Sandwich-structured solid amine CO2 adsorbent and preparation method thereof

A sandwich and adsorbent technology, applied in the field of sandwich structure solid amine CO2 adsorbent and its preparation, can solve the problems of reduced effective utilization rate of amine, increased diffusion resistance, loss of adsorption sites, etc., so as to improve utilization rate and avoid clogging , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

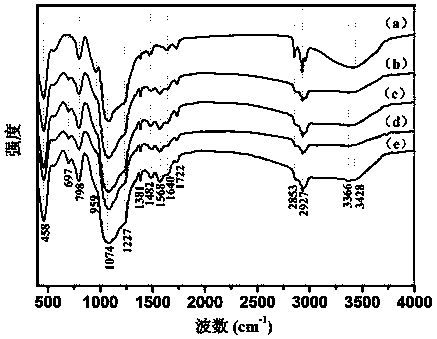

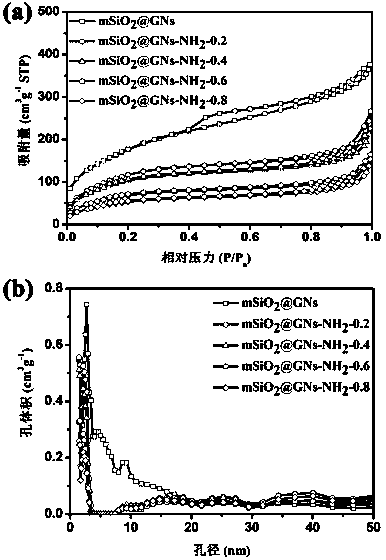

[0031] Graphene oxide (GO) is used as the substrate, the cyclohexane solution of tetraethyl orthosilicate (TEOS) is used as the silicon source, and cetyltrimethylammonium chloride (CTAC) is used as the cationic surfactant. The oil-water layer method Preparation of sandwich structure composites: First, GO powder was ultrasonically dispersed into 100 mL deionized water to obtain a GO dispersion with a concentration of 0.12 mg mL -1; Add 40 mg of NaOH to the dispersion, and stir at 100 °C for 1 h; then add 1.92 g of CTAC, and continue to stir at 100 °C for 3 h; then add 21 mL of TEOS (10 v%) cyclohexane The alkane solution was added dropwise to the above reaction solution, and stirred at 100°C for 24 h; the obtained product was mixed with 100 mL of 0.6 wt% NH 4 NO 3 ethanol solution, stirred vigorously at 80 °C for 24 h to remove the surfactant; GO reduction was performed with 50 mL of 45 wt% HI solution to obtain mSiO 2 @GNs sandwich structure composite materials;

[0032] mS...

Embodiment 2

[0035] Using GO as the substrate, TEOS cyclohexane solution as the silicon source, and CTAC as the cationic surfactant, the sandwich structure composite material was prepared by the oil-water layering method: first, the GO powder was ultrasonically dispersed into 100 mL deionized water to obtain the GO dispersion. Concentration of 1.2 mg mL -1 ; Add 40 mg of NaOH to the dispersion, and stir at 100 °C for 1 h; then add 1.92 g of CTAC, and continue to stir at 100 °C for 3 h; then add 21 mL of TEOS (10 v%) ring The hexane solution was added dropwise to the above reaction solution, and stirred at 100°C for 24 h; the obtained product was mixed with 100 mL of 0.6 wt% NH 4 NO 3 ethanol solution, stirred vigorously at 80 °C for 24 h to remove the surfactant; GO was reduced with 50 mL of 45 wt% HI solution to obtain mSiO 2 @GNs sandwich structure composite materials;

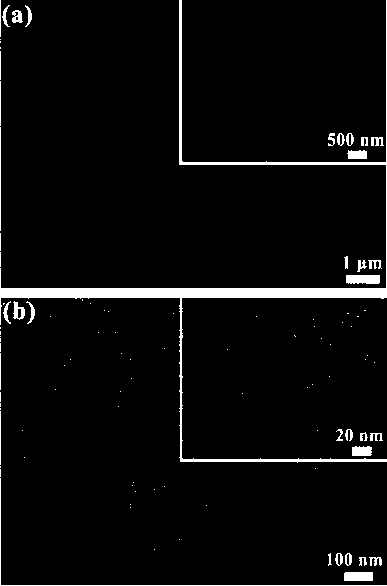

[0036] mSiO 2 The TEM images of @GNs sandwich structure composite materials show that a relatively uniform lamella...

Embodiment 3

[0039] Using GO as the substrate, TEOS cyclohexane solution as the silicon source, and CTAC as the cationic surfactant, the sandwich structure composite material was prepared by the oil-water layering method: first, the GO powder was ultrasonically dispersed into 100 mL deionized water to obtain the GO dispersion. Concentration is 0.3 mg mL -1 ; Add 40 mg of NaOH to the dispersion, and stir at 100 °C for 1 h; then add 1.92 g of CTAC, and continue to stir at 100 °C for 3 h; then add 21 mL of TEOS (10 v%) ring The hexane solution was added dropwise to the above reaction solution, and stirred at 100°C for 24 h; the obtained product was mixed with 100 mL of 0.6 wt% NH 4 NO 3 ethanol solution, stirred vigorously at 80 °C for 24 h to remove the surfactant; GO was reduced with 50 mL of 45 wt% HI solution to obtain mSiO 2 @GNs sandwich structure composite materials;

[0040] mSiO 2 SEM and TEM images of @GNs sandwich structure composites ( figure 1 ) shows that a lamellar sandwic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com