Sandwich structure composite material with elastic core material and preparation method thereof

A composite material and sandwich structure technology, applied in the field of composite materials, can solve the problems of not improving the interface bonding effect between the panel and the core material, poor impact damage resistance, and restricting wider applications, and achieve excellent energy absorption effect, anti- Excellent impact properties and improved interlaminar strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

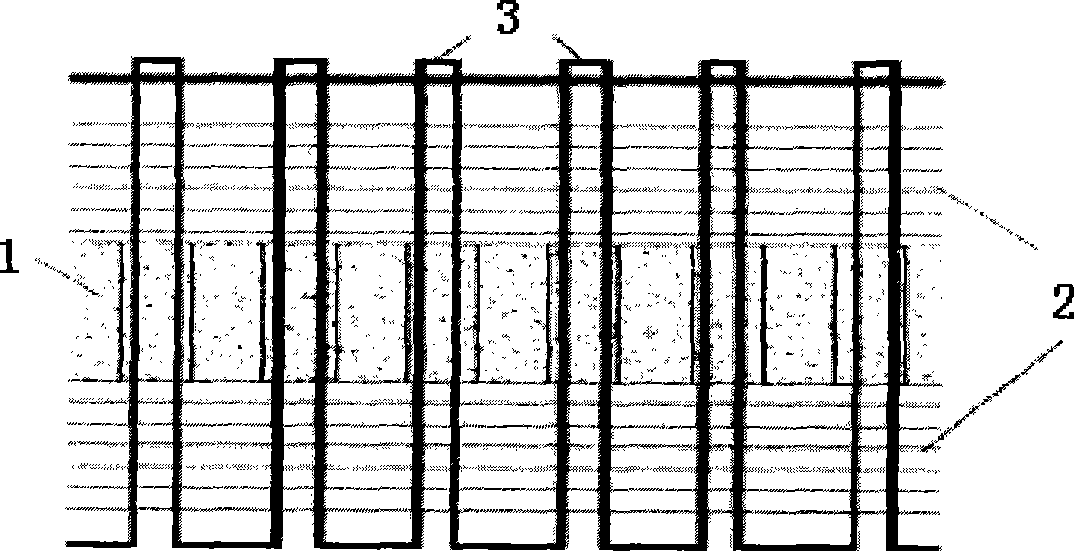

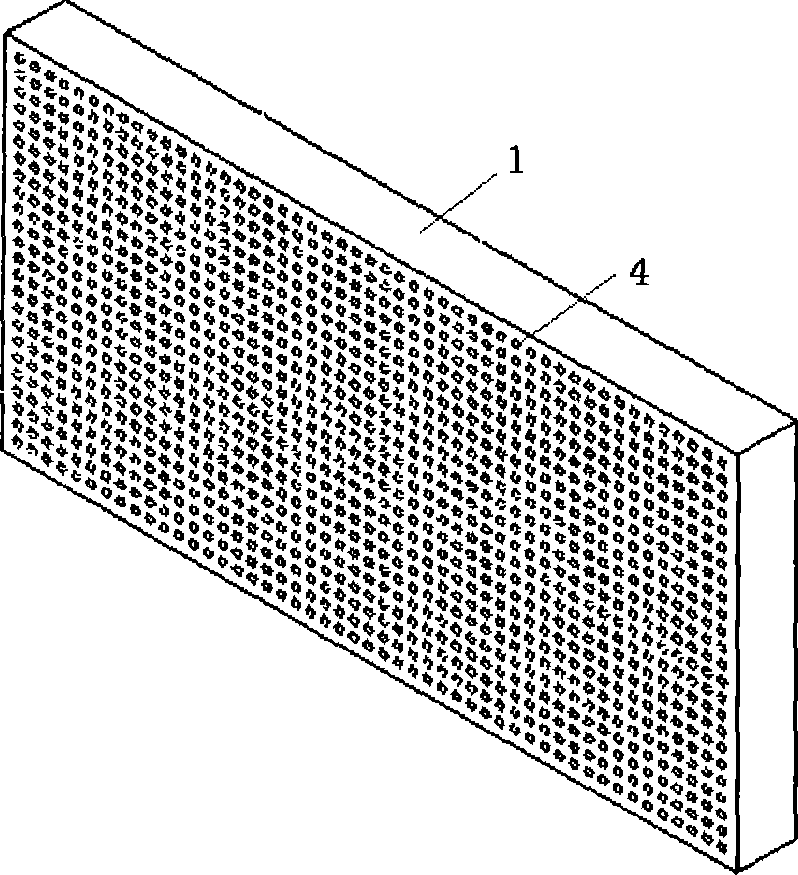

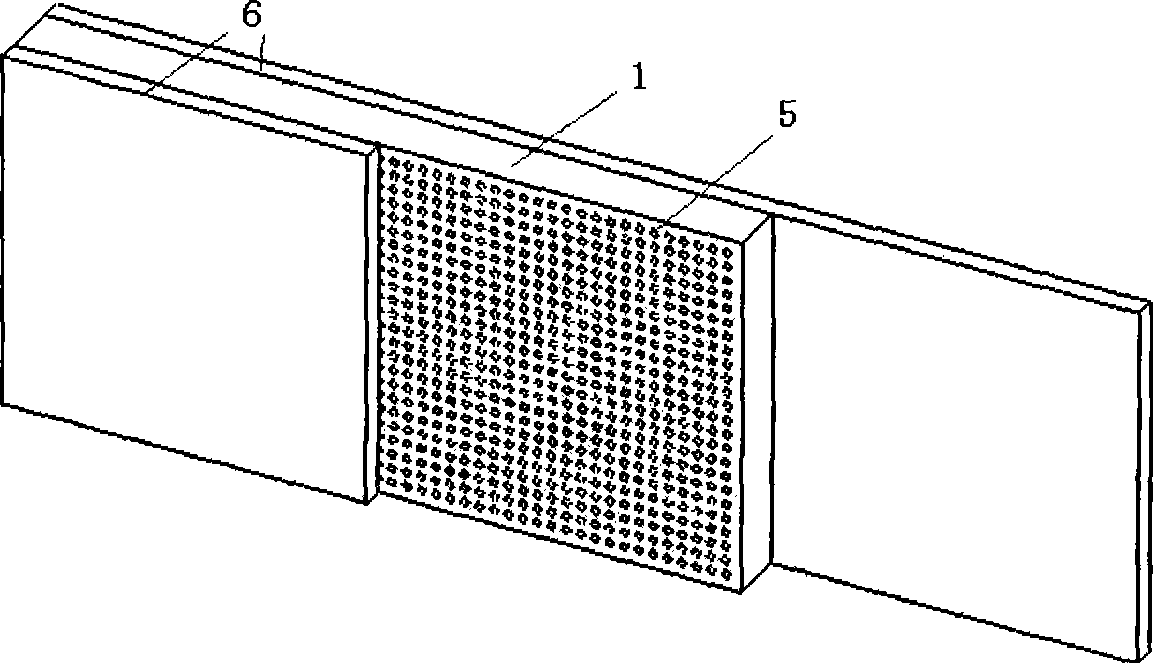

[0020] The fiber yarn 3 used for suturing adopts non-alkali untwisted glass fiber roving (Taishan Glass Fiber Co., Ltd. direct non-alkali non-twisting glass fiber roving T910); The cloth is alkali-free glass fiber untwisted square cloth from Taishan Glass Fiber Co., Ltd.; the resin used for resin column 3 adopts the low-viscosity WHUT-UPR unsaturated resin curing system of the Department of Composite Materials of Wuhan University of Technology. First use a puncher to drill the rubber sheet according to the seam spacing Hole 4, then spread the alkali-free glass fiber cloth up and down on the rubber plate, each 2mm thick. Use glass fiber roving to sew the glass fiber cloth and the rubber sheet together by hand, the stitching method is straight lock stitching, and the stitching distance is 20mm. Finally, vacuum-assisted resin transfer molding (VARTM) is used to impregnate the fiber cloth and sutures with resin, and the sandwich structure is solidified as a whole according to th...

Embodiment 2

