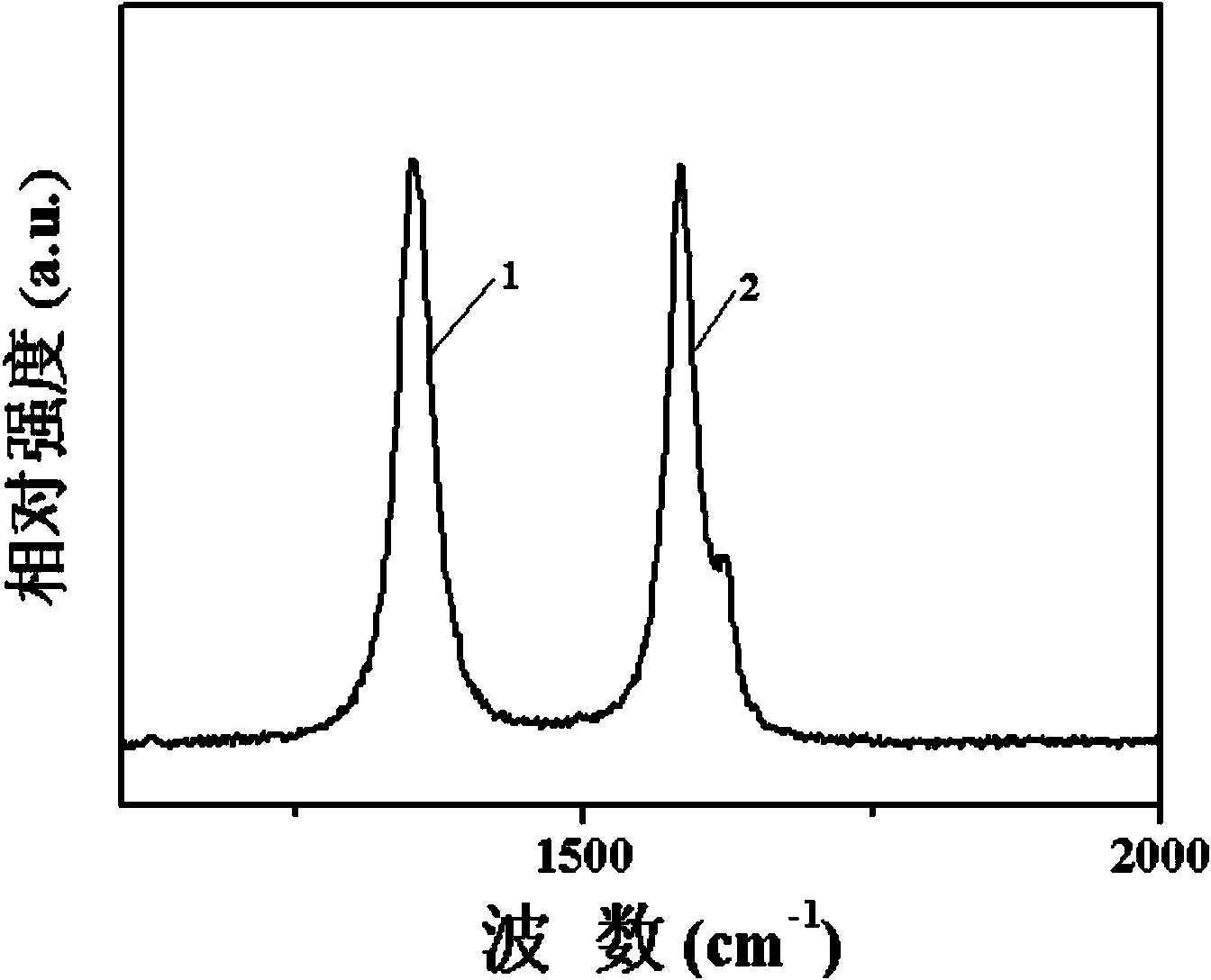

Method for preparing composite electrode material of carbon nano-tube-graphene supercapacitor

A supercapacitor and composite electrode technology, which is applied in the field of composite electrode material preparation, can solve the problem of high temperature of graphene preparation, and achieve the effects of reducing the probability of charge annihilation, improving decomposition efficiency and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of a kind of carbon nanotube-graphene supercapacitor composite electrode material described in this embodiment is specifically carried out according to the following steps:

[0021] 1. Put the substrate material in the plasma-enhanced chemical vapor deposition vacuum device, evacuate to a pressure below 5Pa, feed argon gas with a gas flow rate of 10sccm-50sccm, and adjust the vacuuming speed to put the plasma-enhanced chemical vapor deposition vacuum device The medium pressure is controlled at 100Pa~300Pa, and the temperature is raised to the working temperature of 700℃~900℃ within 30min under the pressure of 100Pa~300Pa and argon atmosphere;

[0022] 2. Feed carbon source gas, adjust the gas flow ratio of carbon source gas and argon to (5-35):80, and adjust the vacuuming speed to control the pressure in the plasma-enhanced chemical vapor deposition vacuum device to 2000Pa-3000Pa, Then deposit under the conditions of radio...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the base material described in step 1 is a silicon chip substrate material with a catalyst thin film on its surface, wherein the silicon wafer with a catalyst thin film on its surface The catalyst film in the substrate material is an iron film with a thickness of 5nm to 50nm, a cobalt film with a thickness of 5nm to 50nm or a nickel film with a thickness of 5nm to 50nm. Others are the same as in the first embodiment.

[0033] The base material described in this specific embodiment can be directly used as a collector of a supercapacitor.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the base material described in step 1 is a silicon wafer substrate material with a catalyst thin film on its surface, wherein the surface is covered with a catalyst The catalyst film in the silicon chip substrate material of the film is an iron film with a thickness of 20nm, a cobalt film with a thickness of 20nm or a nickel film with a thickness of 20nm. Others are the same as in the first or second embodiment.

[0035] The base material described in this specific embodiment can be directly used as a collector of a supercapacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com