Patents

Literature

58 results about "Sandwich-structured composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

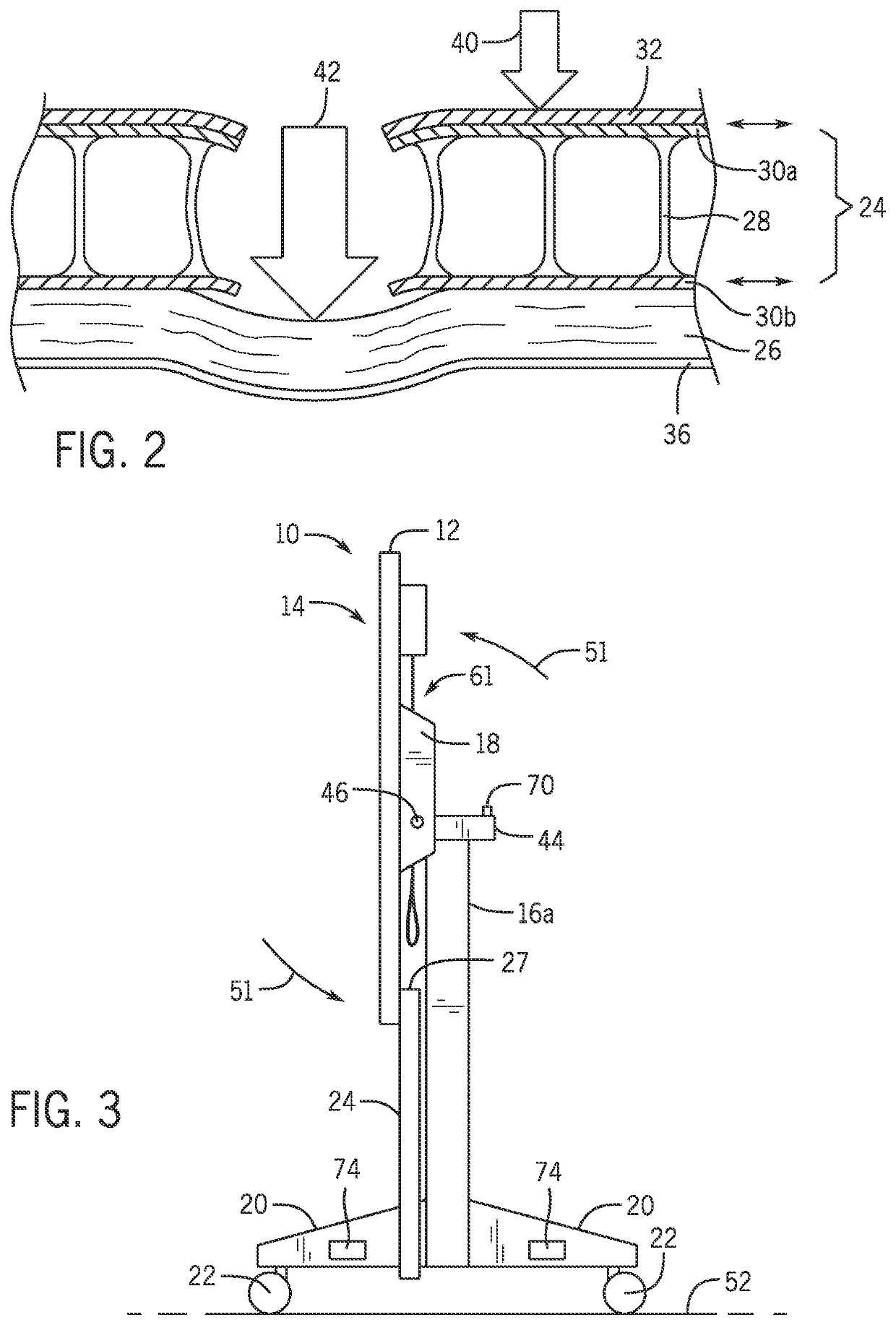

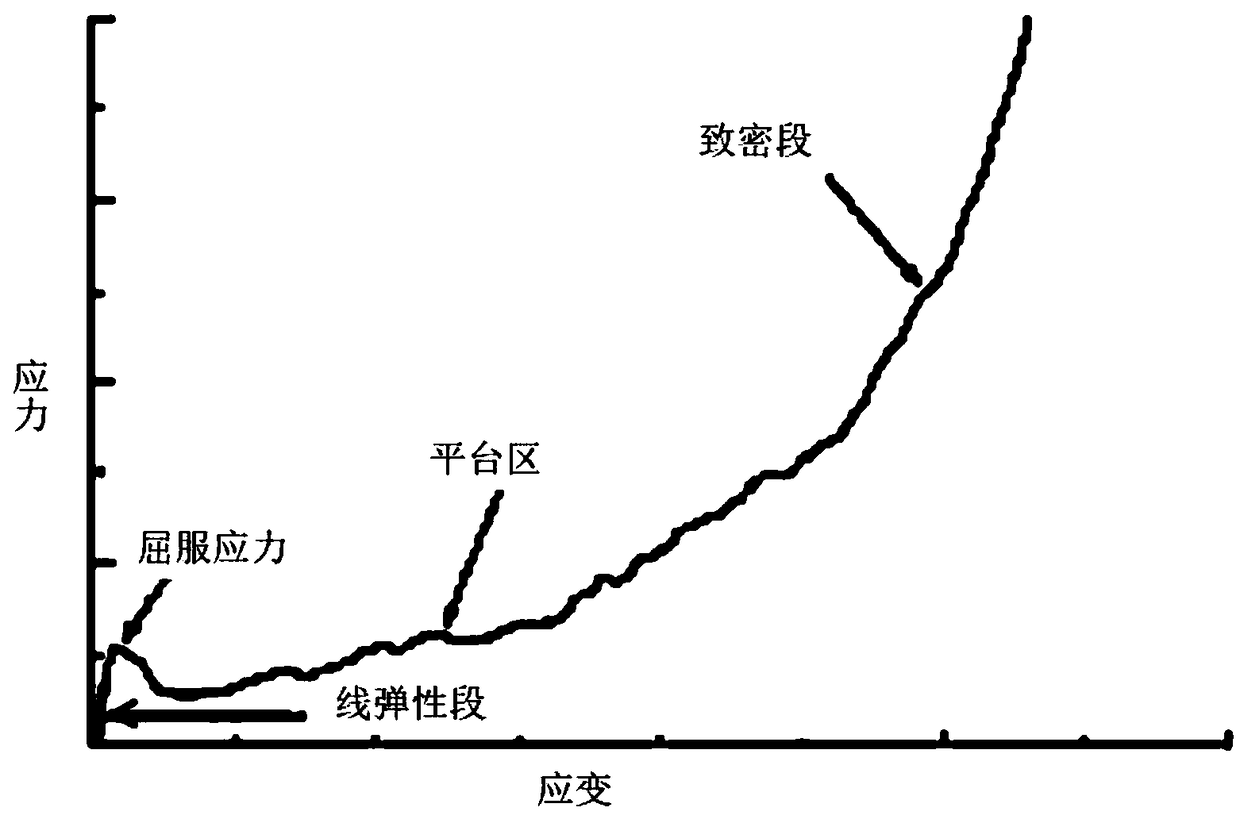

A sandwich-structured composite is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight but thick core. The core material is normally low strength material, but its higher thickness provides the sandwich composite with high bending stiffness with overall low density.

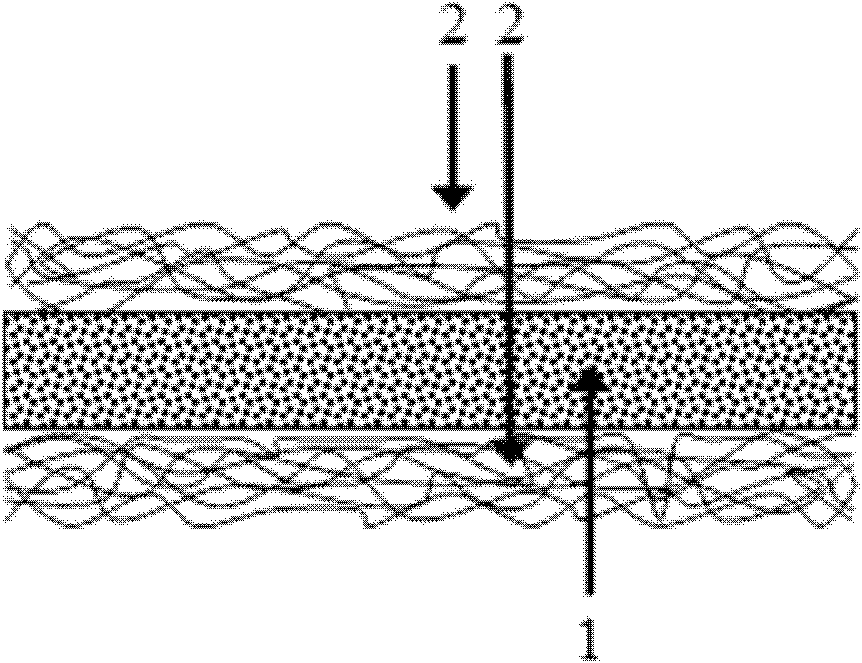

Sandwich structure composite material with elastic core material and preparation method thereof

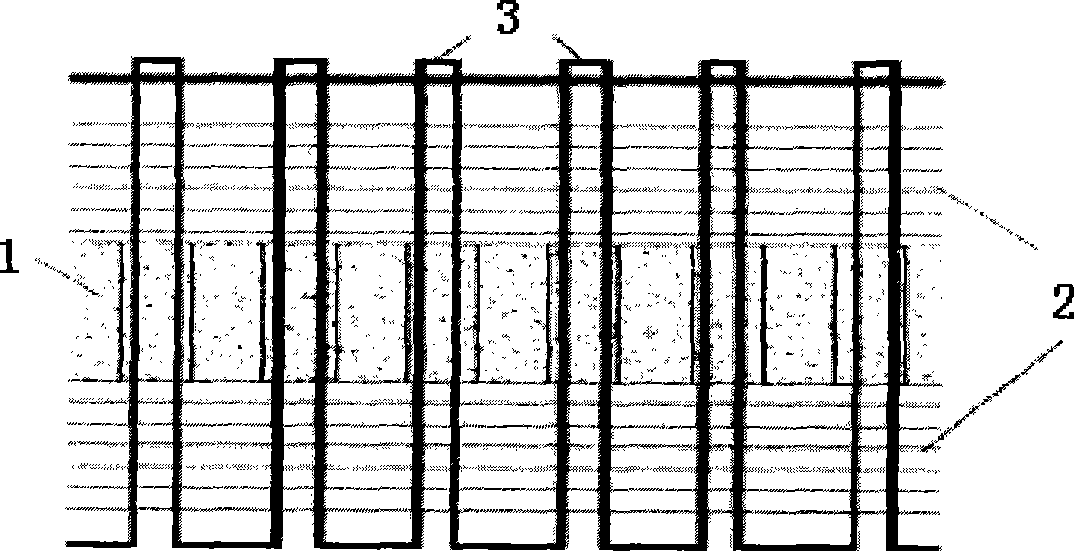

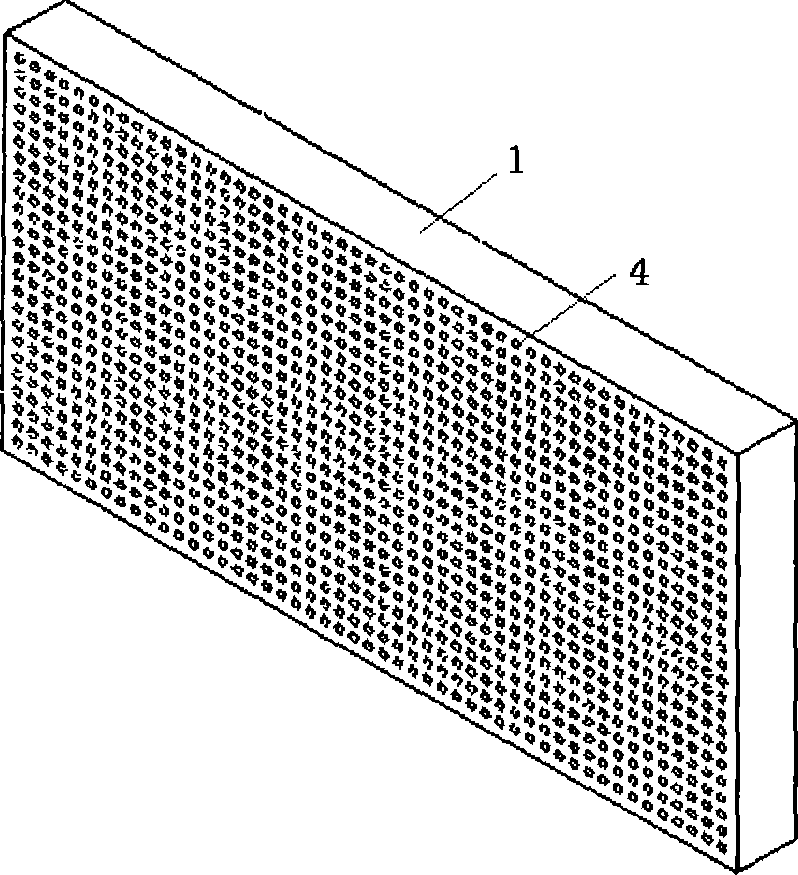

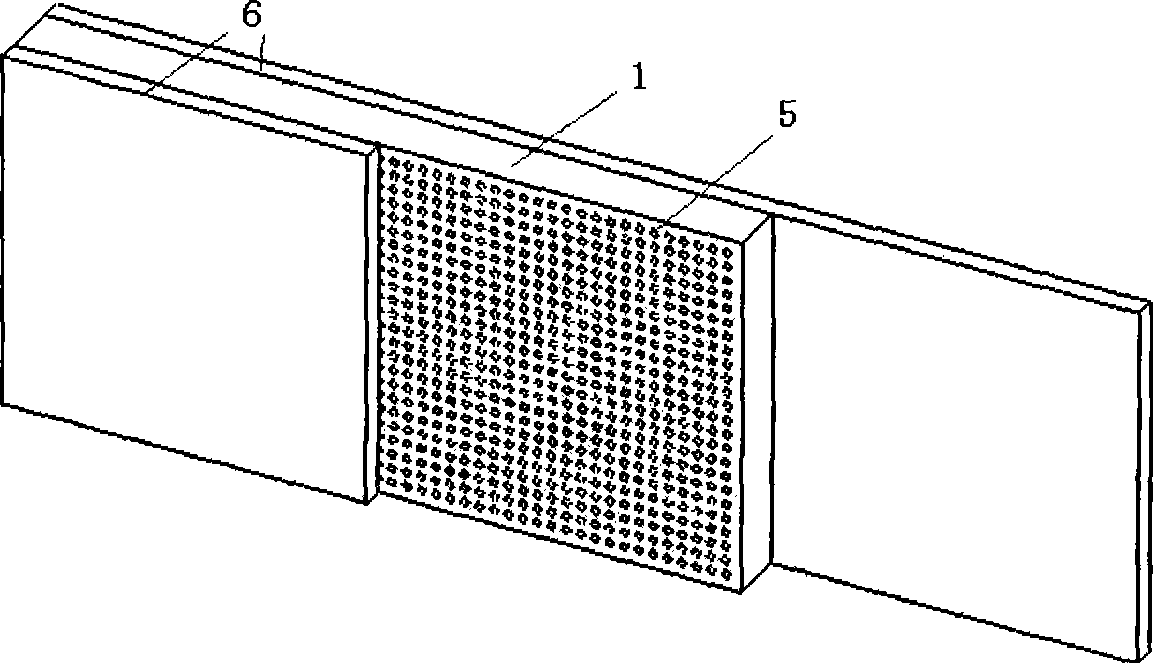

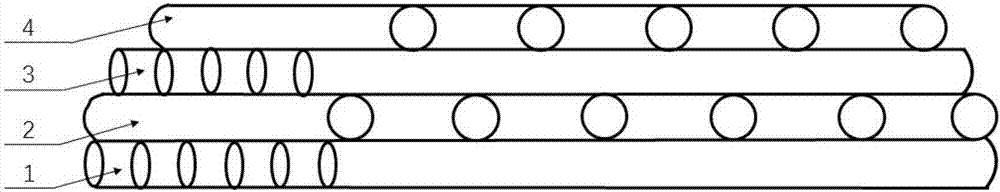

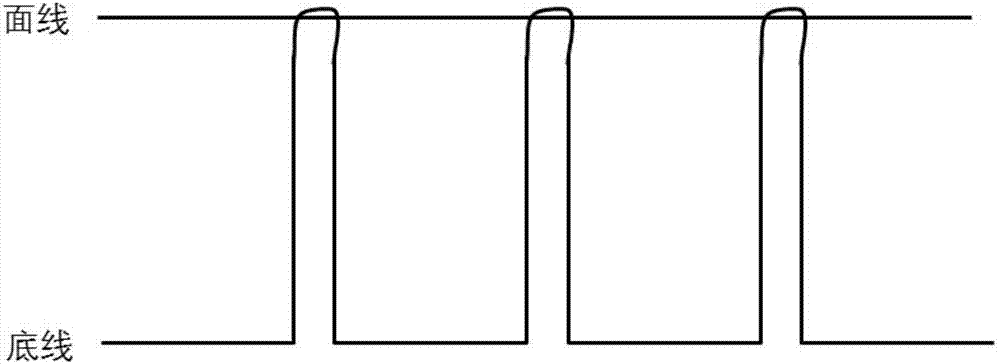

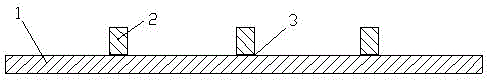

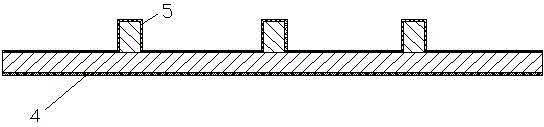

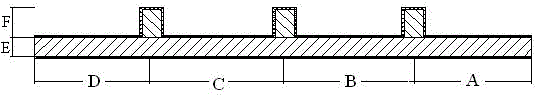

The invention relates to a composite material of sandwich structure with an elastic core material. The composite material consists of upper and lower composite material panels and a porous elastic core material (1) positioned between the upper and lower composite material panels, which are stitched by fiber yarns (3) passing through holes of the elastic core material, wherein the composite material panels are made of fiber cloths (2) and matrix resins of the composite material. The method for preparing the composite material comprises the following steps: drilling holes on the elastic core material (1) at intervals, laying the fiber cloths (2) on the upper surface and the lower surface of the elastic core material, and making the fiber yarns (3) pass through the holes of the core material by a straight stitching lock type stitching method, to make the core material and the fabric cloths into a whole; making the resin soak the fabric cloths and the holes of the core material by the vacuum assisted resin transfer molding; and finally, solidifying and molding the whole by solidification technology, to obtain the composite material. The material has excellent performance, novel structure and simple preparation technology, is easy to operate, and is applicable to the industrialized production.

Owner:WUHAN UNIV OF TECH

Interlayer structure composite material and preparation method thereof

ActiveCN106113738AImprove flexibilityGood surface appearanceSynthetic resin layered productsElectrical equipmentFiberGlass fiber

The invention discloses an interlayer structure composite material and a preparation method thereof. The composite material comprises a hollow glass microbead sandwiched layer and carbon fiber covering layers disposed on two opposite surfaces of the hollow glass microbead sandwiched layer; and the hollow glass microbead sandwiched layer is formed by hot pressing and curing glass fiber preimpregnated cloth made by virtue of a hot melt method and capable of being laid in a flat or curved mold, and the carbon fiber covering layer is formed by hot pressing and curing carbon fiber preimpregnated cloth made by virtue of a hot melt method and a preimpregnating process and capable of being laid in a flat or curved mold. The method comprises the following steps: first preparing carbon fiber preimpregnated cloth, then preparing glass fiber preimpregnated cloth, and covering two surfaces of the glass fiber preimpregnated cloth with the carbon fiber preimpregnated cloth, and hot pressing and molding. The method is simple in process, convenient to operate and low in cost; and the prepared interlayer composite material is low in density, light in weight, high in pressure resistance, excellent in bending performance and good in appearance quality.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

Preparation method of para-aramid paper honeycomb core

InactiveCN106696360AHigh specific strengthHigh specific modulusPaper/cardboard articlesMaterials preparationHoneycomb

The invention belongs to the technical field of composite material preparation, and relates to a preparation method of a para-aramid paper honeycomb core. The preparation method of the para-aramid paper honeycomb core is used for preparing a sandwich-structure composite material, and comprises the four treatment process steps of sequentially gluing and pressing para-aramid paper, stretching and setting the para-aramid paper, glue dipping and solidifying the para-aramid paper, and slicing processing the para-aramid paper. A para-aramid paper honeycomb prepared through the preparation method provided by the invention has higher specific strength and specific modulus, and a more excellent heat-resisting property; and under the same design requirement, the weight of a composite material component can be further reduced. The para-aramid paper honeycomb core prepared by adopting the method provided by the invention has higher strength and modulus, under the same mechanical property design requirement, the weight of the high-performance para-aramid paper honeycomb is reduced greatly, and the para-aramid paper honeycomb core can be widely applied in high-end fields such as aerospace.

