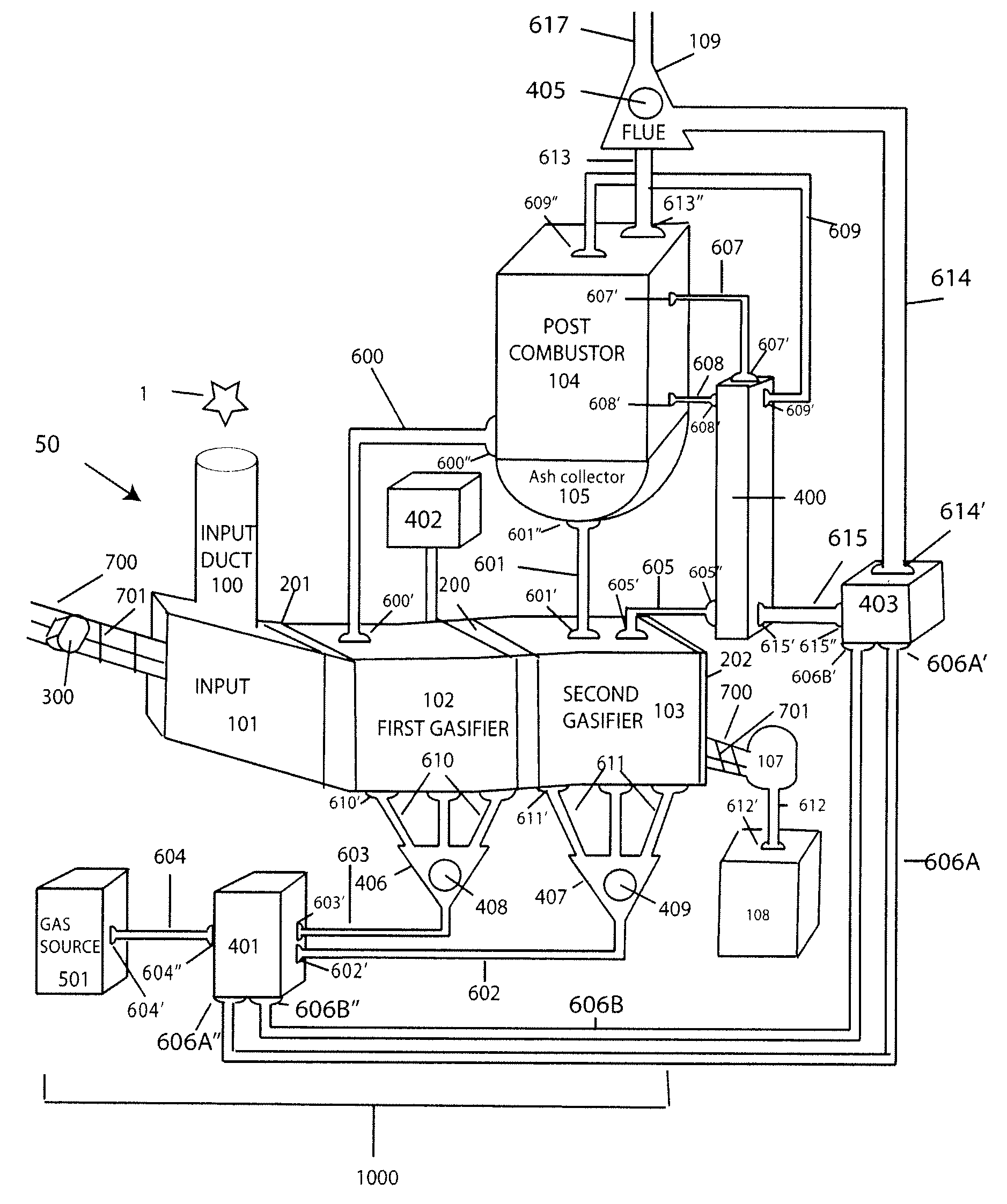

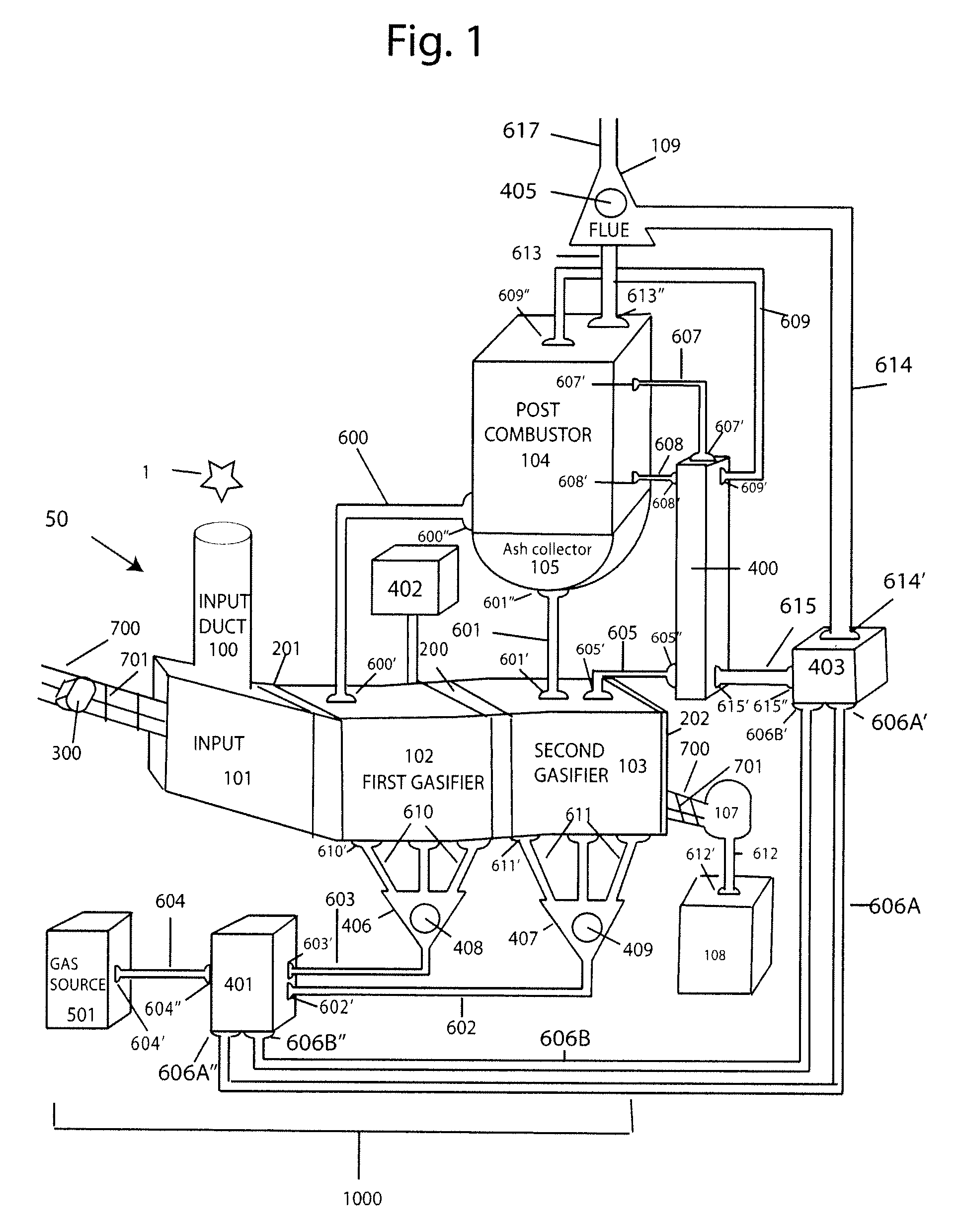

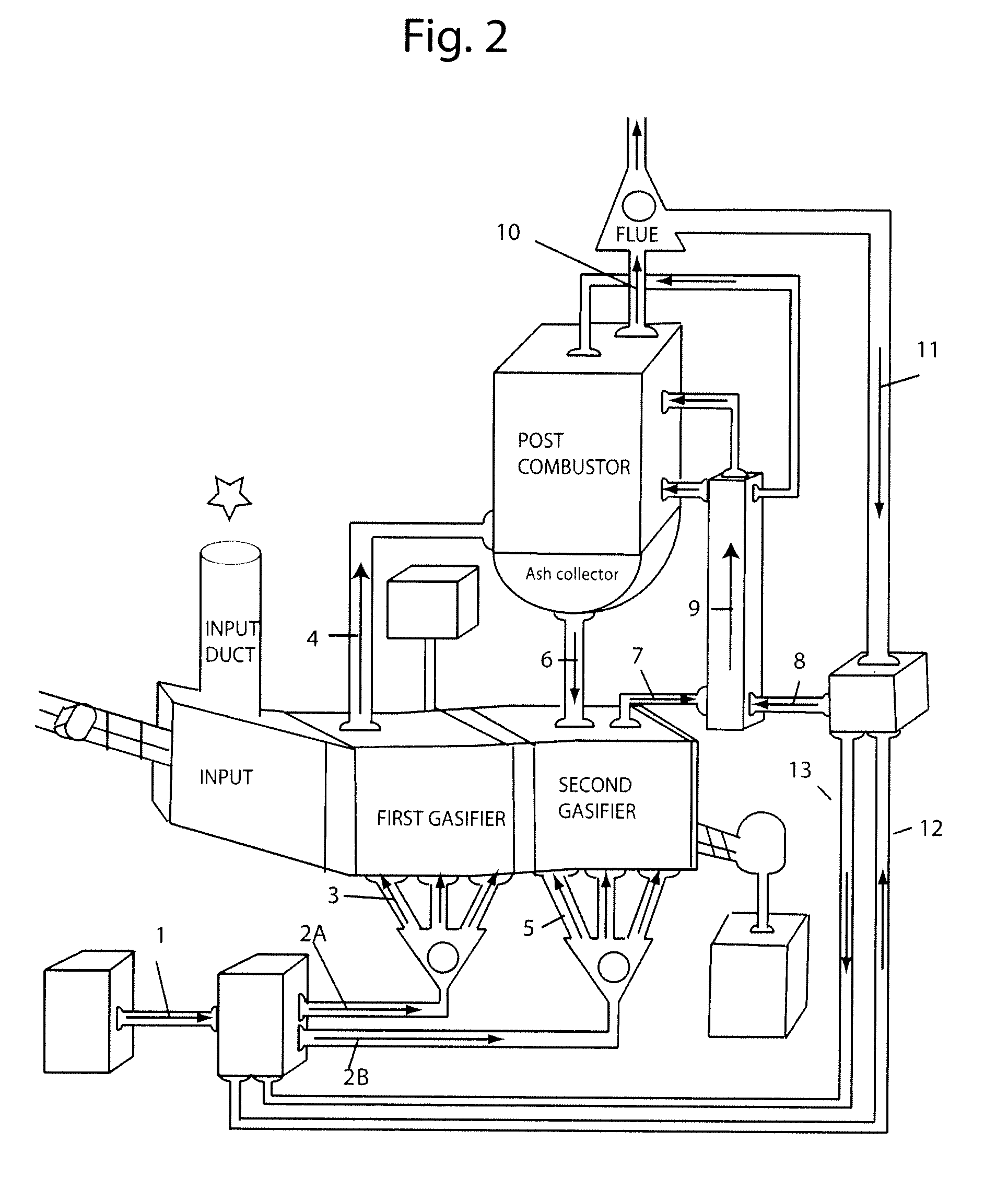

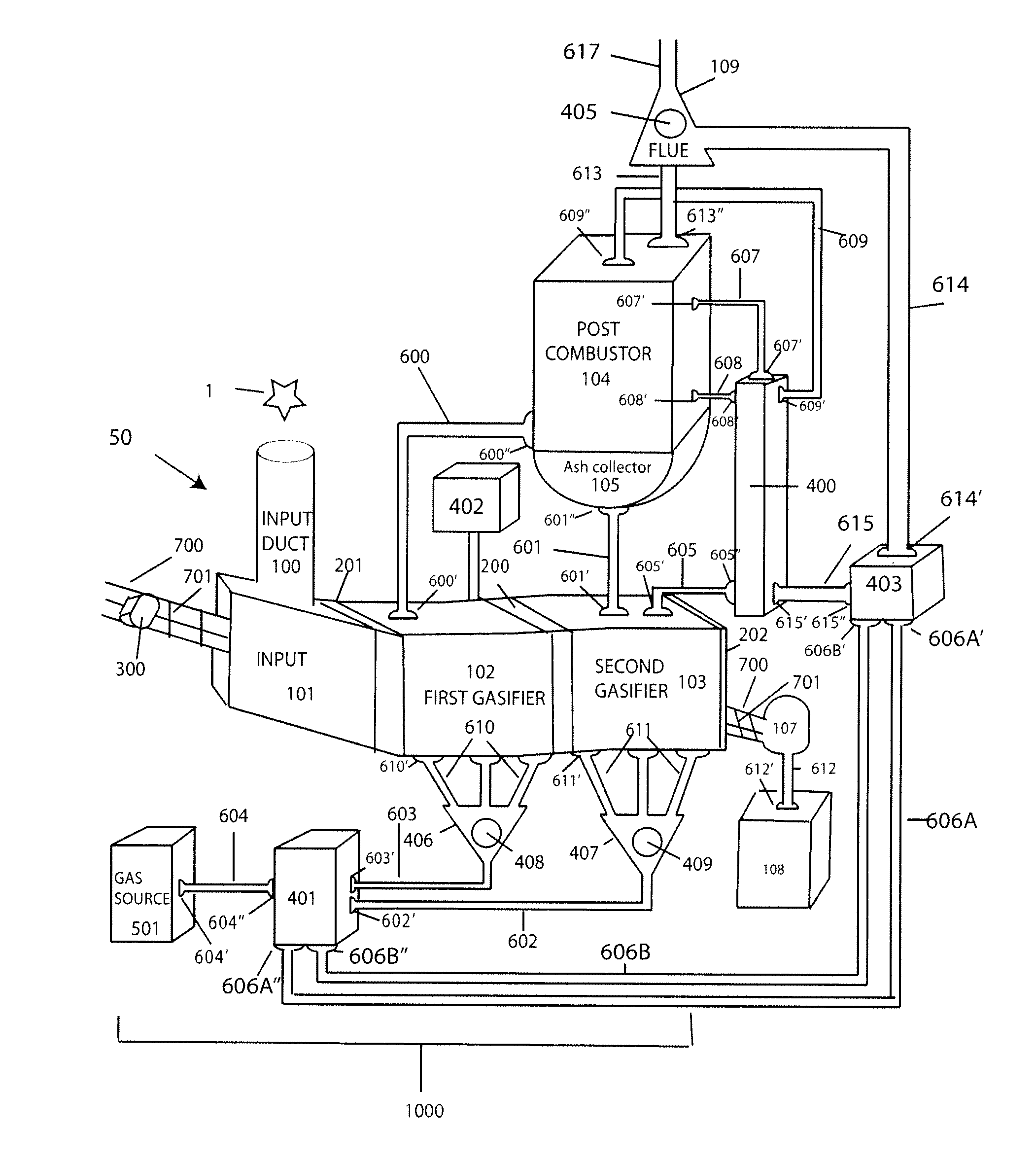

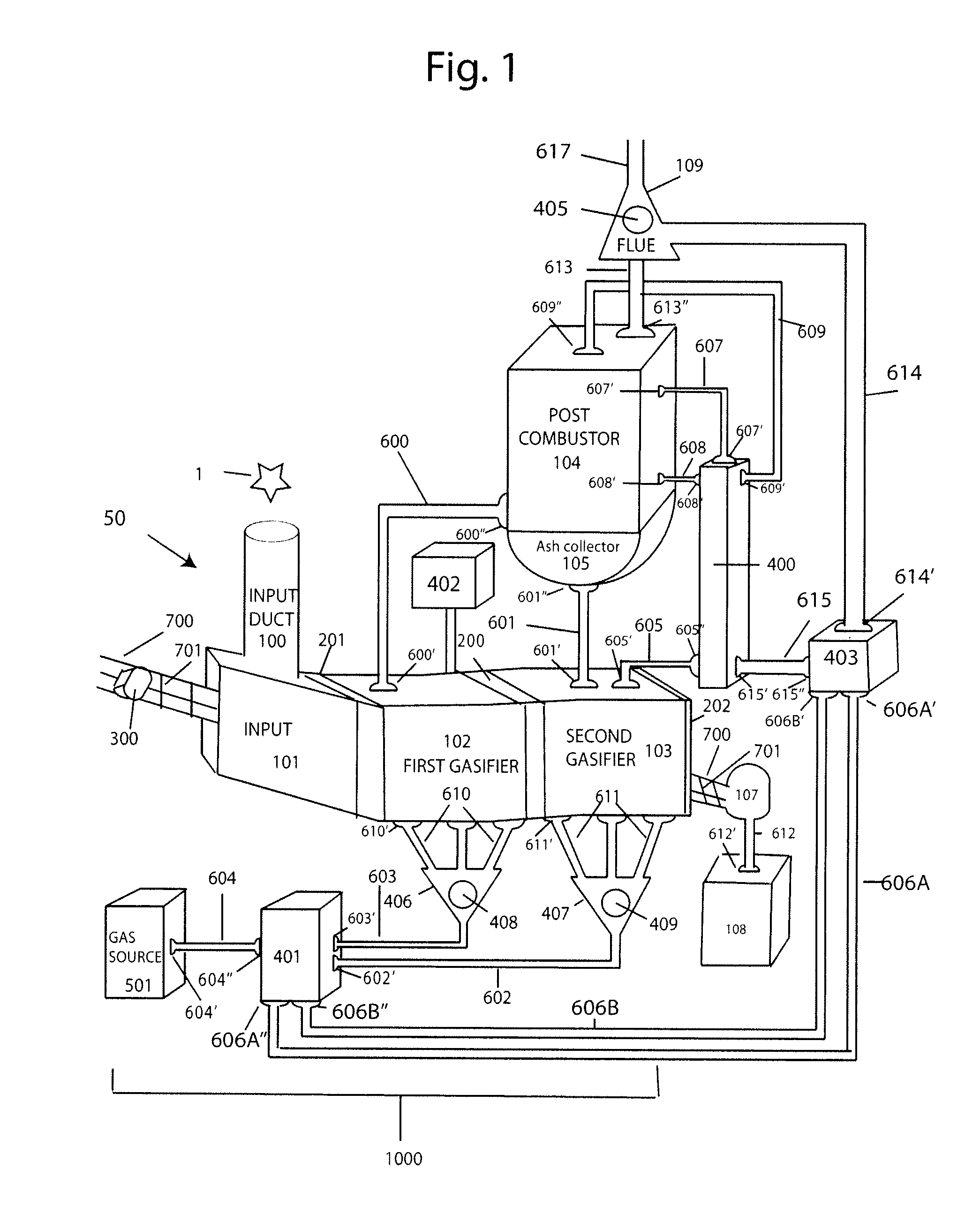

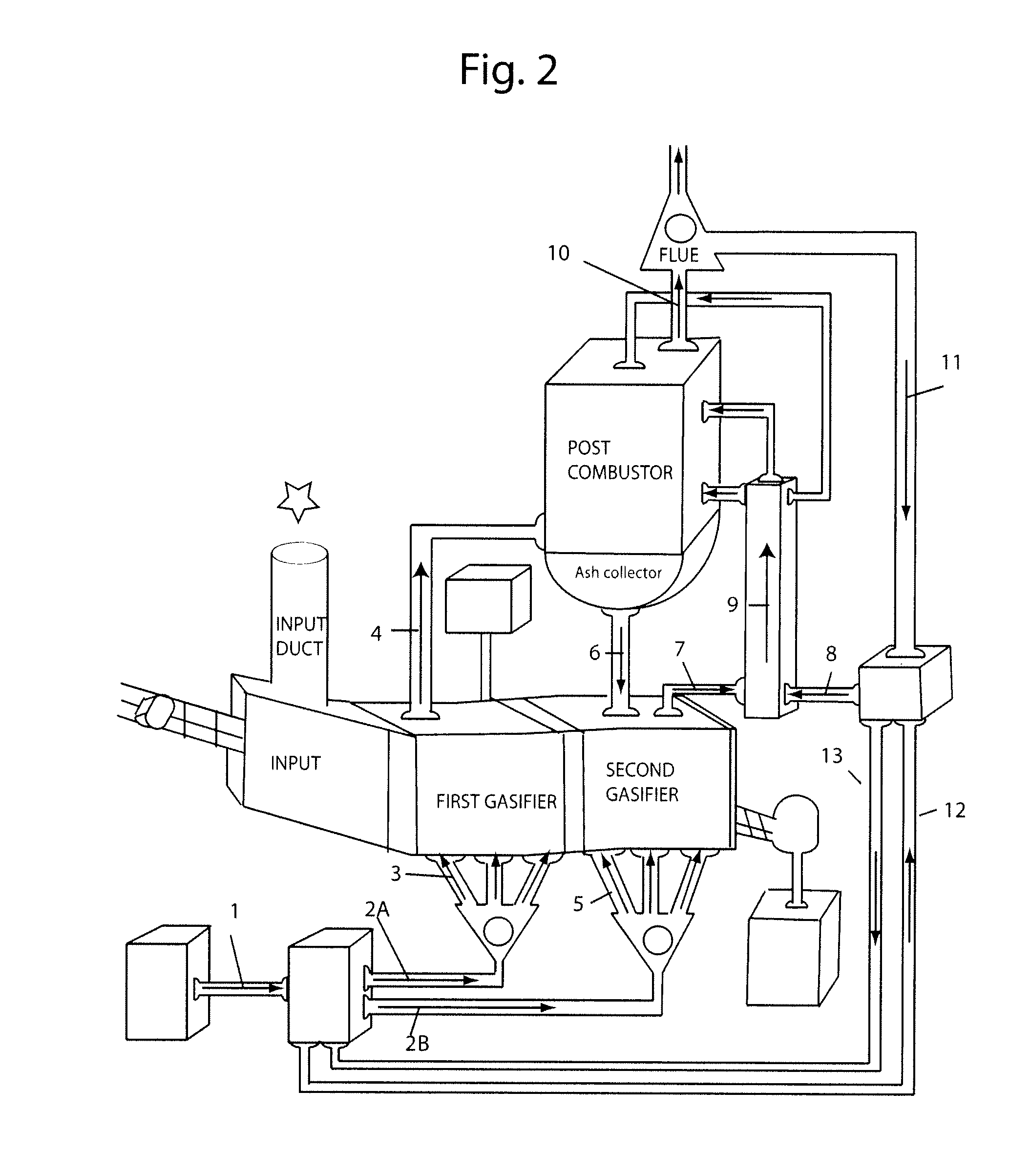

Gasification combustion system

ActiveUS20100288173A1Efficient combustionEmission reductionAir supply regulationIncinerator apparatusCombustion systemProcess engineering

A two stage refuse gasification combustion system for processing refuse is disclosed. The system may contain features such as an advancer, a first and second gasifier, a drier, a gas regulator, and a post combustor. Additionally, methods for regulating gas and advancing refuse through a two stage refuse gasification combustion system are disclosed.

