Cap delivery device of cap screwing machine

A capping machine and cap feeding technology, which is applied in the directions of tightly capping containers with caps, packaging, and conveying objects, etc., can solve the problems of low degree of automation, messy stacking of bottle caps, and complicated cap feeding devices. Simple and effective process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

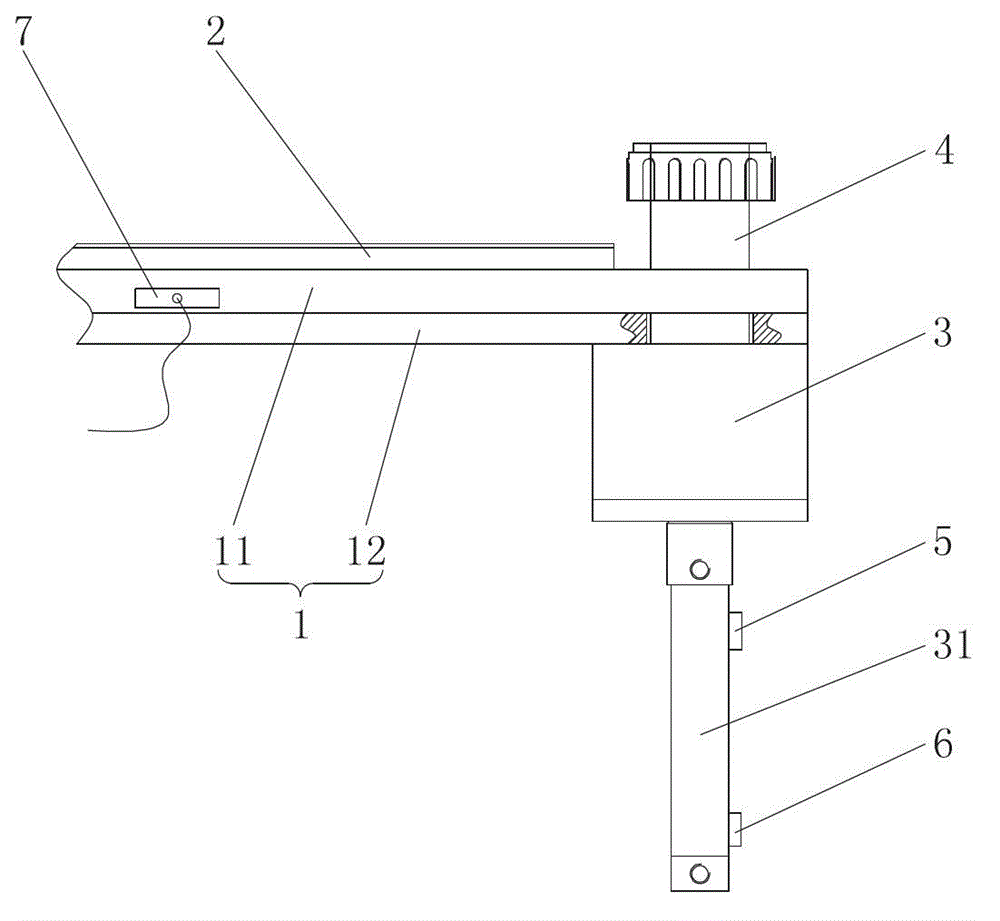

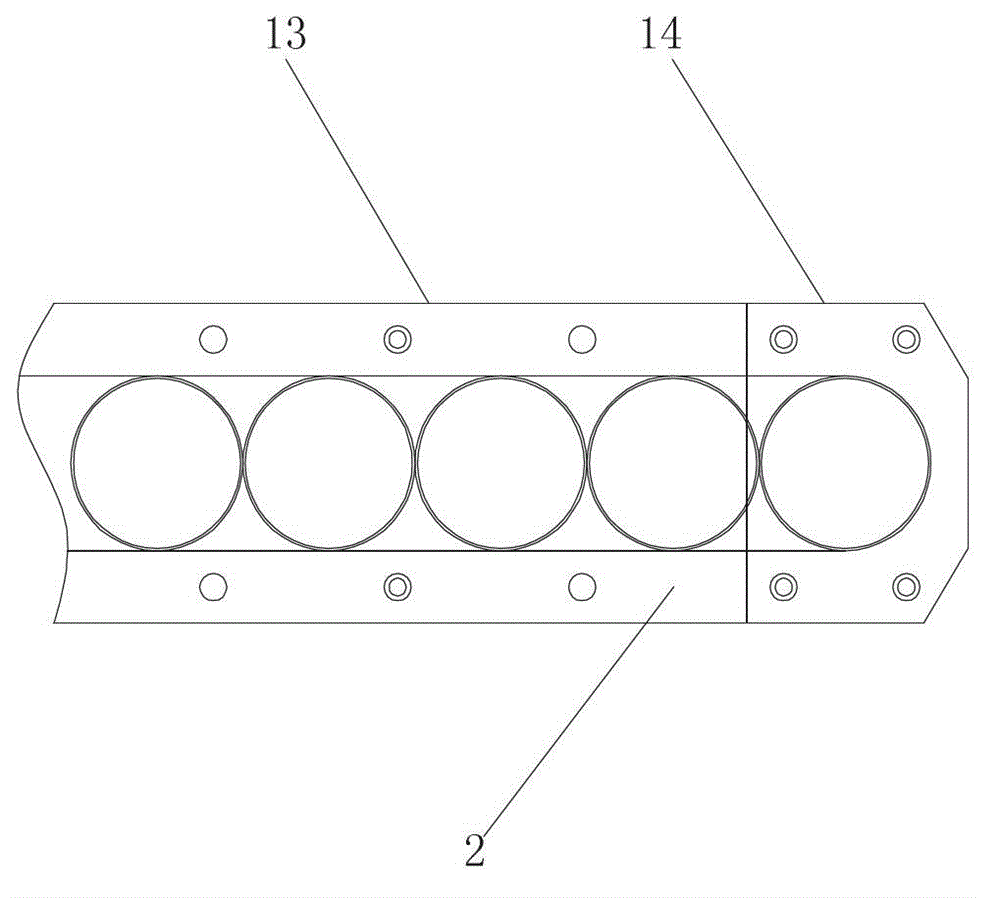

[0010] See figure 1 and figure 2 , the present invention includes a cover guide groove 1 composed of two side plates 11 and a bottom plate 12; the cover guide groove 1 includes a conveying part 13 and a cap sending part 14; the conveying part 13 is covered with a capping plate 2; The gland plate 2 is transparent plexiglass; the base plate 12 of the cover delivery part 14 is provided with a hole, and the cover delivery cylinder 3 is arranged below the base plate 12 of the cover delivery part 14, and the push shaft 31 of the cover delivery cylinder 3 is connected with the cover delivery cylinder 3. The rod 4 is coaxially fixedly connected; the cap sending rod 4 is coaxial with the hole, and the size matches the hole; the cap sending cylinder 3 is provided with an upper limit sensor 5 and a lower limit sensor 6; A lack of cover sensor 7 is provided.

[0011] Under the action of the cap guide groove 1 and the capping plate 2, the bottle caps are arranged in an orderly manner fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com