Owner:AVIC COMPOSITES

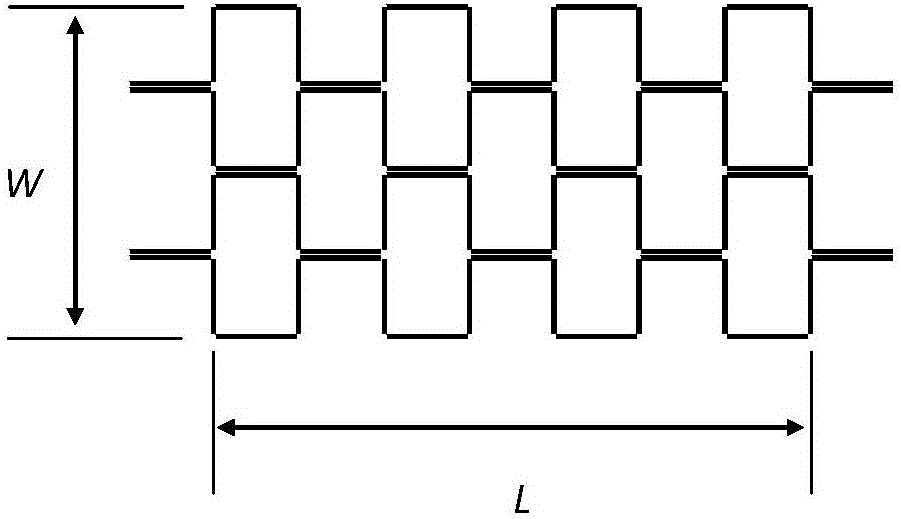

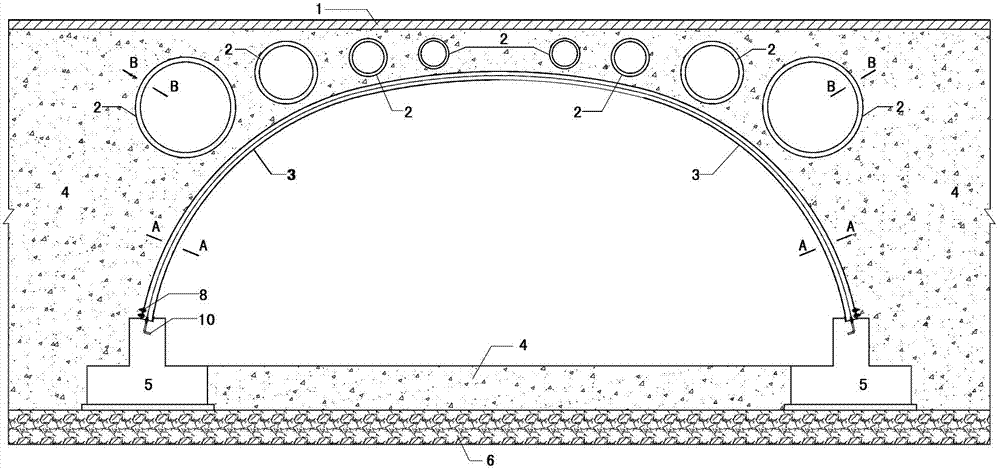

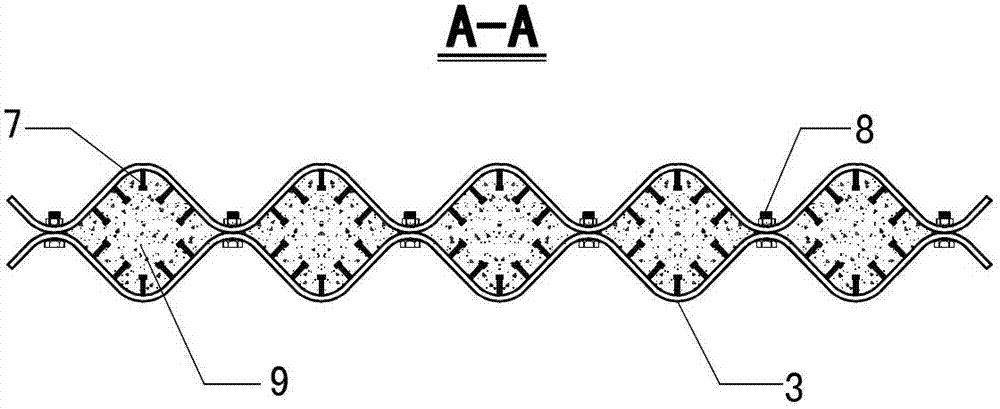

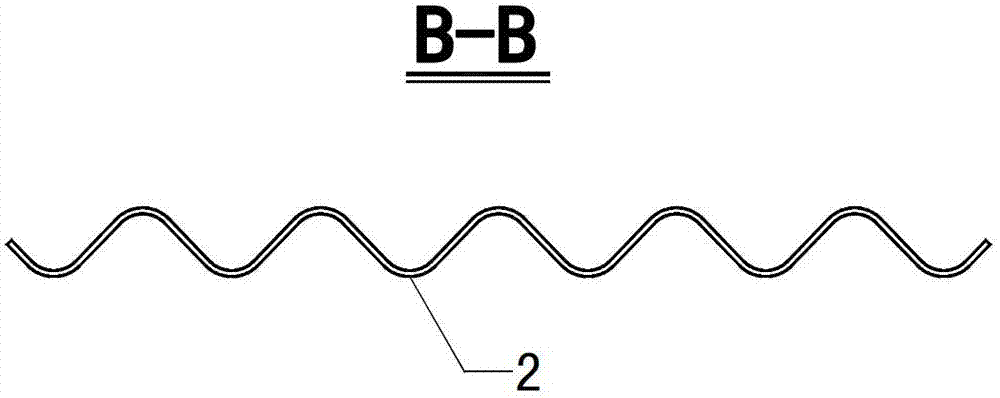

Lattice-type large-span soil-filling composite corrugated steel arch bridge structure

InactiveCN103114520ASimplify the assembly processReduce weightBridge erection/assemblyArch-type bridgeReinforced concreteEconomic benefits

The invention relates to a novel composite arc bridge structure, and particularly discloses a lattice-type large-span soil-filling composite corrugated steel arch bridge structure. Sandwich mortar composite corrugated steel plates are adopted as large-span main arch rings of the composite structure. The corrugated steel plates are connected to form a reversely arranged double-layer plate through bolts, studs are arranged in an interlayer, and filled high-strength mortar forms an integral sandwich composite corrugated steel plate. Corrugated steel tubes are adopted by gastropore. Load is conveyed between the main arch rings and the gastropore by filling soil. The lattice-type large-span soil-filling composite corrugated steel arch bridge structure has the advantages of being low in weight, durable, high in strength, good in flexibility, high in performance, rapid in construction, good in economic benefit and the like, is an ideal alternative to reinforced concrete bridges, can be widely used in the construction of middle-sized bridges (20-50m), and can certainly generate good social economic benefit.

Owner:HUNAN UNIV

Preparation method of water soluble phenolic resin honeycomb core material

InactiveCN107053768AReduce pollutionGood value for moneyPaper/cardboard articlesHoneycombWater soluble

The invention belongs to the technical field of preparation of composite materials, and relates to a preparation method of a water soluble phenolic resin honeycomb core material for preparing a sandwich structured composite material. A five-step treatment process of gluing and pressing, stretching and shaping, gumming and curing, flame retardance and slicing is performed for a plant fiber paper in sequence; compared with traditional meta-position aramid fiber paper honeycombs, the process of preparing the honeycomb core material by the method is environment-friendly, free of the solvent volatilization, low in harm to human bodies and free of the explosion risk; and the prepared honeycomb core material has equivalent performances to the traditional meta-position aramid fiber paper honeycomb core materials, is higher in cost performance, and can be applied to such fields as aircraft interiors and rail transit.

Owner:AVIC COMPOSITES

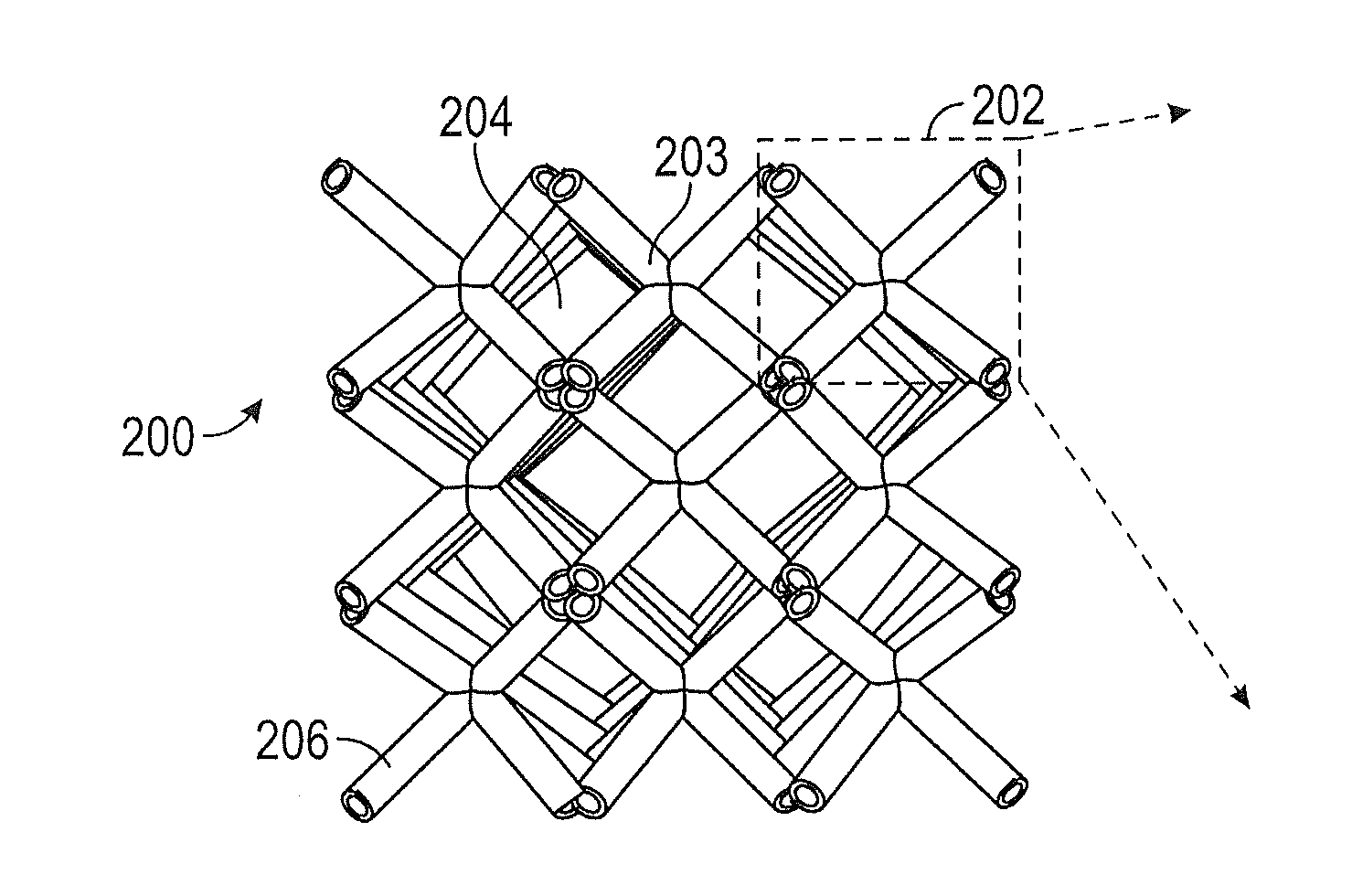

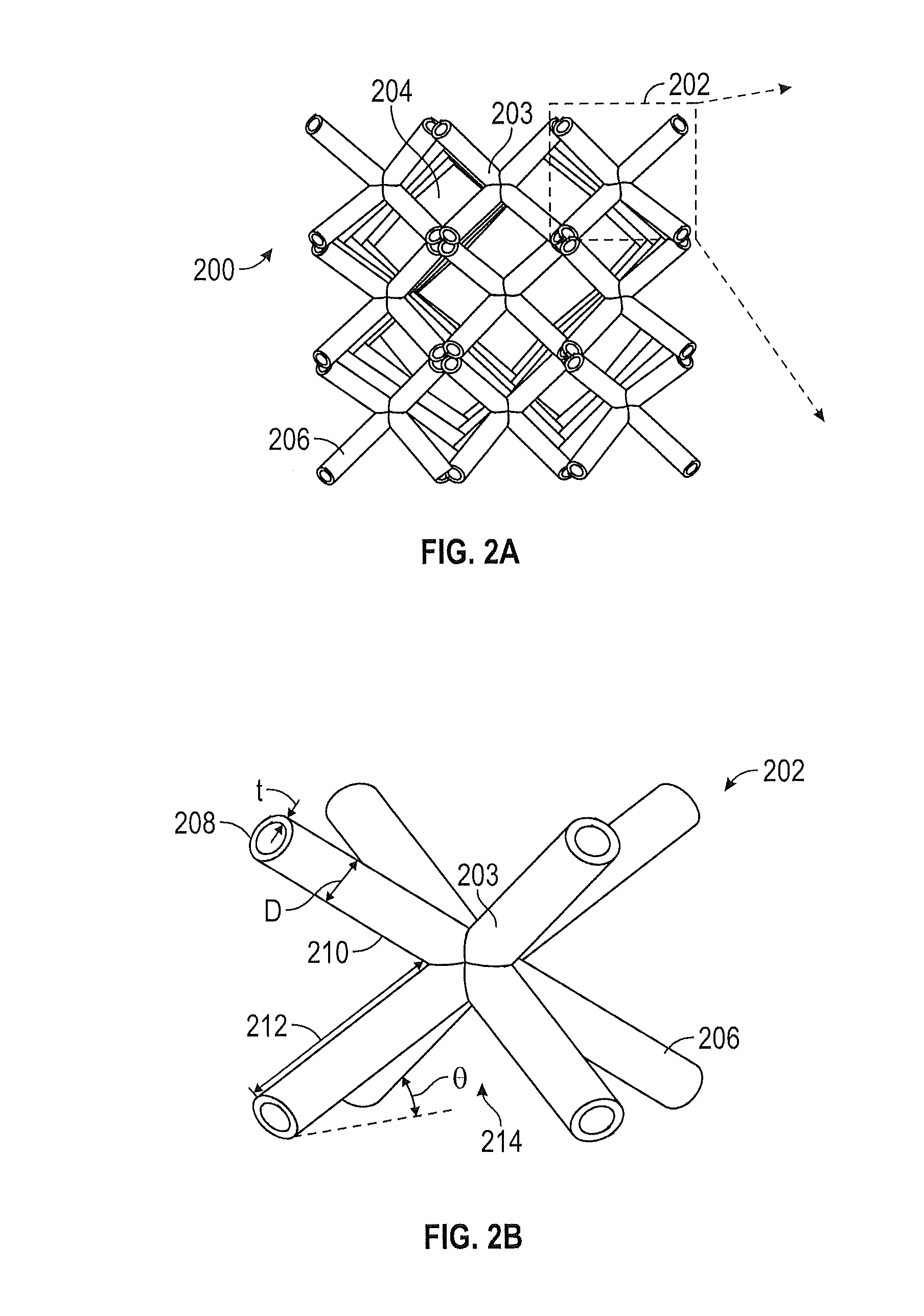

Periodic structured composite and articles therefrom

In one aspect, a material is disclosed, including: a periodic structure including a plurality of unit cells, the plurality of unit cells having a respective plurality of shared nodes, wherein each of the plurality of unit cells has a plurality of members forming an open cell volume; and a matrix material associated with the periodic structure. In another aspect, a method of forming a material is disclosed, including: forming a periodic structure including a plurality of unit cells, the plurality of unit cells having a respective plurality of shared nodes, wherein each of the plurality of unit cells has a plurality of members forming an open cell volume; and associating a matrix material with the periodic structure. Matrix material selection, composition, manufacturing, interfacial bonding modification, and post-treatments of the periodic structure-matrix material composites are disclosed.