Owner:COVANTA ENERGY CORPORATION

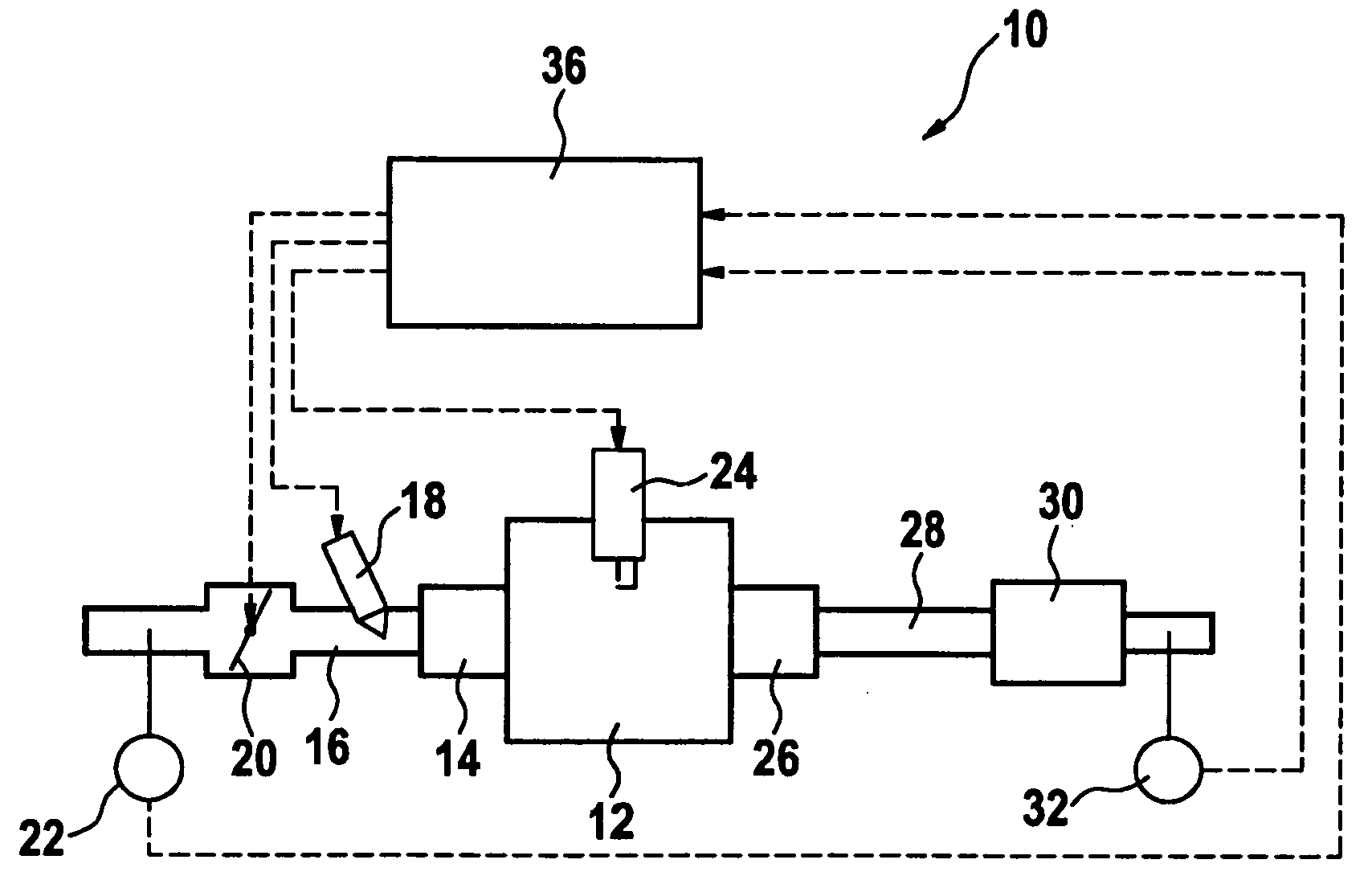

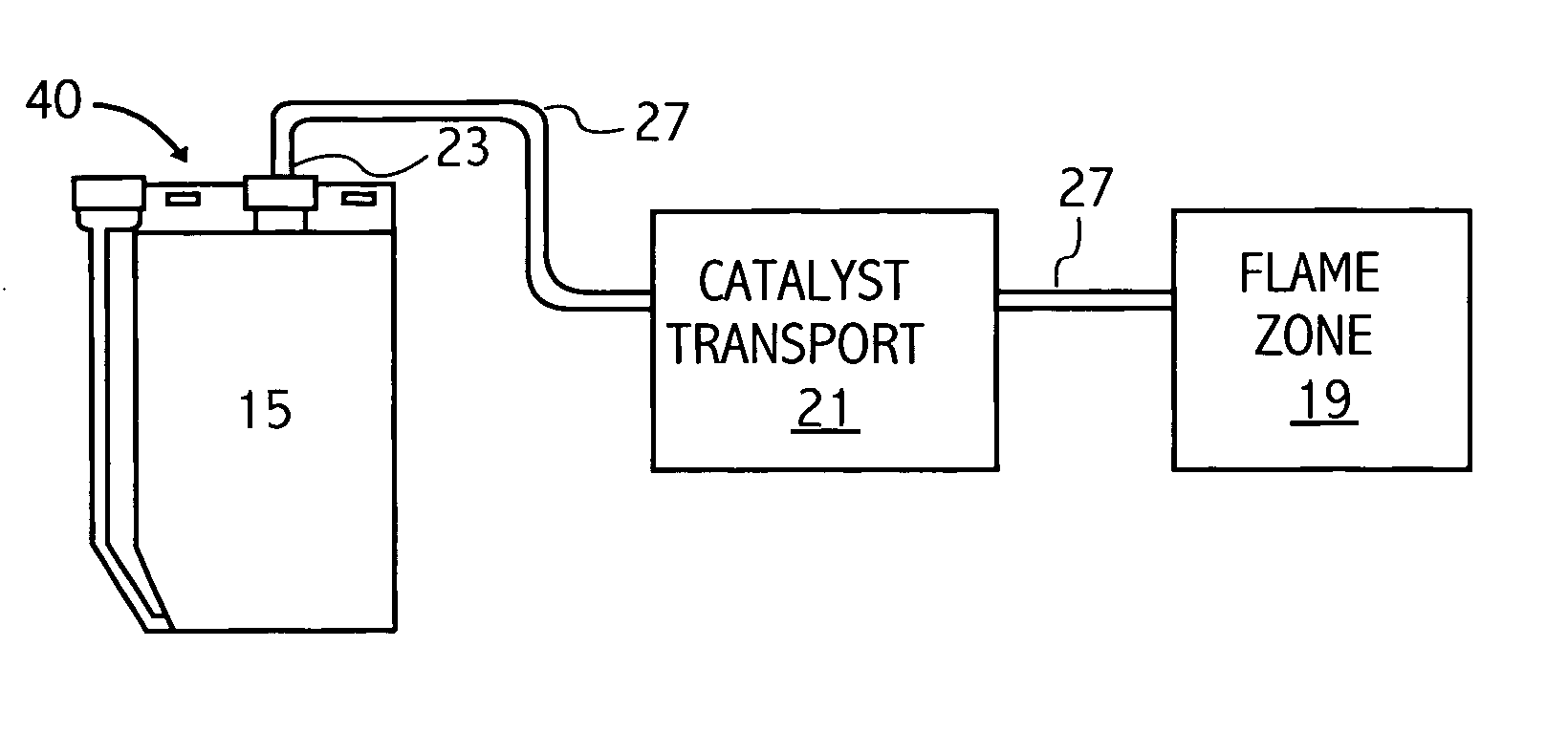

Catalyst composition and method for oxidizing mixtures

InactiveUS20050054522A1Improve efficiencyHarmful emissionLighting and heating apparatusOrganic-compounds/hydrides/coordination-complexes catalystsRheniumPlatinum

A catalyst composition and method for oxidizing fuels is disclosed. The catalyst composition comprises at least one compound having one of a group III, group IIA or Lanthanide element such as, for example, Aluminum, Magnesium or Cesium, and at least one compound having at least one element selected from group IA, group IVA, group VI, group VII, group VIII, group IB, group IIB, and combinations thereof, such as, for example platinum, rhodium and rhenium. A method for oxidizing an fuel, the method comprising providing a fuel and a catalyst mixture; transporting the fuel and the catalyst to the flame zone separately; mixing the fuel and the catalyst; and oxidizing the fuel. The method and catalyst mixture may be used for oxidation of any hydrocarbon based fuel. Improved results from the use of the group III, group IIA or Lanthanide group element include increased power, reduced harmful emissions, and smoother oxidation process.

Owner:HASKEW JAMES W

Method for Operating an Internal Combustion Engine

InactiveUS20090299604A1Guaranteed uptimeTorque and running smoothnessElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

In a method for operating an internal combustion engine, the fuel is supplied to at least one combustion chamber via at least one injector, which method includes the following steps: a) a total injection is divided into a basic injection and at least one measured injection; b) the injection time of the measured injection is successively decreased and the injection time of the basic injection is successively increased so that a total injection quantity ascertained from a valve characteristic curve remains the same.

