Technology for rapidly decaying rice and wheat straws

A rice and wheat straw and decomposition technology, applied in the direction of organic fertilizers, etc., can solve the problems that the common people are difficult to grasp, the straw cannot be completely disposed of, and the promotion is difficult, and achieves the effect of simple method, strong adaptability, and accelerated degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

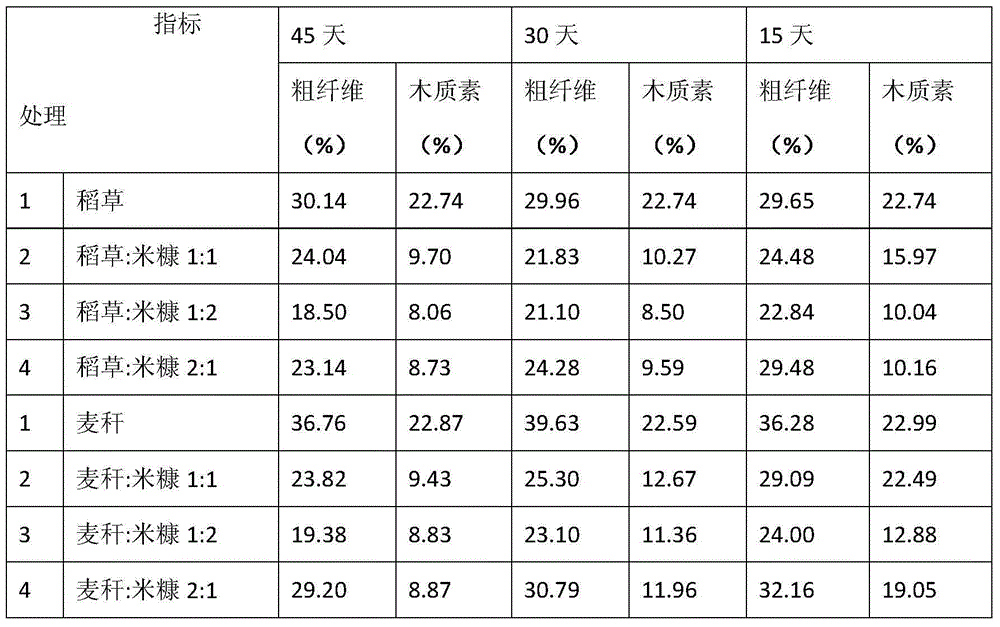

Embodiment 1

[0022] A technology for quickly decomposing rice and wheat straw. The method is to mix 1 part of rice straw with 1 part of rice bran, stir evenly, stack it under the tree, let it ferment and decompose naturally, and turn the pile 10 to 20 days after the mycelium grows. Once, until completely degraded.

Embodiment 2

[0024] A technology for quickly decomposing rice and wheat straw. The method is to mix 1 part of rice straw and 2 parts of rice bran, stir evenly, pile them up in the paddy fields, let them ferment and decompose naturally, and turn them over 10 to 20 days after the mycelium grows. Stack once until completely degraded.

Embodiment 3

[0026] A technology for quickly decomposing rice and wheat straw. The method is to mix 2 parts of rice straw and 1 part of rice bran, stir evenly, pile them up in the paddy fields, let them ferment and decompose naturally, and turn them over 10 to 20 days after the mycelium grows. Stack once until completely degraded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com