Production method of immune electrode

A technology of electrodes and conductive polymers, which is applied in the field of preparation of immune electrodes, can solve the problems that the specificity of antibody-antigen reactions needs to be enhanced, and the stability of electrode modification materials needs to be improved, so as to facilitate a large number of detections, improve detection efficiency and accuracy, The effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

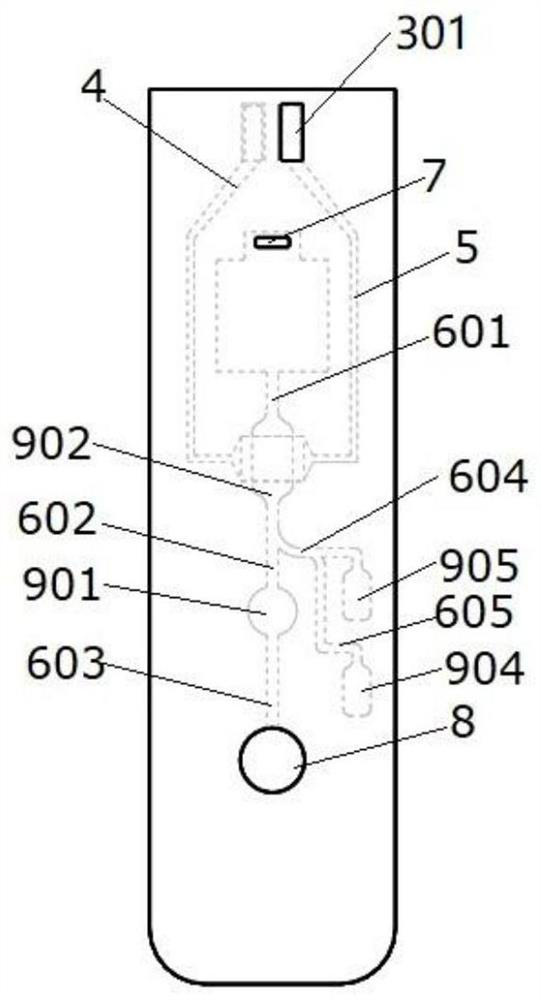

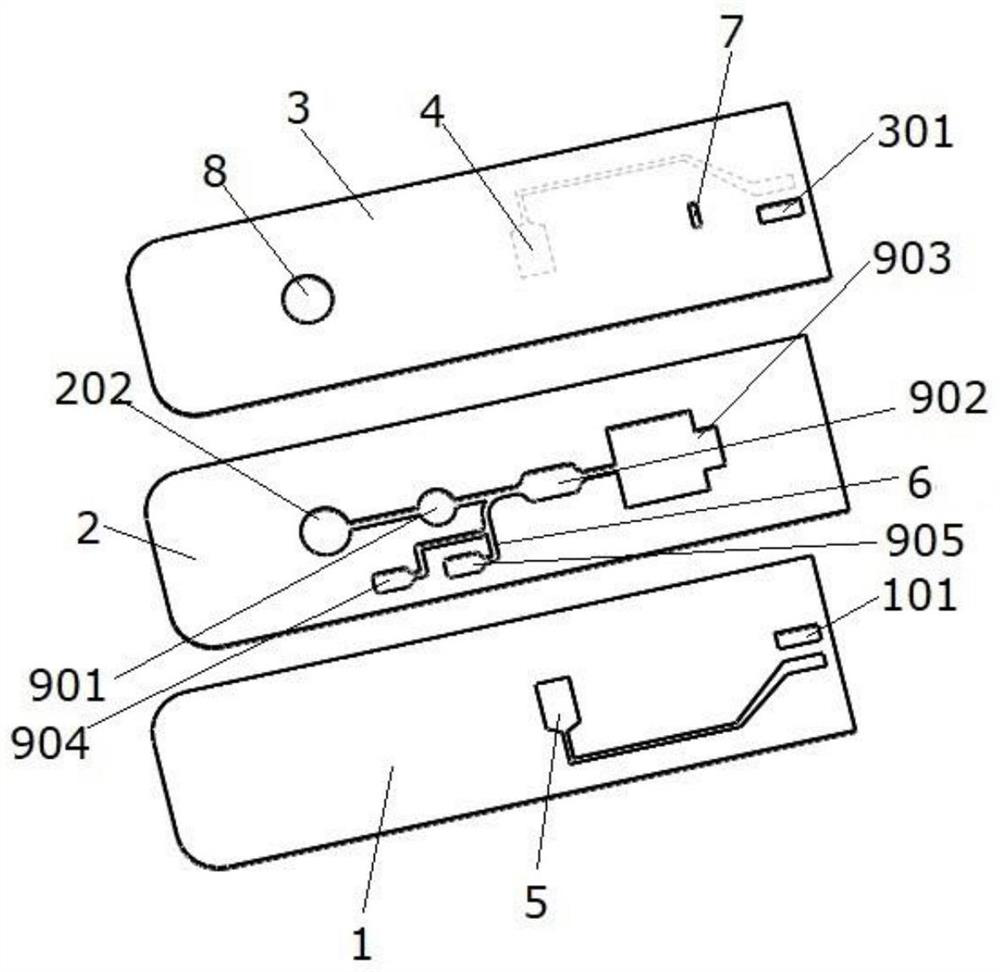

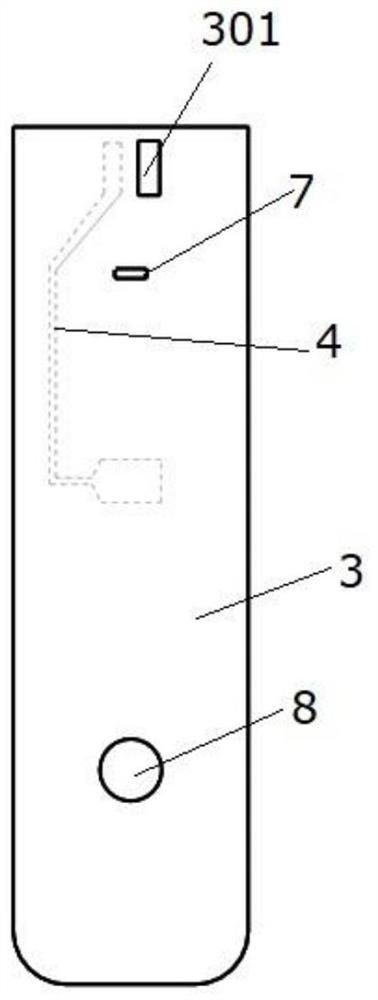

[0067] Embodiment 1: as Figure 9 As shown, the immune electrode includes a base layer 10, a gold layer 11, a conductive polymer layer 12, an antibody layer 13 and a porous protective layer 14, and the base layer 10, a gold layer 11, a conductive polymer layer 12, an antibody layer 13 and a porous protective layer Layers 14 are laminated sequentially from bottom to top, the base layer 10 is a PET flexible base layer; the conductive polymer layer 12 is a polypyrrole layer.

Embodiment 2

[0068] Embodiment 2: the preparation method based on polypyrrole immune electrode of embodiment 1, it comprises the following steps: (1) synthetic polypyrrole layer (conductive polymer layer): prepare polypyrrole layer on the gold-plated base layer after gold plating, obtain polypyrrole layer pyrrole / gold-plated base layer;

[0069] S11 ultrasonically clean the gold-plated PET base layer with ethanol and ultrapure water in turn, and dry it for later use;