Owner:BAKER HUGHES INC

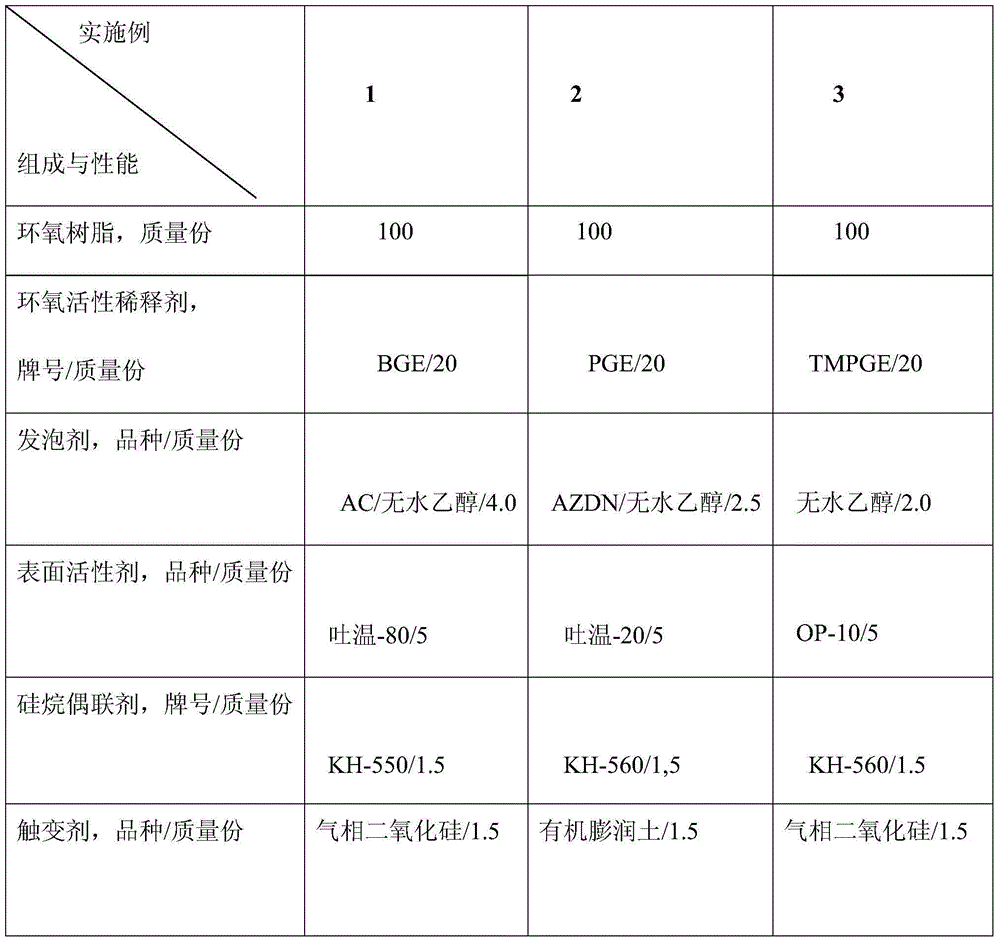

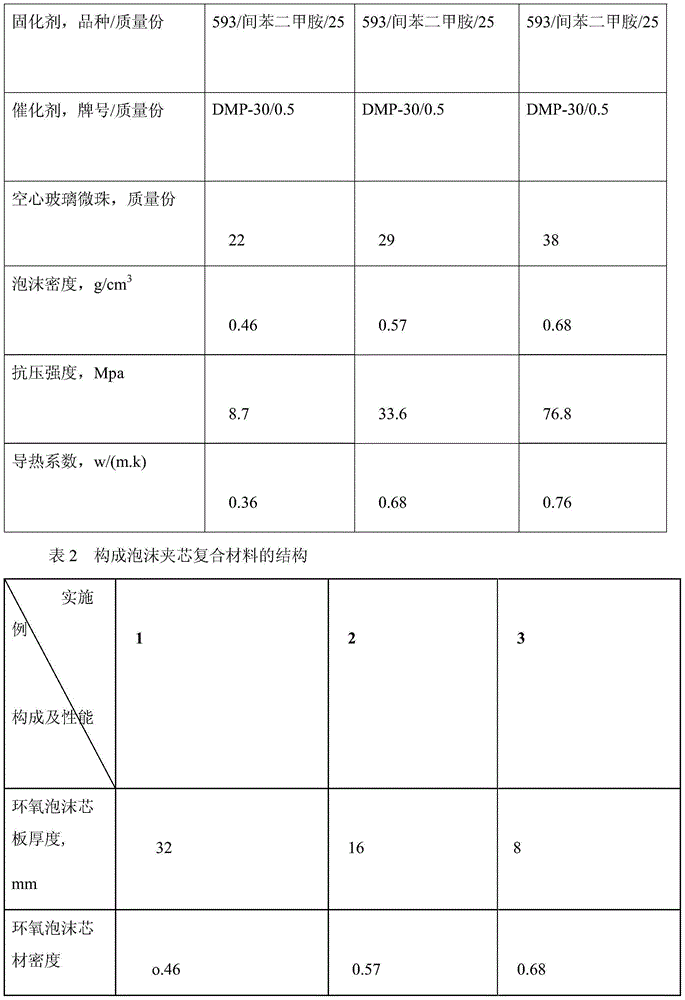

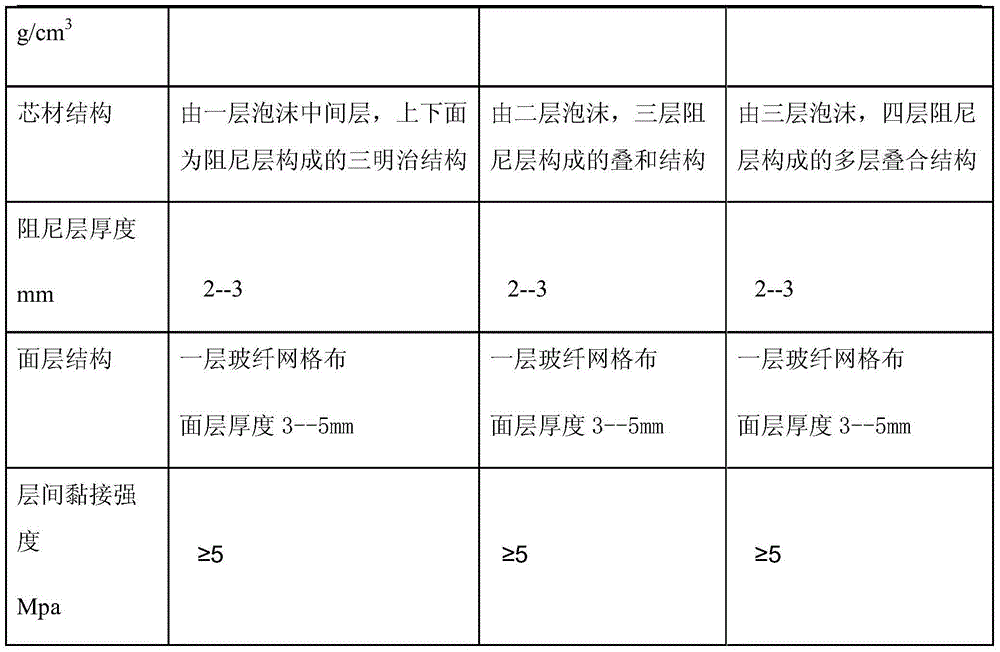

Epoxy foamed sandwich composite material and preparation method thereof

InactiveCN104527181AIncrease stiffnessReduce quality problemsSynthetic resin layered productsLaminationPolyurethane elastomerVibration attenuation

The invention discloses an epoxy foamed sandwich composite material and a preparation method thereof. The sandwich composite material consists of a core material, a surface material and a damping layer, wherein the core material is an epoxy foamed plastic reinforced by a hollow glass bead, the surface material is epoxy glass fiber reinforced by glass fiber gridding cloth, and the damping layer is polyether type polyurethane elastomer. According to the composite material disclosed by the invention, polyurethane elastomer which is excellent in binding performance and damping performance is taken as a bonding and damping layer between the foamed core material and the core material, and between the core material and the surface material; the prepared foamed sandwich structure composite material has the integrated function of light weight, high strength, sound insulation, heat insulation, damping, vibration attenuation and noise reduction, so that the comprehensive performance of the material is improved.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

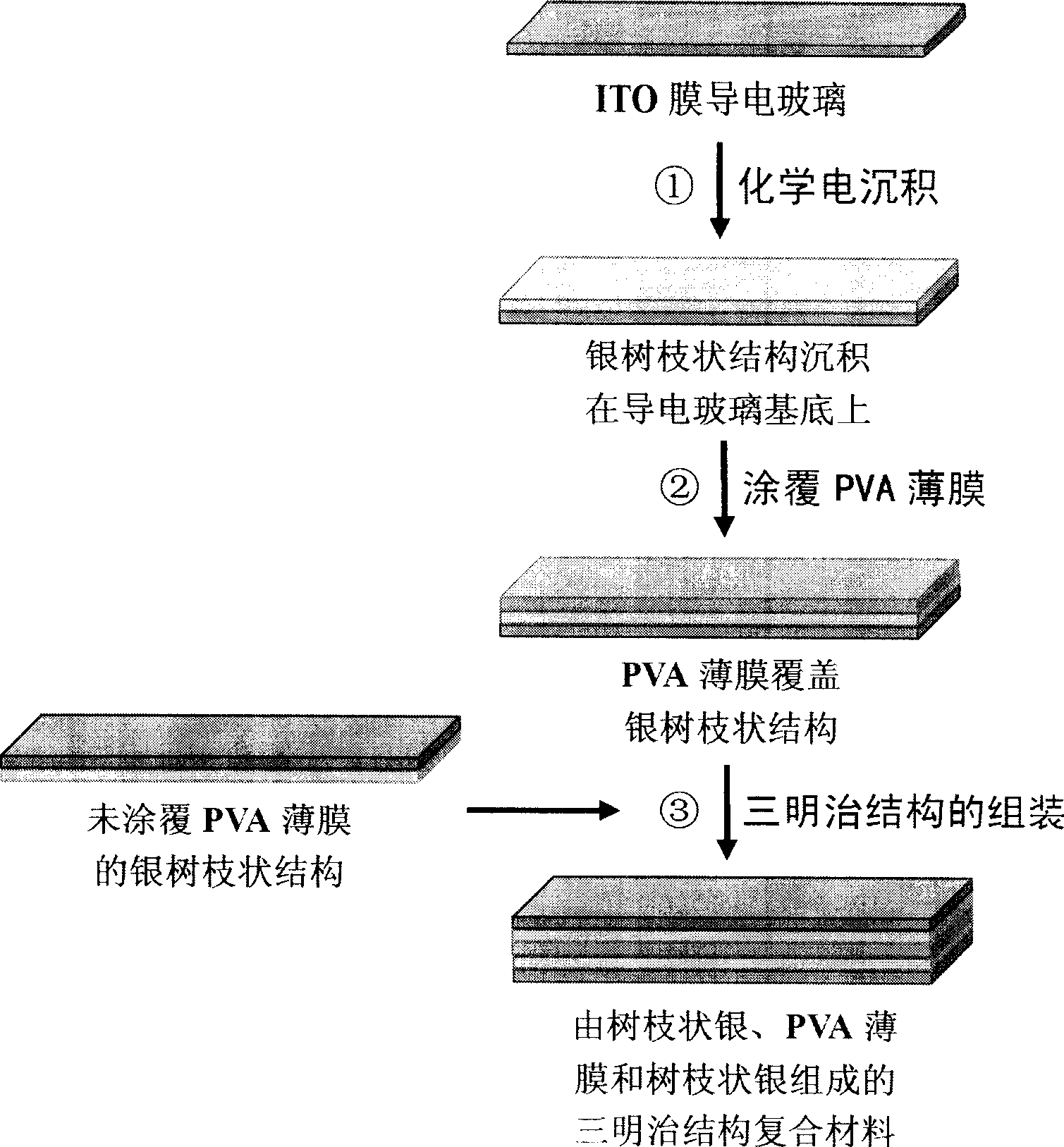

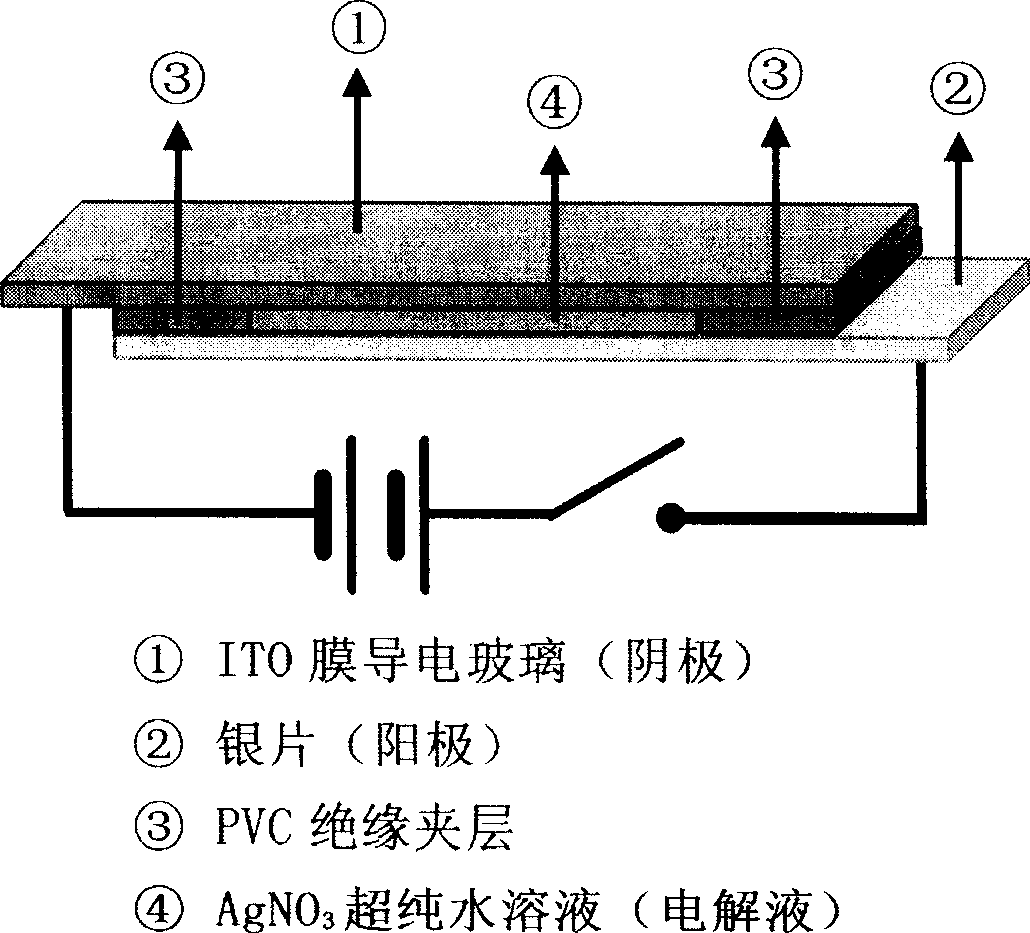

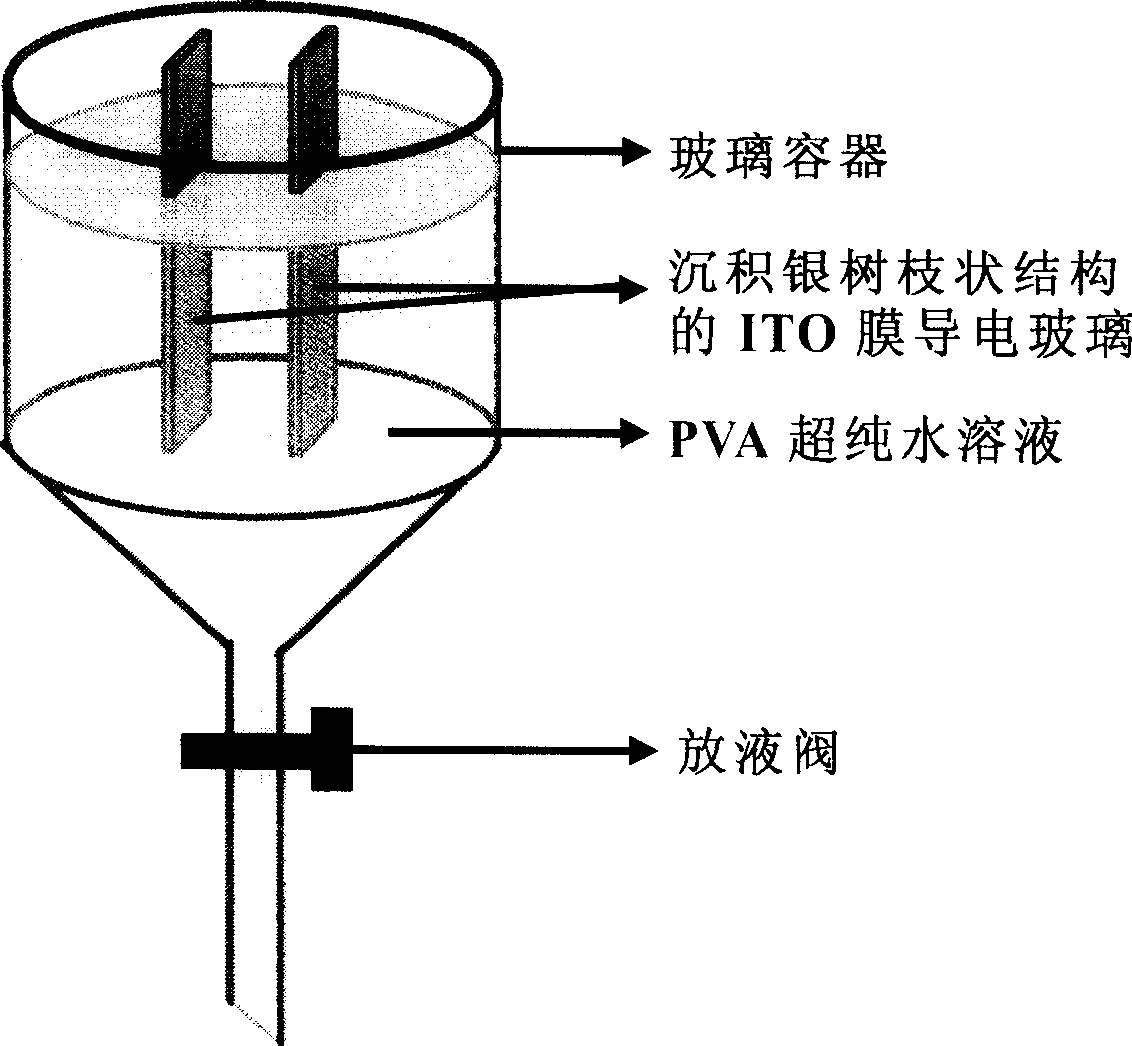

Infrared light transmission sandwich structure composite material based on silver dendritic structure

InactiveCN101468877AHas multi-band transmissive behaviorElectrolytic inorganic material coatingWavelength rangeLight transmission

The invention relates to infrared light transmission sandwich structure composite material based on a silver dendritic structure, in particular to the sandwich structure composite material which is prepared by the following steps: firstly preparing the randomly arranged silver dendritic structure on a conductive glass substrate through a chemical electrodeposition method; then coating a PVA thin film on the surface of the prepared silver dendritic structure through a liquid level coating method; and then laminating, gluing and sealing the silver dendritic structure coated with the PVA thin film with another silver dendritic structure which is not coated with the PVA thin film. The composite material has the multiband transmission characteristic in the infrared band wavelength range from 1.2 to 2.8mu m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

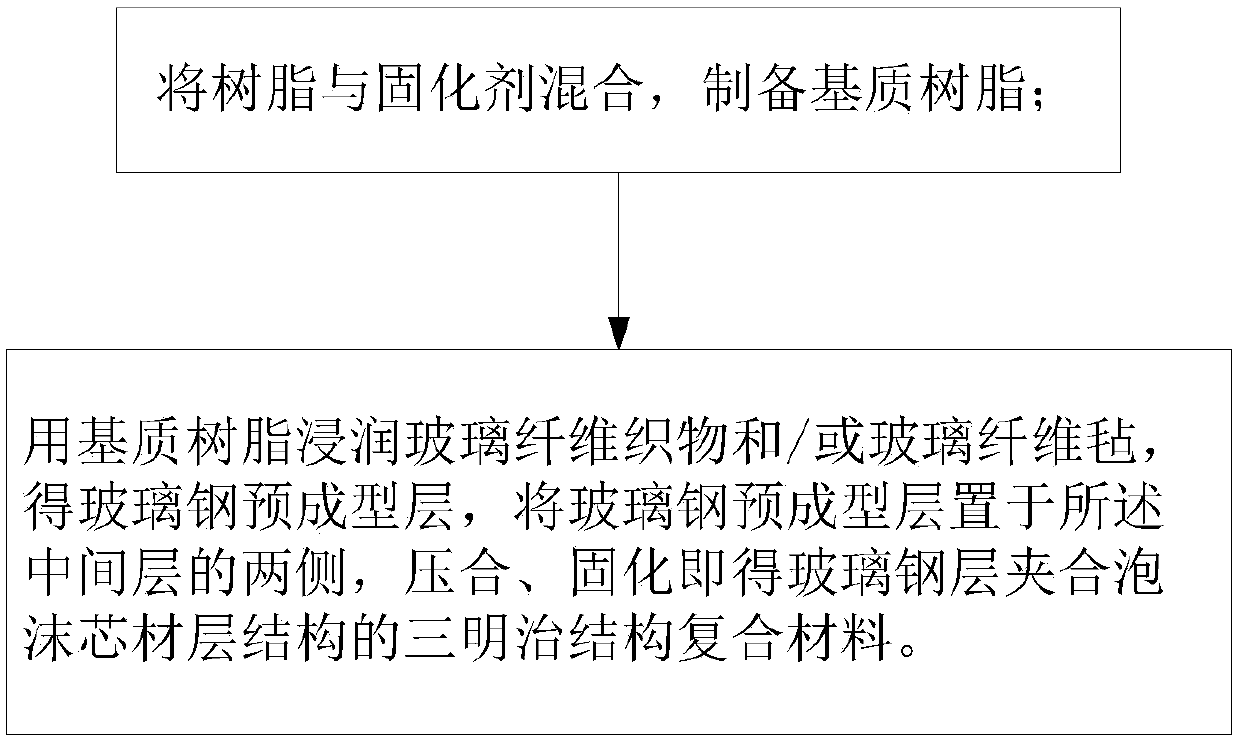

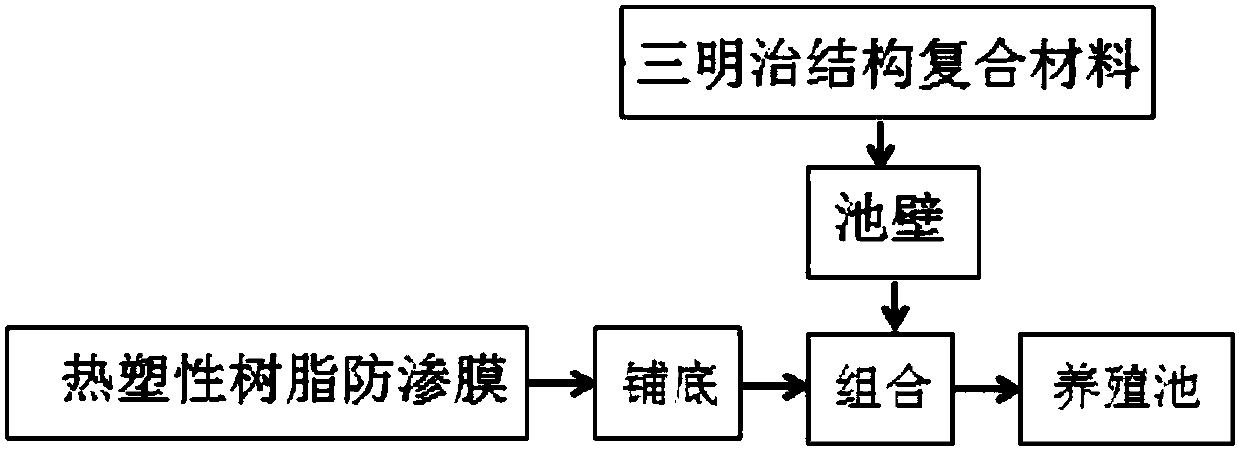

A sandwich-structured composite material and preparation and applications thereof

ActiveCN107745554AIncreased shear strengthImprove toughnessAgricultural articlesLamination ancillary operationsFiberGlass fiber

A preparing method of a sandwich-structured composite material is provided. The composite material includes a first layer, a middle layer and a second layer which are laminated in order. The first layer and the second layer are fiber-reinforced plastic layers. The middle layer is a foam core material layer. The method includes mixing resin and a curing agent to prepare matrix resin; infiltrating aglass fiber fabric and / or glass fiber felt with the matrix resin to obtain fiber-reinforced plastic preform layers; putting the fiber-reinforced plastic preform layers at two sides of the middle layer; performing lamination and solidification to obtain the composite material in which the foam core material layer is sandwiched with the fiber-reinforced plastic layers. The composite material maintains high rigidity and aging resistance characteristics of fiber-reinforced plastic, also utilizes high shearing strength, good toughness and buffer and heat insulation functions of structured foam, can enhance bonding firmness of the layers, can enhance mechanical properties, and can ensure smoothness of external surfaces of the fiber-reinforced plastic layers so as to obtain a good self-cleaningeffect.