Owner:ROBERT BOSCH GMBH

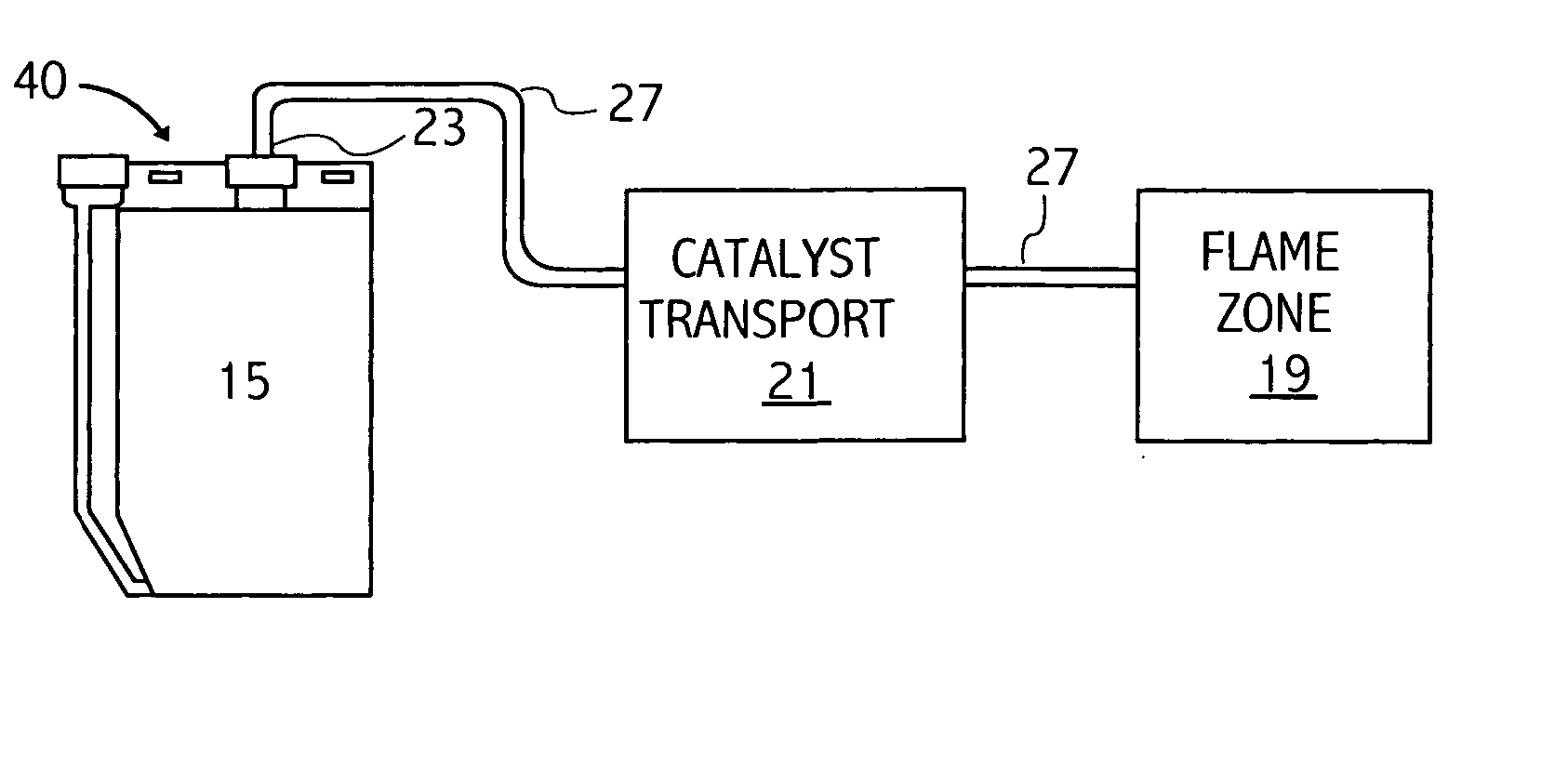

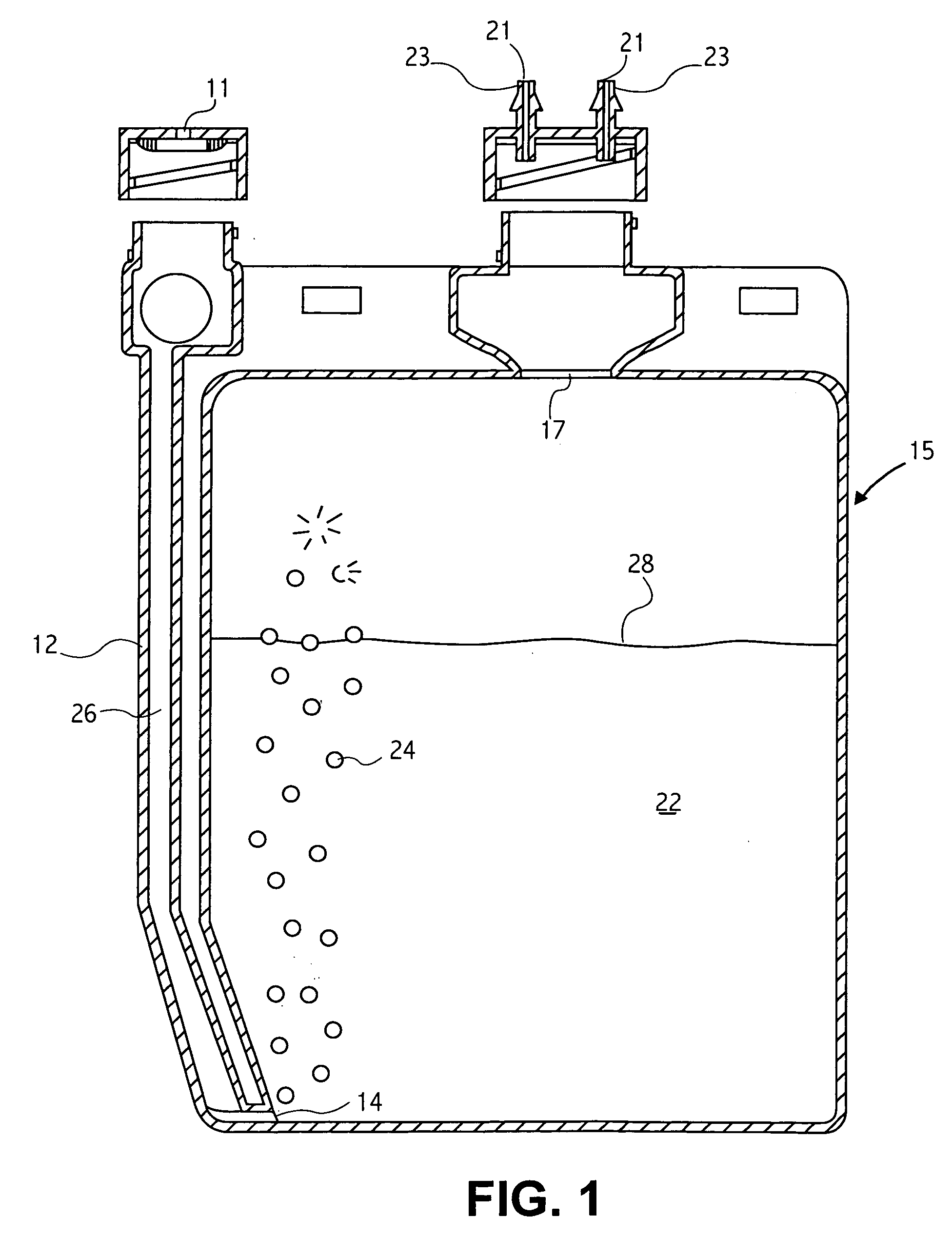

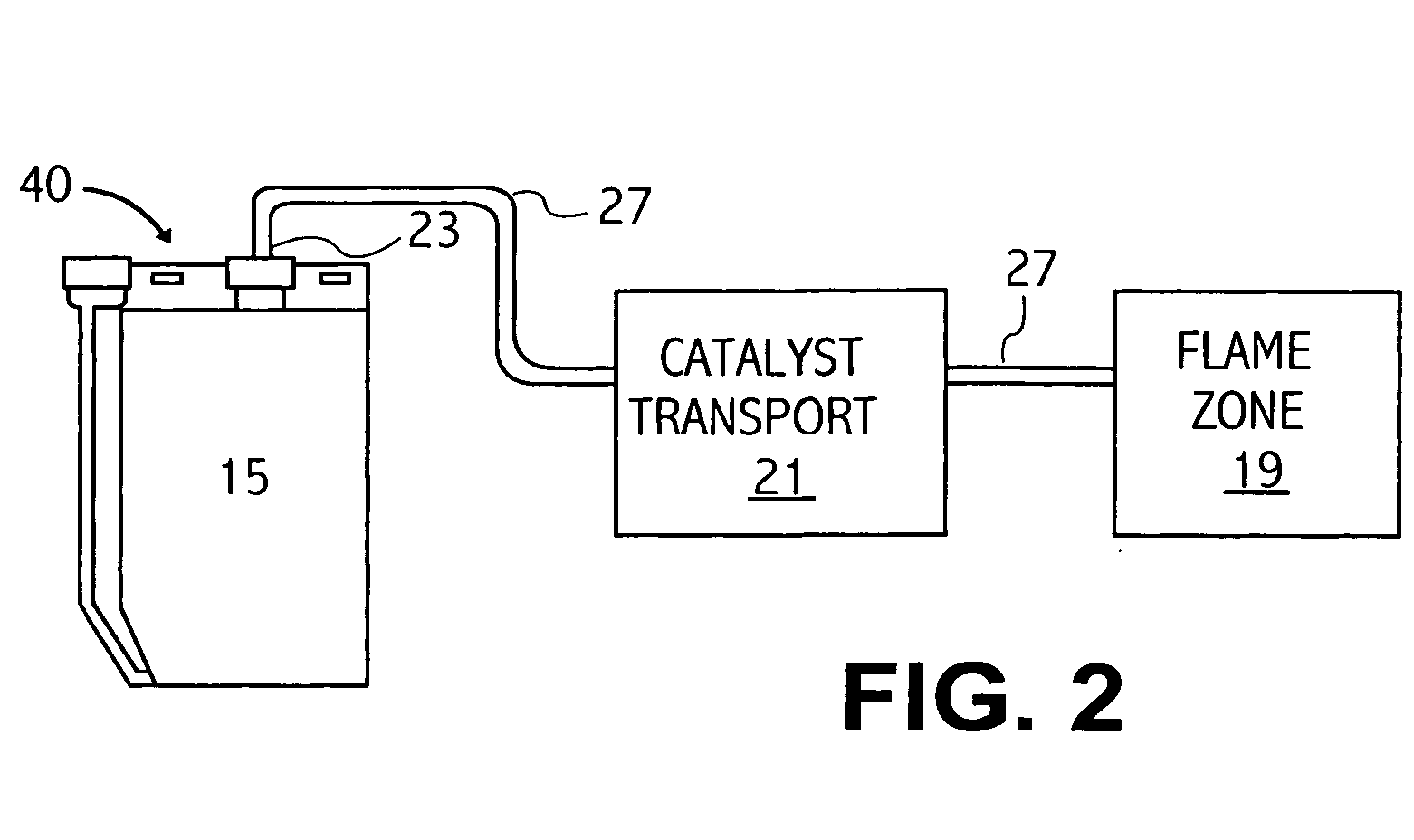

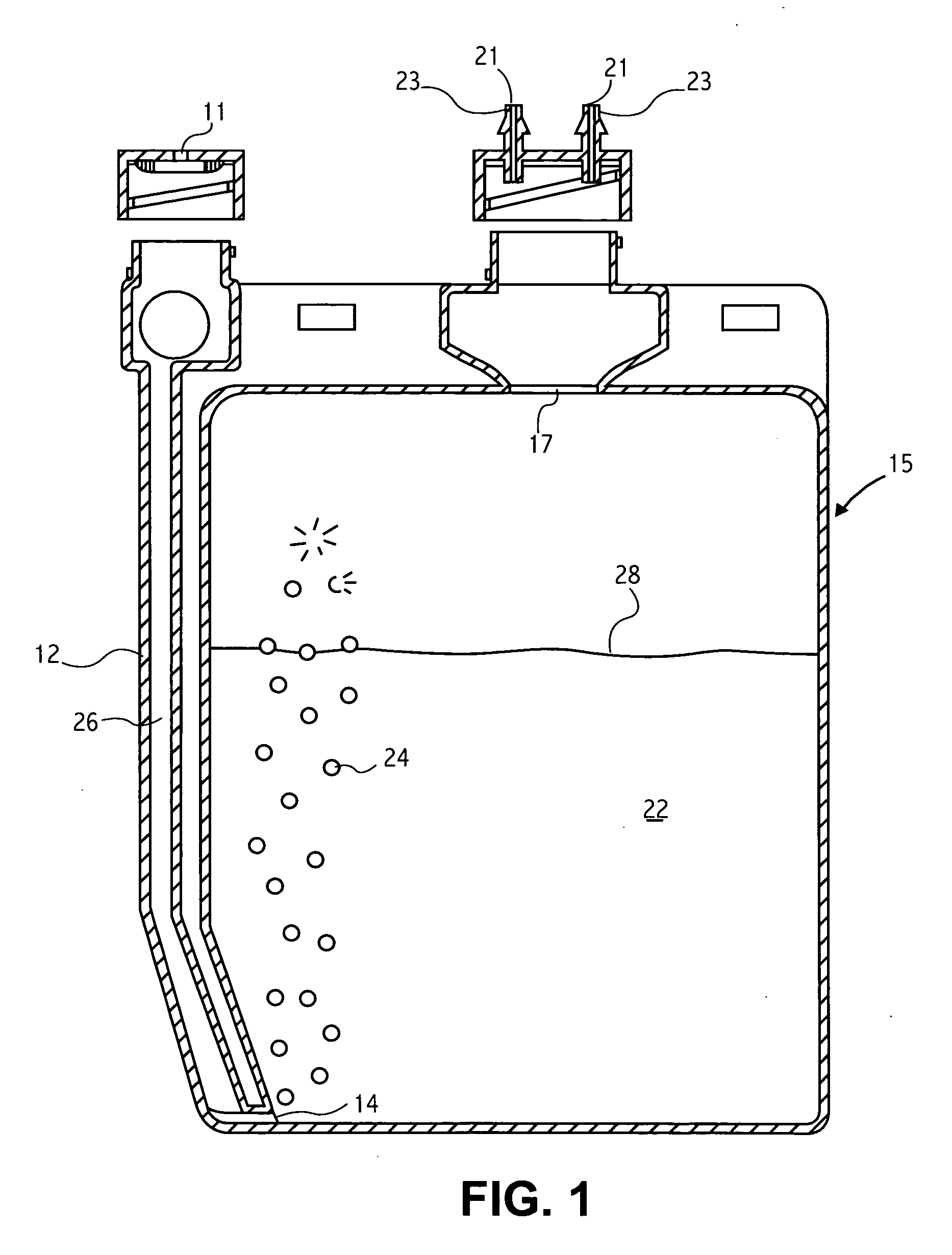

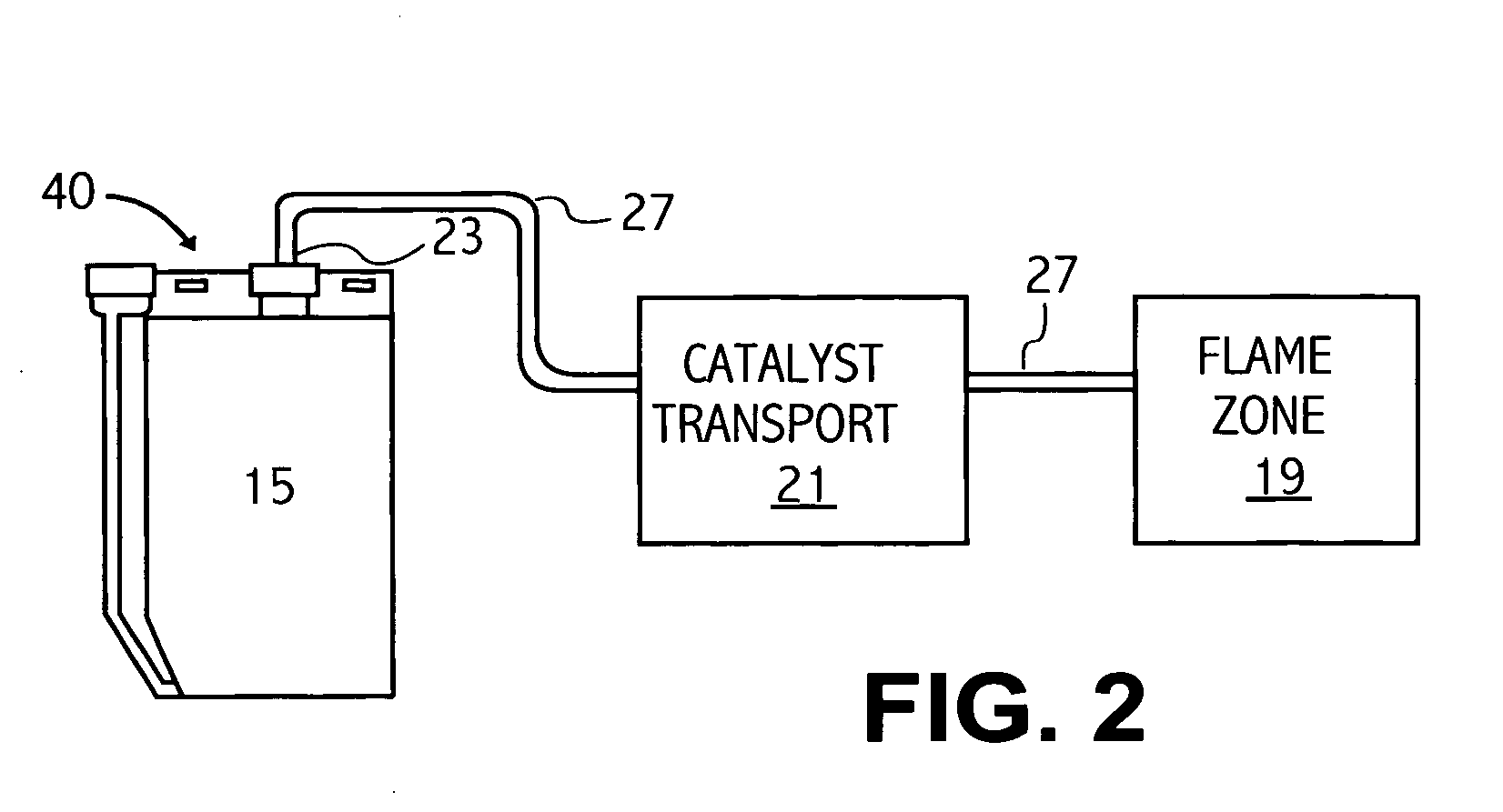

Catalyst delivery chamber and method of delivering catalyst for oxidizing mixtures

