Fiber-reinforced resin honeycomb sandwich structure composite material and preparation method thereof

A fiber-reinforced resin and honeycomb sandwich structure technology, applied in the field of material processing, can solve problems such as low shear strength and weak bonding, and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

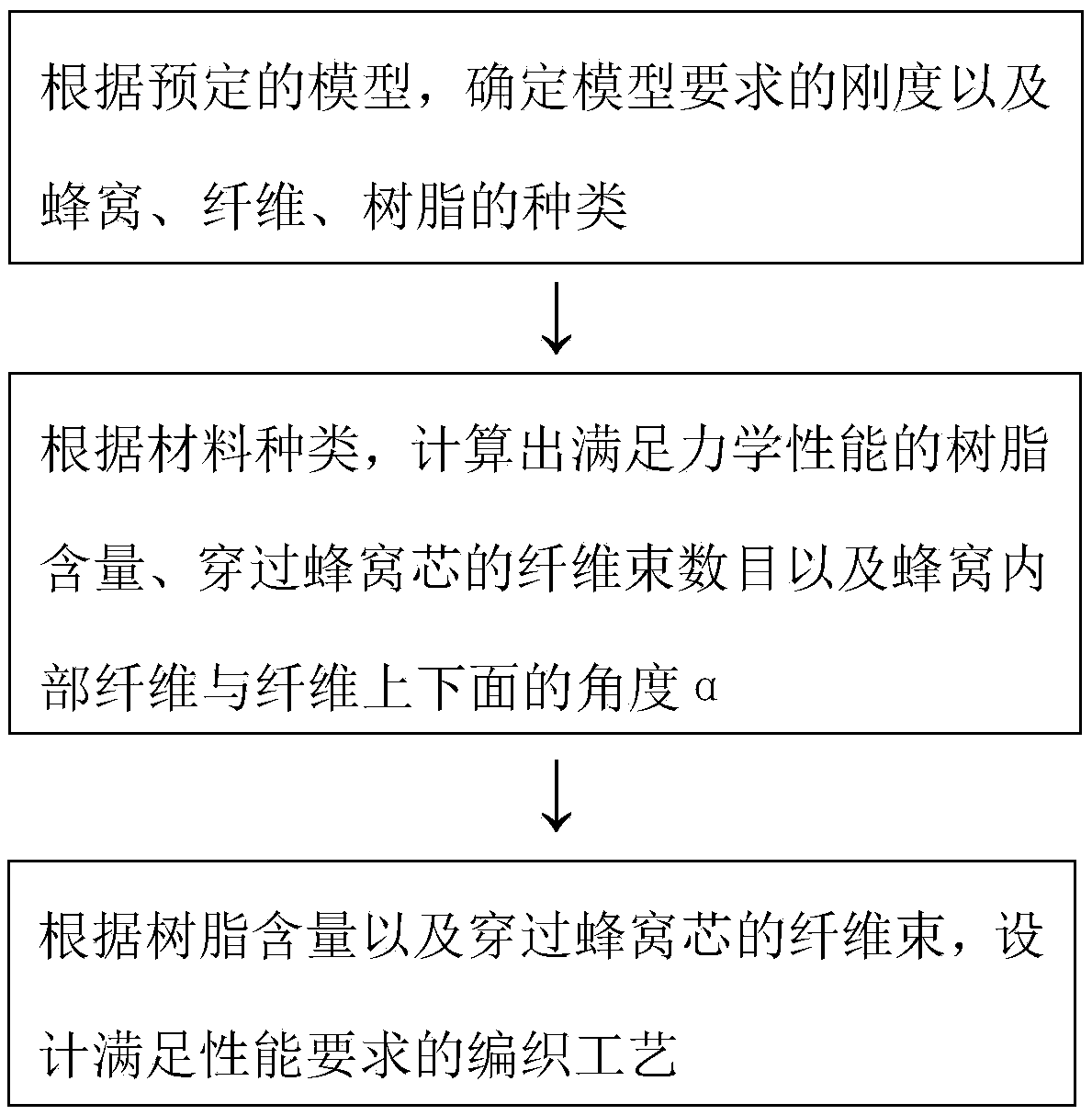

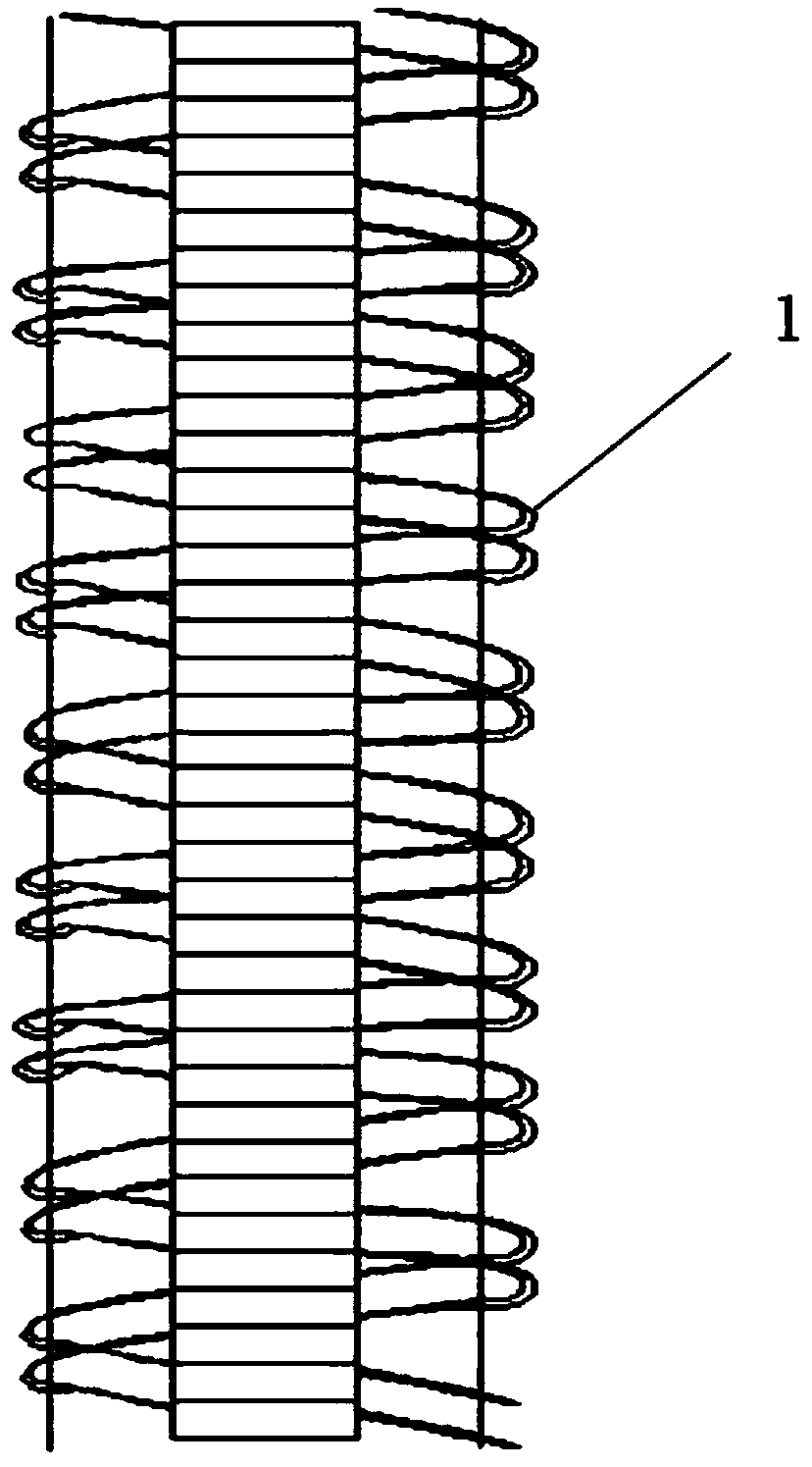

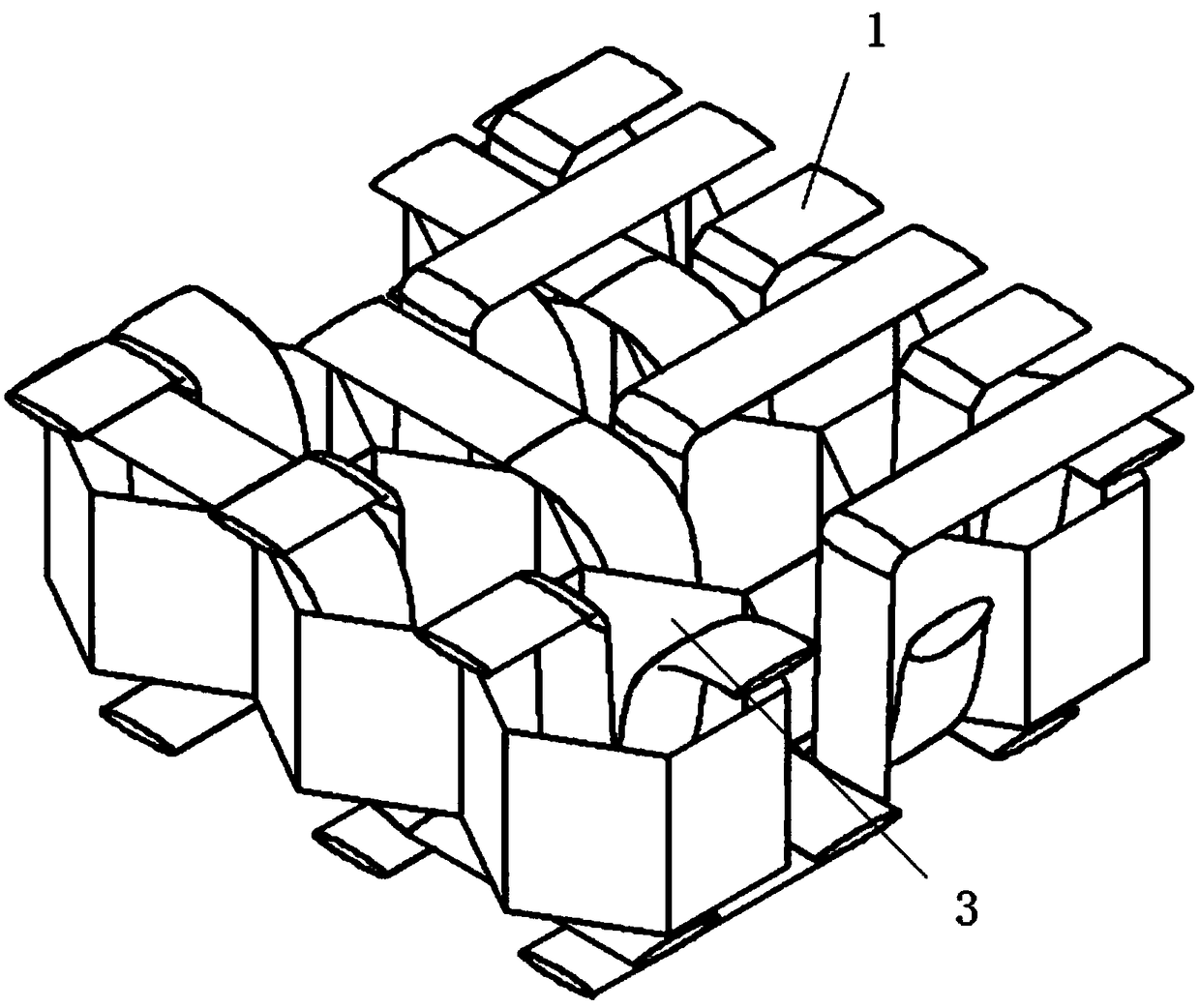

[0027] Such as figure 1 As shown, the invention discloses a fiber-reinforced resin honeycomb sandwich structure composite material and a preparation method thereof, which are composed of a fiber reinforcement, a resin, and a honeycomb material; the fiber reinforcement is a continuous fiber; the resin is a thermosetting resin or Thermoplastic resin; the honeycomb core is composed of aluminum honeycomb, paper honeycomb and other porous core materials. The fiber communicates with the upper and lower fiber surfaces of the honeycomb core to enhance the shear strength of the fiber-reinforced resin honeycomb sandwich structure composite material part. figure 2 Shown is the interpenetration of the internal fibers that join the upper and lower layers of fabric together. image 3 Shown is how the fiber bundles are woven into the interior of the honeycomb when using 3D weaving. Figure 4 In the process, the fiber bundles or fiber filaments connecting the upper and lower fiber cloths s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com