Owner:FSPG HI TECH

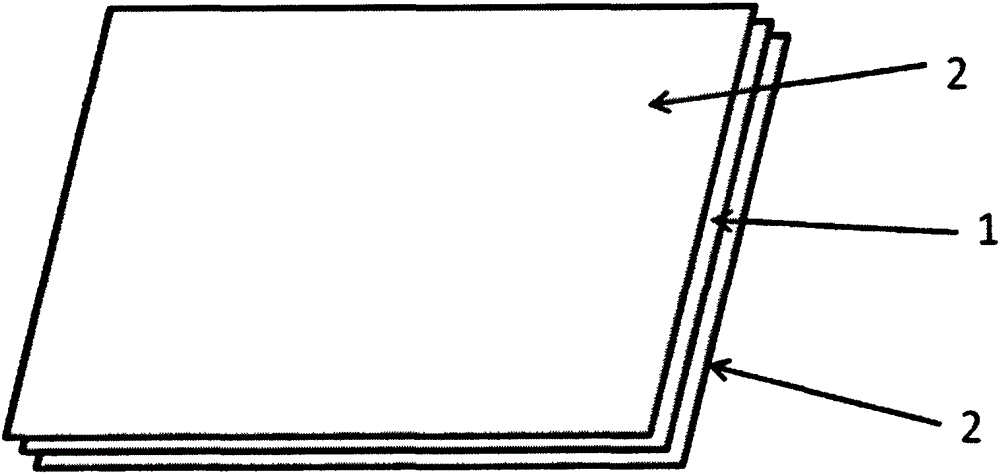

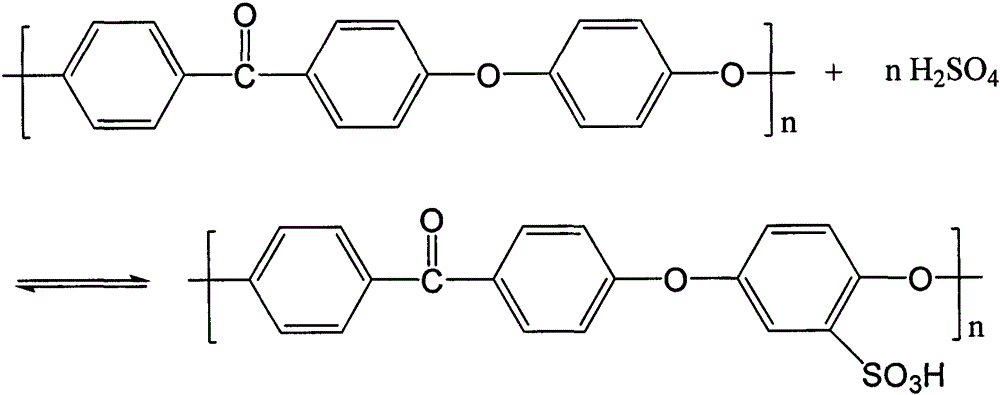

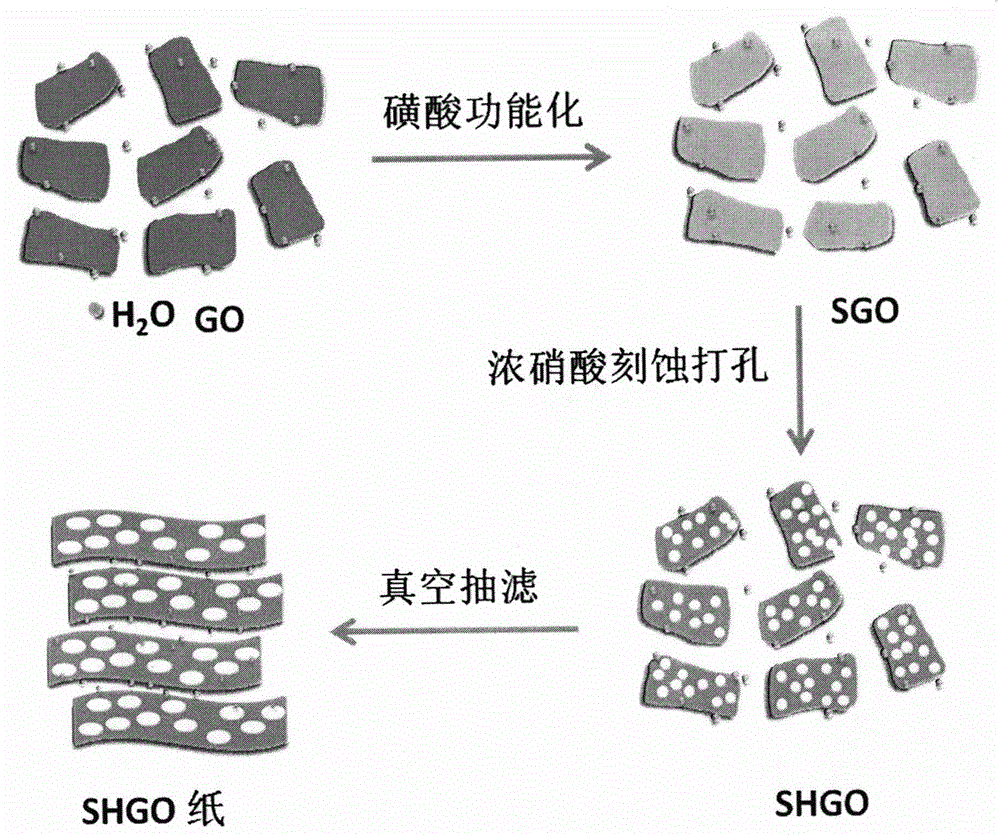

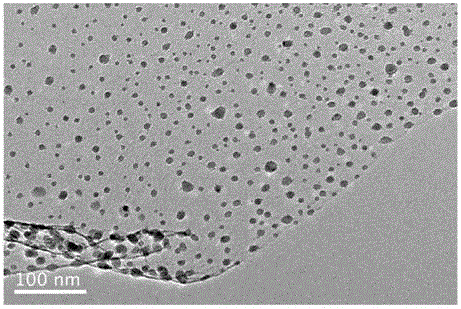

Sandwich structured composite proton exchange membrane, and preparation method and use thereof

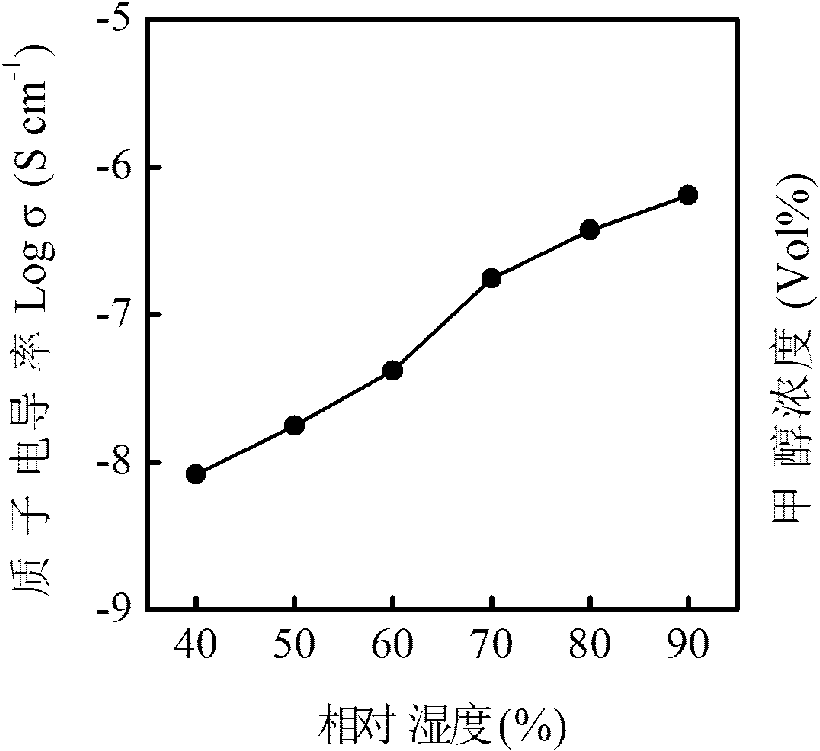

InactiveCN105047844AGood for proton conductionGuaranteed moisture contentCell component detailsFuel cell detailsPolymerWater content

The invention discloses a sandwich structured composite proton exchange membrane, and a preparation method and use thereof. The sandwich structured composite proton exchange membrane is formed by mutually laminating a piece of self-supported sulfonated surface perforated graphene oxide paper of a basis membrane and sulfonated polyether-ether-ketone polymer layers of outer membranes on two surfaces of the basis membrane; and the outer membranes and the basis membrane are mutually connected through hydrogen bonds. The sandwich structured composite proton exchange membrane disclosed by the invention has the advantages that: the introduced self-supported sulfonated surface perforated graphene oxide paper of the basis membrane is connected to a hydrophilic group; simultaneously, the slice layer surface of the self-supported sulfonated surface perforated graphene oxide paper is perforated, so that proton conduction of the proton exchange membrane is carried out easily; the water content in the composite membrane can be kept; furthermore, carbonyl, hydroxyl, carboxyl, phenolic hydroxyl and sulfonyl on the surface of the self-supported sulfonated surface perforated graphene oxide paper have amphiphilic properties and can be interacted with sulfonic acid groups on sulfonated polyether-ether-ketone at two sides of the composite membrane through the hydrogen bonds; therefore, the stability and the uniformity of the composite membrane are greatly improved after the sulfonation degree of the sulfonated polyether-ether-ketone is reduced; and in addition, high proton conductivity is kept.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

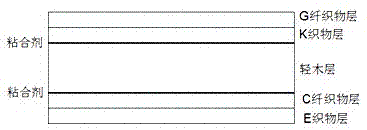

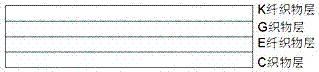

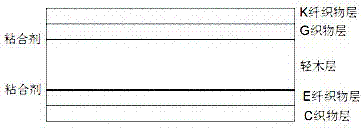

High-speed impact resistance composite material

ActiveCN103660456ALight weightExcellent kinetic energy absorption capacity of projectileSynthetic resin layered productsSurface layerPolyresin

The invention discloses a high-speed impact resistance composite material. An impact surface facing layer, a middle core layer and an impact surface backing layer form a sandwich composite material structure, the core layer consists of microporous materials, the impact surface facing layer and the impact surface backing layer of the sandwich structure composite material are respectively formed by laminating at least four layers of inorganic fiber layers and organic fiber layers, the resin mass content of the inorganic fiber layers is 10 to 40 percent, the inorganic fiber layers need to be near the impact surface facing layer, and the impact surface facing layer, the impact surface backing layer and the core layer are bonded through adhesives. The high-speed impact resistance composite material has the advantages that dynamical anisotropy differences of various high-performance fibers are utilized, and an interlayer hybrid mode is adopted for preparing a surface layer composite material, so the composite material has light weight and excellent elastic body kinetic energy absorption capability; an impact surface facing and impact surface backing asymmetric mode is adopted for designing the sandwich structure composite material, high kinetic energy absorption capability of the composite material is ensured, and the anti-shearing and anti-bending capability of the composite material are also improved.

Owner:ZHEJIANG SCI-TECH UNIV

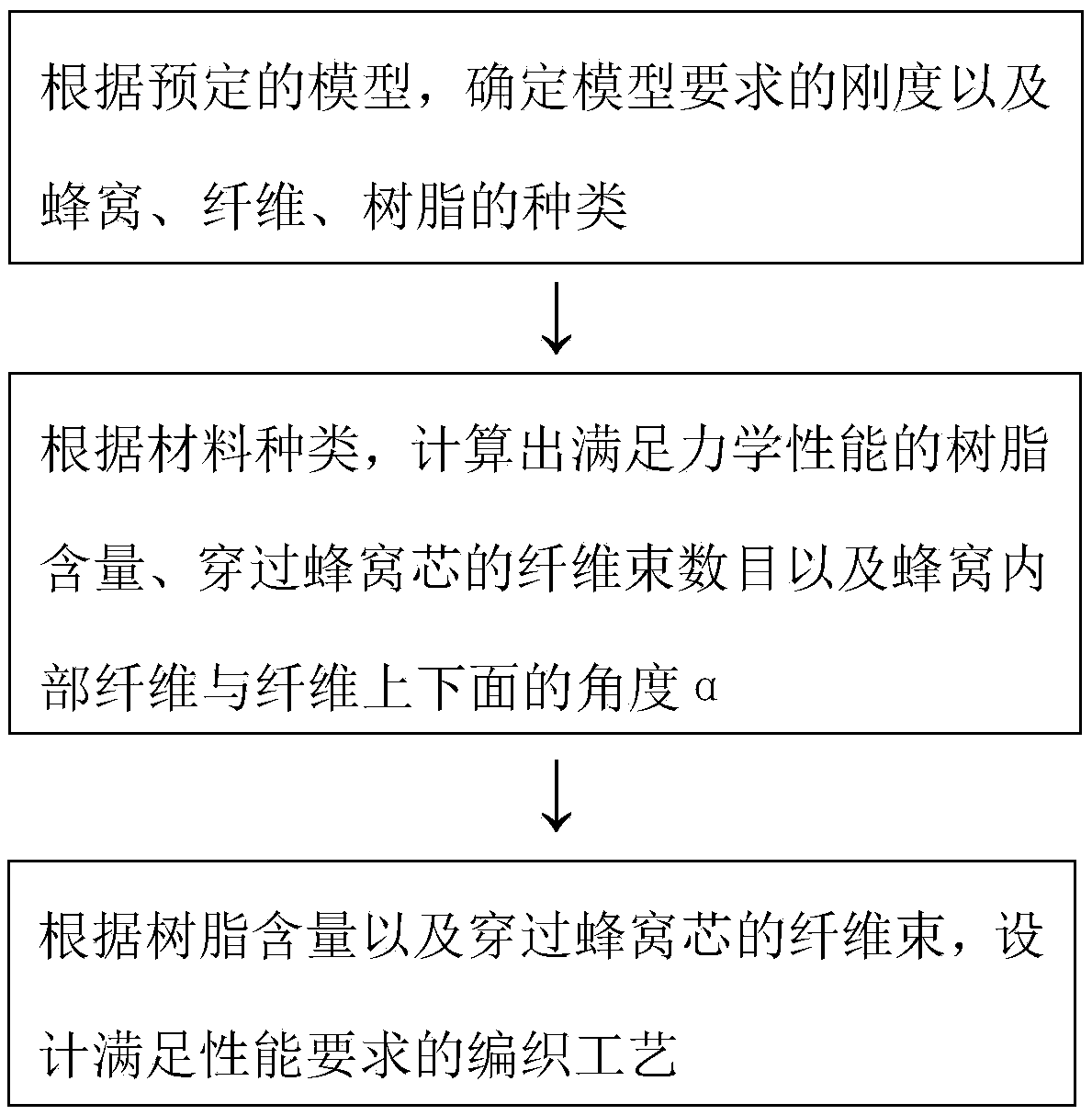

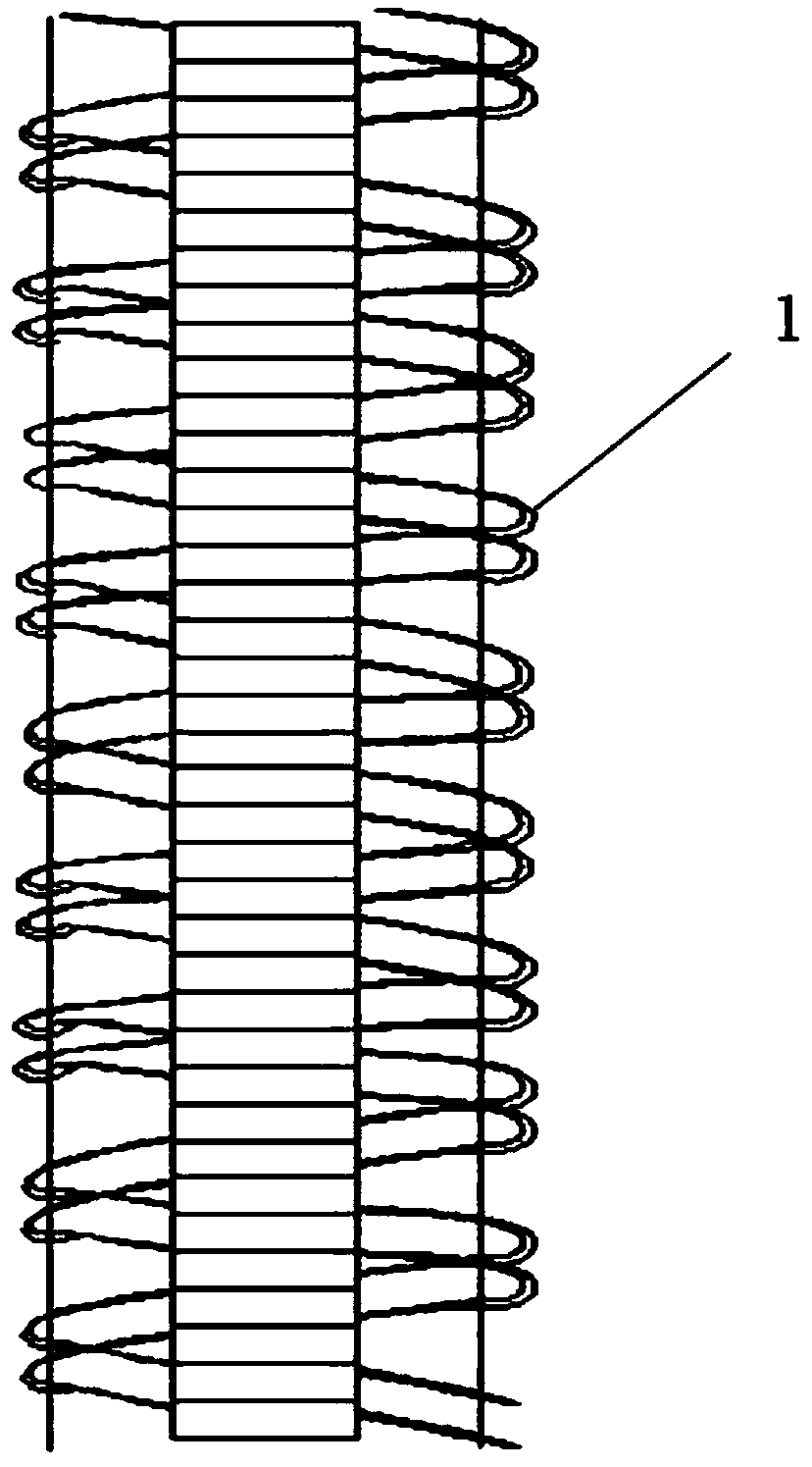

Fiber-reinforced resin honeycomb sandwich structure composite material and preparation method thereof

InactiveCN108973250ASolve the low shear strengthSolve many problems such as low shear strengthLamination ancillary operationsLaminationYarnFiber bundle

The invention discloses a fiber-reinforced resin honeycomb sandwich structure composite material and a preparation process thereof. According to the fiber-reinforced resin honeycomb sandwich structurecomposite material and the preparation process thereof, the upper fiber surface and the lower fiber surface are connected together through fiber yarn or fiber bundles by utilizing 3D weaving or sewing, so that the upper fiber surface and the lower fiber surface have the integrity, and therefore the problems that in an existing fiber-reinforced resin honeycomb sandwich structure material, the shearing strength of the fiber-reinforced resin honeycomb sandwich structure is low due to the fact that fiber layers and honeycombs are not bonded firmly, the connection between fibers and the honeycombsis loosen due to aging of a glue layer, and the like can be solved; and the structure is applicable to 3D weaving, and in addition, the fiber yarn or the fiber bundles can penetrate through a laid fiber reinforcement by utilizing modes such as sewing so as to connect the upper fiber surface and the lower fiber surface; and the operability is high, and the requirement for light weight of railway vehicle is met.

