Portable safe material receiving device for circular knife die cutting equipment

A material receiving device and a convenient technology, which is applied in the field of a portable safety material receiving device for circular knife die-cutting equipment, can solve the problems of material receiving inconvenience, etc., and achieve the effects of improved material receiving efficiency, safe use, and neat delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

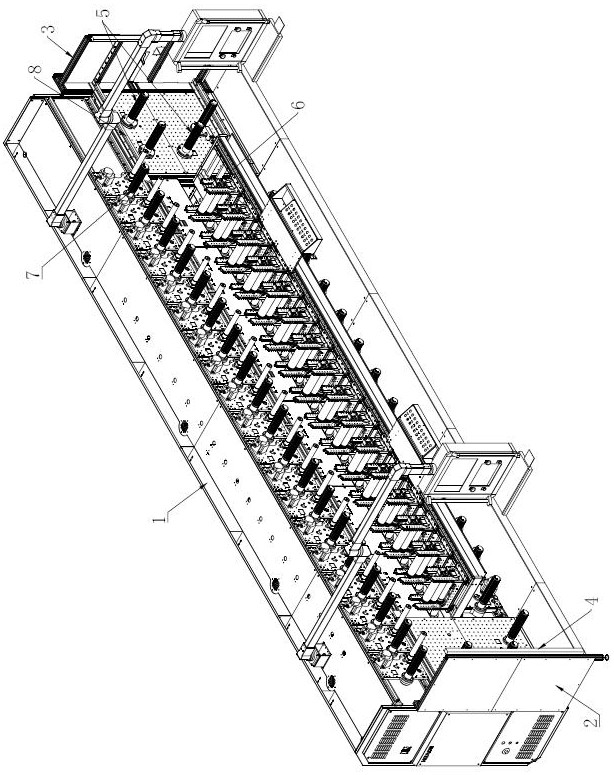

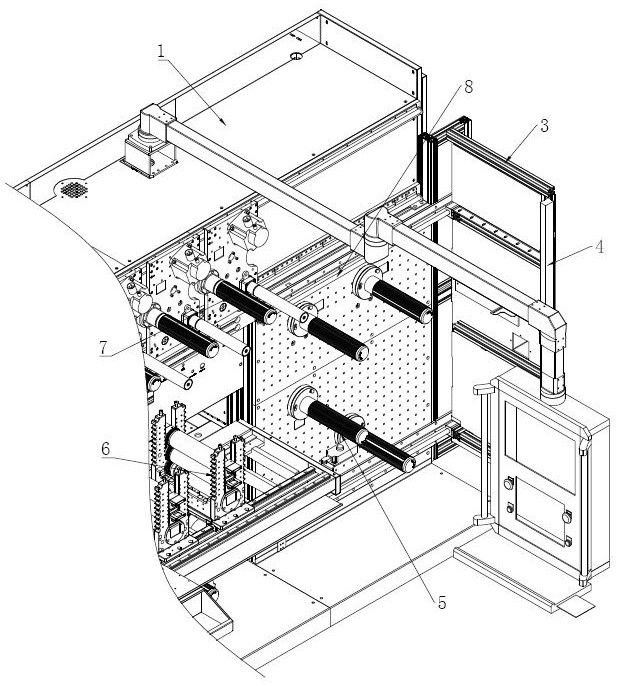

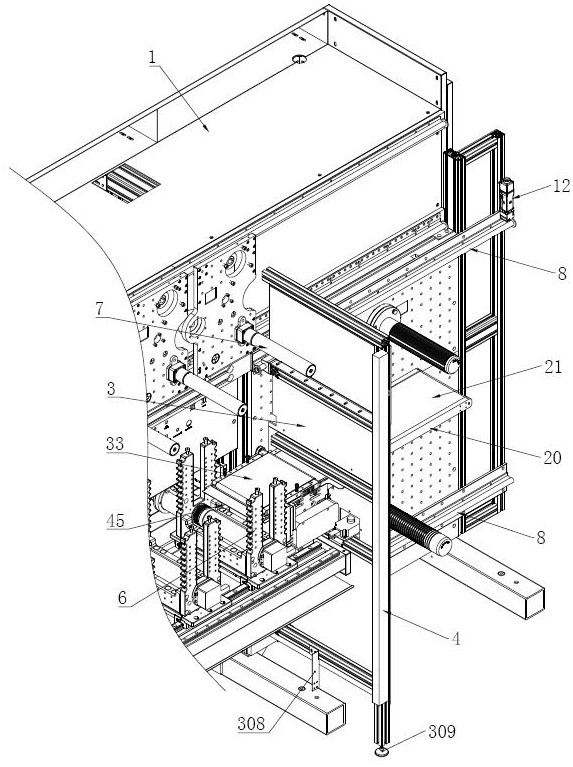

[0083] Such as Figure 1 to Figure 3 As shown, this embodiment provides a portable safety receiving device for circular knife die-cutting equipment, including a frame 1, and also includes a safety grating 4 for ensuring safe operation, and for realizing the winding of strip-shaped products. Material roller 5 and a conveyor for conveying sheet products.

[0084] The feeding end of the frame 1 is fixedly installed with the first grating mounting frame 2, and the discharging end of the frame 1 is slidingly mounted with the second grating mounting frame 3, and the second grating mounting frame 3 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com