InactiveUS20050053875A1Improve efficiencyReduce harmful emissionsLighting and heating apparatusOrganic-compounds/hydrides/coordination-complexes catalystsRheniumLanthanide

A catalyst composition, catalyst delivery chamber and method for oxidizing fuels is disclosed. The catalyst delivery chamber comprises an angled inlet and an outlet chamber. The catalyst composition within the bottle comprises at least one compound having one of a group III, group IIA or Lanthanide element such as, for example, Aluminum, Magnesium or Cesium, and at least one compound having at least one element selected from group IA, group IVA, group VI, group VII, group VIII, group IB, group IIB, and combinations thereof, such as, for example platinum, rhodium and rhenium. A method for oxidizing an fuel, the method comprising providing a fuel and a catalyst mixture; transporting the fuel and the catalyst to the flame zone separately; mixing the fuel and the catalyst; and oxidizing the fuel. The method and catalyst mixture may be used for oxidation of any hydrocarbon based fuel. Improved results from the use of the group III, group IIA or Lanthanide group element include increased power, reduced harmful emissions, and smoother oxidation process.

Owner:HASKEW JAMES W

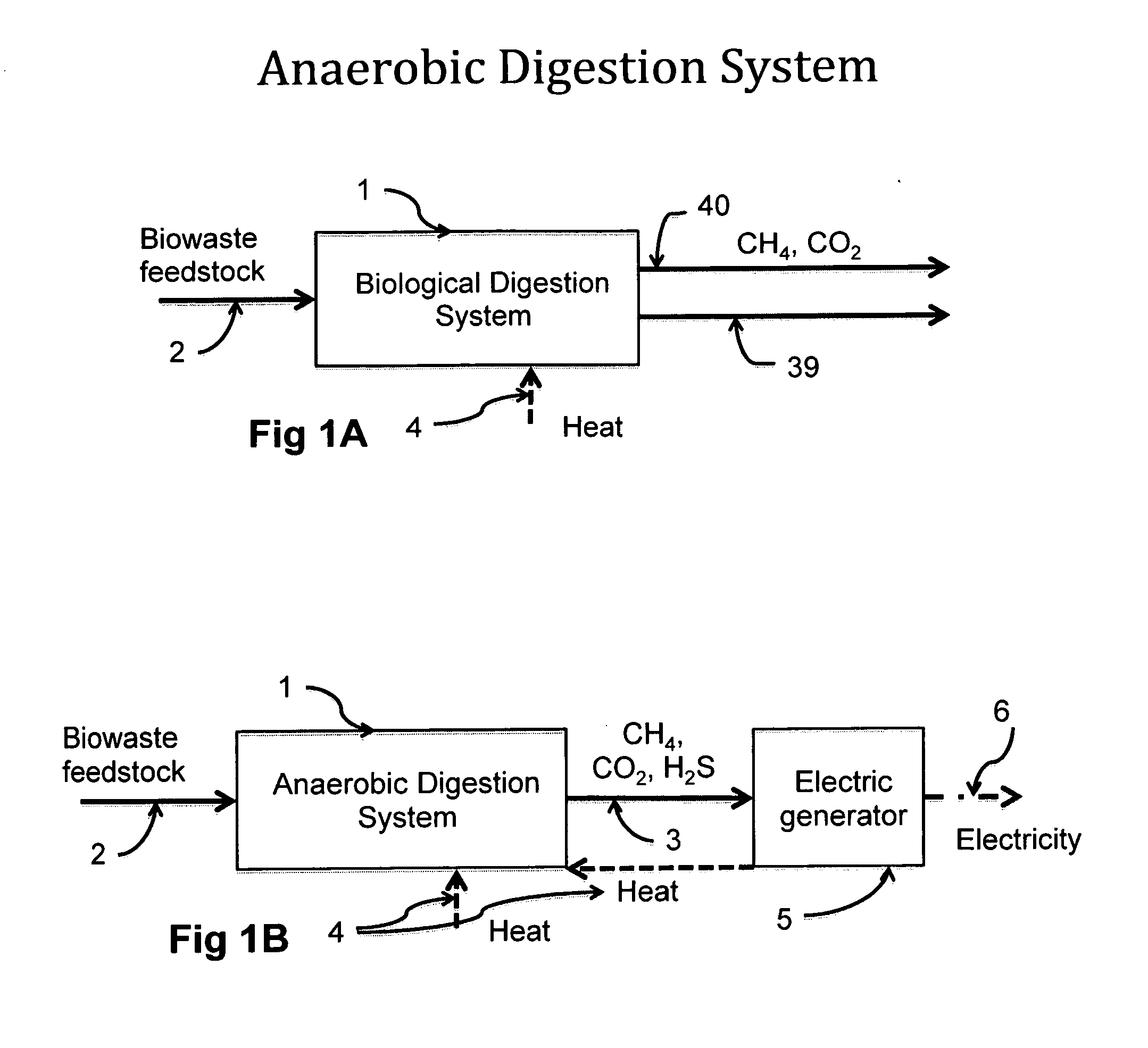

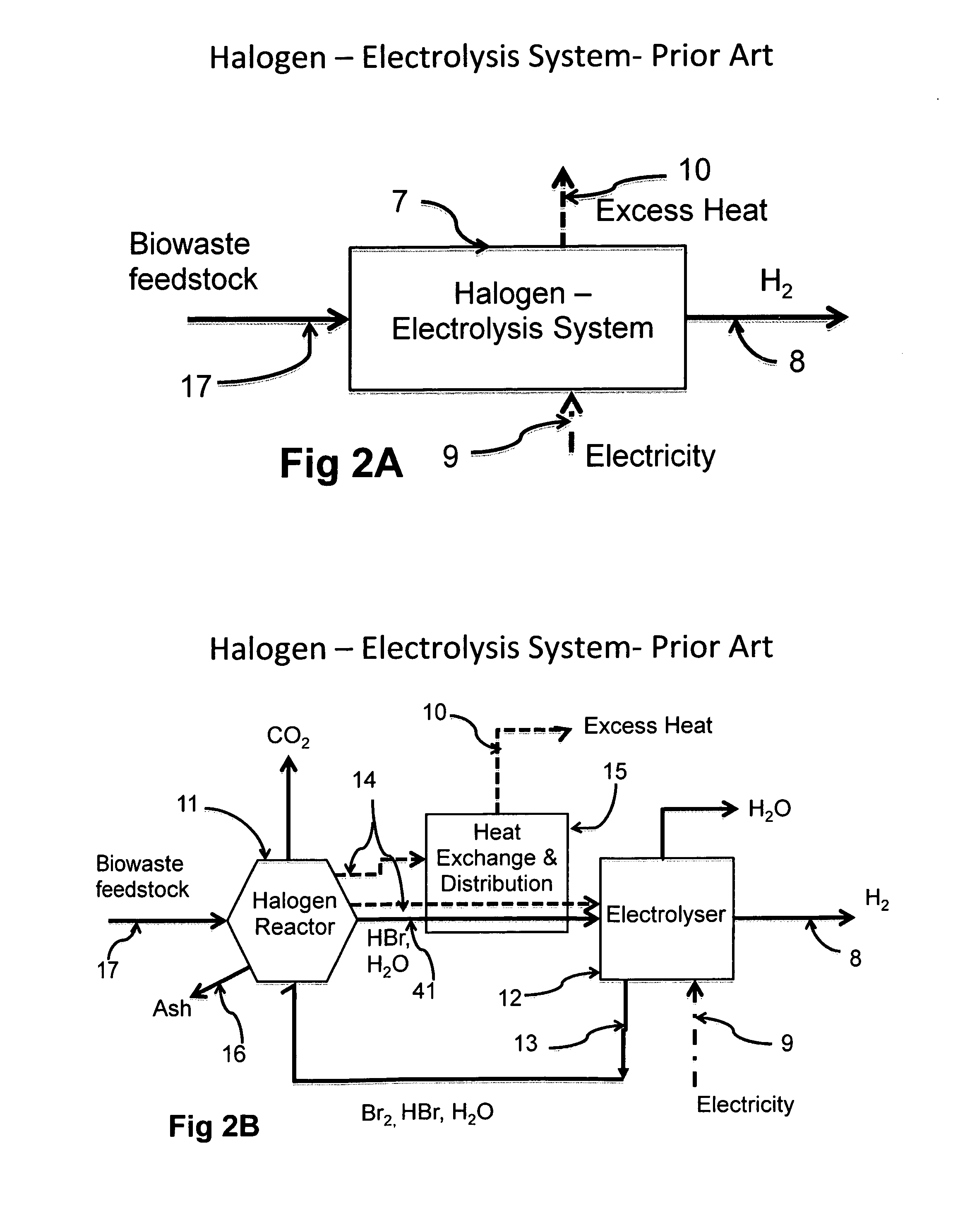

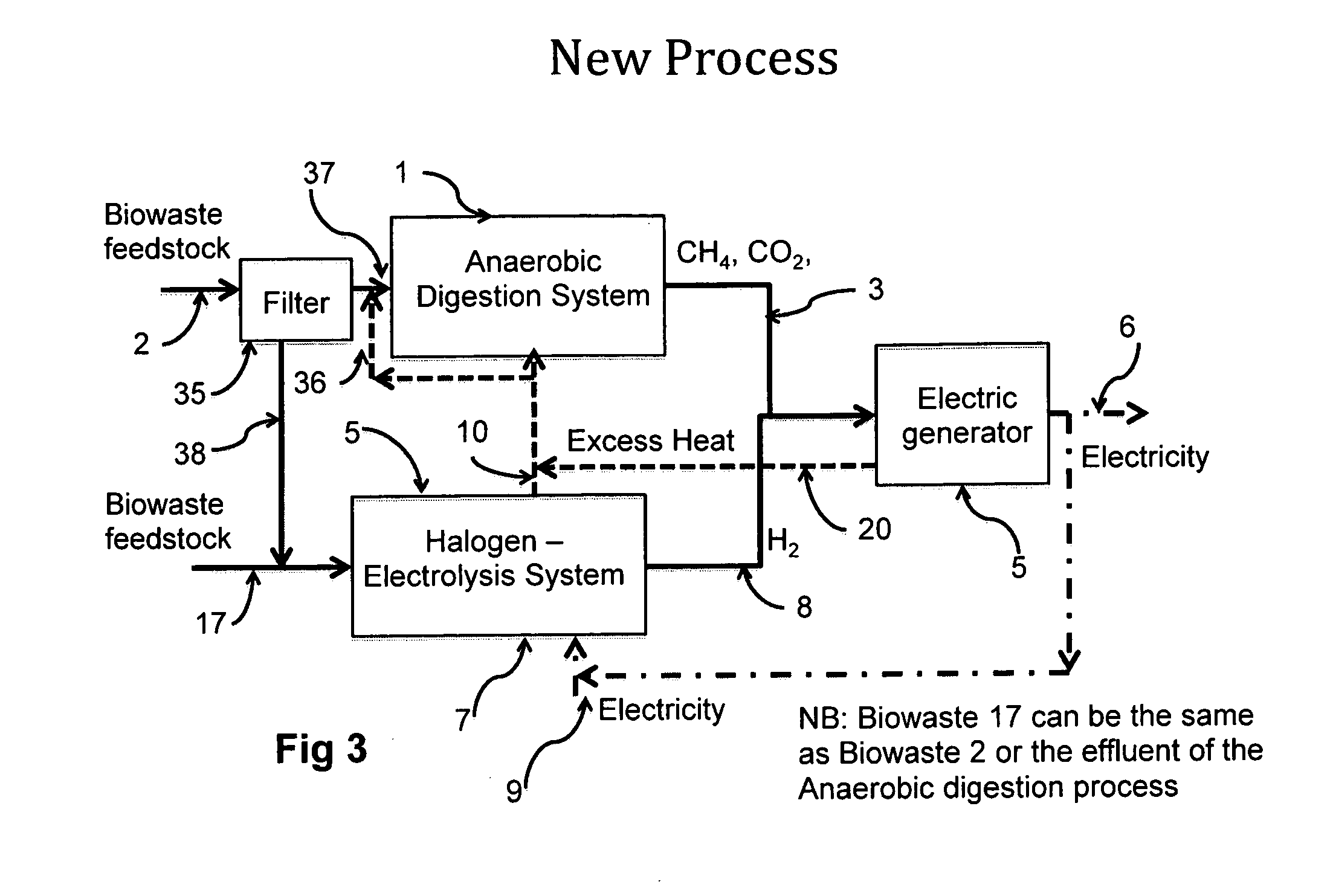

Biological solids processing system and method

InactiveUS20110020862A1Optimizes energy extractionHigh digestionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityHalogen

