Method for preparing electrode material of sandwich structured composite graphene oxide paper

A composite oxidation and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of decreasing the proportion of active materials, reducing the utilization rate of active materials, and increasing electrode resistance, and achieves a good supporting effect. The effect of promoting electron transfer and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

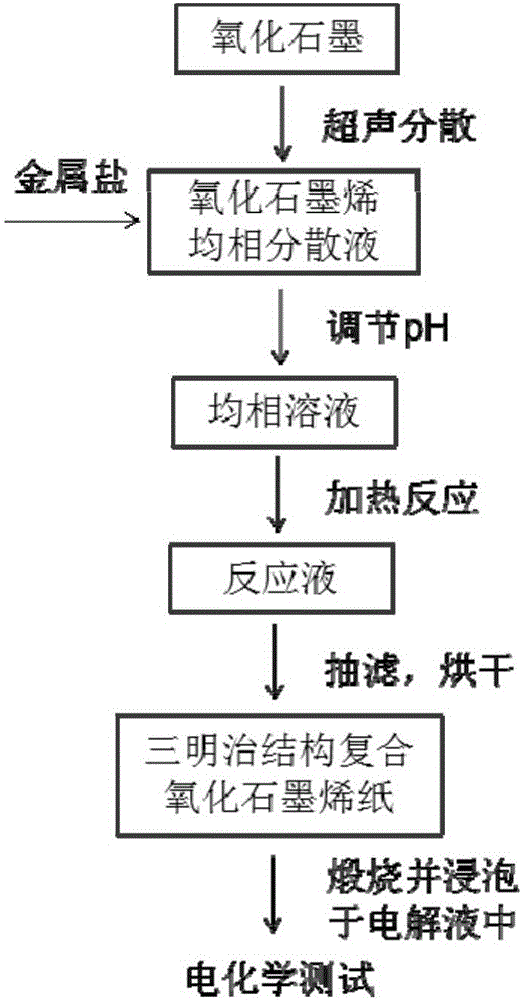

[0019] (1) Take 0.0250g of graphite oxide (15% oxygen content) and ultrasonically disperse it completely in 50ml of ethanol for 1h;

[0020] (2) Take by weighing 1.0913g cobalt nitrate and stir in graphene ethanol solution until completely dissolving;

[0021] (3) Adjust the pH of the homogeneous solution in step (2) to 9, and react at 80° C. for 10 h;

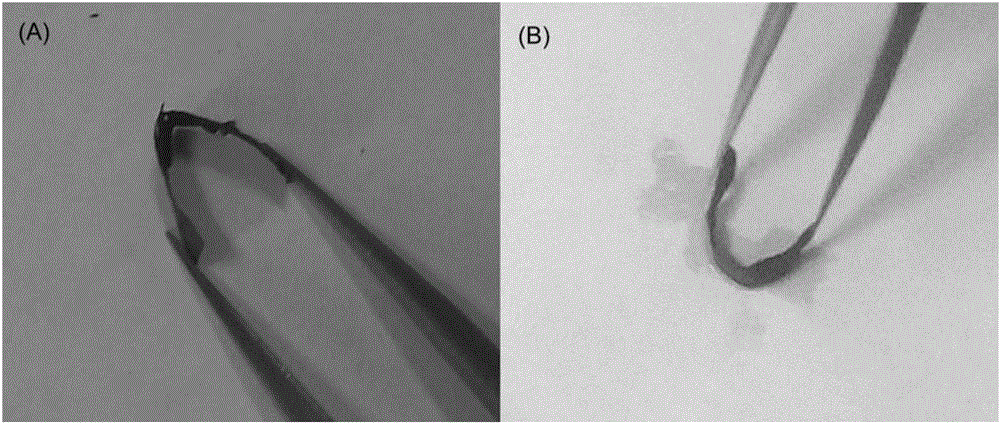

[0022] (4) The solution in step (3) is filtered through a microporous membrane to carry out layer-by-layer self-assembly, and after each washing with deionized water and ethanol for 3 times, it is dried at low temperature to form a sandwich structure composite graphene oxide paper electrode material;

[0023] (5) Calcining the electrode material obtained in step (4) at 150° C. for 1 h, and then soaking it in the electrolyte solution to be tested for 12 h after calcining.

[0024] The composite graphene oxide paper with sandwich structure prepared in Example 1 is used as an electrode material for supercapacitors to obtain a hi...

Embodiment 2

[0026] (1) Take 0.1500g of graphite oxide (25% oxygen content) in 50ml ethylene glycol and ultrasonically 2h to make it completely dispersed;

[0027] (2) take by weighing 12.474g nickel chloride and stir in graphene ethylene glycol solution until completely dissolving;

[0028] (3) Adjust the pH of the homogeneous solution in step (2) to 8, and react at 130° C. for 8 hours;

[0029] (4) The solution in step (3) is filtered through a microporous membrane to carry out layer-by-layer self-assembly, and after each washing with deionized water and ethanol for 3 times, it is dried at low temperature to form a sandwich structure composite graphene oxide paper electrode material;

[0030] (5) Calcining the electrode material obtained in step (4) at 100° C. for 1 h, and then soaking it in the electrolyte solution to be tested for 8 h after calcining.

[0031] The composite graphene oxide paper with sandwich structure prepared in Example 2 is used as an electrode material for a superc...

Embodiment 3

[0033] (1) Weigh 0.0750g of graphite oxide (40% oxygen content) in 50ml ethylene glycol / water mixed solution and ultrasonically 1h to make it completely dispersed;

[0034] (2) Take by weighing 4.1813g manganese sulfate and stir in graphene ethylene glycol / water mixed solution until completely dissolving;

[0035] (3) Adjust the pH of the homogeneous solution in step (2) to 10, and react at 100° C. for 12 hours;

[0036] (4) The solution in step (3) is filtered through a microporous membrane to carry out layer-by-layer self-assembly, and after each washing with deionized water and ethanol for 3 times, it is dried at low temperature to form a sandwich structure composite graphene oxide paper electrode material;

[0037] (5) Calcining the electrode material obtained in step (4) at 170° C. for 0.5 h, and then immersing it in the electrolyte solution to be tested for 16 h after calcining.

[0038] The composite graphene oxide paper with sandwich structure prepared in Example 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com