Large-curvature special-shaped surface large-height honeycomb co-curing sandwich structure composite material and forming method thereof

A technology of sandwich structure and molding method, which is applied to other household appliances, household appliances, household components, etc., can solve the problem that it is difficult to ensure the quality of honeycomb-skin bonding of sandwich structure parts with complex profiles, and it is difficult to meet the requirements of new models of aerospace transporters. Design and use requirements, increase manufacturing cycle and cost, etc., to ensure the quality of interface bonding, avoid instability and collapse, and ensure the effect of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

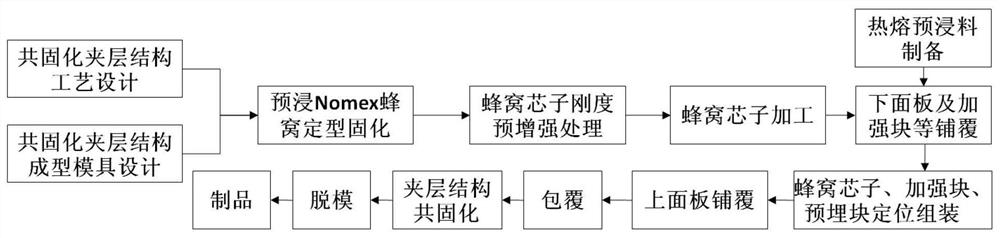

Method used

Image

Examples

Embodiment 1

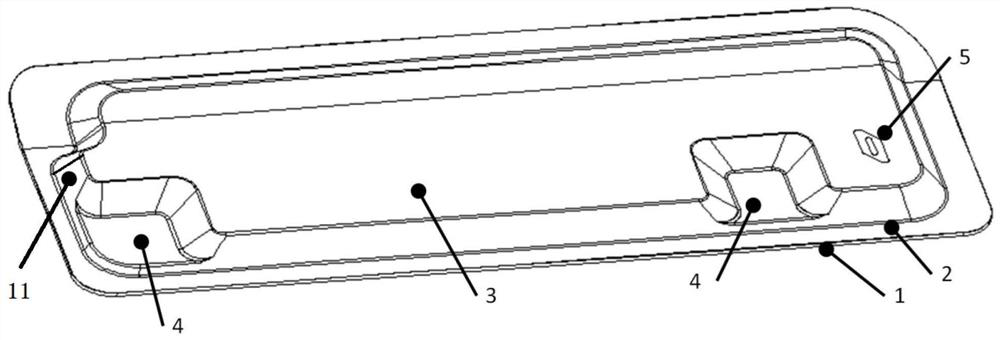

[0063] Such as figure 1 As shown, the large-curvature special-shaped surface and large-height honeycomb co-cured sandwich structure composite material, the inner and outer skins are made of domestic carbon fiber reinforced epoxy resin-based composite materials, the product length is 1300mm, the width is 500mm, and the thickness of the skin lamination area is 5.6mm; the interior of the sandwich structure includes Honeycomb core, carbon / epoxy reinforcement block and metal pre-embedded parts, etc.; the height of the honeycomb core is 35mm, and the circumferential edge of the core is chamfered at 45°. It is required that the delamination defect area in the lamination area is not greater than 1%, and the Z value of a single delamination defect is not greater than 13mm; the debonding area of the sandwich structure adhesive interface is not greater than 1%, and the Z value of a single debonding defect is not greater than 13mm; the honeycomb shrinkage rate is less than 1%, no visibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com