[0070] S12 Fix the dried gold-plated PET base layer on the bottom of a 1000mL beaker, and then add the reaction solution to the beaker, which includes pure water, hydrochloric acid, ferric chloride and pyrrole; first add 400mL of pure water and 6.4 mL1mol / L hydrochloric acid, after stirring evenly, slowly add 0.88g ferric chloride, then stir evenly, place the beaker in ice bath, slowly add 400μL pyrrole under nitrogen atmosphere, and then carry out overnight without light under ice bath nitrogen atmosphere Reaction, the ove...

Embodiment 3

[0080] Embodiment 3: The difference from Example 2 is that the conductive polymer layer in the immune electrode adopts polypyrrole doped with sodium dodecylsulfonate; the preparation method based on polypyrrole immune electrode, its Include the following steps:

[0081] (1) Prepare conductive polymer layer: prepare polypyrrole layer on gold-plated base layer, obtain polypyrrole / gold-plated base layer;

[0082] S11 ultrasonically clean the gold-plated PET base layer with ethanol and ultrapure water in turn, and dry it for later use;

[0083] S12 Fix the gold-plated PET base layer that has been dried for later use at the bottom of a 1000mL beaker, and then add the reaction solution to the beaker, which includes pure water, hydrochloric acid, ferric chloride, pyrrole and sodium dodecylsulfonate (SDS) ; First add 400mL of pure water and 6.4mL of 1mol / L hydrochloric acid to the beaker, after stirring evenly, slowly add 0.88g of ferric chloride and 0.17g of sodium dodecylsulfonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com