[0022] The fiber yarn 3 used for suturing adopts aramid fiber (U.S. DuPont Kevlar 49 aramid fibers); the elastic core material 1 adopts butadiene rubber plate with a thickness of 5mm; the composite material panel 2 is 1; —Esys108 room temperature epoxy resin curing system. First use a puncher to drill the rubber sheet according to the seam spacing Hole 4, and then spread the alkali-free glass fiber cloth up and down on the rubber plate, each 3mm. Use aramid fiber to sew the glass fiber cloth and rubber together through an ordinary industrial sewing machine. The stitching method is straight chain stitching, and the stitching distance is 15mm. Finally, vacuum-assisted resin transfer molding (VARTM) is used to impregnate the fiber cloth and sutures with resin, and the sandwich structure is solidified as a whole according to the curing process. The damping ratio of the prepared composite material is 5.2433% by INV-DASP dynamic test and signal analysis system.

Embodiment 3

[0024] The fiber yarn 3 used for suturing adopts non-alkali untwisted glass fiber roving (Taishan Glass Fiber Co., Ltd. direct non-alkali non-twisting glass fiber roving T980); The cloth is alkali-free glass fiber untwisted square cloth from Taishan Glass Fiber Co., Ltd.; the resin used for resin column 3 adopts the low-viscosity WHUT-Esys208 medium-temperature epoxy resin curing system of the Department of Composite Materials of Wuhan University of Technology. First use a puncher to drill the rubber sheet according to the seam spacing Hole 4, then spread the alkali-free glass fiber cloth up and down on the rubber plate, each 2mm thick. Use glass fiber roving to sew the glass cloth and rubber together by hand, the stitching method is straight lock stitching, and the stitching distance is 10mm. Finally, vacuum-assisted resin transfer molding (VARTM) is used to impregnate the fiber cloth and sutures with resin, and the sandwich structure is solidified as a whole according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com