Owner:JILIN UNIV

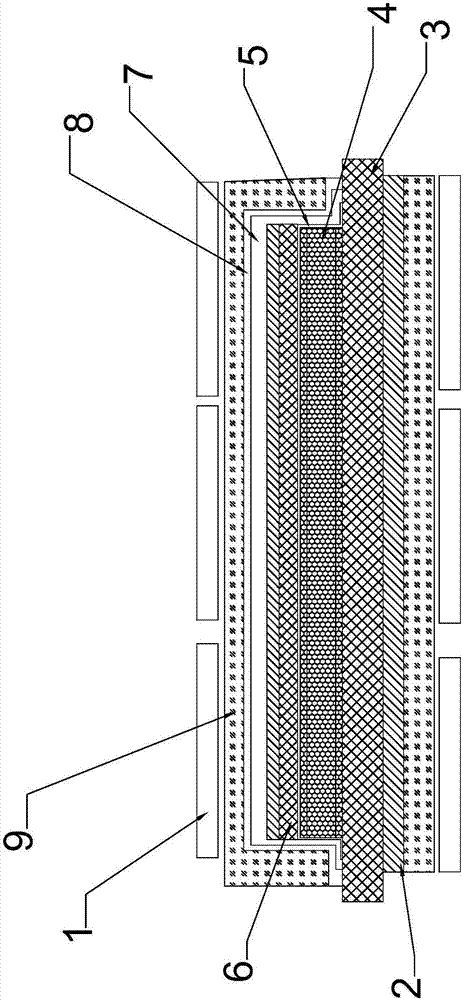

Fast curing method for sandwich structure composite material

The invention discloses a fast curing method for a sandwich structure composite material. A heating layer made of metal is attached to the back side of a die, a rubber layer and a heating layer are added in a vacuum bag, a layer of ventilation and heat preservation material is arranged between the vacuum bag and the heating layer, then air in the vacuum bag is pumped away, and a heating element of the heating layer and the rubber layer in the vacuum bag are adhered into a whole. The vacuum bag and the heating element below the die are coated with heat preservation layers, multiple induction heating coil modules arranged evenly are arranged on the outer sides of the two heat preservation layers separately, the diameter sizes of the induction heating coil modules are 100-250mm, and the induction heating coil modules are arranged at the positions distant from the heating layers by 10mm-20mm. Power needed for temperature rise is greatly reduced compared with traditional methods adopting autoclaves, baking ovens and pressing machines, energy consumption is greatly reduced, the temperature rise rate can be effectively promoted, and the process cycle is greatly shortened.

Owner:山东中航泰达复合材料有限公司 +1

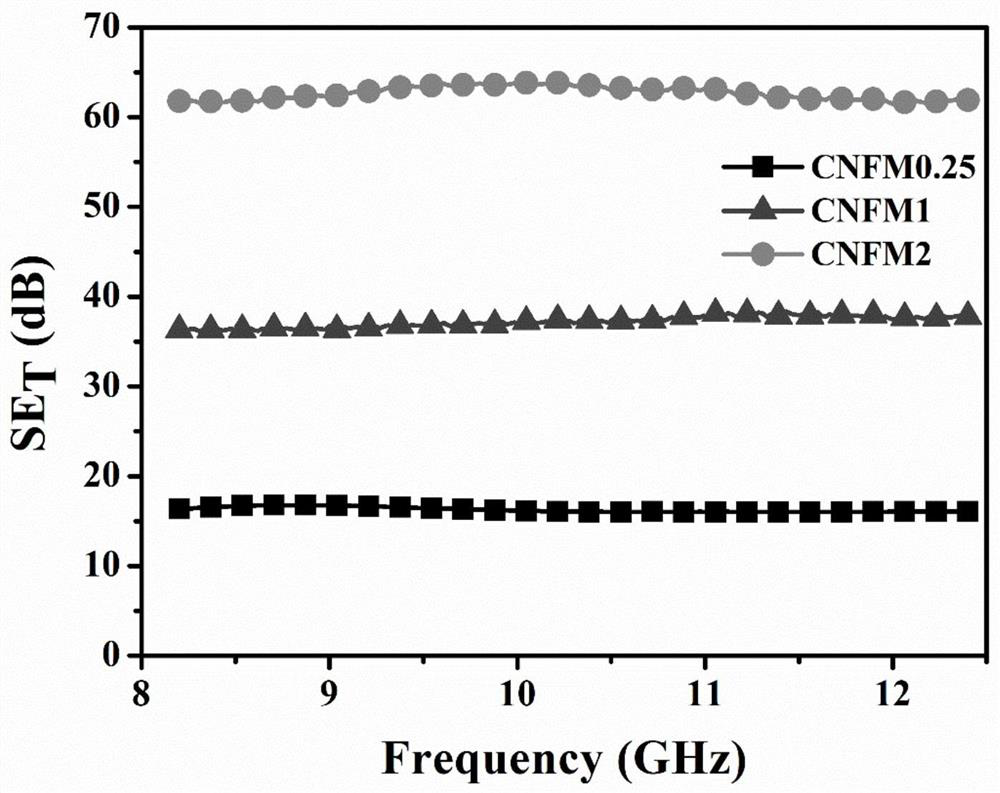

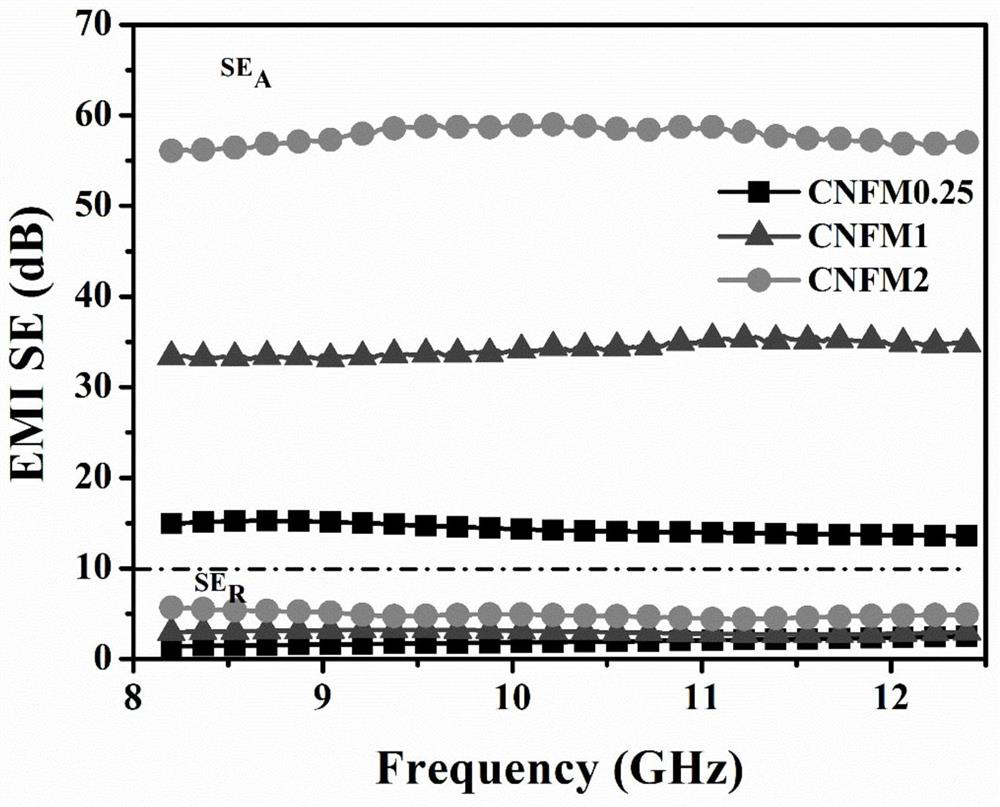

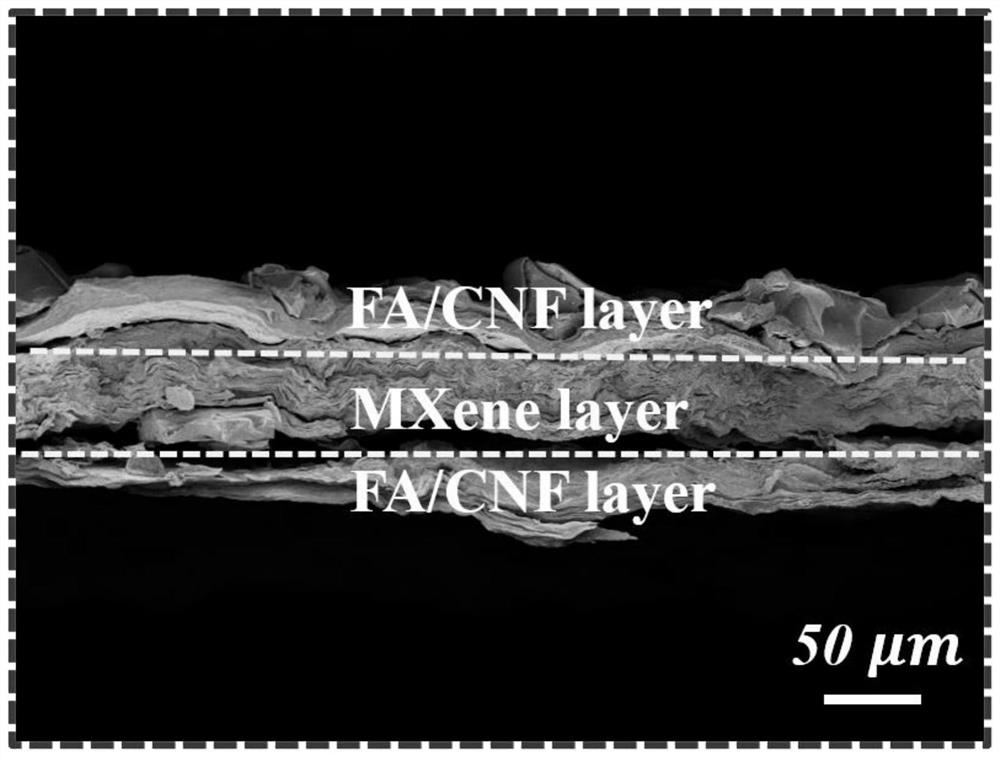

Preparation method of sandwich structure FA/MXene/CNF composite material

PendingCN113645821AImprove mechanical propertiesStrengthen and weakenMagnetic/electric field screeningBiomass carbonCarbonization

The invention discloses a preparation method of a sandwich structure FA / MXene / CNF composite material. The method specifically comprises the following steps: firstly, etching an MAX phase precursor through LiF / HCl to prepare an MXene solution; carbonizing and activating egg white to obtain biomass carbon, and loading Fe3O4 on the surface by a hydrothermal method to obtain FA; mixing FA and CNF solutions, and carrying out suction filtration on a mixed fiber membrane to obtain a bottom layer FA / CNF membrane; carrying out suction filtration on an MXene solution on the FA / CNF bottom layer to obtain a double-layer membrane; adding a mixed solution of FA and CNF solutions to the double-layer membrane, and carrying out suction filtration to obtain an FA / CNF, MXene and FA / CNF three-layer membrane; and finally, stripping from the mixed fiber membrane, and performing hot pressing. Due to the unique design of the composite material, electromagnetic waves can easily enter the composite material, the electromagnetic waves are weakened in the sandwich structure through the absorption-reflection-reabsorption process, and therefore the excellent electromagnetic shielding performance is obtained.

Owner:XIAN UNIV OF TECH

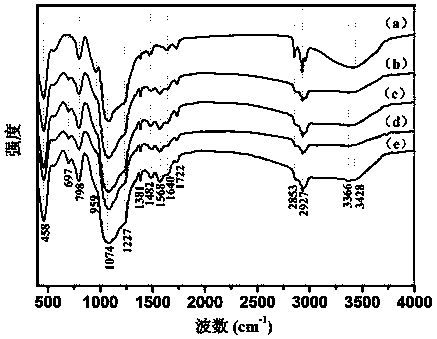

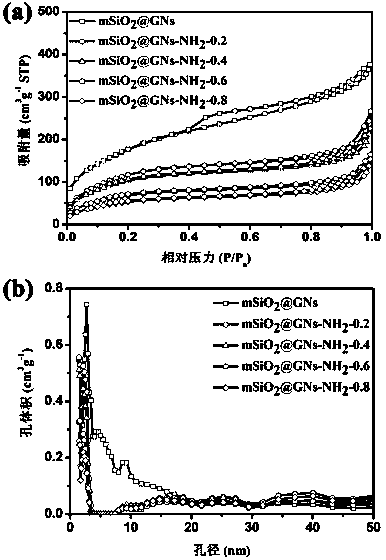

Sandwich-structured solid amine CO2 adsorbent and preparation method thereof

InactiveCN108579707AReasonable designReasonably designed adsorbent with reasonable structureGas treatmentOther chemical processesPore distributionSorbent

The invention discloses a sandwich-structured solid amine CO2 adsorbent. Graphene is taken as a supporting substrate of the adsorbent, mesoporous silica grows on the upper surface and the lower surface of the supporting substrate to obtain a mesoporous silica / graphene sandwich structure, and -NH2 groups are introduced on the surfaces and pore walls of the silica by using a self-assembled monomolecular layer modifying technology in a 'Si-O-Si' covalent bond mode to obtain an ammonia functionalized mesoporous silica / graphene sandwich-structured composite material. The invention further disclosesa preparation method of the adsorbent. The sandwich-structured solid amine CO2 adsorbent has the beneficial effects that from the point of view of thermodynamics and kinetics, a reasonable adsorbentstructure is designed, a preparation process is safe and controllable, the prepared sandwich-structured solid amine adsorbent has high specific surface area and effective hierarchical pore distribution, -NH2 which is grafted in a covalent bond mode can be highly dispersed in pores with different sizes, blockage of pore channels is avoided as much as possible, and the utilization rate of amine is increased effectively.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

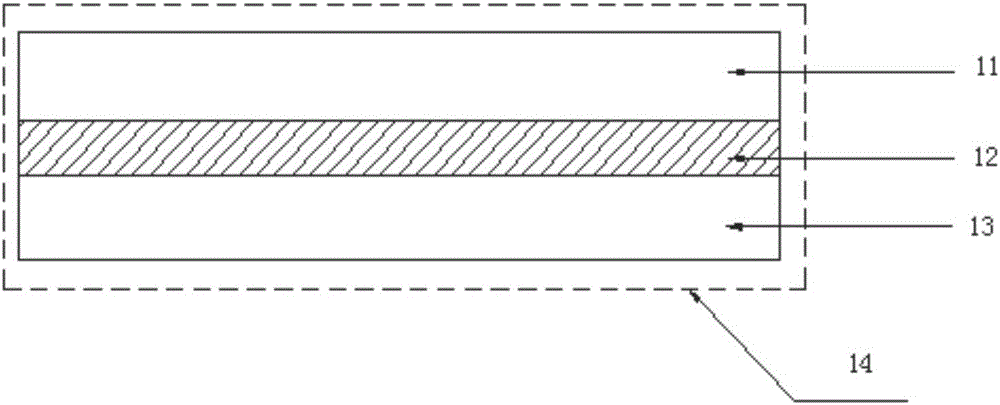

Free-standing sandwich structure composite proton conducting film and preparation method thereof

The invention relates to a free-standing sandwich structure composite proton conducting film and a preparation method thereof in the technical field of a fuel cell. A sandwich structure is formed by an upper organic proton conducting film layer, a lower organic proton conducting film layer and a middle inorganic proton conducting film layer, wherein, the inorganic proton conducting film layer is metallic oxide or phosphorus-containing metallic oxide with proton conducting capacity, and the organic proton conducting film layer is polymer with the proton conducting capacity. The problems of no flexibility of the inorganic proton conducting film layer and high methanol permeability of the organic proton conducting film layer are overcome, and the free-standing sandwich structure composite proton conducting film with proton conducting capacity and very low methanol permeability is obtained, so as to solve technical problems in the prior art.

Owner:SHANGHAI JIAO TONG UNIV

Hemp fibre woven reinforced foam sandwich structure composite material connected by sewing and preparation method thereof

PendingCN107443829AHas a negative Poisson's ratio effectGood shock absorption and energy absorptionDomestic upholsteryProtective equipmentEnergy absorptionFunctional composite

The invention discloses a hemp fibre woven reinforced foam sandwich structure composite material connected by sewing and a preparation method thereof, and relates to the technical field of structural composite materials. The composite material takes a hemp fibre material as a core layer enhancing body and takes a polylactic acid foam material as a core layer substrate; a panel is selected according to specific purpose; the hemp fibre material is made into hemp ropes, and the hemp ropes are woven into a two-dimensionally woven core layer with a negative poisson ratio effect in a crossed manner; the core layer is sewn with the panel; and a sewn preform is placed in a mould cavity of a mould, and the sewn preform is filled with the polylactic acid foam material through a supercritical foaming technology. According to the hemp fibre woven reinforced foam sandwich structure composite material connected by sewing and the preparation method thereof, the advantages of a negative poisson ratio enhanced fibre structure, a sewing process and the polylactic acid foam material are combined; the designability is high; the material is a functional composite material which has the outstanding characteristics of high specific strength, light weight, energy absorption, environment friendliness and the like; and active demands on new materials in the fields, such as national defense, traffic transportation, building and indoor decoration can be met to a certain extent.

