Preparation method of catalyst

A catalyst and modifier technology, applied in the field of catalyst preparation, can solve the problems of difficult regeneration, unsatisfactory activity and catalytic life, and poor mechanical strength of activated carbon, and achieve the effects of increasing electron transfer, increasing electrochemical activity, and inhibiting reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

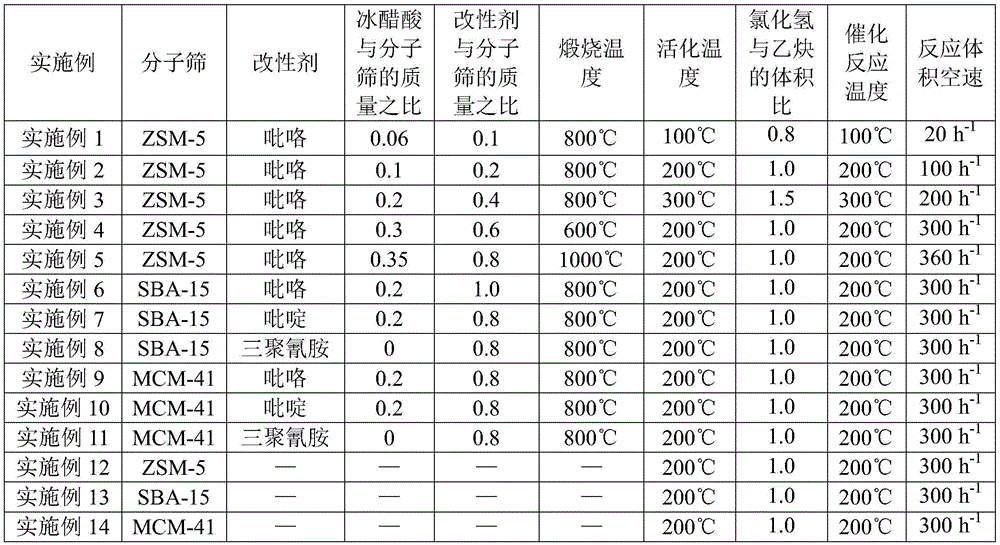

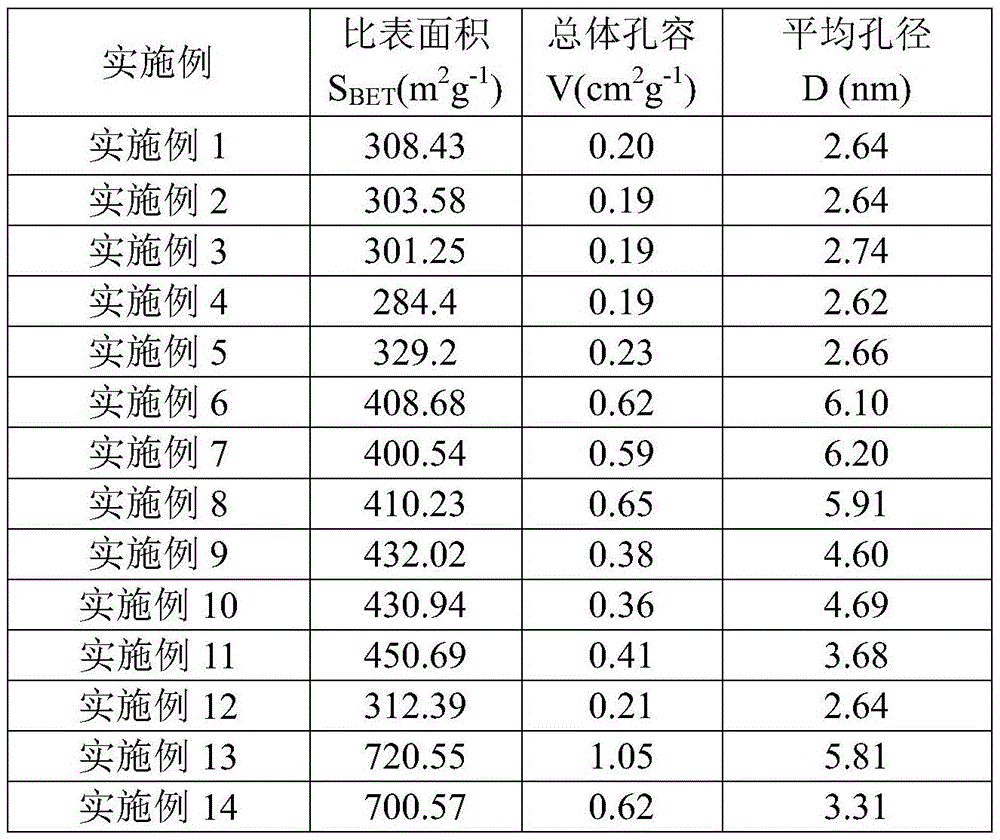

[0020] Catalyst preparation: Weigh 1.50g molecular sieve, stir with 0-0.5mL glacial acetic acid and 50-100mL deionized water for 10-60min to form a slurry solution; add a certain amount of modifier, hydrogen peroxide and deionized water dropwise in sequence, Stir under dark conditions for more than 24 hours. After the reaction is completed, the solution is filtered and dried, and calcined at a certain temperature in a nitrogen atmosphere. The calcined temperature is 600-1000°C to obtain a carrier. The preparation process does not require glacial acetic acid and hydrogen peroxide; using the equal volume impregnation method, disperse 1.5g of the carrier in deionized water for 10-30min ultrasonic treatment, then add the chloroauric acid aqueous solution dropwise into the carrier-dispersed mixture and continue ultrasonication for 10-30min , Stir at room temperature for 1-3h, let stand for more than 24h, and finally dry overnight. The ratio of the mass of the gold element in the ca...

Embodiment 1

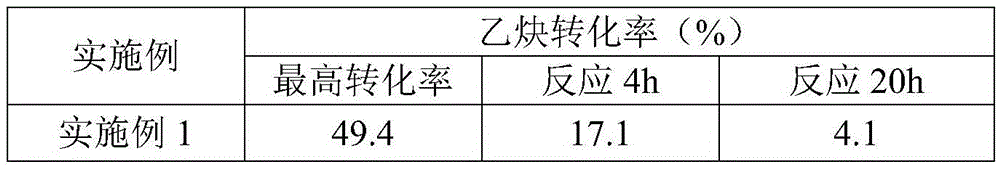

[0023] With reference to the preparation method of the above-mentioned catalyst and the test method for the evaluation of the reactivity of acetylene and hydrogen chloride, the preparation of the catalyst and the evaluation of its catalytic activity were carried out. The test parameters such as the type, the type of modifier, the mass ratio of the modifier and the molecular sieve are shown in Table 1, the characterization of the prepared catalyst is shown in Table 2, and the conversion rate of acetylene is shown in Table 3.

Embodiment 2

[0025] Carry out the preparation of catalyst and the evaluation of catalytic activity with reference to the preparation method of above-mentioned catalyst and acetylene and hydrogen chloride reactivity evaluation test method, the ratio of the quality of gold element in the catalyst and the mass of carrier is 0.5 in the present embodiment, the molecular sieve used in the present embodiment The test parameters such as the type, the type of modifier, the mass ratio of the modifier and the molecular sieve are shown in Table 1, the characterization of the prepared catalyst is shown in Table 2, and the conversion rate of acetylene is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com