The consumption of organic solids with anaerobic digestion to generate usable gases including methane is made more efficient by maintaining the ideal digestion temperature, which is attained by combining the anaerobic digestion process with a halogen digester which produces heat energy and hydrogen gas. With a given biological feedstock four outputs can be generated (methane, hydrogen, electricity, and heat) in the ratio that makes the most economical sense. The process also provides a significant reduction in volume of output solids. The halogen oxidation process can be used on all the anaerobic digester effluent to extract more energy and oxidize a wet feedstock. If there are solids which are not easily digested with the anaerobic process, these solids can be diverted to the halogen digester to derive more energy from the feedstock. Pathogens common to other anaerobic digester effluents are removed. The mixture of methane and hydrogen gas can be compressed to produce an enriched compressed natural gas (CNG) with a variety of uses.

Owner:KAINOS POWER

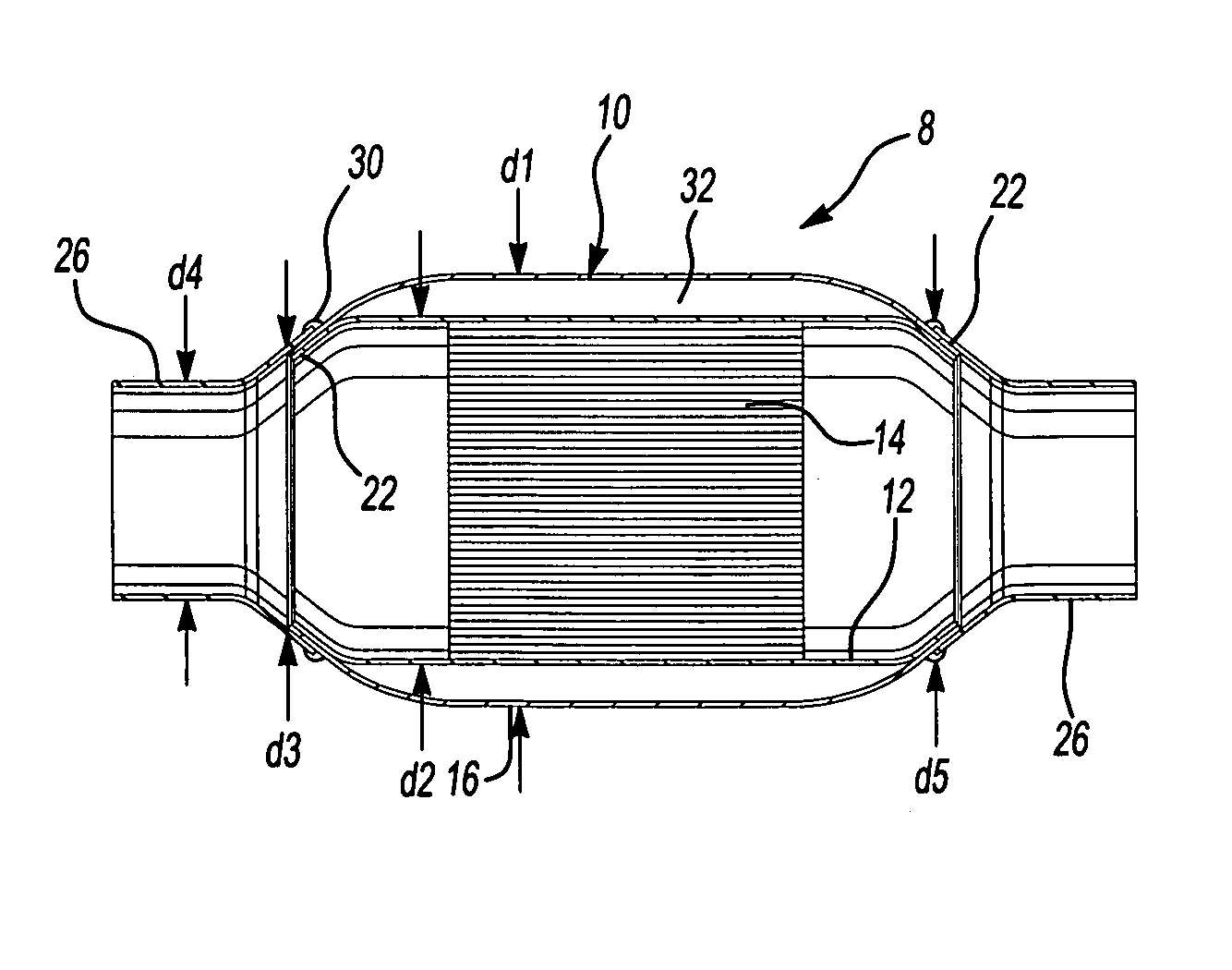

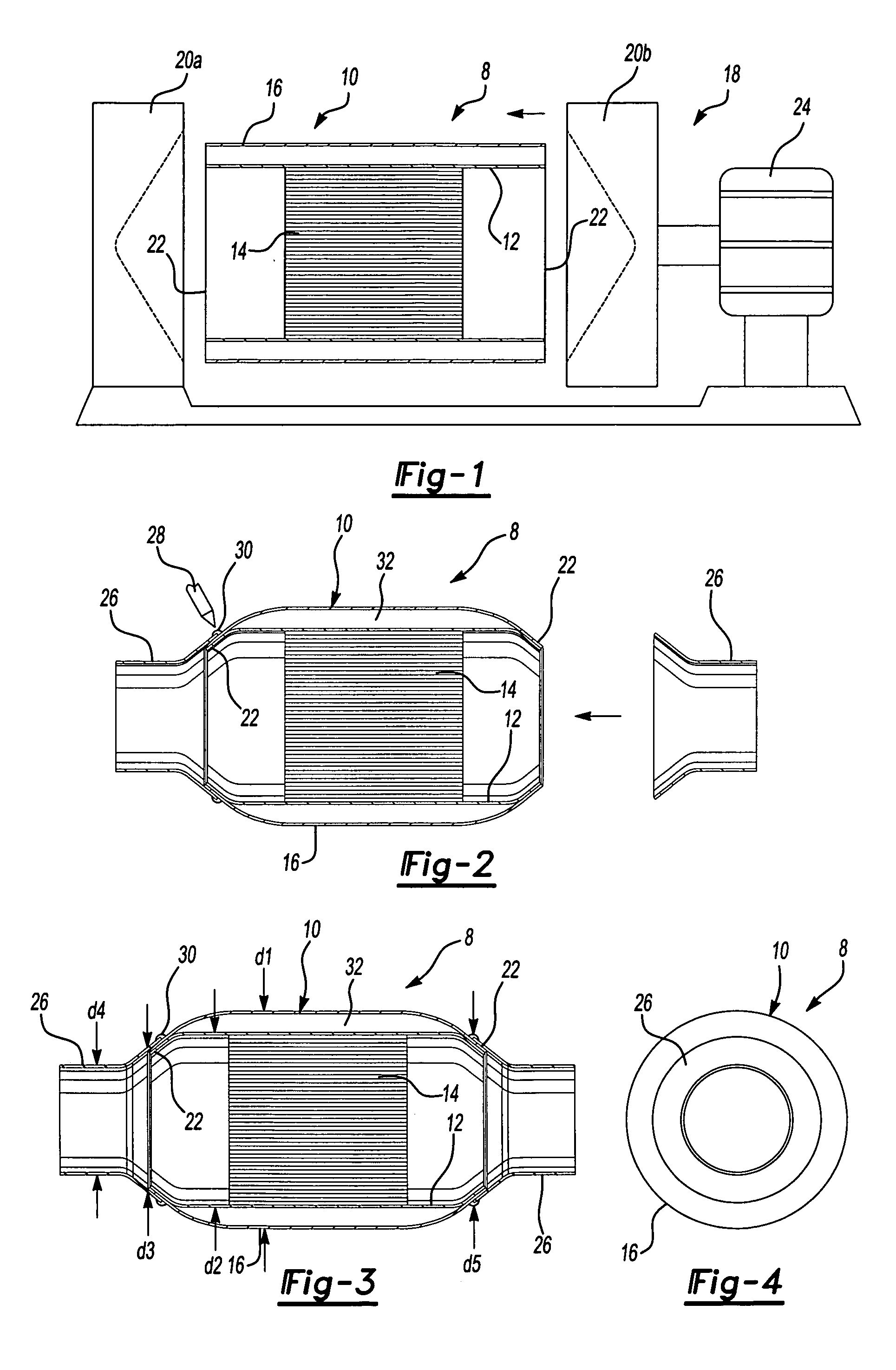

Catalytic converter with integral heat shield device

InactiveUS20050207948A1Reduce harmful emissionsSuitable shapeCombination devicesExhaust apparatusHeat shieldFlange

A catalytic converter includes an inner liner housing a catalyst and an outer liner concentric with the inner liner. In one example, the liners are cylindrical tubes arranged between opposing dies during manufacture. The dies are moved toward one another to plastically deform the ends inwardly to form a conical flange. The forming process provides a sealed cavity between the walls of the inner and outer liners that insulates the hot catalyst housed within the inner liner from the environment exterior of the catalytic converter assembly. First and second tapered connecting tubes are welded onto the opposing ends of the catalytic converter in the area of the flange.