Owner:JILIN UNIV

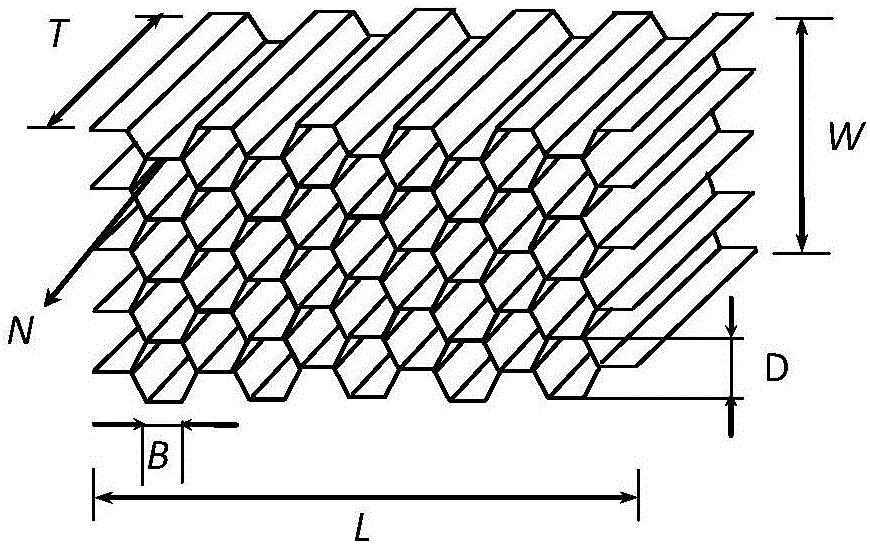

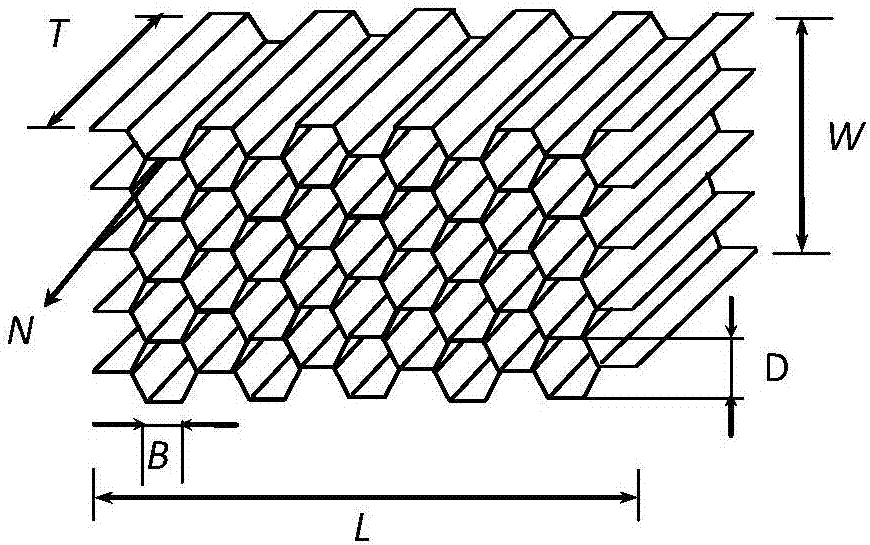

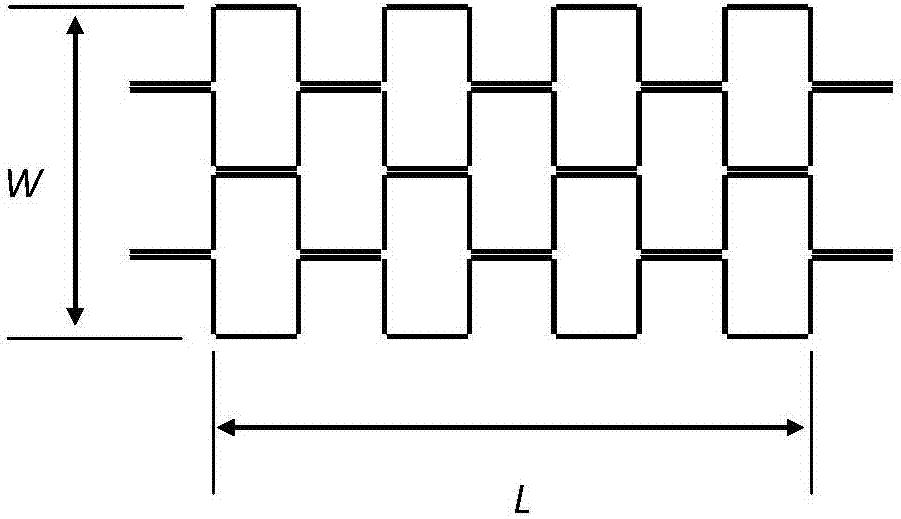

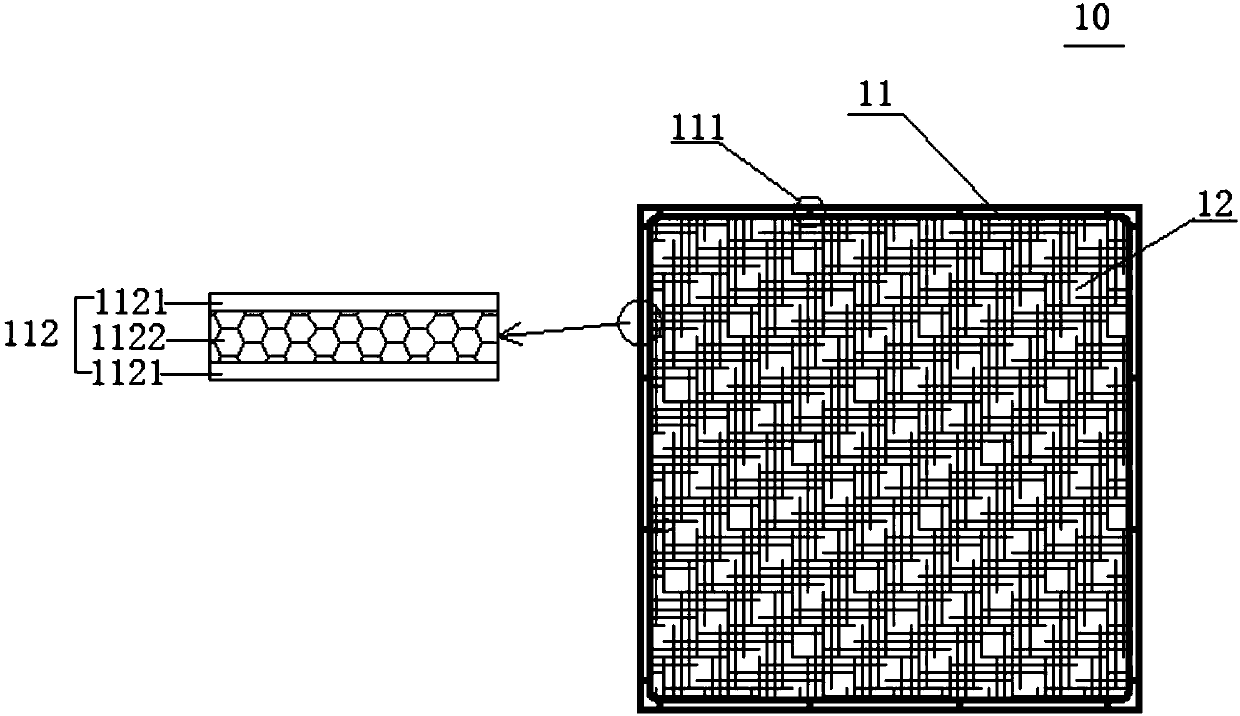

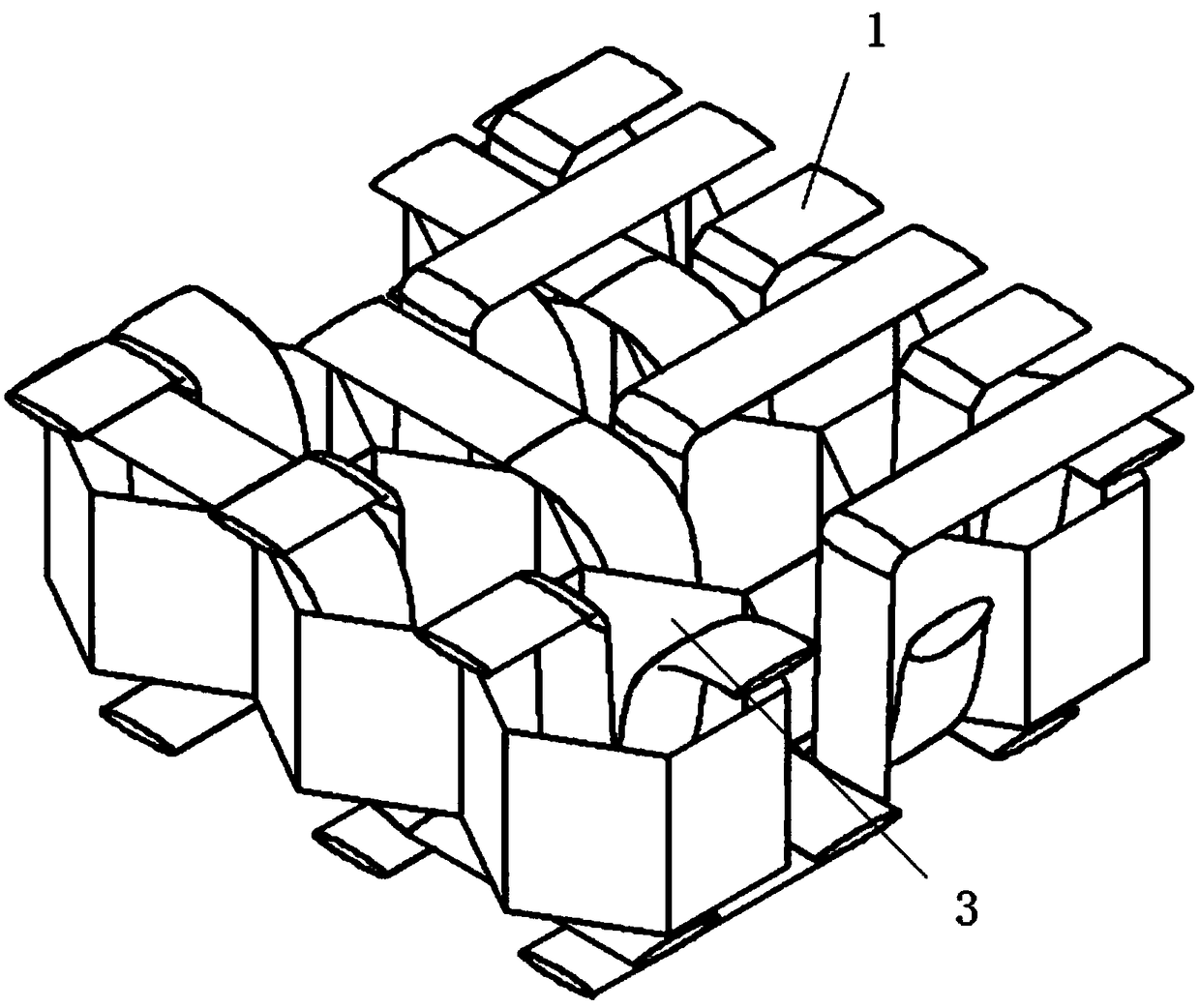

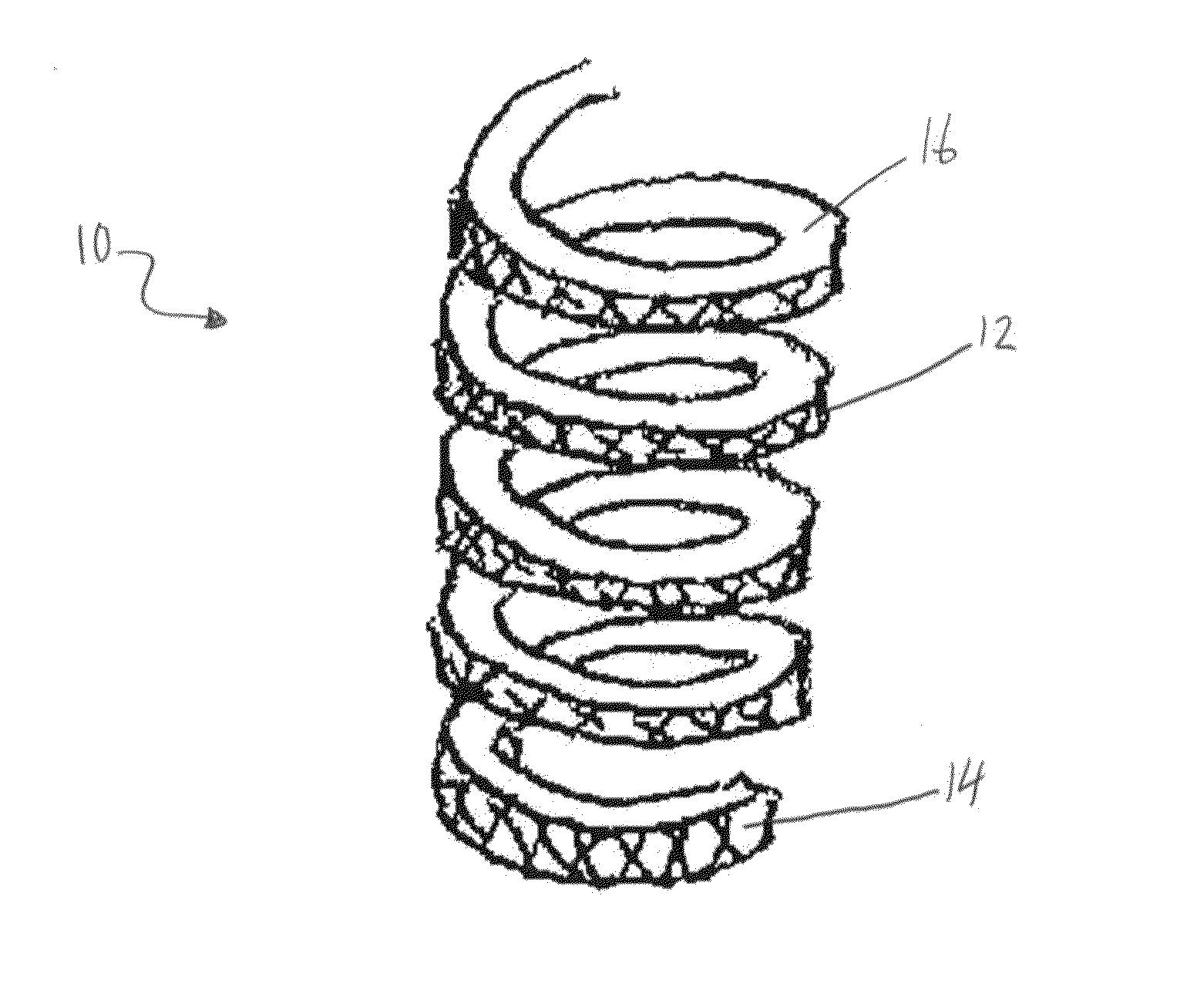

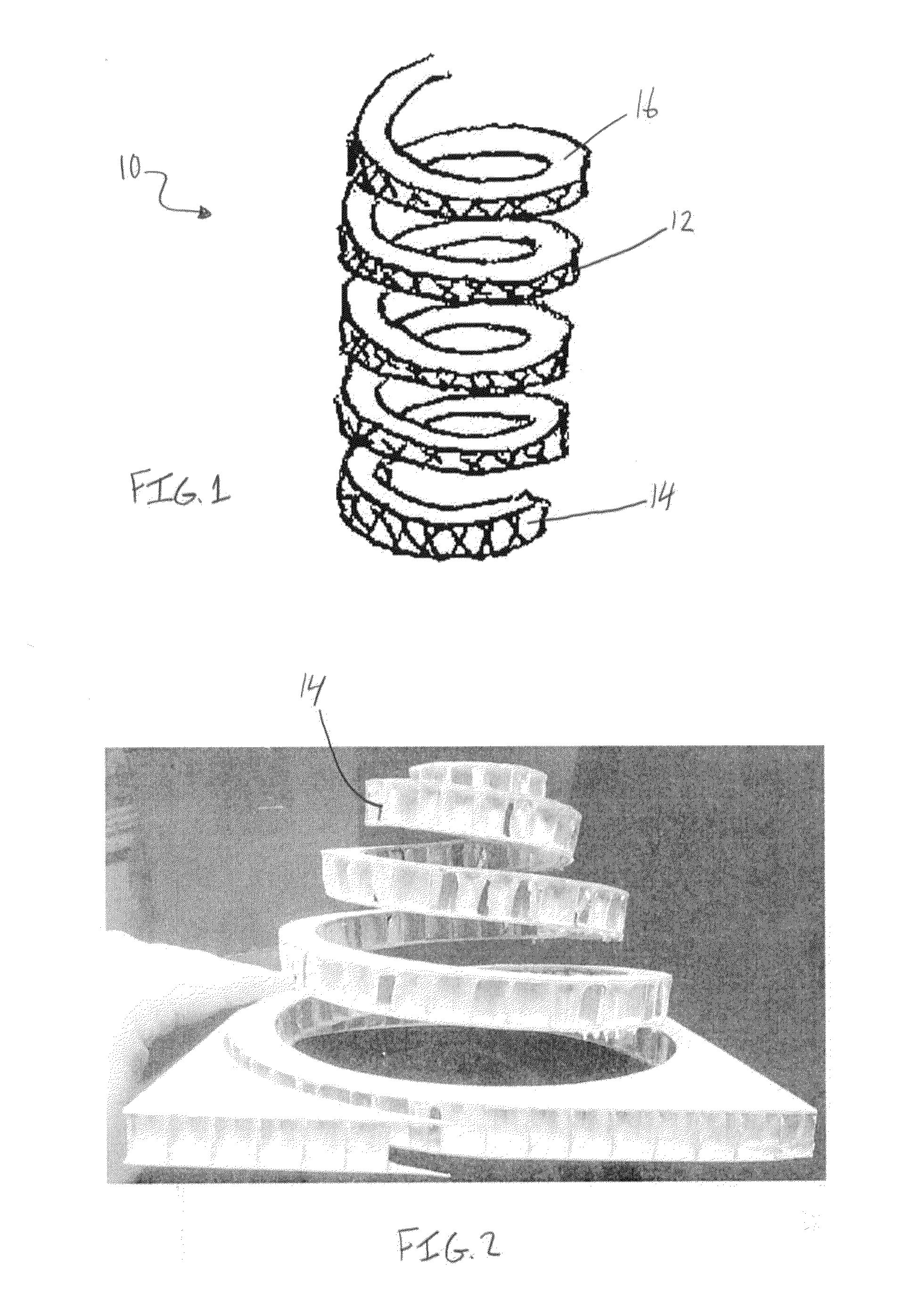

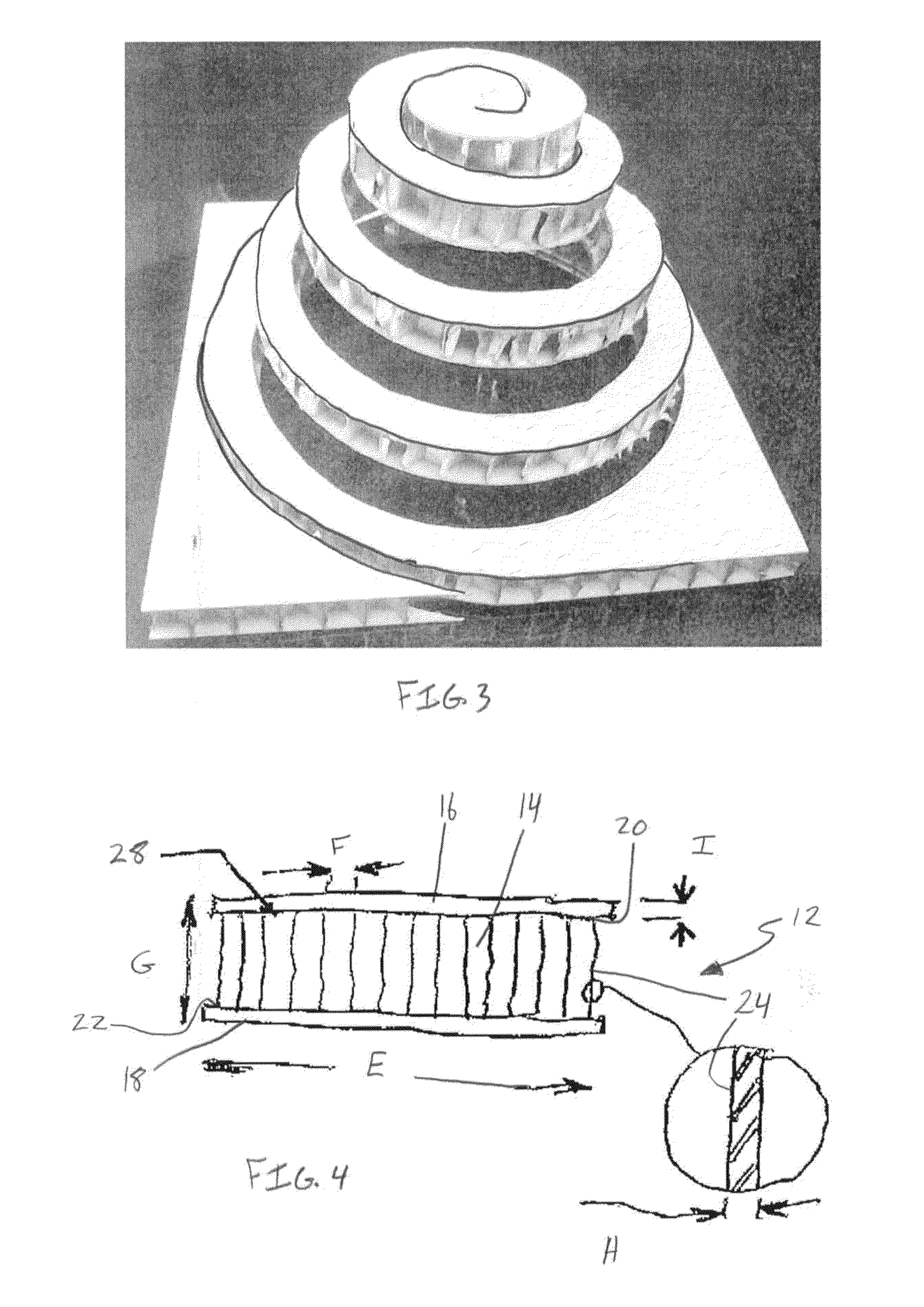

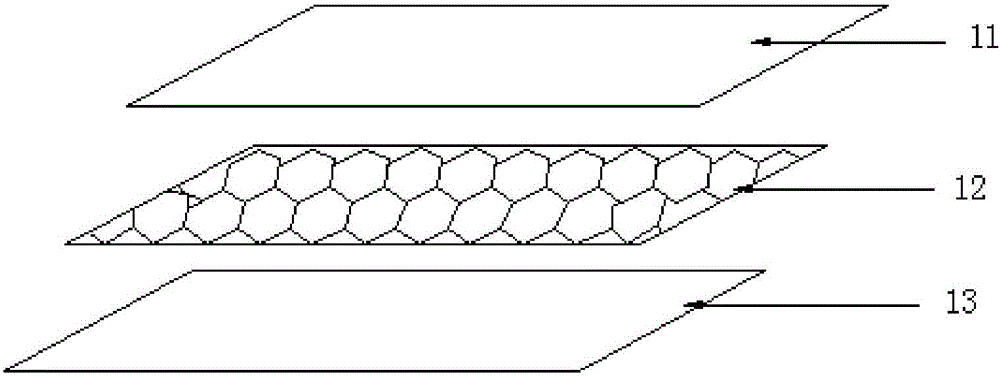

Spring having a core structure

A spring having a sandwich-structured composite including a core structure, a top skin, and a bottom skin. The core structure comprises a framework, or array of geometric shapes designed to absorb and distribute the forces applied to the spring. Preferably the framework comprises an array of hexagonal columns that extend between the top and bottom skins. The top and bottom skins are laminated to a respective top and bottom surface on the core structure. The spring can comprise any suitable type of spring that is well-known in the art, including a leaf spring, a coil spring (or helical spring), a torsion spring (or clock spring), a conical spring, and so forth.

