Heating fuel blend

a heating fuel and blend technology, applied in the field of heating fuel blends, can solve the problems of in-place reserves, and achieve the effects of reducing heating fuel costs, increasing demand for vegetable oils, and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

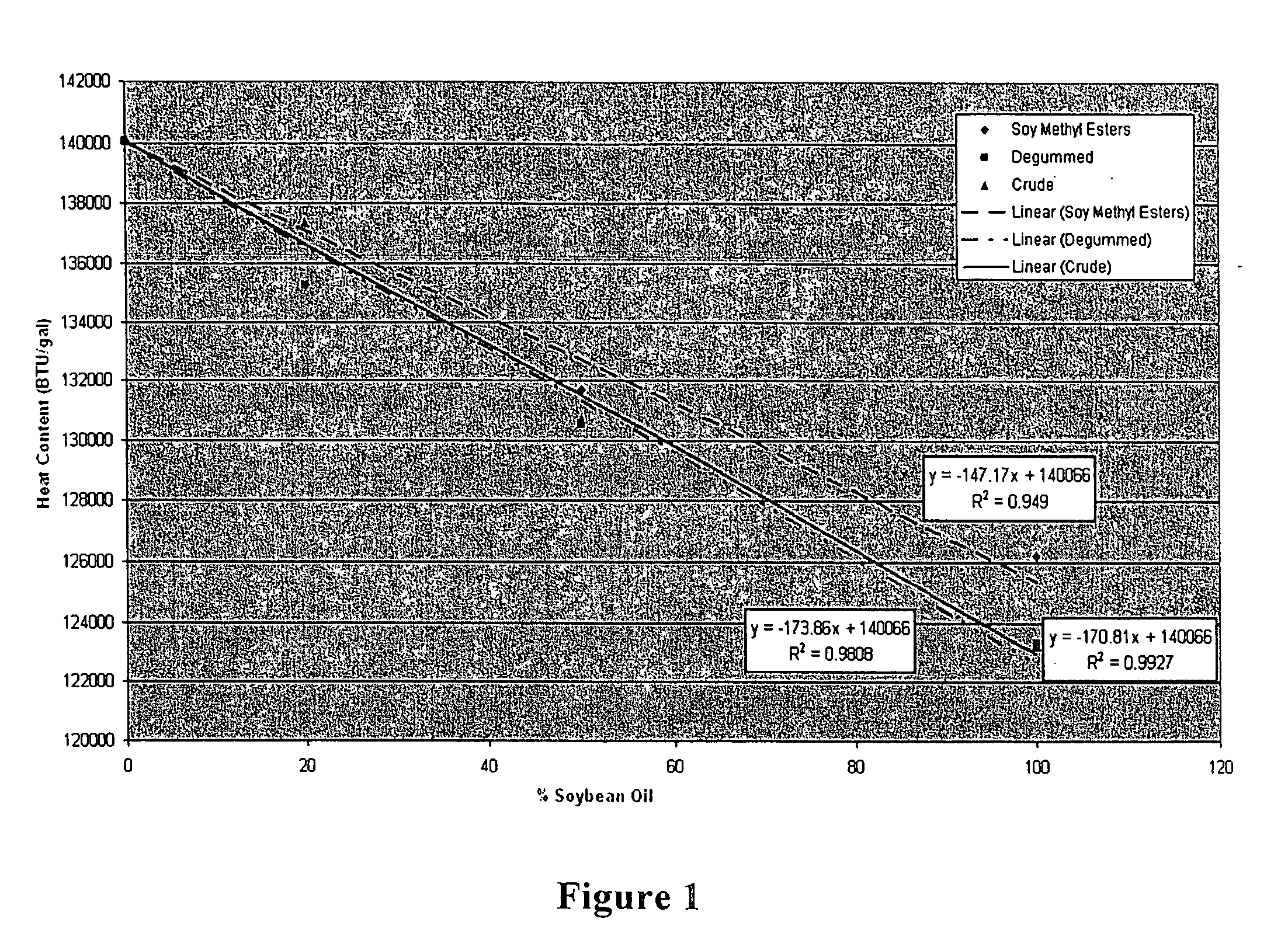

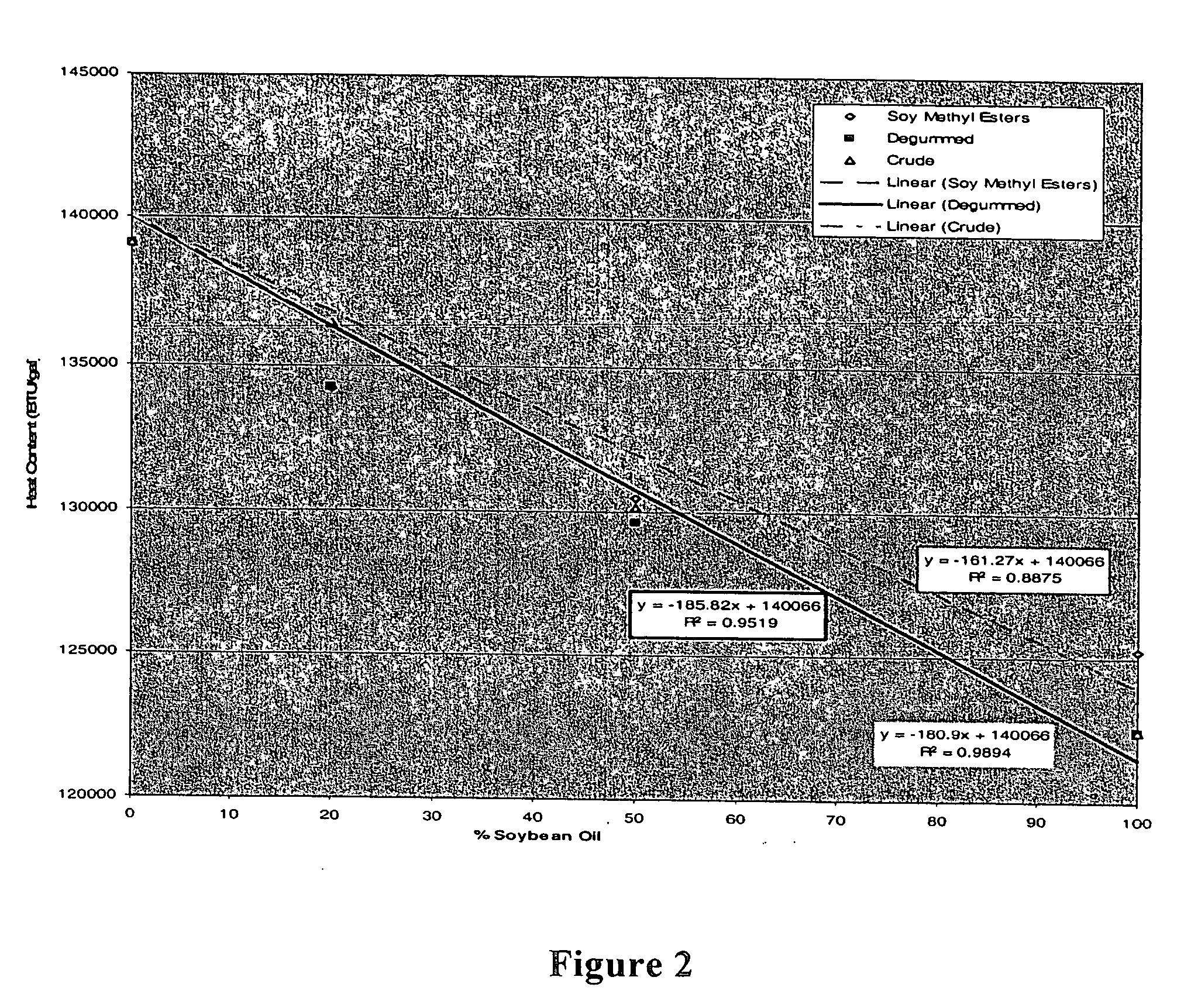

[0018] An embodiment of the invention provides a heating fuel blend comprising a petroleum based fuel and a vegetable oil. The petroleum based fuel can be diesel fuel, fuel oil, and kerosene including but not limited to No. 1 diesel fuel, No. 2 diesel fuel, No. 1 fuel oil, and No. 2 fuel oil.

[0019] The vegetable oil can be selected from the group consisting of soybean oil, cottenseed oil, rapeseed oil, corn oil, peanut oil, sunflowerseed oil, palm kernel oil, copra oil, or other oils of similar composition as listed in table 1 below produced by plants.

TABLE 1Fatty Acid content in Vegetable Oil: Percent by WeightFatty AcidCompositionFatty Acid% by WeightMyristicC14H28O2C14:00.3-6 PalmiticC16H32O2C16:0 2-47PalmitoleicC16H30O2C16:10-1StearicC18H36O2C18:01-6OleicC18H34O2C18:110-52LinoleicC18H32O2C18:2 2-69LenolenicC18H30O2C18:30.3-10 ArachidicC20H40O2C20:00.9-10 BehenicC22H44O2C22:0EicosenoicC20H38O2C20:150-60EurcicC22H42O2C22:1

[0020] The blend preferably comprises a petroleum based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat of combustion | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com