Owner:INT MUFFLER

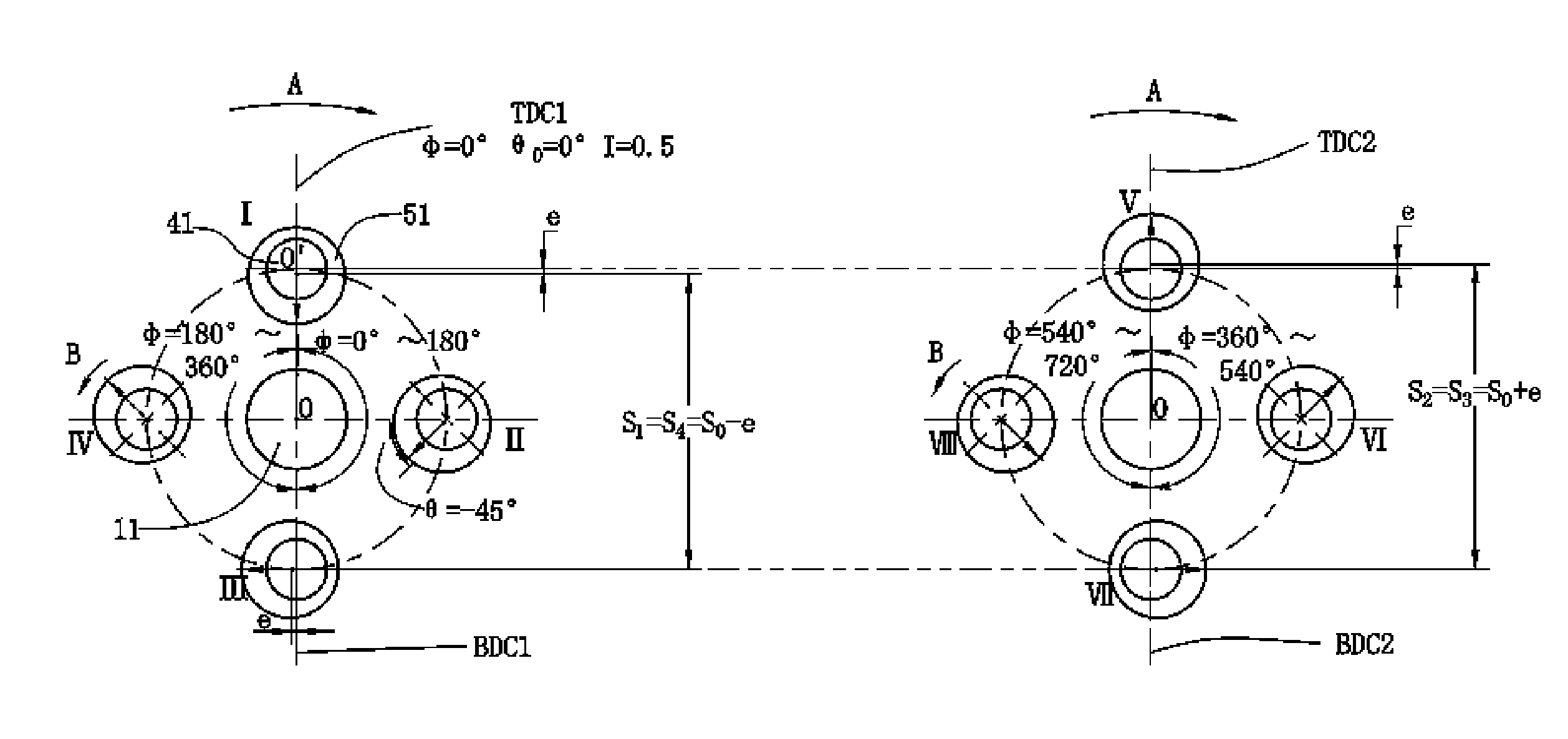

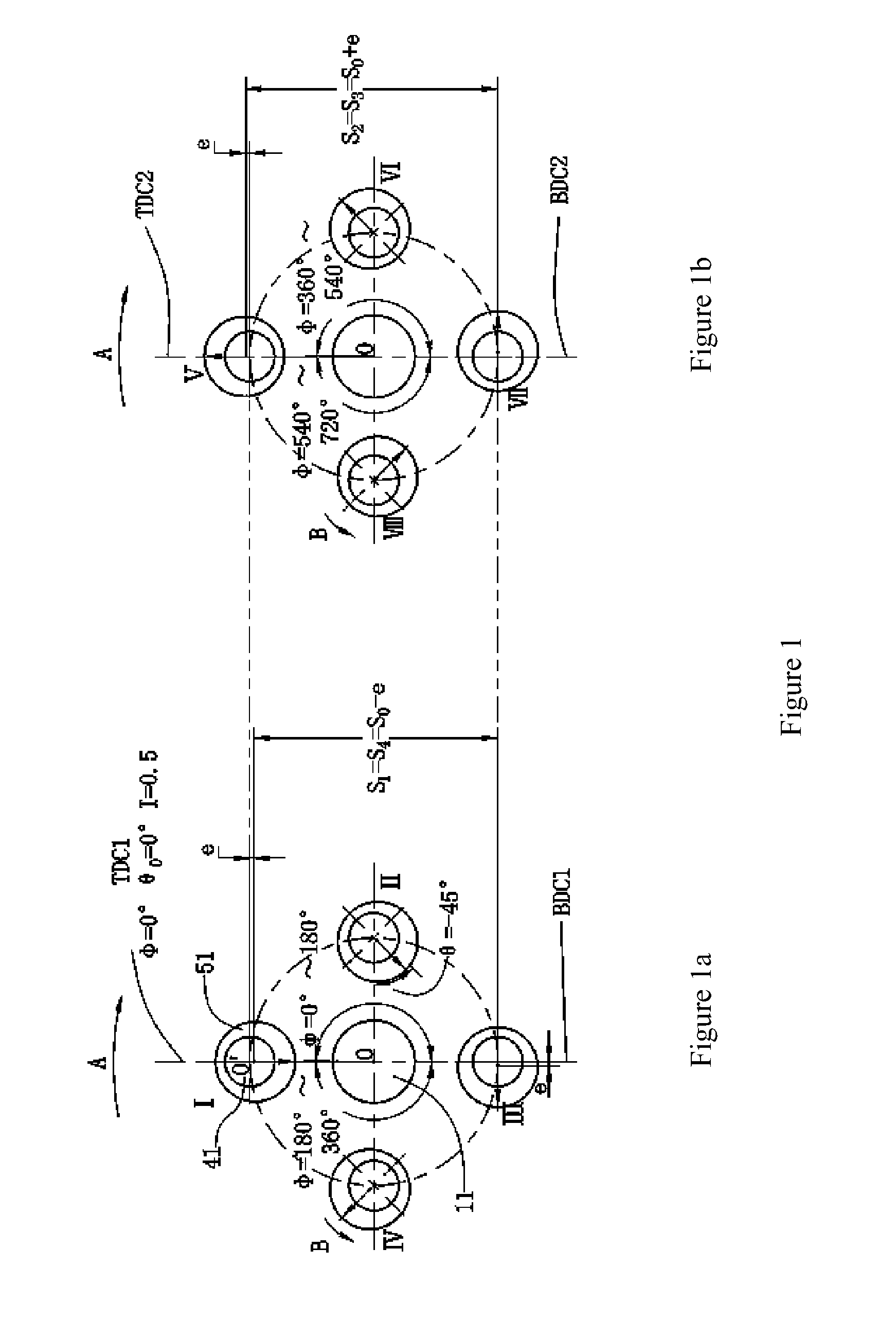

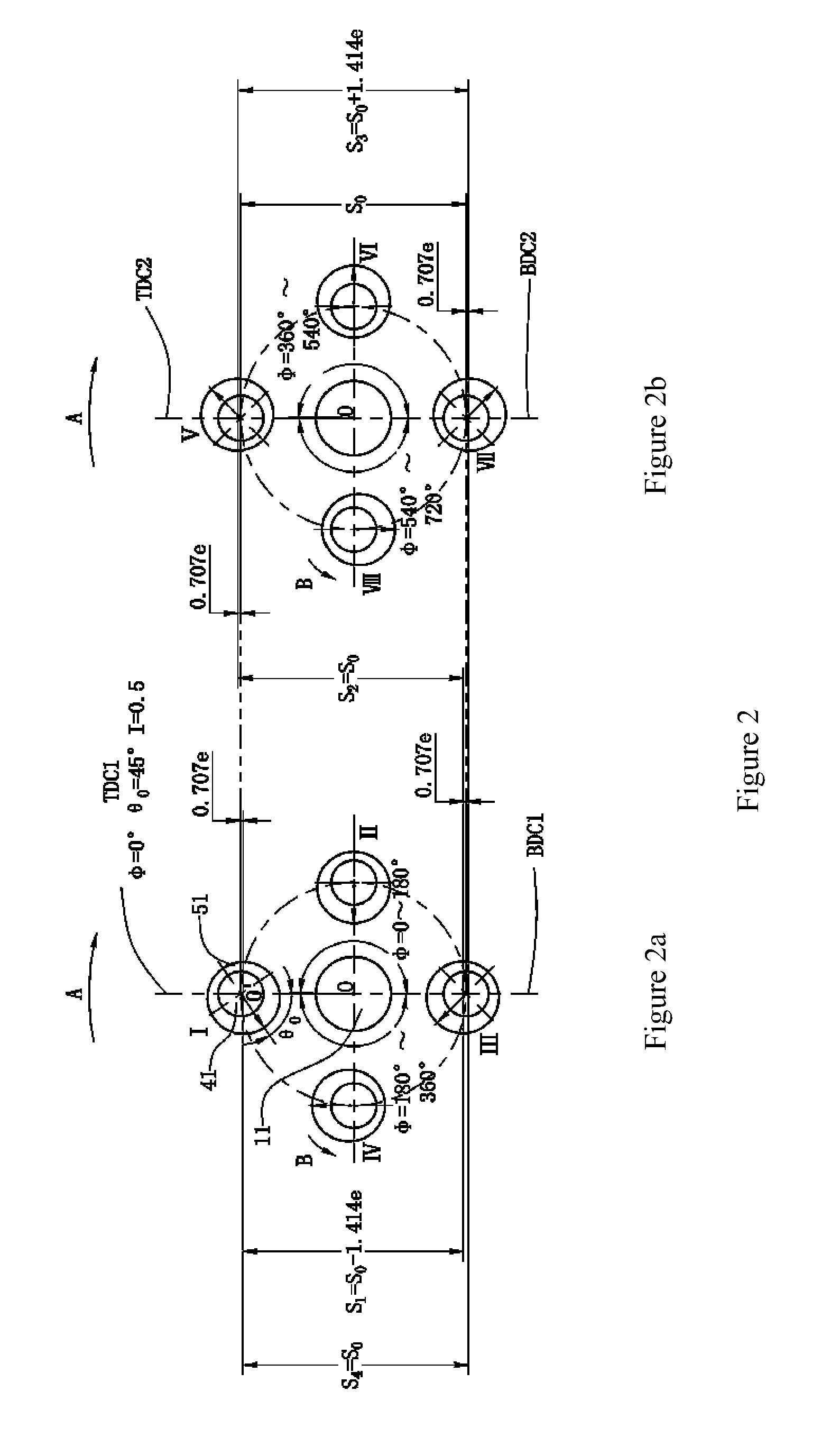

Apparatus with variable compression ratio and variable expansion ratio

ActiveUS20160061105A1No adverse effect to strengthLow costInternal combustion piston enginesEngine controllersDrive shaftGear wheel

Apparatus with variable compression ratio and variable expansion ratio for an internal combustion engine, mounted on the engine crankshaft and the assembly of the piston-connecting rod, comprising an actuating motor, a worm, a worm gear, a sun gear, a first transmission shaft, a plurality of the transmission shafts, a first eccentric sleeve, a plurality of eccentric sleeve, a front gear of the first eccentric sleeve, a plurality of the front gear of the eccentric sleeve, a plurality of the rear gear of the eccentric sleeve, a planetary gear, the rear gear of the first transmission shaft, a plurality of the front gear of the transmission shaft, and a plurality of the rear gear of the transmission shaft. An angle α between the axis of the first transmission shaft and the axis of the crankshaft is not zero, the other axes of the transmission shafts with the axis of the crankshaft coincide, or parallel but do not coincide, or form a non zero angle.