Owner:SCHOLAR PETER ROBERT

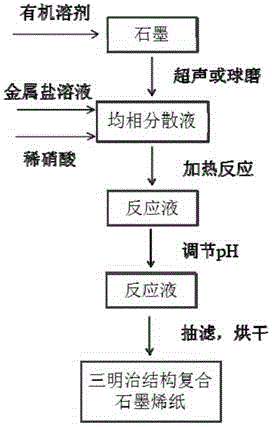

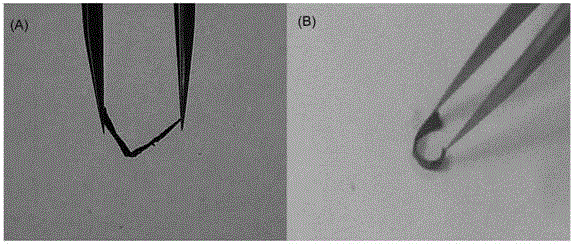

Sandwich-structured composite graphene paper electrode material preparation method

ActiveCN106057497AIntegrity guaranteedImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFiltrationCalcination

The invention belongs to the field of preparation of a composite electrode material, and particularly relates to a sandwich-structured composite graphene paper electrode material preparation method. The sandwich-structured composite graphene paper electrode material is prepared in a one-step method. The method comprises specific steps: graphite is subjected to ultrasonic or ball milling stripping in an organic solvent, a metallic salt solution of a certain concentration is added for mixing until homogeneous phase, diluted HNO3 is then added, reaction at a temperature of 100 to 130 DEG C is carried out for 4 to 8 h, alkali is used for adjusting pH to be 8 to 10 after the reaction, after air pump filtration, washing and low temperature drying, the sandwich-structured composite graphene paper electrode material is obtained, calcination is carried out in order to improve the electrochemical properties of the electrode material, and the electrode material is immersed in an electrolyte after calcinations. Raw materials for preparaing the material of the invention is cheap and easy to obtain, the process is simple and convenient to operate, the production cost is low, industrial production is facilitated, and the prepared electrode material presents excellent electrochemical properties.

Owner:CHANGZHOU UNIV +1

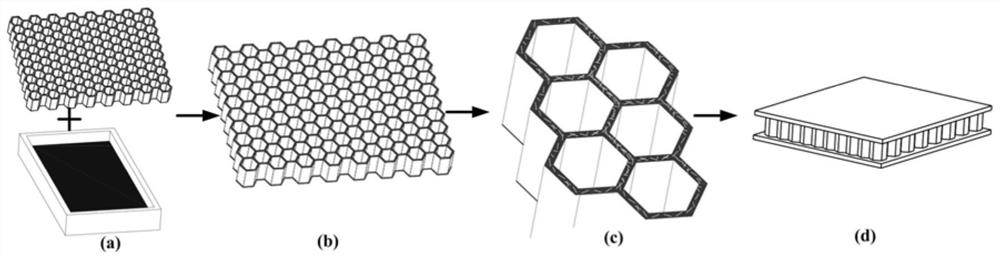

Honeycomb-shaped fabric composite thermoplastic sheet and machining method for molding case shell of trolley case through compression molding

The invention discloses a honeycomb-shaped fabric composite thermoplastic sheet and a machining method for molding a case shell of a trolley case through compression molding, and relates to the technical field of production of trolley cases. The machining method comprises the following three steps: machining of a honey-shaped fabric: yarns are treated in a warping procedure, and are woven as the honey-shaped fabric; and finally, the honey-shaped fabric is shaped and coiled by a hot air type oven; machining of a composite sheet: the shaped honey-shaped fabric and a molten sheet extruded by a screw extruder are extruded by two rollers to form an embedded composite sheet for cooling and coiling; and then, the composite sheet and the extruded molten sheet are extruded and bonded by two rollers again to form a sandwich-structured composite sheet; and molding of the case shell: the sandwich-structured composite sheet is molded by hot pressing through a mold to prepare the case shell of the trolley case. The machining method has the following beneficial effects: the honeycomb-shaped fabric and the thermoplastic sheet are compounded by hot pressing to form the sandwich thermoplastic composite sheet structure; and the case shell of the trolley case is prepared through the composite sheet, so that the trolley case is high in strength and not easy to crack.

Owner:SHANGHAI RUNMI TECH CO LTD

Sandwich-structured composite fabric with polyurethane film layer and applied to spacesuits

InactiveCN109435405ASatisfy the holding pressureSatisfy the purpose of keeping shapeLamination ancillary operationsSpace suitsAging resistanceTear resistance

A sandwich-structured composite fabric with a polyurethane film layer and applied to spacesuits is characterized in that the composite fabric is in a sandwich structure formed by a polyurethane film layer, a lap joint agent and cloth. The sandwich-structured composite fabric with the polyurethane film layer and applied to the spacesuits is provided so as to meet requirements on pressure maintaining and shape keeping of an airtight layer and is capable of effectively improving tear strength to meet requirements on aging resistance, high abrasion resistance, pierce resistance, tear resistance, high reliability and high service life.

Owner:JIANGSU DONGBANG TECH

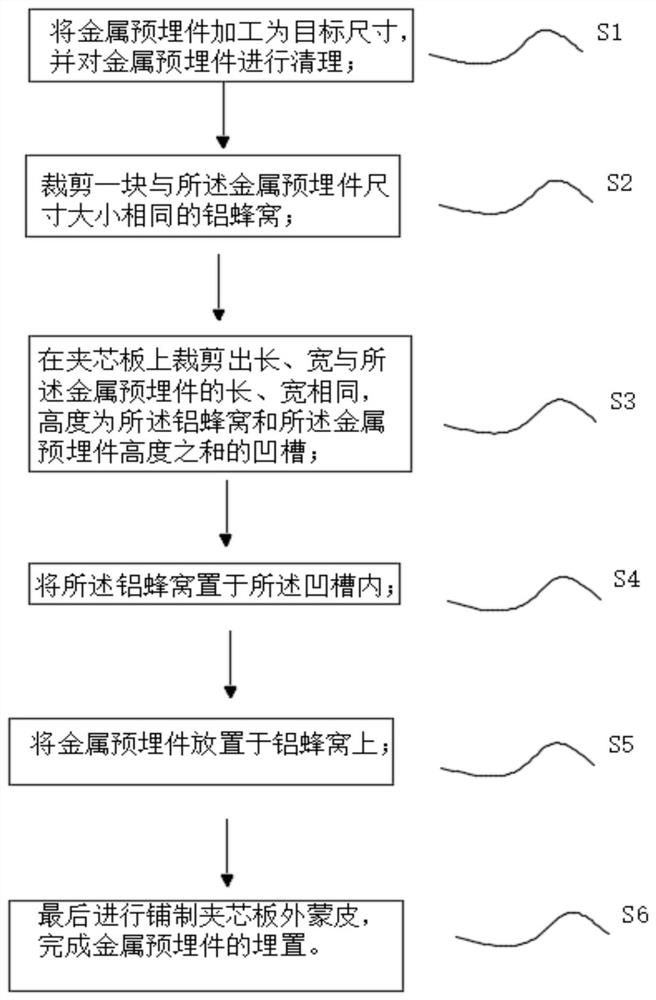

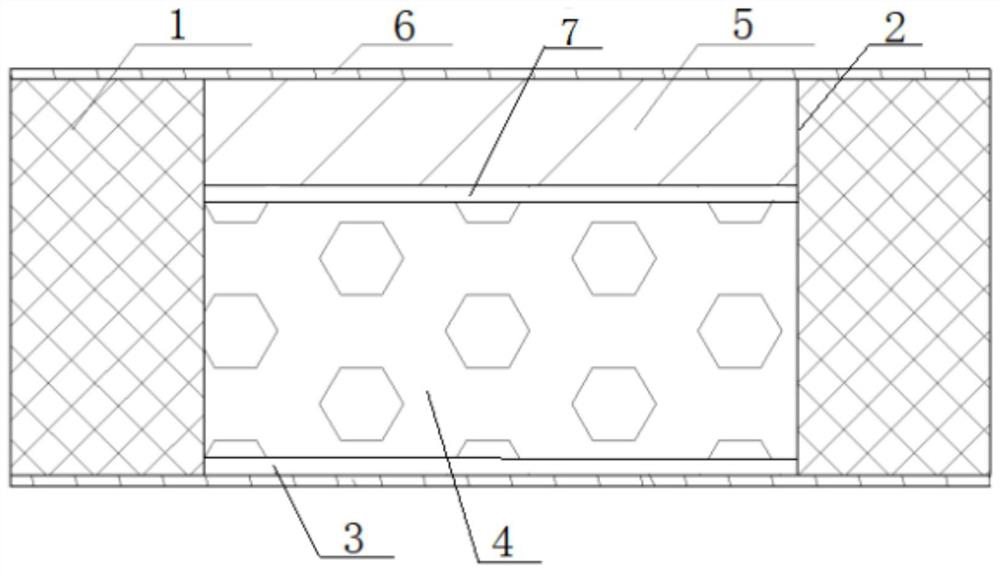

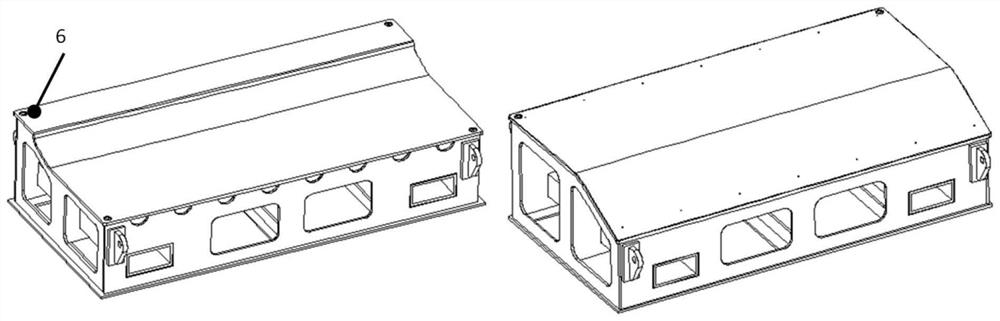

Composite material square cabin wall plate metal embedded part embedding method

PendingCN113978090AReduce bond strengthEasy to fixSuperstructure connectionsMetal layered productsAluminum honeycombSandwich panel

The invention belongs to the technical field of composite material square cabins, and particularly discloses a composite material square cabin metal embedded part embedding method which comprises the steps that machining a metal embedded part into a design size, and cleaning the metal embedded part; cutting an aluminum honeycomb of which the size is the same as that of the metal embedded part; filling the aluminum honeycomb with a honeycomb filling glue, and forming grooves with the same length and width as the metal embedded part and the height being the sum of the height of the aluminum honeycomb and the height of the metal embedded part through cutting in a sandwich panel; placing the filled aluminum honeycomb in the groove with an adhesive film pasted inside; placing the metal embedded part on the aluminum honeycomb with the adhesive film attached to the surface; and laying an outer skin on the metal embedded part, and completing embedding of the metal embedded part. According to the invention, the bonding strength and fatigue resistance of a sandwich structure composite material are improved, and the bearing requirement of the embedded part is met, so that the service life of the sandwich structure composite material is prolonged.

Owner:SHAANXI TIANYI ANTENNA

Sandwich structure composite material and preparation method thereof

ActiveCN106113738BImprove flexibilityGood surface appearanceSynthetic resin layered productsVehicle componentsGlass fiberFiber

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

Technological method for forming large-thickness honeycomb sandwich structure composite material

The invention belongs to the technical field of composite material forming, and relates to a technological method for forming a large-thickness honeycomb sandwich structure composite material. In order to solve the problems of high curing stress and product deformation caused by non-uniform thermal field distribution of the workpiece when the large-thickness honeycomb sandwich structure composite material workpiece is cured, the temperature rise rate of the temperature leading position of the workpiece is effectively reduced by designing the combination of breathable and non-breathable thermal insulation materials, and therefore, the purpose of uniform distribution of the thermal field in the workpiece curing process is achieved. The uniformity of the workpiece curing thermal field is improved, the workpiece curing stress is reduced, and the product quality is improved. The technological method is successfully applied to manufacturing of test pieces of a certain product. The technological method has good application value and economic benefit in the technical field of aeronautical manufacturing.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

Preparation method of honeycomb sandwich structure composite material with high-strength cementing performance

PendingCN114030268AImprove liquidityIncrease melt viscosityLamination ancillary operationsLaminationHoneycombResin adhesive

The invention belongs to the technical field of composite materials, and relates to a preparation method of a honeycomb sandwich structure composite material with high-strength cementing performance. According to the method, adhesive layers are prepared at the ends of the two sides of a honeycomb core material, and in-situ fixation of a reinforcing material at the cementing position of a composite panel and a honeycomb wall is achieved. Under the condition of not influencing the flow of the secondary adhesive film or self-adhesive prepreg resin, the purposes of enhancing the strength of the resin bead and improving the process operability in the forming process are achieved. The forming method is simple and convenient to operate, and the obtained product has excellent panel and core material bonding performance and is particularly suitable for meeting the requirements of the aerospace field for a light high-strength honeycomb sandwich structure.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

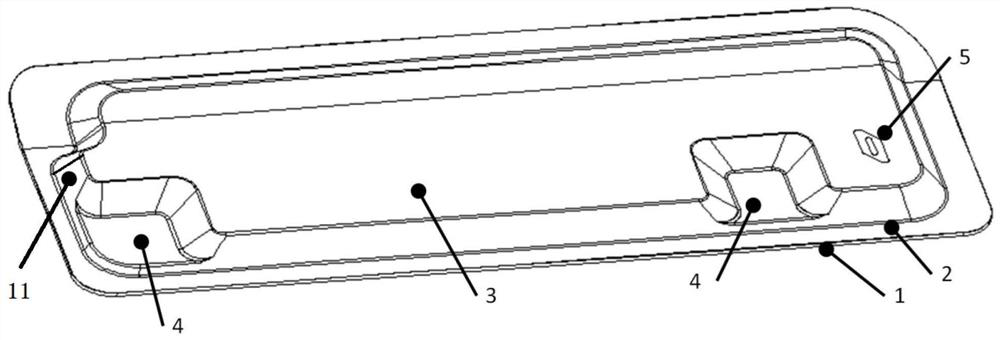

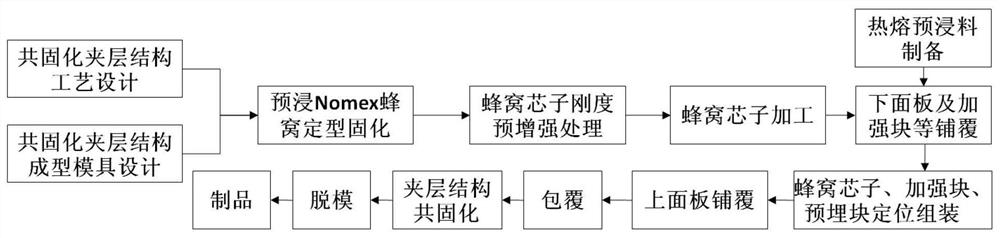

Large-curvature special-shaped surface large-height honeycomb co-curing sandwich structure composite material and forming method thereof

ActiveCN113601878AIncrease stiffnessOptimizing Forming Process ParametersWeight reductionDomestic articlesPolystyreneHoneycomb

The invention provides a large-curvature special-shaped surface large-height honeycomb co-curing sandwich structure composite material and a forming method thereof. The forming method comprises the following steps: shaping and curing a pre-impregnated and semi-cured aramid paper honeycomb on a male die to obtain a honeycomb core blank; placing the honeycomb core blank on a female die, filling polystyrene foam in the range of three to five honeycomb grids inwards according to the net size outline of a honeycomb core, pre-curing the polystyrene foam to obtain a rigidity pre-reinforced honeycomb core blank, and processing the honeycomb core blank to a theoretical size; and preparing a laminated layer of an outer skin, a reinforcing block and an inner skin prepreg from hot-melt prepreg, assembling the laminated layer with a honeycomb core and an embedded part, and curing to obtain the honeycomb co-curing sandwich structure composite material. The honeycomb core rigidity pre-reinforcement, laser projection assisted honeycomb forming and appearance processing technology and the sandwich structure assembly co-curing technology are adopted, collapse deformation of the honeycomb core in the curing forming process is avoided, and the formed composite material has the good internal quality, the good appearance size precision and the good embedded part position precision.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