Owner:SHEN DAZI

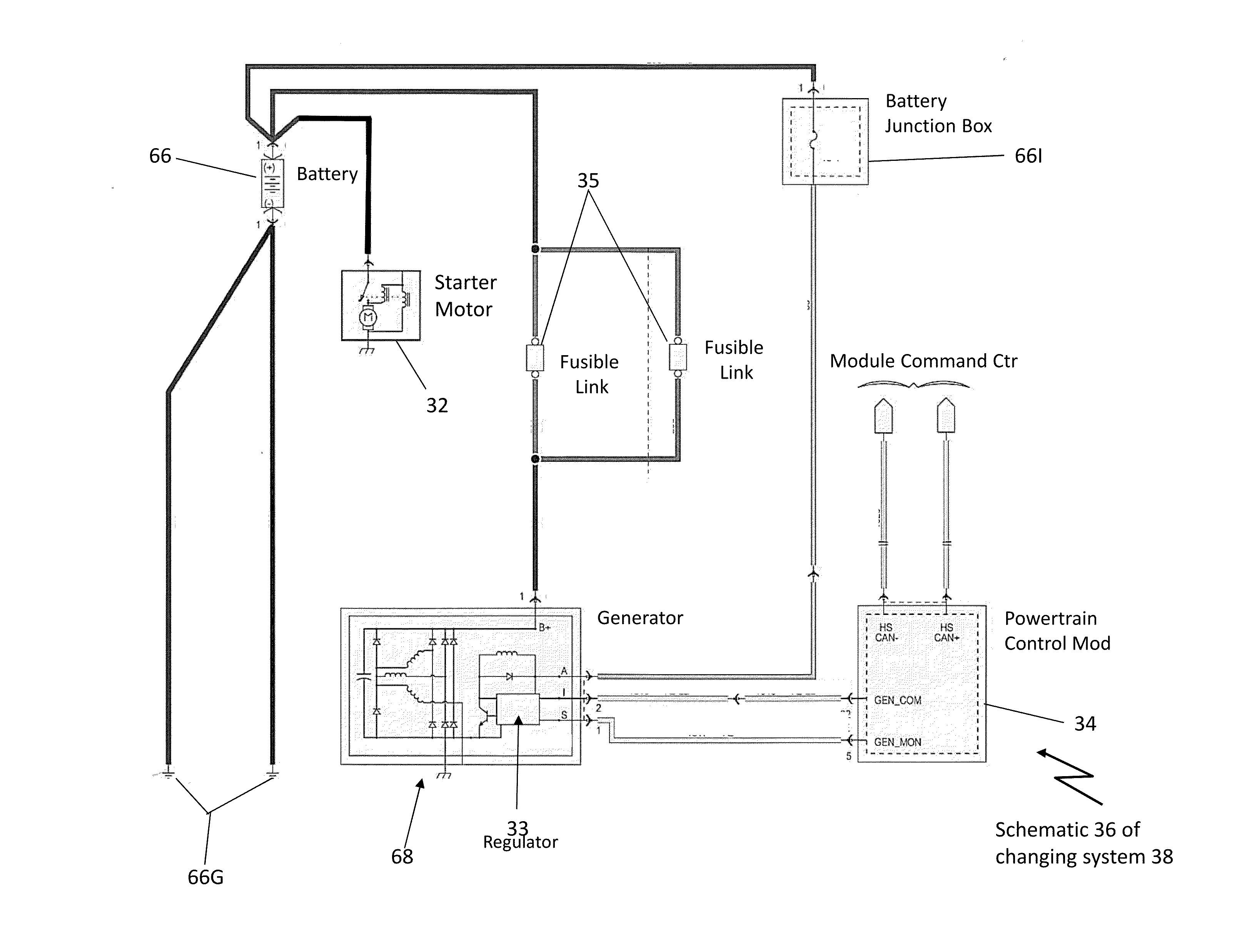

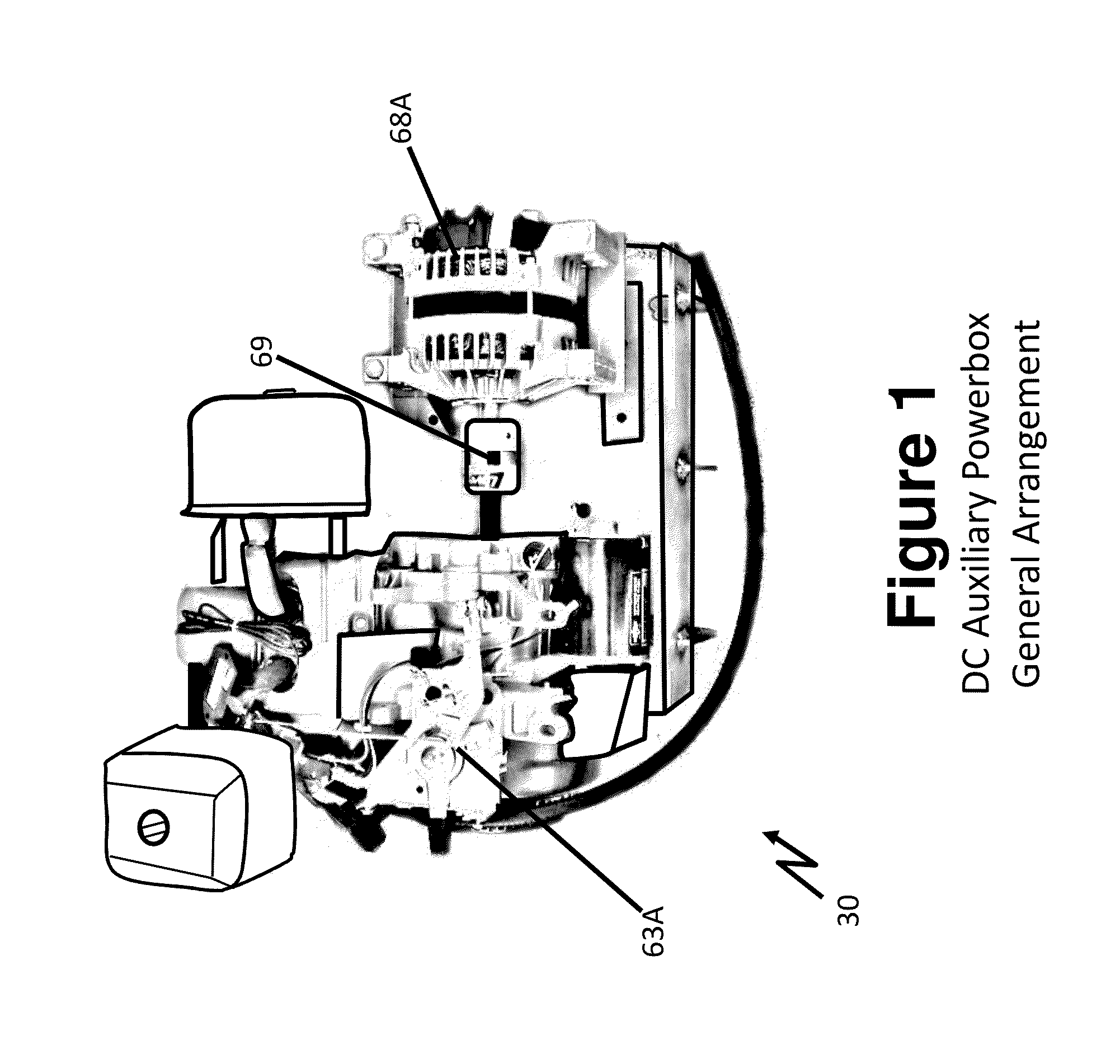

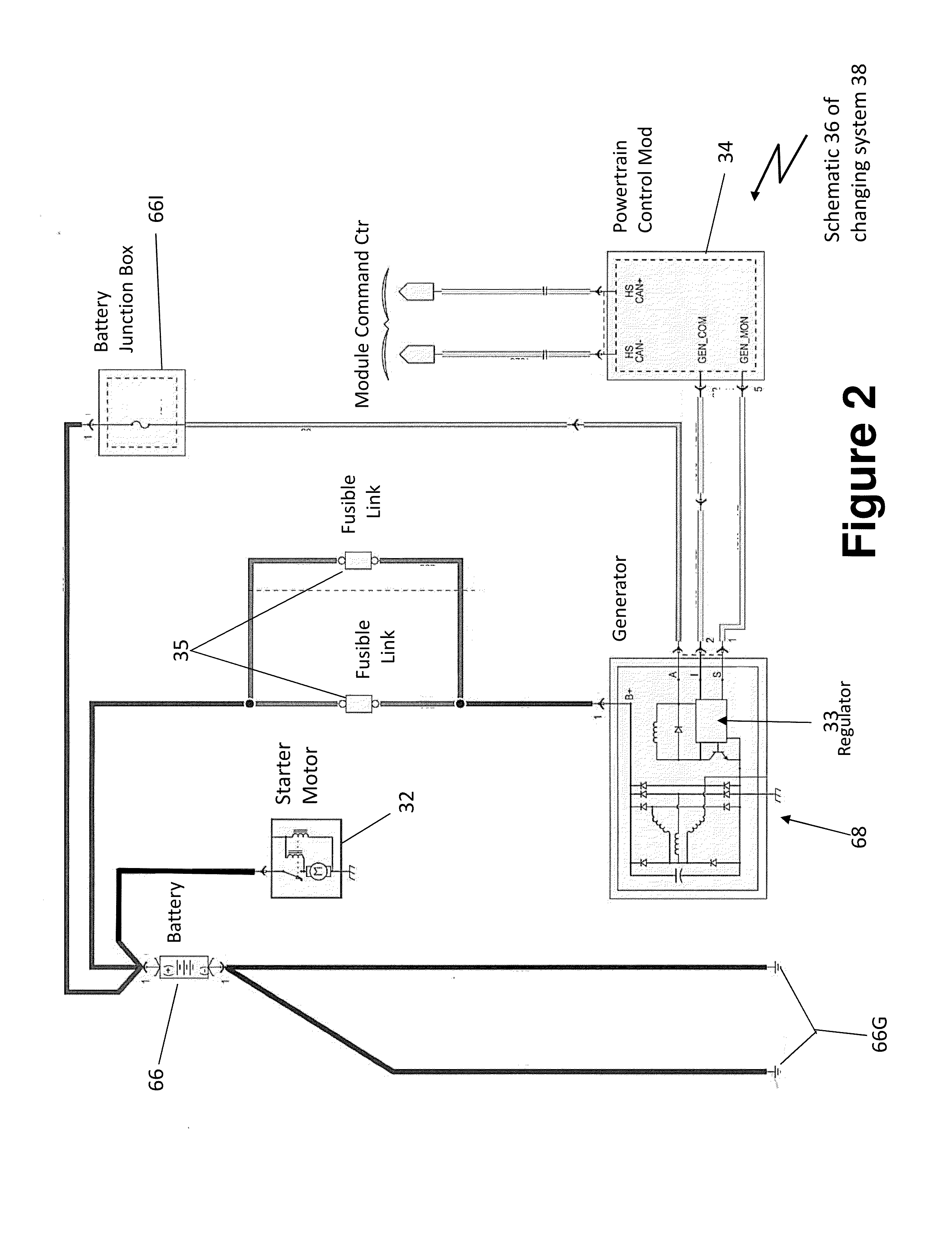

Auxiliary power system called a D C Powerbox

InactiveUS20160229362A1Sufficient powerOutput lossDomestic cooling apparatusLighting and heating apparatusElectricityAlternator

An auxiliary Powerbox to generate electricity through an additional alternator configuration in an emergency vehicle which reduces fuel consumption and minimizes wear factors associated with idling the engine when the vehicle is at rest and when the vehicle's primary engine is not operating. The system is an auxiliary system that provides electrical power by means of a small internal combustion engine and an alternator and is intended to provide electrical power to a vehicle when the main engine of the vehicle is shut down. The system, the DC Powerbox, has an independent fuel system and cooling system however the fuel and cooling systems could be incorporated into the vehicles respected systems.

Owner:BRUTUS STEVEN +1

Fire Grate for Enhanced Combustion with Vertical and Horizontal Expansion Sleeves

InactiveUS20110005509A1Reduce harmful emissionsHarmful emissionDomestic stoves or rangesWater heatersParticulatesCombustion chamber

An improved fire grate may provide fresh oxygen rich air to a secondary combustion zone, created by the improved fire grate, of a combustion chamber where a combustion gas stream is typically oxygen starved assisting in the burning process of incompletely burned particulates and reducing other harmful emissions. A baffle plate may be introduced in the secondary combustion zone to increase a combustion chamber temperature, encourage mixing of oxygen starved air with oxygen rich air and increase a residence time of the combustion gas within the combustion chamber. These aspects of the baffle plate promote more efficient burning of the biomass / fuel. Additionally, log lighter(s) may be disposed in the secondary combustion zone to increase a temperature of the combustion chamber for the purposes of reducing harmful emissions. The improved fire grate may be horizontally and vertically adjusted to fit within different sized fireplace combustion chambers.

Owner:EARTHS FLAME

Gasification combustion system

InactiveUS20100294179A1Efficient combustionEmission reductionAir supply regulationIncinerator apparatusCombustion systemProcess engineering

A two stage refuse gasification combustion system for processing refuse is disclosed. The system may contain features such as an advancer, a first and second gasifier, a drier, a gas regulator, and a post combustor. Additionally, methods for regulating gas and advancing refuse through a two stage refuse gasification combustion system are disclosed.

Owner:COVANTA ENERGY CORPORATION

Microprocessor controlled automated mixing system, cogeneration system and adaptive/predictive control for use therewith

InactiveUS8583350B1Easy to useReduce dependenceLevel controlDigital data processing detailsOn boardCogeneration

A microprocessor controlled automated, multi-fuel apparatus to blend hydrogen, bio-fuel and / or natural or propane gases. This novel multi-stage apparatus first converts cooking oils into bio-fuel. The system automatically blends the bio-fuel with at least one of or both hydrogen gas, generated by a self-contained on-board hydrogen electrolyzer, and / or natural or propane gases. This blended “Hyenrich” gaseous fuel drives various processes including, but not limited to, cogeneration systems and electrical generators to produce “green” electricity by utilizing an adaptive and predictive learning algorithms to significantly reduce cost per kilowatt and lessen dependency on the over taxed utility grid, while simultaneously reducing emissions of CO, CO2 and NOx, making the method and apparatus an environmentally-friendly energy device.

Owner:HYCOGEN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com