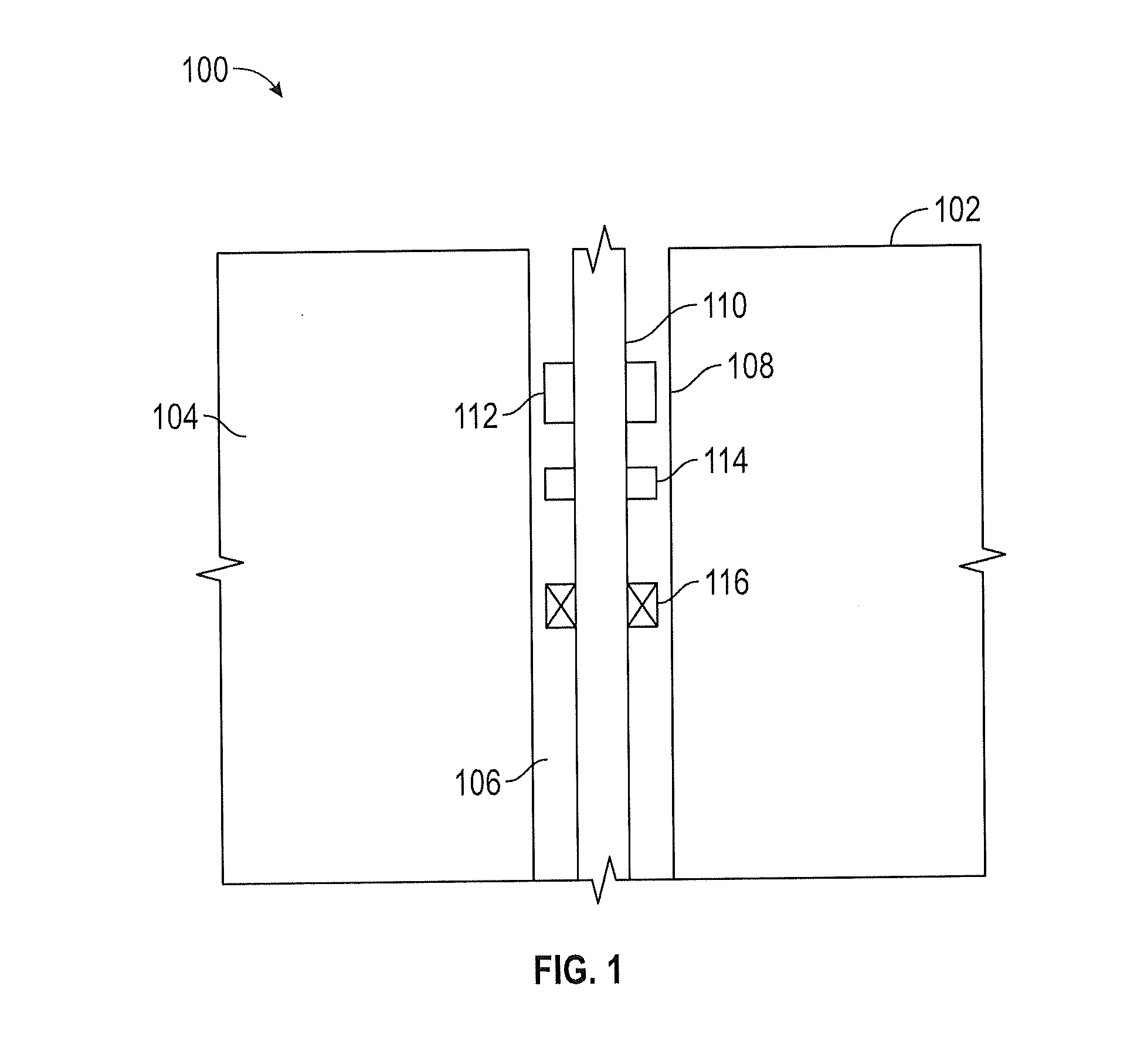

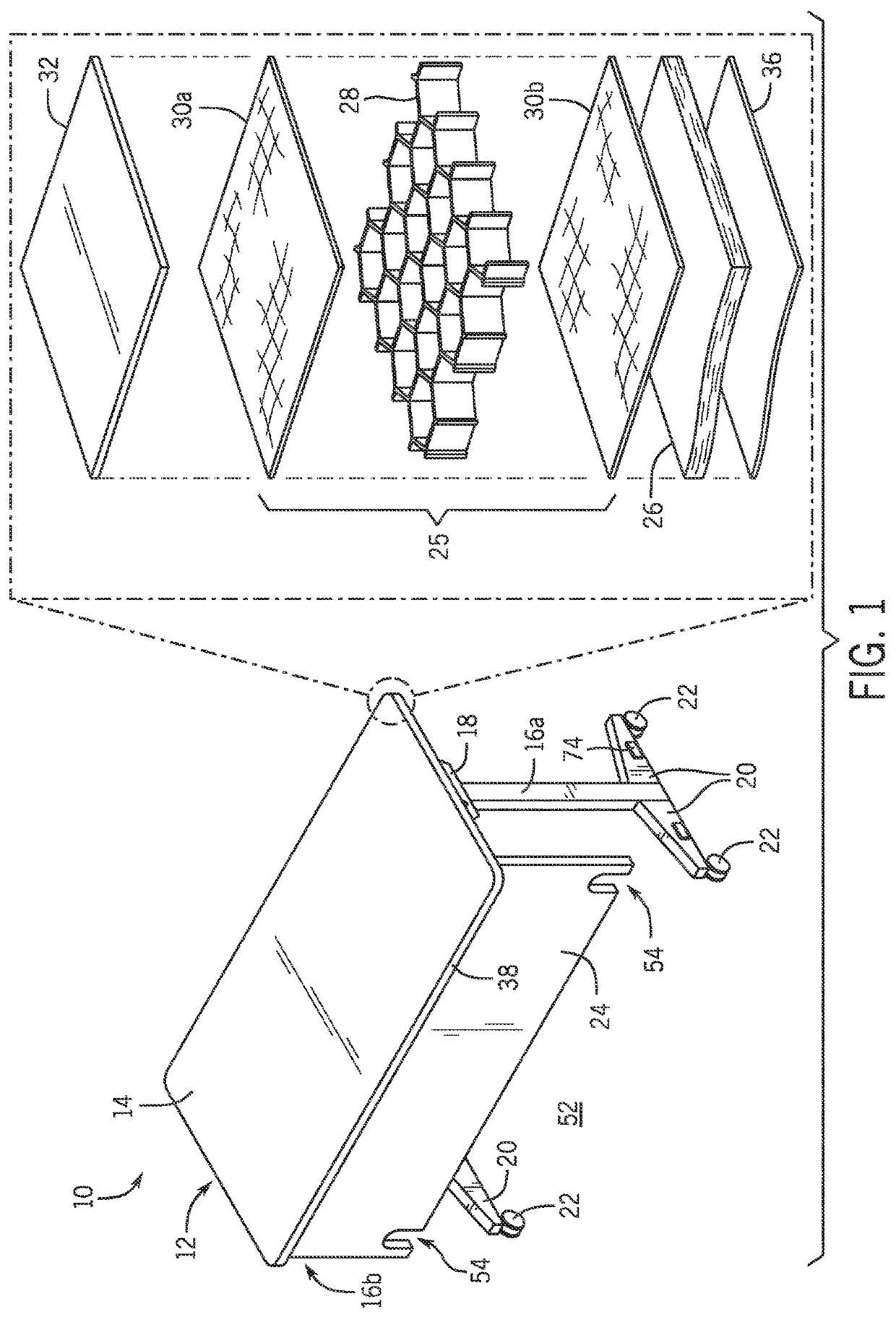

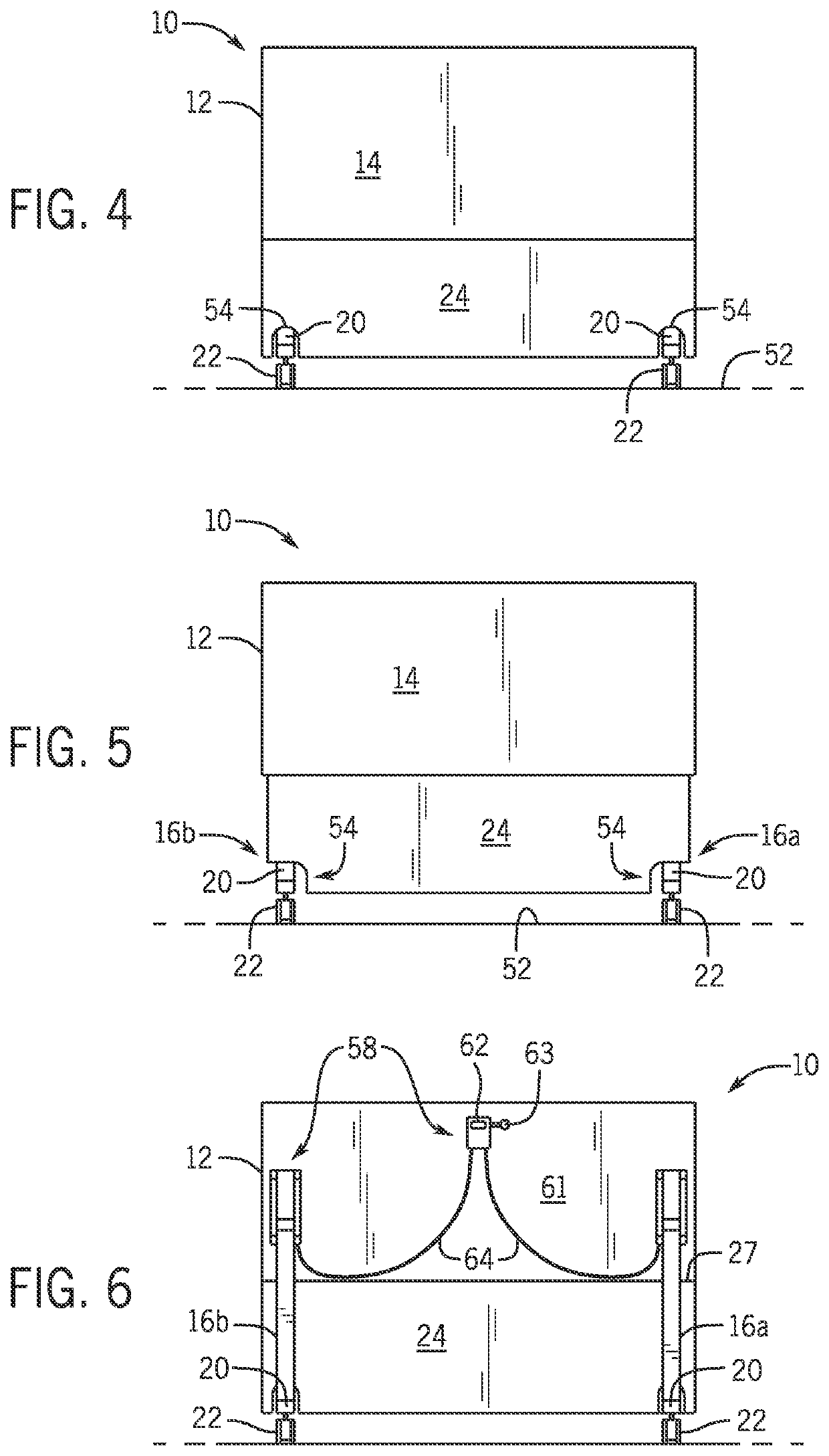

Lightweight Table Providing a Protective Shield

PendingUS20220167739A1Increase stiffnessLower resistanceFurniture partsSchool benchesHigh stiffnessClassical mechanics

A projectile-resistant table provides a reduced weight by employing separate structures for table stiffness and projectile resistance, for example, using a sandwich structure composite with high stiffness and tow projectile resistance for table integrity and a flexible fiber mat with low stiffness but high projectile resistance for shielding.

Owner:PS FURNITURE

Foamed aluminum material of Kagome honeycomb core structure as well as preparing method and application thereof

ActiveCN108838398AWith energy absorption and noise reductionHigh specific stiffnessFoaming agentEnergy absorption

The invention discloses a foamed aluminum material of a Kagome honeycomb core structure as well as a preparing method and an application thereof. The material is prepared by adding a thickening agentand a foaming agent into aluminum alloy melt and, after stirring, cooling and grinding, carrying out foaming in a Kagome honeycomb structure die. The preparing method specifically comprises the following steps: after heating aluminum alloy into the aluminum alloy melt, adding the thickening agent and the foaming agent while stirring; before the foaming of the foaming agent, cooling and condensingthe melt treated in the former step into a solid, and grinding the solid into powder; and adding the powder obtained in the former step into the Kagome honeycomb structure die previously made, carrying out heating for melting and heat insulation for foaming and carrying out cooling to obtain the foamed aluminum material of the Kagome honeycomb core structure. Compared with the prior art, the material not only has the common properties of energy absorption, noise reducing, light weight, high specific rigidity, high specific strength, heat resistance and the like, but also has great energy absorbing and heat dissipating functions.

Owner:ZHUHAI INST OF ADVANCED TECH

Sandwich structure composite material containing reinforcing ribs and manufacturing method thereof

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

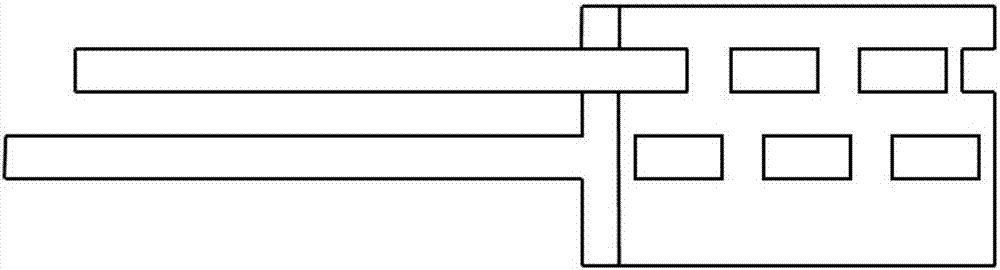

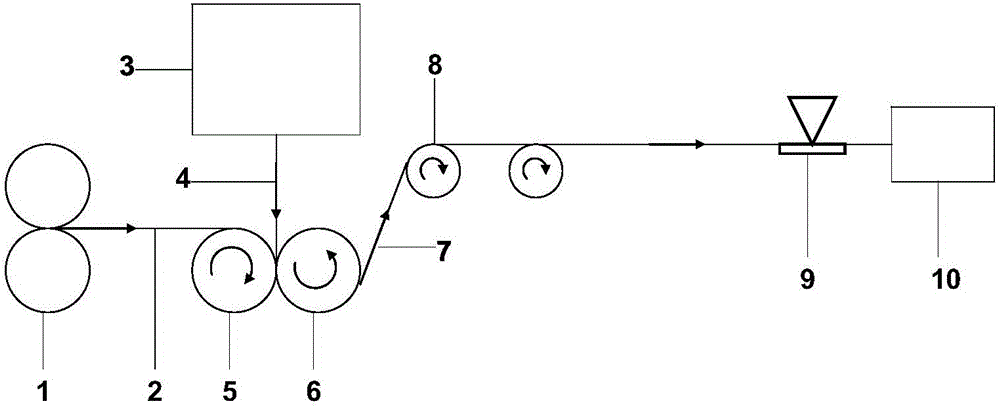

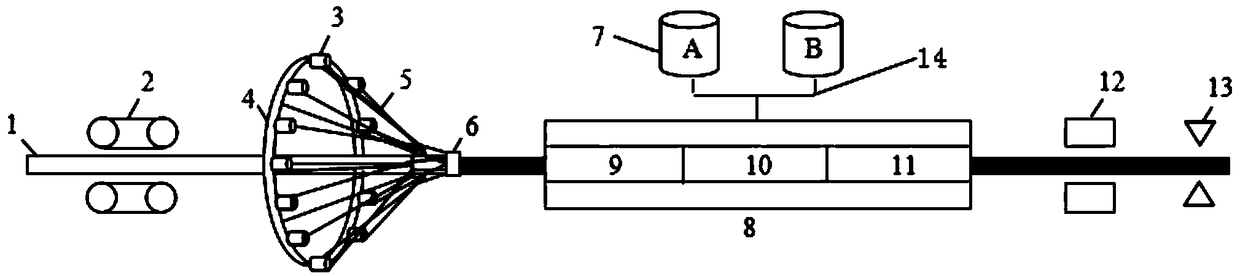

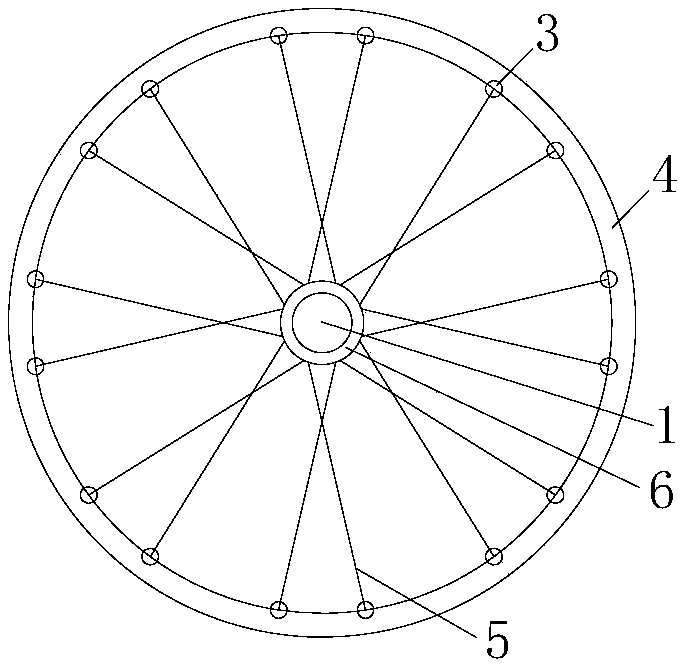

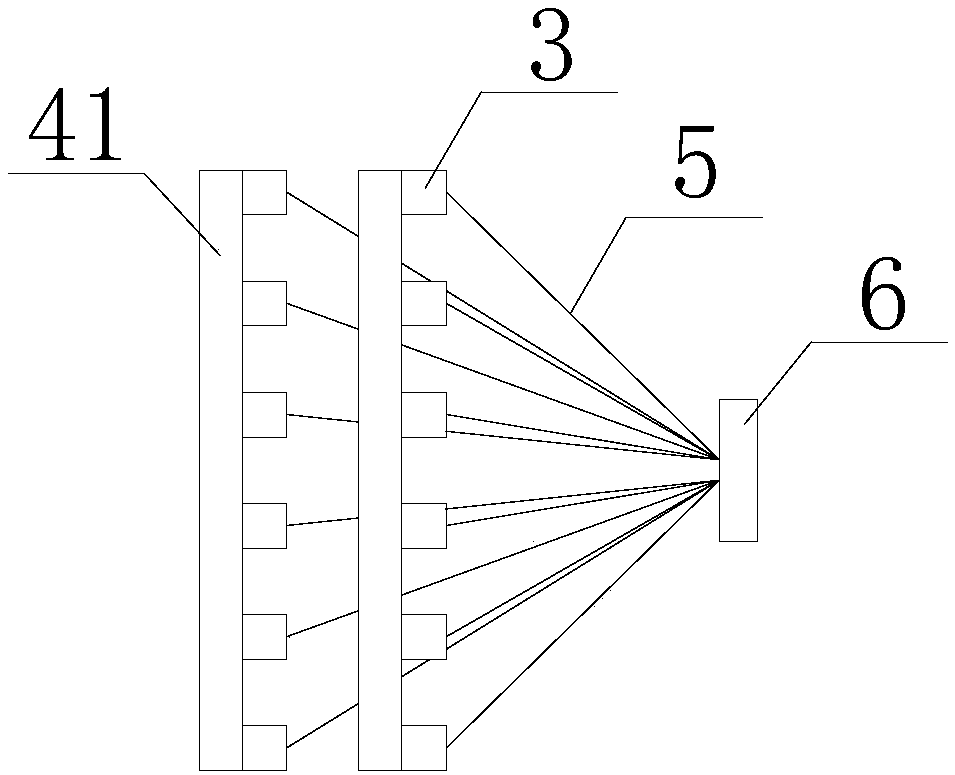

Sandwich structure composite material one-step preparation injection molding device and method

The invention provides a sandwich structure composite material one-step preparation injection molding device. The device is used for machining a core material. The device comprises a feeding unit, a fiber weaving machine, an injection molding die, a pulling unit and a cutting unit, wherein the fiber weaving machine is annular, and the core material passes through the fiber weaving machine; a bobbin is disposed on the fiber weaving machine, single-way fibers are disposed in the bobbin, one ends of the single-way fibers are connected with the surface of the core material in an abutting mode through a forming plate, the core material penetrates through a channel in the injection molding die, the feeding unit, the fiber weaving machine, the injection molding die, the pulling unit and the cutting unit are arranged in sequence in the length direction of the core material. The invention further provides a sandwich structure composite material one-step preparation injection molding method. Thecore material passes through the feeding unit, the fiber weaving machine, the injection molding die, the pulling unit and the cutting unit in sequence, and a sandwich structure composite material isformed. Fiber pipes adopt clockwise and anticlockwise fiber weaving, and interweaving and fiber mechanical property loss does not exist.

Owner:杭州碳谱新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com